Shinjiro Sueda

Fabrica: Dual-Arm Assembly of General Multi-Part Objects via Integrated Planning and Learning

Jun 05, 2025Abstract:Multi-part assembly poses significant challenges for robots to execute long-horizon, contact-rich manipulation with generalization across complex geometries. We present Fabrica, a dual-arm robotic system capable of end-to-end planning and control for autonomous assembly of general multi-part objects. For planning over long horizons, we develop hierarchies of precedence, sequence, grasp, and motion planning with automated fixture generation, enabling general multi-step assembly on any dual-arm robots. The planner is made efficient through a parallelizable design and is optimized for downstream control stability. For contact-rich assembly steps, we propose a lightweight reinforcement learning framework that trains generalist policies across object geometries, assembly directions, and grasp poses, guided by equivariance and residual actions obtained from the plan. These policies transfer zero-shot to the real world and achieve 80% successful steps. For systematic evaluation, we propose a benchmark suite of multi-part assemblies resembling industrial and daily objects across diverse categories and geometries. By integrating efficient global planning and robust local control, we showcase the first system to achieve complete and generalizable real-world multi-part assembly without domain knowledge or human demonstrations. Project website: http://fabrica.csail.mit.edu/

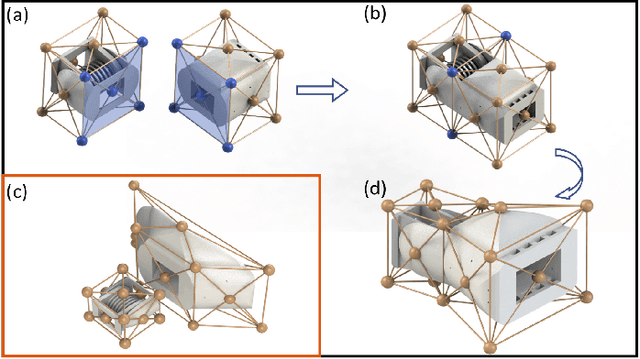

ASAP: Automated Sequence Planning for Complex Robotic Assembly with Physical Feasibility

Sep 29, 2023Abstract:The automated assembly of complex products requires a system that can automatically plan a physically feasible sequence of actions for assembling many parts together. In this paper, we present ASAP, a physics-based planning approach for automatically generating such a sequence for general-shaped assemblies. ASAP accounts for gravity to design a sequence where each sub-assembly is physically stable with a limited number of parts being held and a support surface. We apply efficient tree search algorithms to reduce the combinatorial complexity of determining such an assembly sequence. The search can be guided by either geometric heuristics or graph neural networks trained on data with simulation labels. Finally, we show the superior performance of ASAP at generating physically realistic assembly sequence plans on a large dataset of hundreds of complex product assemblies. We further demonstrate the applicability of ASAP on both simulation and real-world robotic setups. Project website: asap.csail.mit.edu

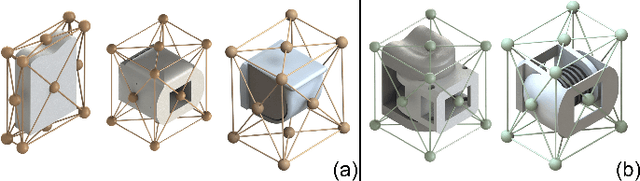

Assemble Them All: Physics-Based Planning for Generalizable Assembly by Disassembly

Nov 08, 2022Abstract:Assembly planning is the core of automating product assembly, maintenance, and recycling for modern industrial manufacturing. Despite its importance and long history of research, planning for mechanical assemblies when given the final assembled state remains a challenging problem. This is due to the complexity of dealing with arbitrary 3D shapes and the highly constrained motion required for real-world assemblies. In this work, we propose a novel method to efficiently plan physically plausible assembly motion and sequences for real-world assemblies. Our method leverages the assembly-by-disassembly principle and physics-based simulation to efficiently explore a reduced search space. To evaluate the generality of our method, we define a large-scale dataset consisting of thousands of physically valid industrial assemblies with a variety of assembly motions required. Our experiments on this new benchmark demonstrate we achieve a state-of-the-art success rate and the highest computational efficiency compared to other baseline algorithms. Our method also generalizes to rotational assemblies (e.g., screws and puzzles) and solves 80-part assemblies within several minutes.

Multi-Agent Path Planning with Asymmetric Interactions In Tight Spaces

Apr 01, 2022

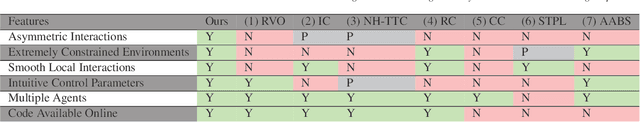

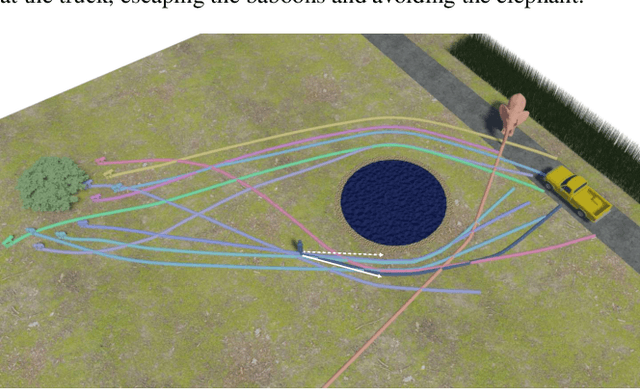

Abstract:By starting with the assumption that motion is fundamentally a decision making problem, we use the world-line concept from Special Relativity as the inspiration for a novel multi-agent path planning method. We have identified a particular set of problems that have so far been overlooked by previous works. We present our solution for the global path planning problem for each agent and ensure smooth local collision avoidance for each pair of agents in the scene. We accomplish this by modeling the trajectories of the agents through 2D space and time as curves in 3D. Global path planning is solved using a modified Djikstra's algorithm to ensure that initial trajectories for agents do not intersect. We then solve for smooth local trajectories using a quasi-Newton interior point solver, providing the trajectory curves with a radius to turn them into rods. Subsequently, resolving collision of the rods ensures that no two agents are in the same spatial position at the same time. This space-time formulation allows us to simulate previously ignored phenomena such as highly asymmetric interactions in very constrained environments. It also provides a solution for scenes with unnaturally symmetric agent alignments without the need for jittering agent positions or velocities.

An End-to-End Differentiable Framework for Contact-Aware Robot Design

Jul 15, 2021

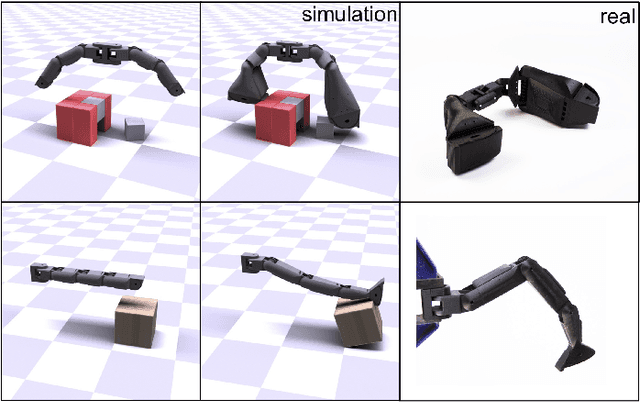

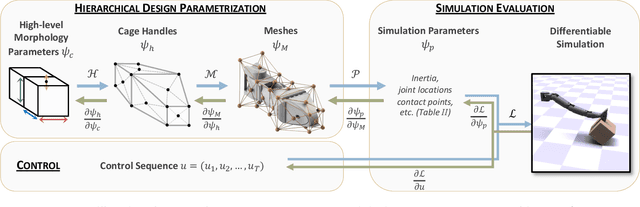

Abstract:The current dominant paradigm for robotic manipulation involves two separate stages: manipulator design and control. Because the robot's morphology and how it can be controlled are intimately linked, joint optimization of design and control can significantly improve performance. Existing methods for co-optimization are limited and fail to explore a rich space of designs. The primary reason is the trade-off between the complexity of designs that is necessary for contact-rich tasks against the practical constraints of manufacturing, optimization, contact handling, etc. We overcome several of these challenges by building an end-to-end differentiable framework for contact-aware robot design. The two key components of this framework are: a novel deformation-based parameterization that allows for the design of articulated rigid robots with arbitrary, complex geometry, and a differentiable rigid body simulator that can handle contact-rich scenarios and computes analytical gradients for a full spectrum of kinematic and dynamic parameters. On multiple manipulation tasks, our framework outperforms existing methods that either only optimize for control or for design using alternate representations or co-optimize using gradient-free methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge