Christopher E. Mower

Data-driven Interpretable Hybrid Robot Dynamics

Dec 10, 2025Abstract:We study data-driven identification of interpretable hybrid robot dynamics, where an analytical rigid-body dynamics model is complemented by a learned residual torque term. Using symbolic regression and sparse identification of nonlinear dynamics (SINDy), we recover compact closed-form expressions for this residual from joint-space data. In simulation on a 7-DoF Franka arm with known dynamics, these interpretable models accurately recover inertial, Coriolis, gravity, and viscous effects with very small relative error and outperform neural-network baselines in both accuracy and generalization. On real data from a 7-DoF WAM arm, symbolic-regression residuals generalize substantially better than SINDy and neural networks, which tend to overfit, and suggest candidate new closed-form formulations that extend the nominal dynamics model for this robot. Overall, the results indicate that interpretable residual dynamics models provide compact, accurate, and physically meaningful alternatives to black-box function approximators for torque prediction.

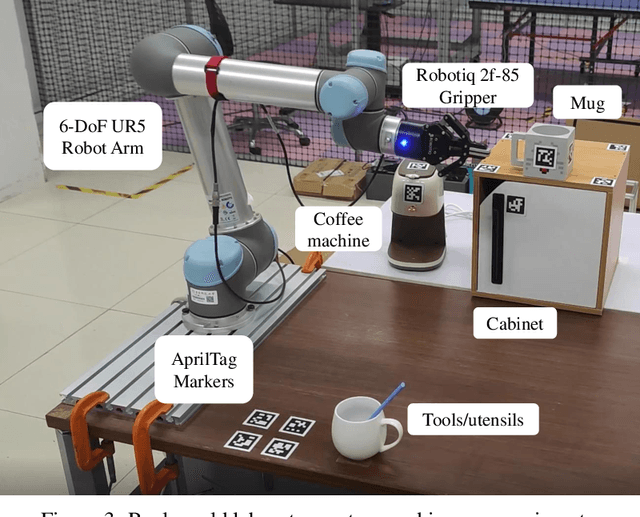

Experience is the Best Teacher: Grounding VLMs for Robotics through Self-Generated Memory

Jul 22, 2025Abstract:Vision-language models (VLMs) have been widely adopted in robotics to enable autonomous planning. However, grounding VLMs, originally trained on internet data, to diverse real-world robots remains a challenge. This paper presents ExpTeach, a framework that grounds VLMs to physical robots by building a self-generated memory of real-world experiences. In ExpTeach, the VLM autonomously plans actions, verifies outcomes, reflects on failures, and adapts robot behaviors in a closed loop. The self-generated experiences during this process are then summarized into a long-term memory, enabling retrieval of learned knowledge to guide future tasks via retrieval-augmented generation (RAG). Additionally, ExpTeach enhances the spatial understanding of VLMs with an on-demand image annotation module. In experiments, we show that reflection improves success rates from 36% to 84% on four challenging robotic tasks and observe the emergence of intelligent object interactions, including creative tool use. Across extensive tests on 12 real-world scenarios (including eight unseen ones), we find that grounding with long-term memory boosts single-trial success rates from 22% to 80%, demonstrating the effectiveness and generalizability of ExpTeach.

Hydra: Marker-Free RGB-D Hand-Eye Calibration

Apr 29, 2025Abstract:This work presents an RGB-D imaging-based approach to marker-free hand-eye calibration using a novel implementation of the iterative closest point (ICP) algorithm with a robust point-to-plane (PTP) objective formulated on a Lie algebra. Its applicability is demonstrated through comprehensive experiments using three well known serial manipulators and two RGB-D cameras. With only three randomly chosen robot configurations, our approach achieves approximately 90% successful calibrations, demonstrating 2-3x higher convergence rates to the global optimum compared to both marker-based and marker-free baselines. We also report 2 orders of magnitude faster convergence time (0.8 +/- 0.4 s) for 9 robot configurations over other marker-free methods. Our method exhibits significantly improved accuracy (5 mm in task space) over classical approaches (7 mm in task space) whilst being marker-free. The benchmarking dataset and code are open sourced under Apache 2.0 License, and a ROS 2 integration with robot abstraction is provided to facilitate deployment.

Al-Khwarizmi: Discovering Physical Laws with Foundation Models

Feb 03, 2025

Abstract:Inferring physical laws from data is a central challenge in science and engineering, including but not limited to healthcare, physical sciences, biosciences, social sciences, sustainability, climate, and robotics. Deep networks offer high-accuracy results but lack interpretability, prompting interest in models built from simple components. The Sparse Identification of Nonlinear Dynamics (SINDy) method has become the go-to approach for building such modular and interpretable models. SINDy leverages sparse regression with L1 regularization to identify key terms from a library of candidate functions. However, SINDy's choice of candidate library and optimization method requires significant technical expertise, limiting its widespread applicability. This work introduces Al-Khwarizmi, a novel agentic framework for physical law discovery from data, which integrates foundational models with SINDy. Leveraging LLMs, VLMs, and Retrieval-Augmented Generation (RAG), our approach automates physical law discovery, incorporating prior knowledge and iteratively refining candidate solutions via reflection. Al-Khwarizmi operates in two steps: it summarizes system observations-comprising textual descriptions, raw data, and plots-followed by a secondary step that generates candidate feature libraries and optimizer configurations to identify hidden physics laws correctly. Evaluating our algorithm on over 198 models, we demonstrate state-of-the-art performance compared to alternatives, reaching a 20 percent increase against the best-performing alternative.

Vision and Contact based Optimal Control for Autonomous Trocar Docking

Jul 31, 2024Abstract:Future operating theatres will be equipped with robots to perform various surgical tasks including, for example, endoscope control. Human-in-the-loop supervisory control architectures where the surgeon selects from several autonomous sequences is already being successfully applied in preclinical tests. Inserting an endoscope into a trocar or introducer is a key step for every keyhole surgical procedure -- hereafter we will only refer to this device as a "trocar". Our goal is to develop a controller for autonomous trocar docking. Autonomous trocar docking is a version of the peg-in-hole problem. Extensive work in the robotics literature addresses this problem. The peg-in-hole problem has been widely studied in the context of assembly where, typically, the hole is considered static and rigid to interaction. In our case, however, the trocar is not fixed and responds to interaction. We consider a variety of surgical procedures where surgeons will utilize contact between the endoscope and trocar in order to complete the insertion successfully. To the best of our knowledge, we have not found literature that explores this particular generalization of the problem directly. Our primary contribution in this work is an optimal control formulation for automated trocar docking. We use a nonlinear optimization program to model the task, minimizing a cost function subject to constraints to find optimal joint configurations. The controller incorporates a geometric model for insertion and a force-feedback (FF) term to ensure patient safety by preventing excessive interaction forces with the trocar. Experiments, demonstrated on a real hardware lab setup, validate the approach. Our method successfully achieves trocar insertion on our real robot lab setup, and simulation trials demonstrate its ability to reduce interaction forces.

ROS-LLM: A ROS framework for embodied AI with task feedback and structured reasoning

Jun 28, 2024

Abstract:We present a framework for intuitive robot programming by non-experts, leveraging natural language prompts and contextual information from the Robot Operating System (ROS). Our system integrates large language models (LLMs), enabling non-experts to articulate task requirements to the system through a chat interface. Key features of the framework include: integration of ROS with an AI agent connected to a plethora of open-source and commercial LLMs, automatic extraction of a behavior from the LLM output and execution of ROS actions/services, support for three behavior modes (sequence, behavior tree, state machine), imitation learning for adding new robot actions to the library of possible actions, and LLM reflection via human and environment feedback. Extensive experiments validate the framework, showcasing robustness, scalability, and versatility in diverse scenarios, including long-horizon tasks, tabletop rearrangements, and remote supervisory control. To facilitate the adoption of our framework and support the reproduction of our results, we have made our code open-source. You can access it at: https://github.com/huawei-noah/HEBO/tree/master/ROSLLM.

Semi-Autonomous Laparoscopic Robot Docking with Learned Hand-Eye Information Fusion

May 09, 2024Abstract:In this study, we introduce a novel shared-control system for key-hole docking operations, combining a commercial camera with occlusion-robust pose estimation and a hand-eye information fusion technique. This system is used to enhance docking precision and force-compliance safety. To train a hand-eye information fusion network model, we generated a self-supervised dataset using this docking system. After training, our pose estimation method showed improved accuracy compared to traditional methods, including observation-only approaches, hand-eye calibration, and conventional state estimation filters. In real-world phantom experiments, our approach demonstrated its effectiveness with reduced position dispersion (1.23\pm 0.81 mm vs. 2.47 \pm 1.22 mm) and force dispersion (0.78\pm 0.57 N vs. 1.15 \pm 0.97 N) compared to the control group. These advancements in semi-autonomy co-manipulation scenarios enhance interaction and stability. The study presents an anti-interference, steady, and precision solution with potential applications extending beyond laparoscopic surgery to other minimally invasive procedures.

Excitation Trajectory Optimization for Dynamic Parameter Identification Using Virtual Constraints in Hands-on Robotic System

Jan 29, 2024

Abstract:This paper proposes a novel, more computationally efficient method for optimizing robot excitation trajectories for dynamic parameter identification, emphasizing self-collision avoidance. This addresses the system identification challenges for getting high-quality training data associated with co-manipulated robotic arms that can be equipped with a variety of tools, a common scenario in industrial but also clinical and research contexts. Utilizing the Unified Robotics Description Format (URDF) to implement a symbolic Python implementation of the Recursive Newton-Euler Algorithm (RNEA), the approach aids in dynamically estimating parameters such as inertia using regression analyses on data from real robots. The excitation trajectory was evaluated and achieved on par criteria when compared to state-of-the-art reported results which didn't consider self-collision and tool calibrations. Furthermore, physical Human-Robot Interaction (pHRI) admittance control experiments were conducted in a surgical context to evaluate the derived inverse dynamics model showing a 30.1\% workload reduction by the NASA TLX questionnaire.

LBR-Stack: ROS 2 and Python Integration of KUKA FRI for Med and IIWA Robots

Nov 21, 2023

Abstract:The LBR-Stack is a collection of packages that simplify the usage and extend the capabilities of KUKA's Fast Robot Interface (FRI). It is designed for mission critical hard real-time applications. Supported are the KUKA LBR Med7/14 and KUKA LBR iiwa7/14 robots in the Gazebo simulation and for communication with real hardware.

OpTaS: An Optimization-based Task Specification Library for Trajectory Optimization and Model Predictive Control

Jan 31, 2023

Abstract:This paper presents OpTaS, a task specification Python library for Trajectory Optimization (TO) and Model Predictive Control (MPC) in robotics. Both TO and MPC are increasingly receiving interest in optimal control and in particular handling dynamic environments. While a flurry of software libraries exists to handle such problems, they either provide interfaces that are limited to a specific problem formulation (e.g. TracIK, CHOMP), or are large and statically specify the problem in configuration files (e.g. EXOTica, eTaSL). OpTaS, on the other hand, allows a user to specify custom nonlinear constrained problem formulations in a single Python script allowing the controller parameters to be modified during execution. The library provides interface to several open source and commercial solvers (e.g. IPOPT, SNOPT, KNITRO, SciPy) to facilitate integration with established workflows in robotics. Further benefits of OpTaS are highlighted through a thorough comparison with common libraries. An additional key advantage of OpTaS is the ability to define optimal control tasks in the joint space, task space, or indeed simultaneously. The code for OpTaS is easily installed via pip, and the source code with examples can be found at https://github.com/cmower/optas.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge