Wanlin Li

TaF-VLA: Tactile-Force Alignment in Vision-Language-Action Models for Force-aware Manipulation

Jan 30, 2026Abstract:Vision-Language-Action (VLA) models have recently emerged as powerful generalists for robotic manipulation. However, due to their predominant reliance on visual modalities, they fundamentally lack the physical intuition required for contact-rich tasks that require precise force regulation and physical reasoning. Existing attempts to incorporate vision-based tactile sensing into VLA models typically treat tactile inputs as auxiliary visual textures, thereby overlooking the underlying correlation between surface deformation and interaction dynamics. To bridge this gap, we propose a paradigm shift from tactile-vision alignment to tactile-force alignment. Here, we introduce TaF-VLA, a framework that explicitly grounds high-dimensional tactile observations in physical interaction forces. To facilitate this, we develop an automated tactile-force data acquisition device and curate the TaF-Dataset, comprising over 10 million synchronized tactile observations, 6-axis force/torque, and matrix force map. To align sequential tactile observations with interaction forces, the central component of our approach is the Tactile-Force Adapter (TaF-Adapter), a tactile sensor encoder that extracts discretized latent information for encoding tactile observations. This mechanism ensures that the learned representations capture history-dependent, noise-insensitive physical dynamics rather than static visual textures. Finally, we integrate this force-aligned encoder into a VLA backbone. Extensive real-world experiments demonstrate that TaF-VLA policy significantly outperforms state-of-the-art tactile-vision-aligned and vision-only baselines on contact-rich tasks, verifying its ability to achieve robust, force-aware manipulation through cross-modal physical reasoning.

Tactile-Force Alignment in Vision-Language-Action Models for Force-aware Manipulation

Jan 28, 2026Abstract:Vision-Language-Action (VLA) models have recently emerged as powerful generalists for robotic manipulation. However, due to their predominant reliance on visual modalities, they fundamentally lack the physical intuition required for contact-rich tasks that require precise force regulation and physical reasoning. Existing attempts to incorporate vision-based tactile sensing into VLA models typically treat tactile inputs as auxiliary visual textures, thereby overlooking the underlying correlation between surface deformation and interaction dynamics. To bridge this gap, we propose a paradigm shift from tactile-vision alignment to tactile-force alignment. Here, we introduce TaF-VLA, a framework that explicitly grounds high-dimensional tactile observations in physical interaction forces. To facilitate this, we develop an automated tactile-force data acquisition device and curate the TaF-Dataset, comprising over 10 million synchronized tactile observations, 6-axis force/torque, and matrix force map. To align sequential tactile observations with interaction forces, the central component of our approach is the Tactile-Force Adapter (TaF-Adapter), a tactile sensor encoder that extracts discretized latent information for encoding tactile observations. This mechanism ensures that the learned representations capture history-dependent, noise-insensitive physical dynamics rather than static visual textures. Finally, we integrate this force-aligned encoder into a VLA backbone. Extensive real-world experiments demonstrate that TaF-VLA policy significantly outperforms state-of-the-art tactile-vision-aligned and vision-only baselines on contact-rich tasks, verifying its ability to achieve robust, force-aware manipulation through cross-modal physical reasoning.

PP-Tac: Paper Picking Using Tactile Feedback in Dexterous Robotic Hands

Apr 23, 2025

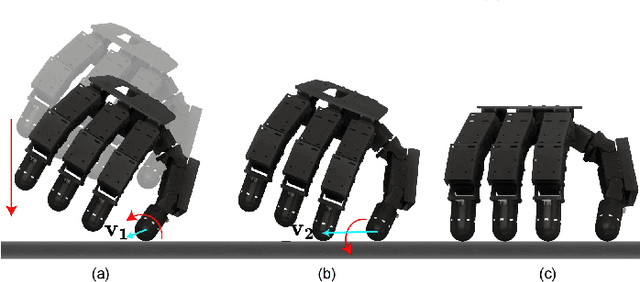

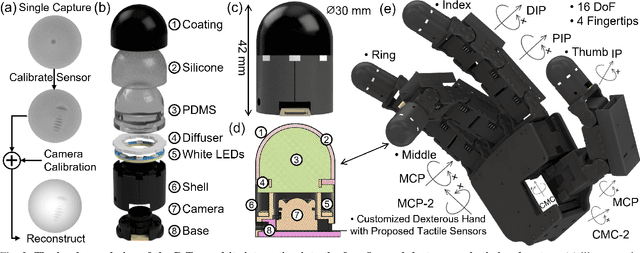

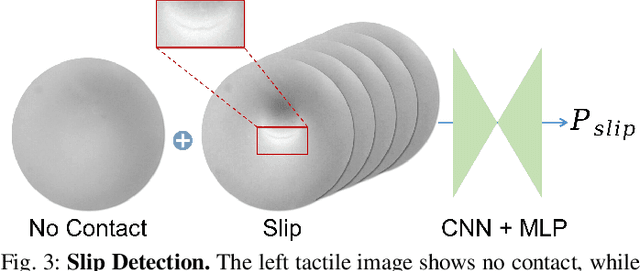

Abstract:Robots are increasingly envisioned as human companions, assisting with everyday tasks that often involve manipulating deformable objects. Although recent advances in robotic hardware and embodied AI have expanded their capabilities, current systems still struggle with handling thin, flat, and deformable objects such as paper and fabric. This limitation arises from the lack of suitable perception techniques for robust state estimation under diverse object appearances, as well as the absence of planning techniques for generating appropriate grasp motions. To bridge these gaps, this paper introduces PP-Tac, a robotic system for picking up paper-like objects. PP-Tac features a multi-fingered robotic hand with high-resolution omnidirectional tactile sensors \sensorname. This hardware configuration enables real-time slip detection and online frictional force control that mitigates such slips. Furthermore, grasp motion generation is achieved through a trajectory synthesis pipeline, which first constructs a dataset of finger's pinching motions. Based on this dataset, a diffusion-based policy is trained to control the hand-arm robotic system. Experiments demonstrate that PP-Tac can effectively grasp paper-like objects of varying material, thickness, and stiffness, achieving an overall success rate of 87.5\%. To our knowledge, this work is the first attempt to grasp paper-like deformable objects using a tactile dexterous hand. Our project webpage can be found at: https://peilin-666.github.io/projects/PP-Tac/

Embedding high-resolution touch across robotic hands enables adaptive human-like grasping

Dec 19, 2024

Abstract:Developing robotic hands that adapt to real-world dynamics remains a fundamental challenge in robotics and machine intelligence. Despite significant advances in replicating human hand kinematics and control algorithms, robotic systems still struggle to match human capabilities in dynamic environments, primarily due to inadequate tactile feedback. To bridge this gap, we present F-TAC Hand, a biomimetic hand featuring high-resolution tactile sensing (0.1mm spatial resolution) across 70% of its surface area. Through optimized hand design, we overcome traditional challenges in integrating high-resolution tactile sensors while preserving the full range of motion. The hand, powered by our generative algorithm that synthesizes human-like hand configurations, demonstrates robust grasping capabilities in dynamic real-world conditions. Extensive evaluation across 600 real-world trials demonstrates that this tactile-embodied system significantly outperforms non-tactile alternatives in complex manipulation tasks (p<0.0001). These results provide empirical evidence for the critical role of rich tactile embodiment in developing advanced robotic intelligence, offering new perspectives on the relationship between physical sensing capabilities and intelligent behavior.

MiniTac: An Ultra-Compact 8 mm Vision-Based Tactile Sensor for Enhanced Palpation in Robot-Assisted Minimally Invasive Surgery

Oct 30, 2024Abstract:Robot-assisted minimally invasive surgery (RAMIS) provides substantial benefits over traditional open and laparoscopic methods. However, a significant limitation of RAMIS is the surgeon's inability to palpate tissues, a crucial technique for examining tissue properties and detecting abnormalities, restricting the widespread adoption of RAMIS. To overcome this obstacle, we introduce MiniTac, a novel vision-based tactile sensor with an ultra-compact cross-sectional diameter of 8 mm, designed for seamless integration into mainstream RAMIS devices, particularly the Da Vinci surgical systems. MiniTac features a novel mechanoresponsive photonic elastomer membrane that changes color distribution under varying contact pressures. This color change is captured by an embedded miniature camera, allowing MiniTac to detect tumors both on the tissue surface and in deeper layers typically obscured from endoscopic view. MiniTac's efficacy has been rigorously tested on both phantoms and ex-vivo tissues. By leveraging advanced mechanoresponsive photonic materials, MiniTac represents a significant advancement in integrating tactile sensing into RAMIS, potentially expanding its applicability to a wider array of clinical scenarios that currently rely on traditional surgical approaches.

Large-scale Deployment of Vision-based Tactile Sensors on Multi-fingered Grippers

Aug 05, 2024Abstract:Vision-based Tactile Sensors (VBTSs) show significant promise in that they can leverage image measurements to provide high-spatial-resolution human-like performance. However, current VBTS designs, typically confined to the fingertips of robotic grippers, prove somewhat inadequate, as many grasping and manipulation tasks require multiple contact points with the object. With an end goal of enabling large-scale, multi-surface tactile sensing via VBTSs, our research (i) develops a synchronized image acquisition system with minimal latency,(ii) proposes a modularized VBTS design for easy integration into finger phalanges, and (iii) devises a zero-shot calibration approach to improve data efficiency in the simultaneous calibration of multiple VBTSs. In validating the system within a miniature 3-fingered robotic gripper equipped with 7 VBTSs we demonstrate improved tactile perception performance by covering the contact surfaces of both gripper fingers and palm. Additionally, we show that our VBTS design can be seamlessly integrated into various end-effector morphologies significantly reducing the data requirements for calibration.

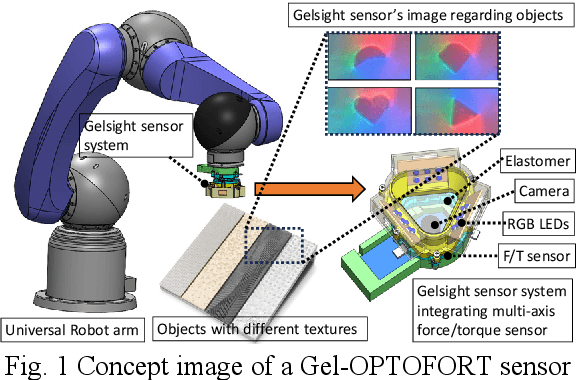

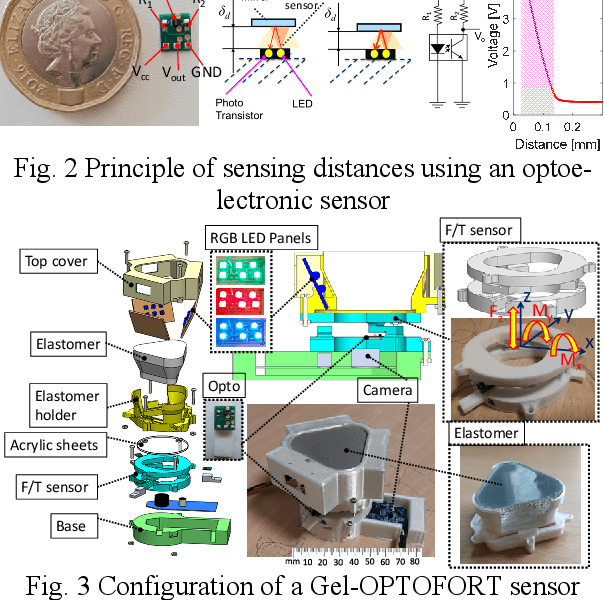

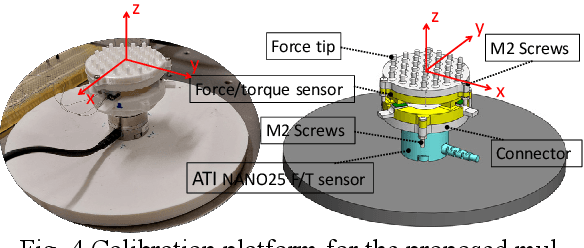

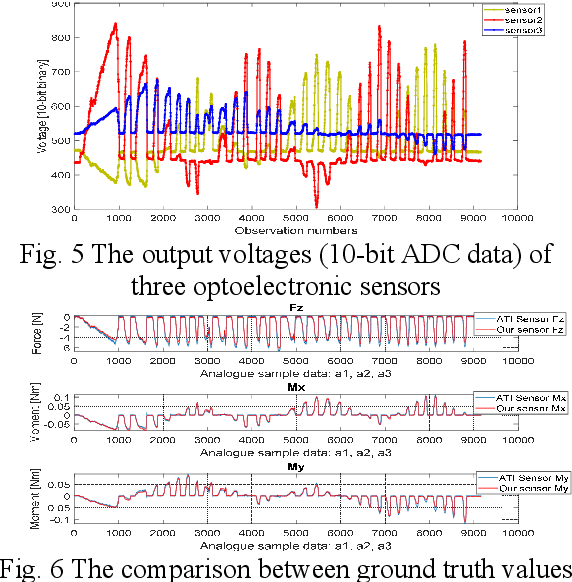

Gel-OPTOFORT Sensor: Multi-axis Force/Torque Measurement and Geometry Observation Using GelSight and Optoelectronic Sensor Technology

Jul 22, 2024

Abstract:Although conventional GelSight-based tactile and force/torque sensors excel in detecting objects' geometry and texture information while simultaneously sensing multi-axis forces, their performance is limited by the camera's lower frame rates and the inherent properties of the elastomer. These limitations restrict their ability to measure higher force ranges at high sampling frequencies. Besides, due to the coupling of the Gelsight sensor unit and multi-axis force/torque unit structurally, the force/torque measurement ranges of the Gelsight-based force/torque sensors are not adjustable. To address these weaknesses, this paper proposes the GEL-OPTOFORT sensor that combines a GelSight sensor and an optoelectronic sensor-based force/torque sensor.

Tac-Man: Tactile-Informed Prior-Free Manipulation of Articulated Objects

Mar 04, 2024Abstract:Integrating robotics into human-centric environments such as homes, necessitates advanced manipulation skills as robotic devices will need to engage with articulated objects like doors and drawers. Key challenges in robotic manipulation are the unpredictability and diversity of these objects' internal structures, which render models based on priors, both explicit and implicit, inadequate. Their reliability is significantly diminished by pre-interaction ambiguities, imperfect structural parameters, encounters with unknown objects, and unforeseen disturbances. Here, we present a prior-free strategy, Tac-Man, focusing on maintaining stable robot-object contact during manipulation. Utilizing tactile feedback, but independent of object priors, Tac-Man enables robots to proficiently handle a variety of articulated objects, including those with complex joints, even when influenced by unexpected disturbances. Demonstrated in both real-world experiments and extensive simulations, it consistently achieves near-perfect success in dynamic and varied settings, outperforming existing methods. Our results indicate that tactile sensing alone suffices for managing diverse articulated objects, offering greater robustness and generalization than prior-based approaches. This underscores the importance of detailed contact modeling in complex manipulation tasks, especially with articulated objects. Advancements in tactile sensors significantly expand the scope of robotic applications in human-centric environments, particularly where accurate models are difficult to obtain.

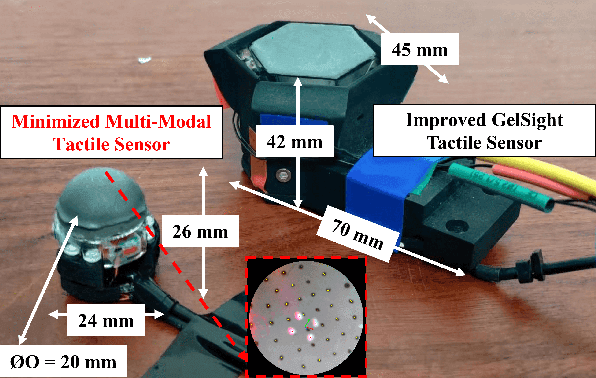

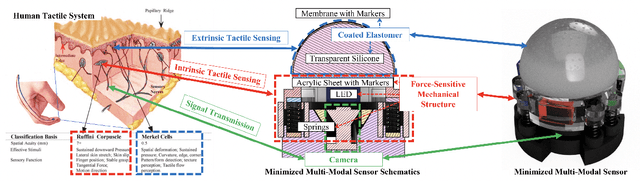

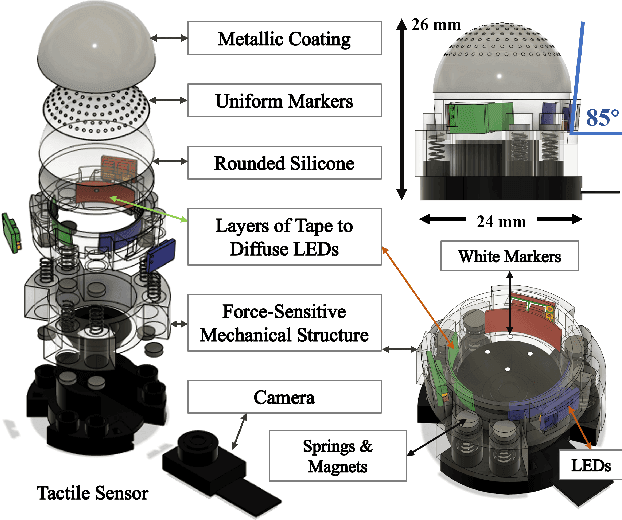

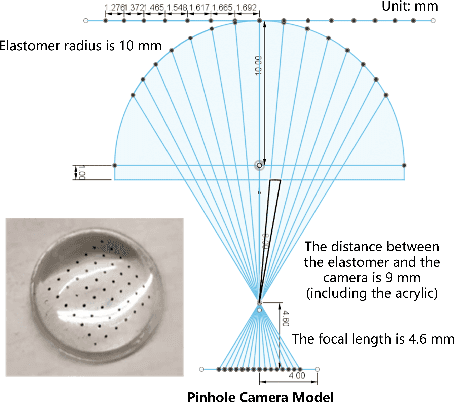

A Miniaturised Camera-based Multi-Modal Tactile Sensor

Mar 06, 2023

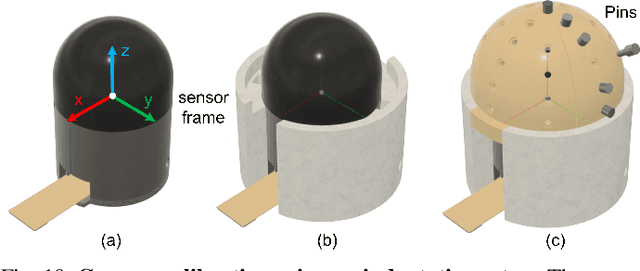

Abstract:In conjunction with huge recent progress in camera and computer vision technology, camera-based sensors have increasingly shown considerable promise in relation to tactile sensing. In comparison to competing technologies (be they resistive, capacitive or magnetic based), they offer super-high-resolution, while suffering from fewer wiring problems. The human tactile system is composed of various types of mechanoreceptors, each able to perceive and process distinct information such as force, pressure, texture, etc. Camera-based tactile sensors such as GelSight mainly focus on high-resolution geometric sensing on a flat surface, and their force measurement capabilities are limited by the hysteresis and non-linearity of the silicone material. In this paper, we present a miniaturised dome-shaped camera-based tactile sensor that allows accurate force and tactile sensing in a single coherent system. The key novelty of the sensor design is as follows. First, we demonstrate how to build a smooth silicone hemispheric sensing medium with uniform markers on its curved surface. Second, we enhance the illumination of the rounded silicone with diffused LEDs. Third, we construct a force-sensitive mechanical structure in a compact form factor with usage of springs to accurately perceive forces. Our multi-modal sensor is able to acquire tactile information from multi-axis forces, local force distribution, and contact geometry, all in real-time. We apply an end-to-end deep learning method to process all the information.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge