Eugen Solowjow

GrowSplat: Constructing Temporal Digital Twins of Plants with Gaussian Splats

May 16, 2025

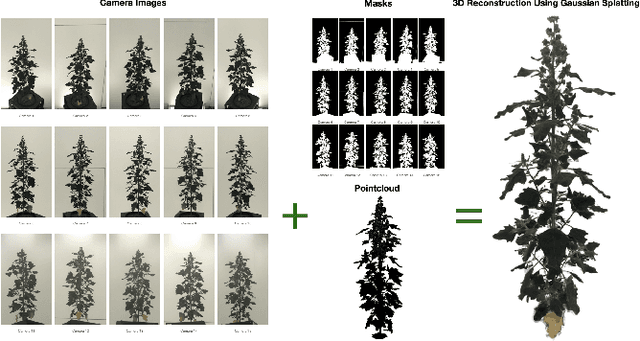

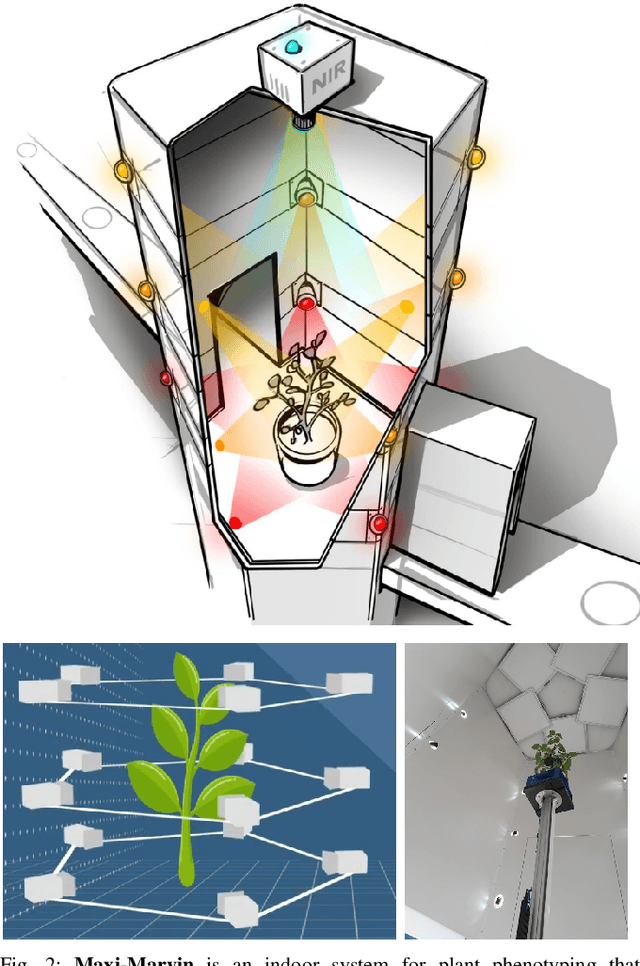

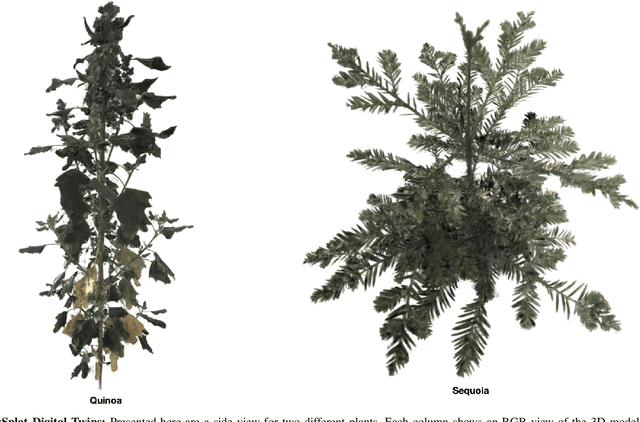

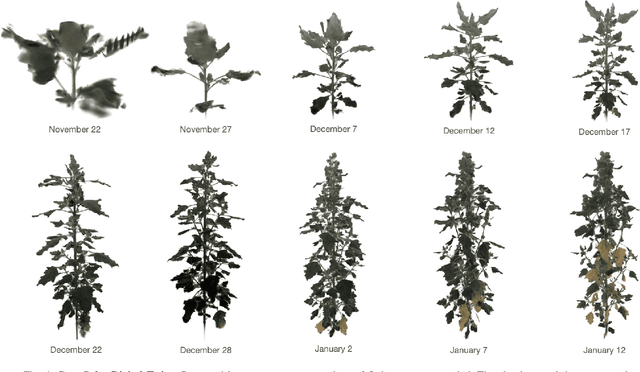

Abstract:Accurate temporal reconstructions of plant growth are essential for plant phenotyping and breeding, yet remain challenging due to complex geometries, occlusions, and non-rigid deformations of plants. We present a novel framework for building temporal digital twins of plants by combining 3D Gaussian Splatting with a robust sample alignment pipeline. Our method begins by reconstructing Gaussian Splats from multi-view camera data, then leverages a two-stage registration approach: coarse alignment through feature-based matching and Fast Global Registration, followed by fine alignment with Iterative Closest Point. This pipeline yields a consistent 4D model of plant development in discrete time steps. We evaluate the approach on data from the Netherlands Plant Eco-phenotyping Center, demonstrating detailed temporal reconstructions of Sequoia and Quinoa species. Videos and Images can be seen at https://berkeleyautomation.github.io/GrowSplat/

Verifiable Learned Behaviors via Motion Primitive Composition: Applications to Scooping of Granular Media

Sep 26, 2023Abstract:A robotic behavior model that can reliably generate behaviors from natural language inputs in real time would substantially expedite the adoption of industrial robots due to enhanced system flexibility. To facilitate these efforts, we construct a framework in which learned behaviors, created by a natural language abstractor, are verifiable by construction. Leveraging recent advancements in motion primitives and probabilistic verification, we construct a natural-language behavior abstractor that generates behaviors by synthesizing a directed graph over the provided motion primitives. If these component motion primitives are constructed according to the criteria we specify, the resulting behaviors are probabilistically verifiable. We demonstrate this verifiable behavior generation capacity in both simulation on an exploration task and on hardware with a robot scooping granular media.

Can Machines Garden? Systematically Comparing the AlphaGarden vs. Professional Horticulturalists

Jun 29, 2023

Abstract:The AlphaGarden is an automated testbed for indoor polyculture farming which combines a first-order plant simulator, a gantry robot, a seed planting algorithm, plant phenotyping and tracking algorithms, irrigation sensors and algorithms, and custom pruning tools and algorithms. In this paper, we systematically compare the performance of the AlphaGarden to professional horticulturalists on the staff of the UC Berkeley Oxford Tract Greenhouse. The humans and the machine tend side-by-side polyculture gardens with the same seed arrangement. We compare performance in terms of canopy coverage, plant diversity, and water consumption. Results from two 60-day cycles suggest that the automated AlphaGarden performs comparably to professional horticulturalists in terms of coverage and diversity, and reduces water consumption by as much as 44%. Code, videos, and datasets are available at https://sites.google.com/berkeley.edu/systematiccomparison.

IIFL: Implicit Interactive Fleet Learning from Heterogeneous Human Supervisors

Jun 27, 2023

Abstract:Imitation learning has been applied to a range of robotic tasks, but can struggle when (1) robots encounter edge cases that are not represented in the training data (distribution shift) or (2) the human demonstrations are heterogeneous: taking different paths around an obstacle, for instance (multimodality). Interactive fleet learning (IFL) mitigates distribution shift by allowing robots to access remote human teleoperators during task execution and learn from them over time, but is not equipped to handle multimodality. Recent work proposes Implicit Behavior Cloning (IBC), which is able to represent multimodal demonstrations using energy-based models (EBMs). In this work, we propose addressing both multimodality and distribution shift with Implicit Interactive Fleet Learning (IIFL), the first extension of implicit policies to interactive imitation learning (including the single-robot, single-human setting). IIFL quantifies uncertainty using a novel application of Jeffreys divergence to EBMs. While IIFL is more computationally expensive than explicit methods, results suggest that IIFL achieves 4.5x higher return on human effort in simulation experiments and an 80% higher success rate in a physical block pushing task over (Explicit) IFL, IBC, and other baselines when human supervision is heterogeneous.

Learning on the Job: Self-Rewarding Offline-to-Online Finetuning for Industrial Insertion of Novel Connectors from Vision

Oct 27, 2022Abstract:Learning-based methods in robotics hold the promise of generalization, but what can be done if a learned policy does not generalize to a new situation? In principle, if an agent can at least evaluate its own success (i.e., with a reward classifier that generalizes well even when the policy does not), it could actively practice the task and finetune the policy in this situation. We study this problem in the setting of industrial insertion tasks, such as inserting connectors in sockets and setting screws. Existing algorithms rely on precise localization of the connector or socket and carefully managed physical setups, such as assembly lines, to succeed at the task. But in unstructured environments such as homes or even some industrial settings, robots cannot rely on precise localization and may be tasked with previously unseen connectors. Offline reinforcement learning on a variety of connector insertion tasks is a potential solution, but what if the robot is tasked with inserting previously unseen connector? In such a scenario, we will still need methods that can robustly solve such tasks with online practice. One of the main observations we make in this work is that, with a suitable representation learning and domain generalization approach, it can be significantly easier for the reward function to generalize to a new but structurally similar task (e.g., inserting a new type of connector) than for the policy. This means that a learned reward function can be used to facilitate the finetuning of the robot's policy in situations where the policy fails to generalize in zero shot, but the reward function generalizes successfully. We show that such an approach can be instantiated in the real world, pretrained on 50 different connectors, and successfully finetuned to new connectors via the learned reward function. Videos can be viewed at https://sites.google.com/view/learningonthejob

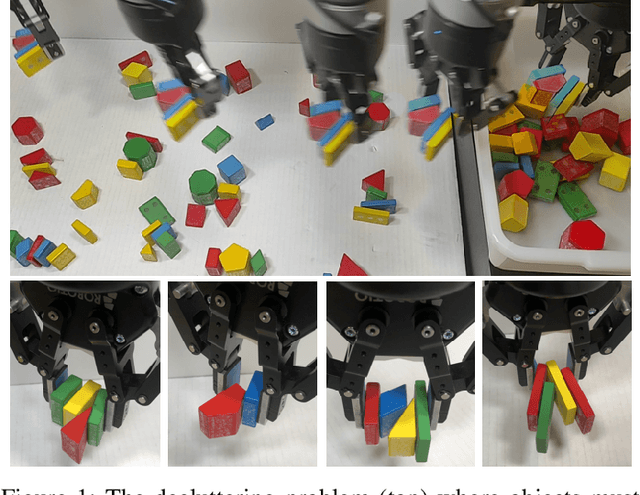

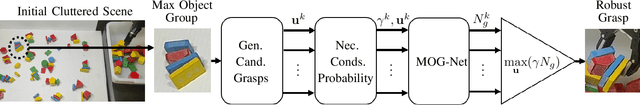

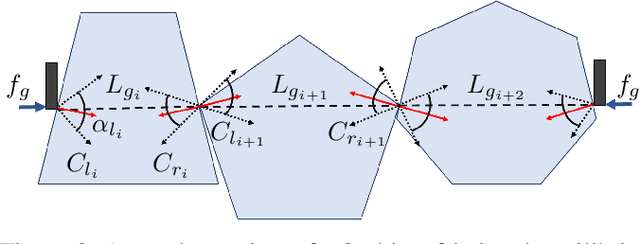

Learning to Efficiently Plan Robust Frictional Multi-Object Grasps

Oct 13, 2022

Abstract:We consider a decluttering problem where multiple rigid convex polygonal objects rest in randomly placed positions and orientations on a planar surface and must be efficiently transported to a packing box using both single and multi-object grasps. Prior work considered frictionless multi-object grasping. In this paper, we introduce friction to increase picks per hour. We train a neural network using real examples to plan robust multi-object grasps. In physical experiments, we find an 11.7% increase in success rates, a 1.7x increase in picks per hour, and an 8.2x decrease in grasp planning time compared to prior work on multi-object grasping. Videos are available at https://youtu.be/pEZpHX5FZIs.

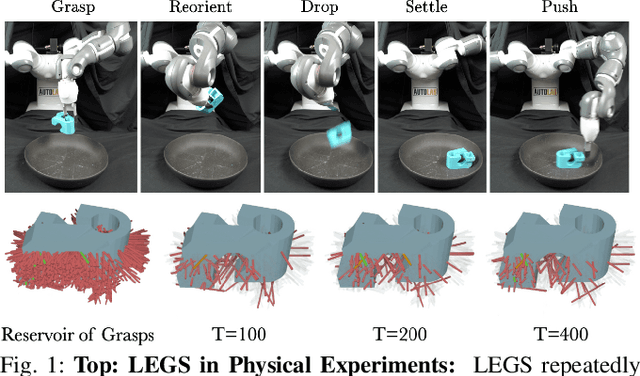

LEGS: Learning Efficient Grasp Sets for Exploratory Grasping

Nov 29, 2021

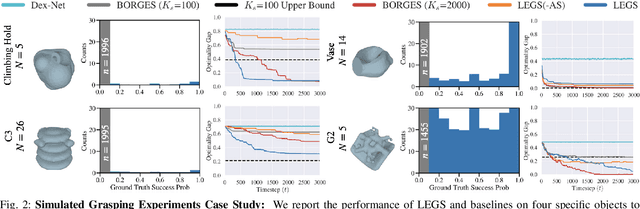

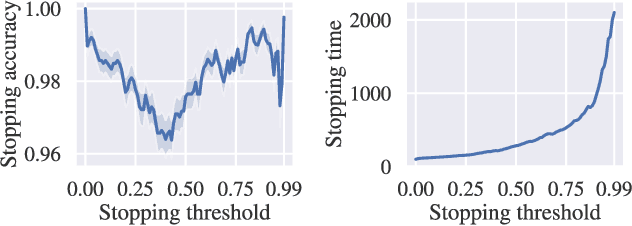

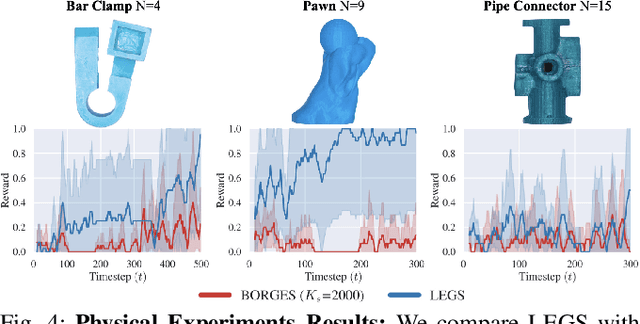

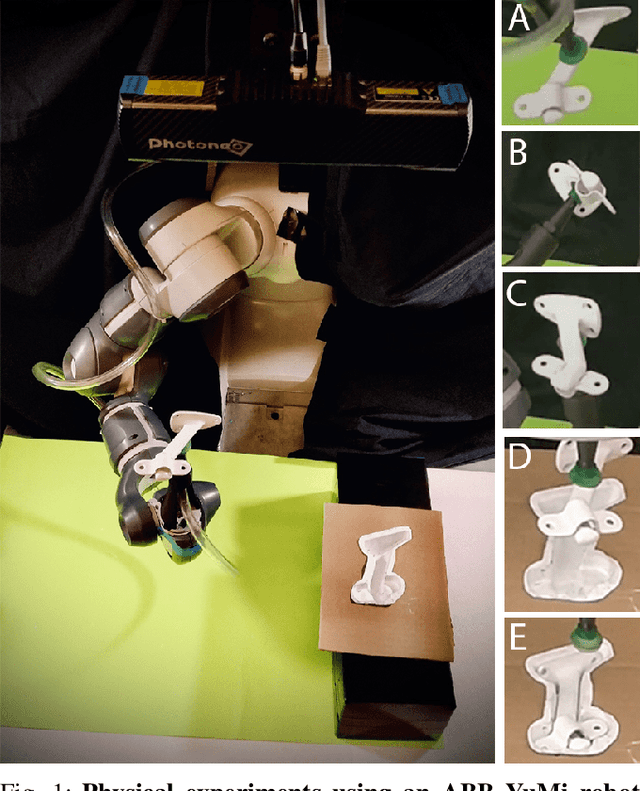

Abstract:Previous work defined Exploratory Grasping, where a robot iteratively grasps and drops an unknown complex polyhedral object to discover a set of robust grasps for each recognizably distinct stable pose of the object. Recent work used a multi-armed bandit model with a small set of candidate grasps per pose; however, for objects with few successful grasps, this set may not include the most robust grasp. We present Learned Efficient Grasp Sets (LEGS), an algorithm that can efficiently explore thousands of possible grasps by constructing small active sets of promising grasps and uses learned confidence bounds to determine when, with high confidence, it can stop exploring the object. Experiments suggest that LEGS can identify a high-quality grasp more efficiently than prior algorithms which do not learn active sets. In simulation experiments, we measure the optimality gap between the success probability of the best grasp identified by LEGS and baselines and that of the true most robust grasp. After 3000 steps of exploration, LEGS outperforms baseline algorithms on 10 of the 14 Dex-Net Adversarial objects and 25 of the 39 EGAD! objects. We then develop a self-supervised grasping system, where the robot explores grasps with minimal human intervention. Physical experiments across 3 objects suggest that LEGS converges to high-performing grasps significantly faster than baselines. See \url{https://sites.google.com/view/legs-exp-grasping} for supplemental material and videos.

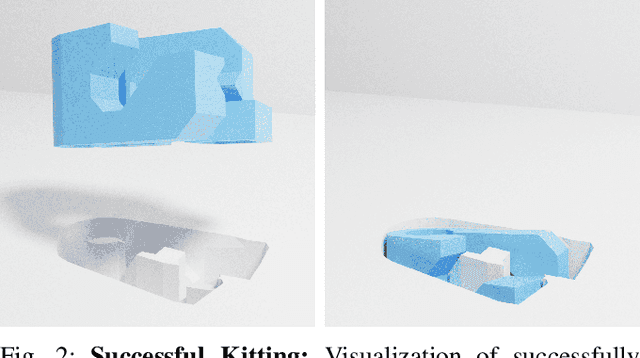

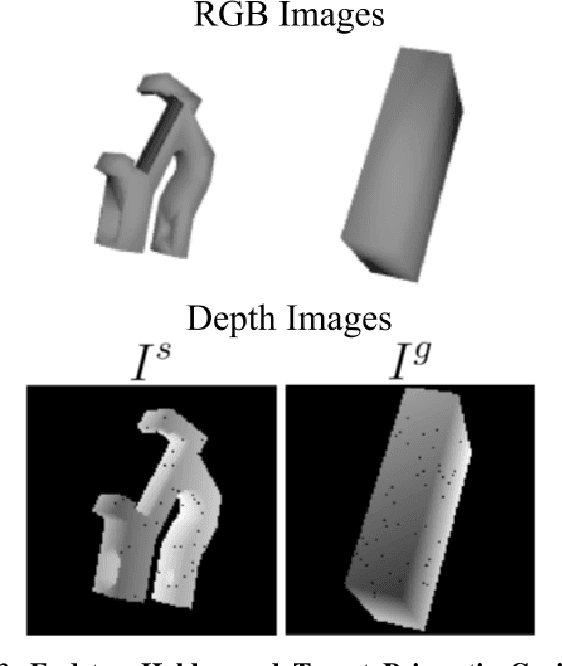

Kit-Net: Self-Supervised Learning to Kit Novel 3D Objects into Novel 3D Cavities

Jul 13, 2021

Abstract:In industrial part kitting, 3D objects are inserted into cavities for transportation or subsequent assembly. Kitting is a critical step as it can decrease downstream processing and handling times and enable lower storage and shipping costs. We present Kit-Net, a framework for kitting previously unseen 3D objects into cavities given depth images of both the target cavity and an object held by a gripper in an unknown initial orientation. Kit-Net uses self-supervised deep learning and data augmentation to train a convolutional neural network (CNN) to robustly estimate 3D rotations between objects and matching concave or convex cavities using a large training dataset of simulated depth images pairs. Kit-Net then uses the trained CNN to implement a controller to orient and position novel objects for insertion into novel prismatic and conformal 3D cavities. Experiments in simulation suggest that Kit-Net can orient objects to have a 98.9% average intersection volume between the object mesh and that of the target cavity. Physical experiments with industrial objects succeed in 18% of trials using a baseline method and in 63% of trials with Kit-Net. Video, code, and data are available at https://github.com/BerkeleyAutomation/Kit-Net.

Meta-Reinforcement Learning for Robotic Industrial Insertion Tasks

May 23, 2020

Abstract:Robotic insertion tasks are characterized by contact and friction mechanics, making them challenging for conventional feedback control methods due to unmodeled physical effects. Reinforcement learning (RL) is a promising approach for learning control policies in such settings. However, RL can be unsafe during exploration and might require a large amount of real-world training data, which is expensive to collect. In this paper, we study how to use meta-reinforcement learning to solve the bulk of the problem in simulation by solving a family of simulated industrial insertion tasks and then adapt policies quickly in the real world. We demonstrate our approach by training an agent to successfully perform challenging real-world insertion tasks using less than 20 trials of real-world experience. Videos and other material are available at https://pearl-insertion.github.io/

Information-Collection in Robotic Process Monitoring: An Active Perception Approach

May 01, 2020

Abstract:Active perception systems maximizing information gain to support both monitoring and decision making have seen considerable application in recent work. In this paper, we propose and demonstrate a method of acquiring and extrapolating information in an active sensory system through use of a Bayesian Filter. Our approach is motivated by manufacturing processes, where automated visual tracking of system states may aid in fault diagnosis, certification of parts and safety; in extreme cases, our approach may enable novel manufacturing processes relying on monitoring solutions beyond passive perception. We demonstrate how using a Bayesian Filter in active perception scenarios permits reasoning about future actions based on measured as well as unmeasured but propagated state elements, thereby increasing substantially the quality of information available to decision making algorithms used in control of overarching processes. We demonstrate use of our active perception system in physical experiments, where we use a time-varying Kalman Filter to resolve uncertainty for a representative system capturing in additive manufacturing.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge