Zehan Ma

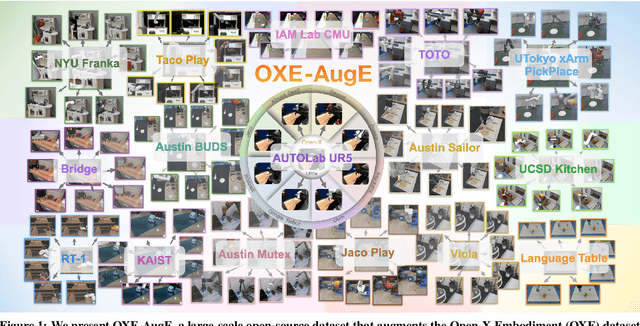

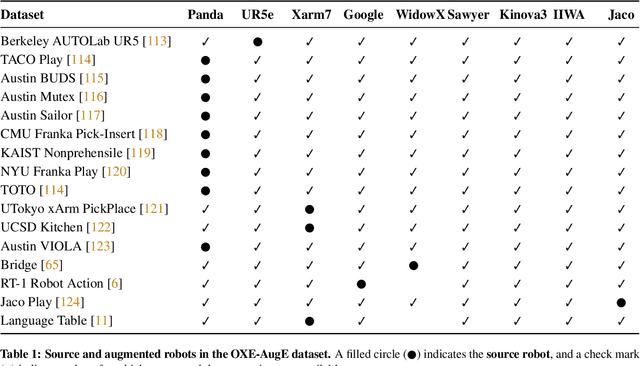

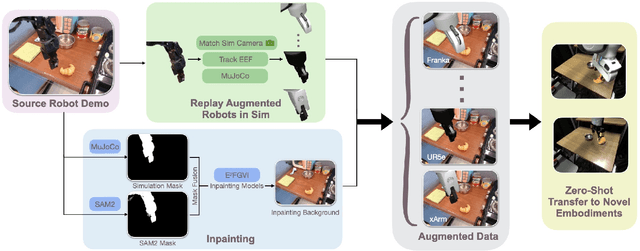

OXE-AugE: A Large-Scale Robot Augmentation of OXE for Scaling Cross-Embodiment Policy Learning

Dec 15, 2025

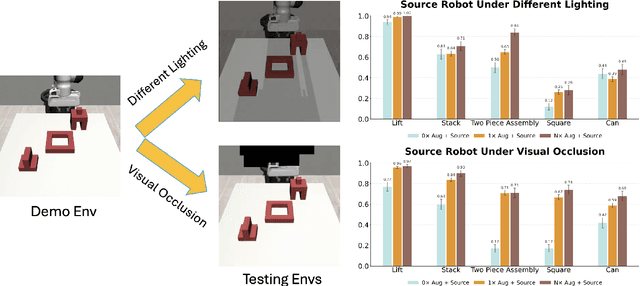

Abstract:Large and diverse datasets are needed for training generalist robot policies that have potential to control a variety of robot embodiments -- robot arm and gripper combinations -- across diverse tasks and environments. As re-collecting demonstrations and retraining for each new hardware platform are prohibitively costly, we show that existing robot data can be augmented for transfer and generalization. The Open X-Embodiment (OXE) dataset, which aggregates demonstrations from over 60 robot datasets, has been widely used as the foundation for training generalist policies. However, it is highly imbalanced: the top four robot types account for over 85\% of its real data, which risks overfitting to robot-scene combinations. We present AugE-Toolkit, a scalable robot augmentation pipeline, and OXE-AugE, a high-quality open-source dataset that augments OXE with 9 different robot embodiments. OXE-AugE provides over 4.4 million trajectories, more than triple the size of the original OXE. We conduct a systematic study of how scaling robot augmentation impacts cross-embodiment learning. Results suggest that augmenting datasets with diverse arms and grippers improves policy performance not only on the augmented robots, but also on unseen robots and even the original robots under distribution shifts. In physical experiments, we demonstrate that state-of-the-art generalist policies such as OpenVLA and $π_0$ benefit from fine-tuning on OXE-AugE, improving success rates by 24-45% on previously unseen robot-gripper combinations across four real-world manipulation tasks. Project website: https://OXE-AugE.github.io/.

Omni-Scan: Creating Visually-Accurate Digital Twin Object Models Using a Bimanual Robot with Handover and Gaussian Splat Merging

Aug 01, 2025Abstract:3D Gaussian Splats (3DGSs) are 3D object models derived from multi-view images. Such "digital twins" are useful for simulations, virtual reality, marketing, robot policy fine-tuning, and part inspection. 3D object scanning usually requires multi-camera arrays, precise laser scanners, or robot wrist-mounted cameras, which have restricted workspaces. We propose Omni-Scan, a pipeline for producing high-quality 3D Gaussian Splat models using a bi-manual robot that grasps an object with one gripper and rotates the object with respect to a stationary camera. The object is then re-grasped by a second gripper to expose surfaces that were occluded by the first gripper. We present the Omni-Scan robot pipeline using DepthAny-thing, Segment Anything, as well as RAFT optical flow models to identify and isolate objects held by a robot gripper while removing the gripper and the background. We then modify the 3DGS training pipeline to support concatenated datasets with gripper occlusion, producing an omni-directional (360 degree view) model of the object. We apply Omni-Scan to part defect inspection, finding that it can identify visual or geometric defects in 12 different industrial and household objects with an average accuracy of 83%. Interactive videos of Omni-Scan 3DGS models can be found at https://berkeleyautomation.github.io/omni-scan/

Robo2VLM: Visual Question Answering from Large-Scale In-the-Wild Robot Manipulation Datasets

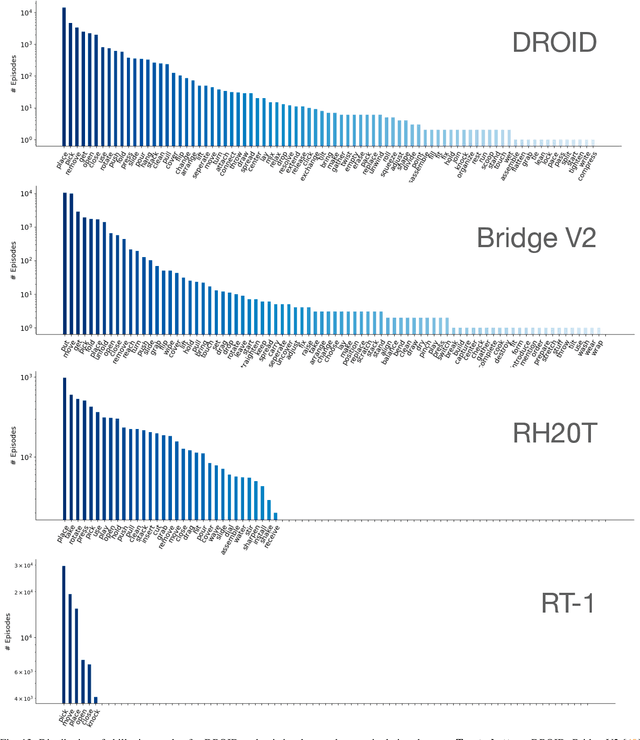

May 21, 2025Abstract:Vision-Language Models (VLMs) acquire real-world knowledge and general reasoning ability through Internet-scale image-text corpora. They can augment robotic systems with scene understanding and task planning, and assist visuomotor policies that are trained on robot trajectory data. We explore the reverse paradigm - using rich, real, multi-modal robot trajectory data to enhance and evaluate VLMs. In this paper, we present Robo2VLM, a Visual Question Answering (VQA) dataset generation framework for VLMs. Given a human tele-operated robot trajectory, Robo2VLM derives ground-truth from non-visual and non-descriptive sensory modalities, such as end-effector pose, gripper aperture, and force sensing. Based on these modalities, it segments the robot trajectory into a sequence of manipulation phases. At each phase, Robo2VLM uses scene and interaction understanding to identify 3D properties of the robot, task goal, and the target object. The properties are used to generate representative VQA queries - images with textural multiple-choice questions - based on spatial, goal-conditioned, and interaction reasoning question templates. We curate Robo2VLM-1, a large-scale in-the-wild dataset with 684,710 questions covering 463 distinct scenes and 3,396 robotic manipulation tasks from 176k real robot trajectories. Results suggest that Robo2VLM-1 can benchmark and improve VLM capabilities in spatial and interaction reasoning.

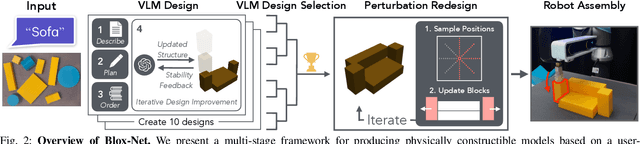

Blox-Net: Generative Design-for-Robot-Assembly Using VLM Supervision, Physics Simulation, and a Robot with Reset

Sep 25, 2024

Abstract:Generative AI systems have shown impressive capabilities in creating text, code, and images. Inspired by the rich history of research in industrial ''Design for Assembly'', we introduce a novel problem: Generative Design-for-Robot-Assembly (GDfRA). The task is to generate an assembly based on a natural language prompt (e.g., ''giraffe'') and an image of available physical components, such as 3D-printed blocks. The output is an assembly, a spatial arrangement of these components, and instructions for a robot to build this assembly. The output must 1) resemble the requested object and 2) be reliably assembled by a 6 DoF robot arm with a suction gripper. We then present Blox-Net, a GDfRA system that combines generative vision language models with well-established methods in computer vision, simulation, perturbation analysis, motion planning, and physical robot experimentation to solve a class of GDfRA problems with minimal human supervision. Blox-Net achieved a Top-1 accuracy of 63.5% in the ''recognizability'' of its designed assemblies (eg, resembling giraffe as judged by a VLM). These designs, after automated perturbation redesign, were reliably assembled by a robot, achieving near-perfect success across 10 consecutive assembly iterations with human intervention only during reset prior to assembly. Surprisingly, this entire design process from textual word (''giraffe'') to reliable physical assembly is performed with zero human intervention.

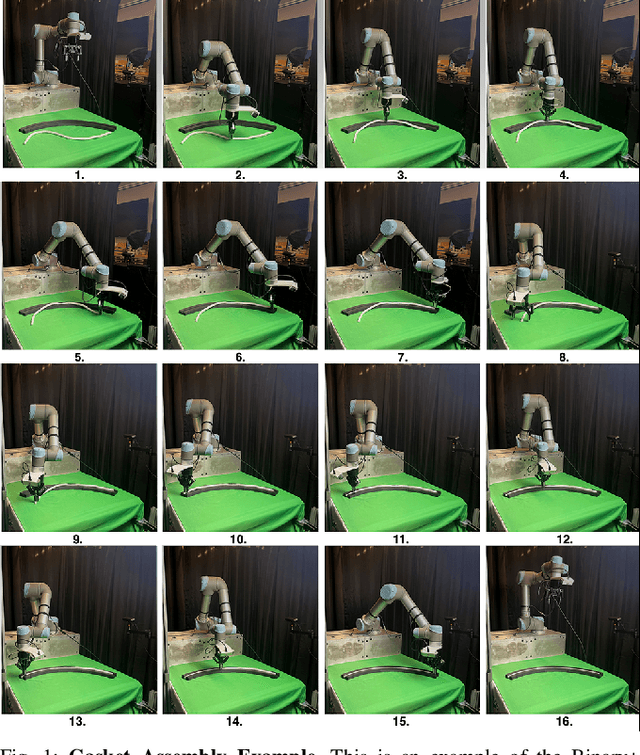

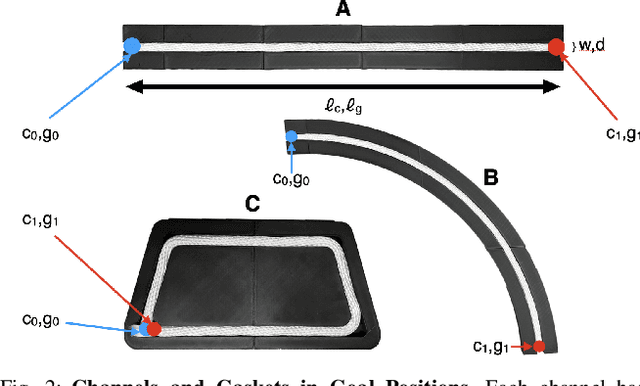

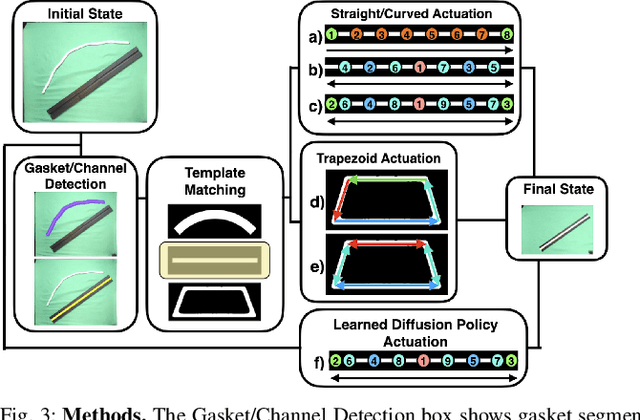

Automating Deformable Gasket Assembly

Aug 22, 2024

Abstract:In Gasket Assembly, a deformable gasket must be aligned and pressed into a narrow channel. This task is common for sealing surfaces in the manufacturing of automobiles, appliances, electronics, and other products. Gasket Assembly is a long-horizon, high-precision task and the gasket must align with the channel and be fully pressed in to achieve a secure fit. To compare approaches, we present 4 methods for Gasket Assembly: one policy from deep imitation learning and three procedural algorithms. We evaluate these methods with 100 physical trials. Results suggest that the Binary+ algorithm succeeds in 10/10 on the straight channel whereas the learned policy based on 250 human teleoperated demonstrations succeeds in 8/10 trials and is significantly slower. Code, CAD models, videos, and data can be found at https://berkeleyautomation.github.io/robot-gasket/

DROID: A Large-Scale In-The-Wild Robot Manipulation Dataset

Mar 19, 2024

Abstract:The creation of large, diverse, high-quality robot manipulation datasets is an important stepping stone on the path toward more capable and robust robotic manipulation policies. However, creating such datasets is challenging: collecting robot manipulation data in diverse environments poses logistical and safety challenges and requires substantial investments in hardware and human labour. As a result, even the most general robot manipulation policies today are mostly trained on data collected in a small number of environments with limited scene and task diversity. In this work, we introduce DROID (Distributed Robot Interaction Dataset), a diverse robot manipulation dataset with 76k demonstration trajectories or 350 hours of interaction data, collected across 564 scenes and 84 tasks by 50 data collectors in North America, Asia, and Europe over the course of 12 months. We demonstrate that training with DROID leads to policies with higher performance and improved generalization ability. We open source the full dataset, policy learning code, and a detailed guide for reproducing our robot hardware setup.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge