Yunsheng Tian

Fabrica: Dual-Arm Assembly of General Multi-Part Objects via Integrated Planning and Learning

Jun 05, 2025Abstract:Multi-part assembly poses significant challenges for robots to execute long-horizon, contact-rich manipulation with generalization across complex geometries. We present Fabrica, a dual-arm robotic system capable of end-to-end planning and control for autonomous assembly of general multi-part objects. For planning over long horizons, we develop hierarchies of precedence, sequence, grasp, and motion planning with automated fixture generation, enabling general multi-step assembly on any dual-arm robots. The planner is made efficient through a parallelizable design and is optimized for downstream control stability. For contact-rich assembly steps, we propose a lightweight reinforcement learning framework that trains generalist policies across object geometries, assembly directions, and grasp poses, guided by equivariance and residual actions obtained from the plan. These policies transfer zero-shot to the real world and achieve 80% successful steps. For systematic evaluation, we propose a benchmark suite of multi-part assemblies resembling industrial and daily objects across diverse categories and geometries. By integrating efficient global planning and robust local control, we showcase the first system to achieve complete and generalizable real-world multi-part assembly without domain knowledge or human demonstrations. Project website: http://fabrica.csail.mit.edu/

Boundary Exploration for Bayesian Optimization With Unknown Physical Constraints

Feb 12, 2024Abstract:Bayesian optimization has been successfully applied to optimize black-box functions where the number of evaluations is severely limited. However, in many real-world applications, it is hard or impossible to know in advance which designs are feasible due to some physical or system limitations. These issues lead to an even more challenging problem of optimizing an unknown function with unknown constraints. In this paper, we observe that in such scenarios optimal solution typically lies on the boundary between feasible and infeasible regions of the design space, making it considerably more difficult than that with interior optima. Inspired by this observation, we propose BE-CBO, a new Bayesian optimization method that efficiently explores the boundary between feasible and infeasible designs. To identify the boundary, we learn the constraints with an ensemble of neural networks that outperform the standard Gaussian Processes for capturing complex boundaries. Our method demonstrates superior performance against state-of-the-art methods through comprehensive experiments on synthetic and real-world benchmarks.

ASAP: Automated Sequence Planning for Complex Robotic Assembly with Physical Feasibility

Sep 29, 2023Abstract:The automated assembly of complex products requires a system that can automatically plan a physically feasible sequence of actions for assembling many parts together. In this paper, we present ASAP, a physics-based planning approach for automatically generating such a sequence for general-shaped assemblies. ASAP accounts for gravity to design a sequence where each sub-assembly is physically stable with a limited number of parts being held and a support surface. We apply efficient tree search algorithms to reduce the combinatorial complexity of determining such an assembly sequence. The search can be guided by either geometric heuristics or graph neural networks trained on data with simulation labels. Finally, we show the superior performance of ASAP at generating physically realistic assembly sequence plans on a large dataset of hundreds of complex product assemblies. We further demonstrate the applicability of ASAP on both simulation and real-world robotic setups. Project website: asap.csail.mit.edu

Assemble Them All: Physics-Based Planning for Generalizable Assembly by Disassembly

Nov 08, 2022Abstract:Assembly planning is the core of automating product assembly, maintenance, and recycling for modern industrial manufacturing. Despite its importance and long history of research, planning for mechanical assemblies when given the final assembled state remains a challenging problem. This is due to the complexity of dealing with arbitrary 3D shapes and the highly constrained motion required for real-world assemblies. In this work, we propose a novel method to efficiently plan physically plausible assembly motion and sequences for real-world assemblies. Our method leverages the assembly-by-disassembly principle and physics-based simulation to efficiently explore a reduced search space. To evaluate the generality of our method, we define a large-scale dataset consisting of thousands of physically valid industrial assemblies with a variety of assembly motions required. Our experiments on this new benchmark demonstrate we achieve a state-of-the-art success rate and the highest computational efficiency compared to other baseline algorithms. Our method also generalizes to rotational assemblies (e.g., screws and puzzles) and solves 80-part assemblies within several minutes.

Evolution Gym: A Large-Scale Benchmark for Evolving Soft Robots

Jan 24, 2022

Abstract:Both the design and control of a robot play equally important roles in its task performance. However, while optimal control is well studied in the machine learning and robotics community, less attention is placed on finding the optimal robot design. This is mainly because co-optimizing design and control in robotics is characterized as a challenging problem, and more importantly, a comprehensive evaluation benchmark for co-optimization does not exist. In this paper, we propose Evolution Gym, the first large-scale benchmark for co-optimizing the design and control of soft robots. In our benchmark, each robot is composed of different types of voxels (e.g., soft, rigid, actuators), resulting in a modular and expressive robot design space. Our benchmark environments span a wide range of tasks, including locomotion on various types of terrains and manipulation. Furthermore, we develop several robot co-evolution algorithms by combining state-of-the-art design optimization methods and deep reinforcement learning techniques. Evaluating the algorithms on our benchmark platform, we observe robots exhibiting increasingly complex behaviors as evolution progresses, with the best evolved designs solving many of our proposed tasks. Additionally, even though robot designs are evolved autonomously from scratch without prior knowledge, they often grow to resemble existing natural creatures while outperforming hand-designed robots. Nevertheless, all tested algorithms fail to find robots that succeed in our hardest environments. This suggests that more advanced algorithms are required to explore the high-dimensional design space and evolve increasingly intelligent robots -- an area of research in which we hope Evolution Gym will accelerate progress. Our website with code, environments, documentation, and tutorials is available at http://evogym.csail.mit.edu.

JoinABLe: Learning Bottom-up Assembly of Parametric CAD Joints

Nov 24, 2021

Abstract:Physical products are often complex assemblies combining a multitude of 3D parts modeled in computer-aided design (CAD) software. CAD designers build up these assemblies by aligning individual parts to one another using constraints called joints. In this paper we introduce JoinABLe, a learning-based method that assembles parts together to form joints. JoinABLe uses the weak supervision available in standard parametric CAD files without the help of object class labels or human guidance. Our results show that by making network predictions over a graph representation of solid models we can outperform multiple baseline methods with an accuracy (79.53%) that approaches human performance (80%). Finally, to support future research we release the Fusion 360 Gallery assembly dataset, containing assemblies with rich information on joints, contact surfaces, holes, and the underlying assembly graph structure.

AutoOED: Automated Optimal Experiment Design Platform

Apr 13, 2021

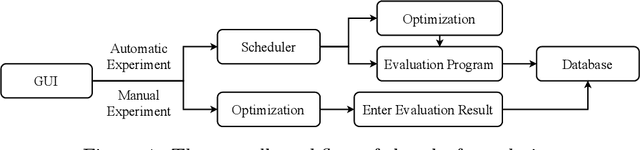

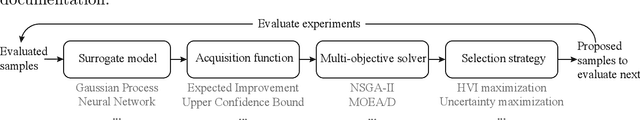

Abstract:We present AutoOED, an Optimal Experiment Design platform powered with automated machine learning to accelerate the discovery of optimal solutions. The platform solves multi-objective optimization problems in time- and data-efficient manner by automatically guiding the design of experiments to be evaluated. To automate the optimization process, we implement several multi-objective Bayesian optimization algorithms with state-of-the-art performance. AutoOED is open-source and written in Python. The codebase is modular, facilitating extensions and tailoring the code, serving as a testbed for machine learning researchers to easily develop and evaluate their own multi-objective Bayesian optimization algorithms. An intuitive graphical user interface (GUI) is provided to visualize and guide the experiments for users with little or no experience with coding, machine learning, or optimization. Furthermore, a distributed system is integrated to enable parallelized experimental evaluations by independent workers in remote locations. The platform is available at https://autooed.org.

Artificial Intelligence for Prosthetics - challenge solutions

Feb 07, 2019

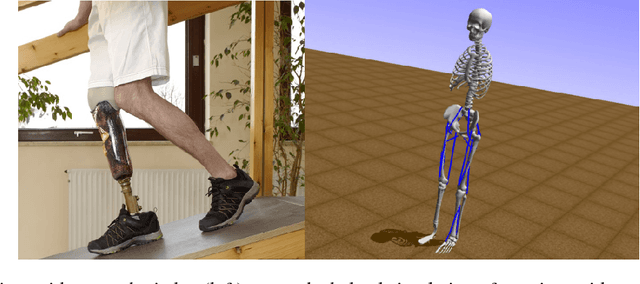

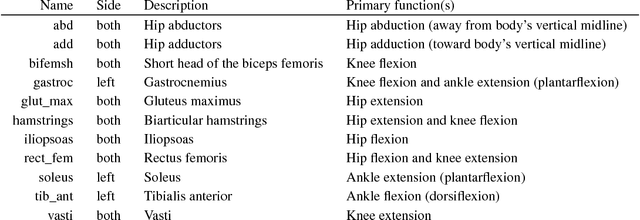

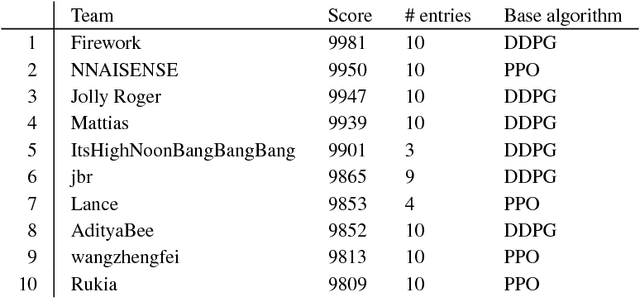

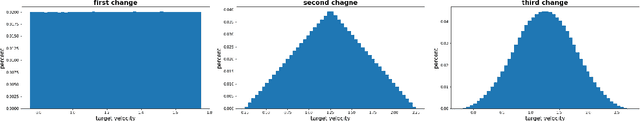

Abstract:In the NeurIPS 2018 Artificial Intelligence for Prosthetics challenge, participants were tasked with building a controller for a musculoskeletal model with a goal of matching a given time-varying velocity vector. Top participants were invited to describe their algorithms. In this work, we describe the challenge and present thirteen solutions that used deep reinforcement learning approaches. Many solutions use similar relaxations and heuristics, such as reward shaping, frame skipping, discretization of the action space, symmetry, and policy blending. However, each team implemented different modifications of the known algorithms by, for example, dividing the task into subtasks, learning low-level control, or by incorporating expert knowledge and using imitation learning.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge