Shuangyue Yu

Design and Actuator Optimization of Lightweight and Compliant Knee Exoskeleton for Mobility Assistance of Children with Crouch Gait

Jan 01, 2021

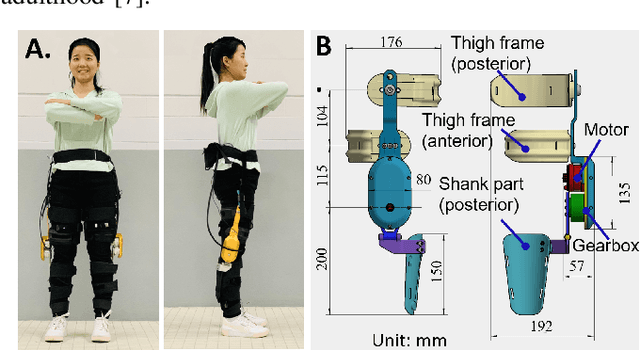

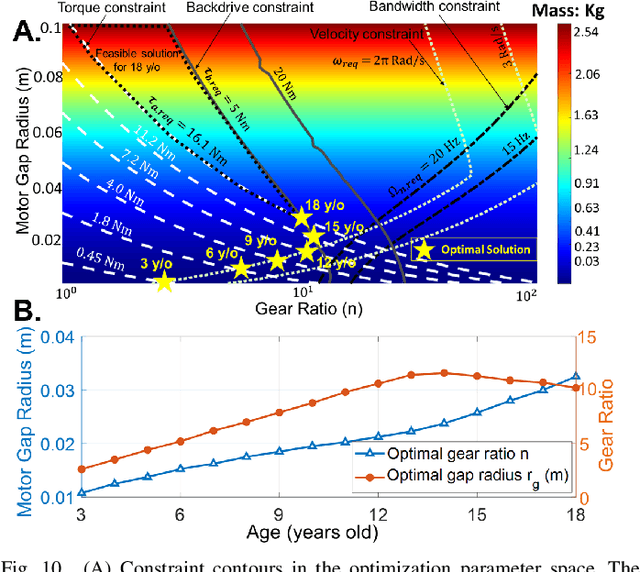

Abstract:Pediatric exoskeletons offer great promise to increase mobility for children with crouch gait caused by cerebral palsy. A lightweight, compliant and user-specific actuator is critical for maximizing the benefits of an exoskeleton to users. To date, pediatric exoskeletons generally use the same actuators as adult exoskeletons, which are heavy and resistive to natural movement. There is yet no easy way for robotic exoskeletons to accommodate the changes in design requirements that occur as a child ages. We developed a lightweight (1.65 kg unilateral mass) and compliant pediatric knee exoskeleton with a bandwidth of 22.6 Hz that can provide torque assistance to children with crouch gait using high torque density motor. Experimental results demonstrated that the robot exhibited low mechanical impedance (1.79 Nm average backdrive torque) under the unpowered condition and 0.32 Nm with zero-torque tracking control. Root mean square (RMS) error of torque tracking result is less than 0.73 Nm (5.7% with respect to 12 Nm torque). To achieve optimal age-specific performance, we proposed the first optimization framework that considered both motor and transmission of the actuator system that can produce optimal settings for children between 3 and 18 years old. The optimization generated an optimal motor air gap radius that monotonically increases with age from 0.011 to 0.033 meters, and optimal gear ratio varies from 2.6 to 11.6 (3-13 years old) and 11.6 to 10.2 (13-18 years old), leading to actuators of minimal mass.

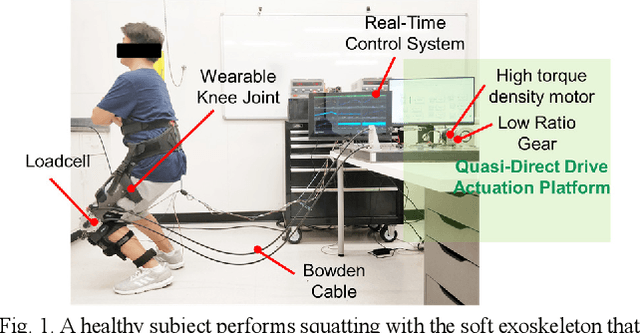

Quasi-Direct Drive Actuation for a Lightweight Hip Exoskeleton with High Backdrivability and High Bandwidth

Apr 01, 2020

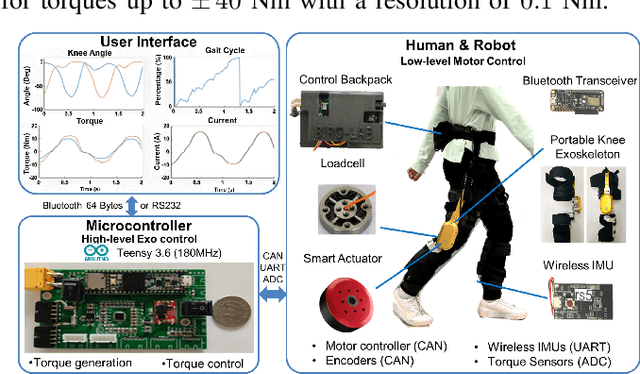

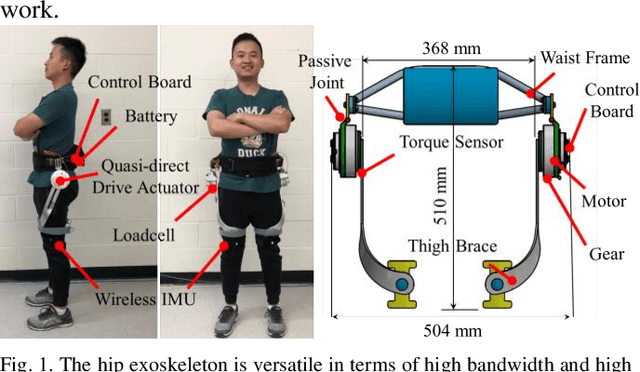

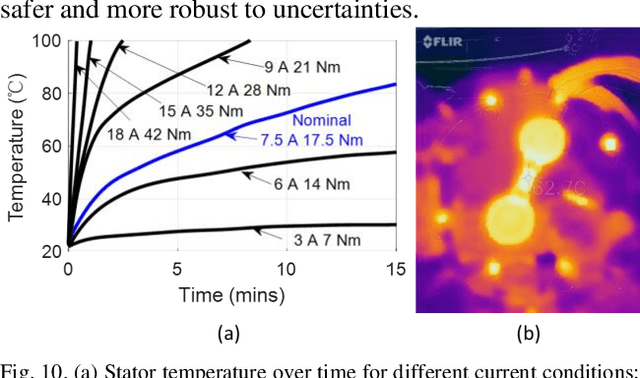

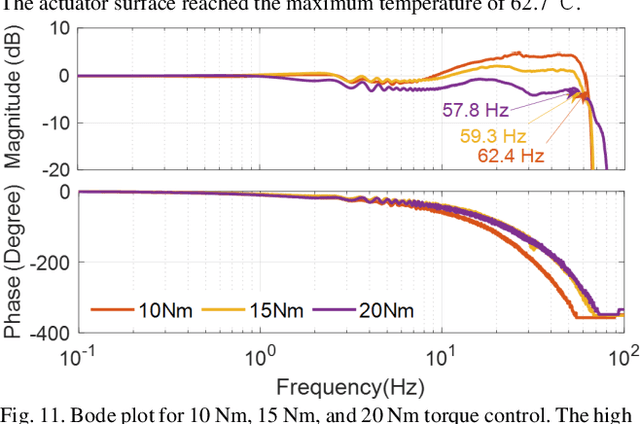

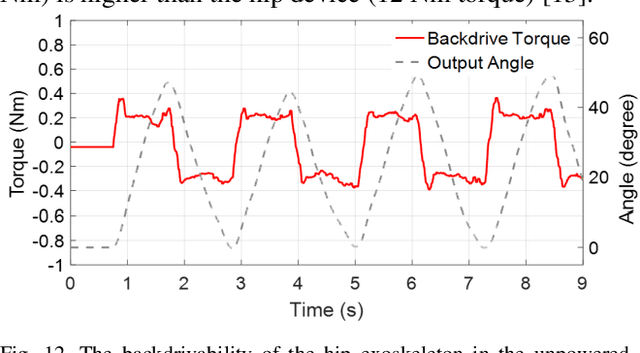

Abstract:High-performance actuators are crucial to enable mechanical versatility of lower-limb wearable robots, which are required to be lightweight, highly backdrivable, and with high bandwidth. State-of-the-art actuators, e.g., series elastic actuators (SEAs), have to compromise bandwidth to improve compliance (i.e., backdrivability). In this paper, we describe the design and human-robot interaction modeling of a portable hip exoskeleton based on our custom quasi-direct drive (QDD) actuation (i.e., a high torque density motor with low ratio gear). We also present a model-based performance benchmark comparison of representative actuators in terms of torque capability, control bandwidth, backdrivability, and force tracking accuracy. This paper aims to corroborate the underlying philosophy of "design for control", namely meticulous robot design can simplify control algorithms while ensuring high performance. Following this idea, we create a lightweight bilateral hip exoskeleton (overall mass is 3.4 kg) to reduce joint loadings during normal activities, including walking and squatting. Experimental results indicate that the exoskeleton is able to produce high nominal torque (17.5 Nm), high backdrivability (0.4 Nm backdrive torque), high bandwidth (62.4 Hz), and high control accuracy (1.09 Nm root mean square tracking error, i.e., 5.4% of the desired peak torque). Its controller is versatile to assist walking at different speeds (0.8-1.4 m/s) and squatting at 2 s cadence. This work demonstrates significant improvement in backdrivability and control bandwidth compared with state-of-the-art exoskeletons powered by the conventional actuation or SEA.

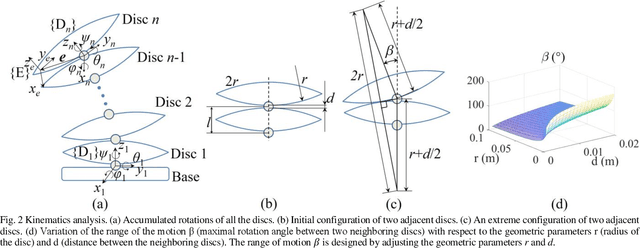

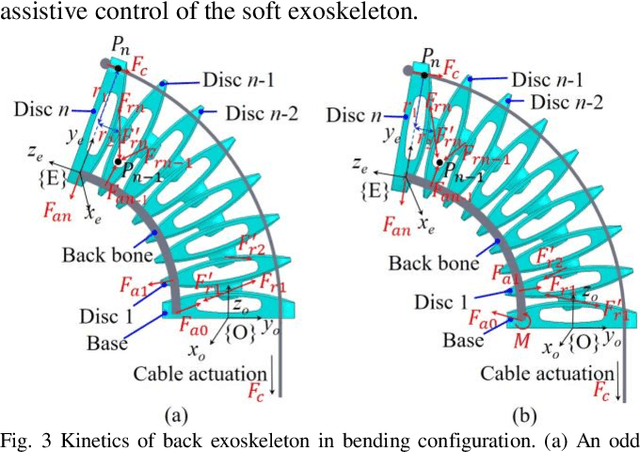

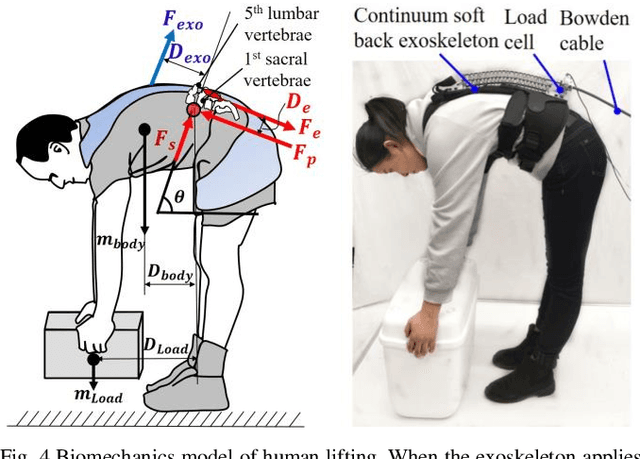

Spine-Inspired Continuum Soft Exoskeleton for Stoop Lifting Assistance

Jul 04, 2019

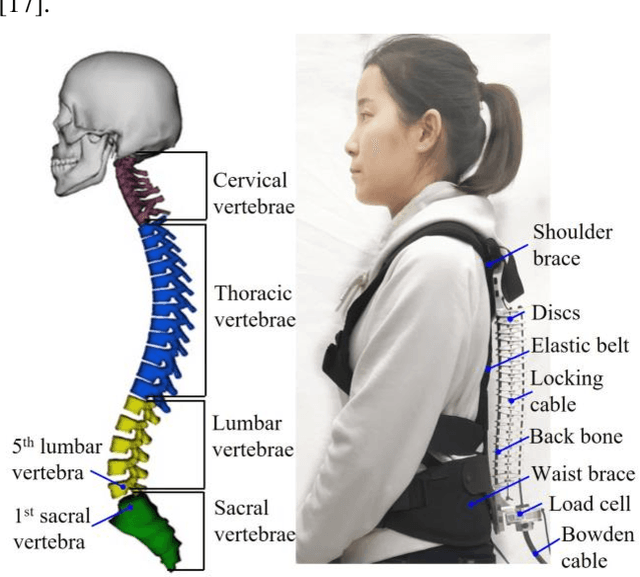

Abstract:Back injuries are the most prevalent work-related musculoskeletal disorders and represent a major cause of disability. Although innovations in wearable robots aim to alleviate this hazard, the majority of existing exoskeletons are obtrusive because the rigid linkage design limits natural movement, thus causing ergonomic risk. Moreover, these existing systems are typically only suitable for one type of movement assistance, not ubiquitous for a wide variety of activities. To fill in this gap, this paper presents a new wearable robot design approach continuum soft exoskeleton. This spine-inspired wearable robot is unobtrusive and assists both squat and stoops while not impeding walking motion. To tackle the challenge of the unique anatomy of spine that is inappropriate to be simplified as a single degree of freedom joint, our robot is conformal to human anatomy and it can reduce multiple types of forces along the human spine such as the spinae muscle force, shear, and compression force of the lumbar vertebrae. We derived kinematics and kinetics models of this mechanism and established an analytical biomechanics model of human-robot interaction. Quantitative analysis of disc compression force, disc shear force and muscle force was performed in simulation. We further developed a virtual impedance control strategy to deliver force control and compensate hysteresis of Bowden cable transmission. The feasibility of the prototype was experimentally tested on three healthy subjects. The root mean square error of force tracking is 6.63 N (3.3 % of the 200N peak force) and it demonstrated that it can actively control the stiffness to the desired value. This continuum soft exoskeleton represents a feasible solution with the potential to reduce back pain for multiple activities and multiple forces along the human spine.

* 8 pages, 13 figures

A Soft High Force Hand Exoskeleton for Rehabilitation and Assistance of Spinal Cord Injury and Stroke Individuals

Feb 19, 2019

Abstract:Individuals with spinal cord injury (SCI) and stroke who is lack of manipulation capability have a particular need for robotic hand exoskeletons. Among assistive and rehabilitative medical exoskeletons, there exists a sharp trade-off between device power on the one hand and ergonomics and portability on other, devices that provide stronger grasping assistance do so at the cost of patient comfort. This paper proposes using fin-ray inspired, cable-driven finger orthoses to generate high fingertip forces without the painful compressive and shear stresses commonly associated with conventional cable-drive exoskeletons. With combination cable-driven transmission and segmented-finger orthoses, the exoskeleton transmitted larger forces and applied torques discretely to the fingers, leading to strong fingertip forces. A prototype of the finger orthoses and associated cable transmission was fabricated, and force transmission tests of the prototype in the finger flexion mode demonstrated a 2:1 input-output ratio between cable tension and fingertip force, with a maximum fingertip force of 22 N. Moreover, the proposed design provides a comfortable experience for wearers thanks to its lightweight and conformal properties to the hands.

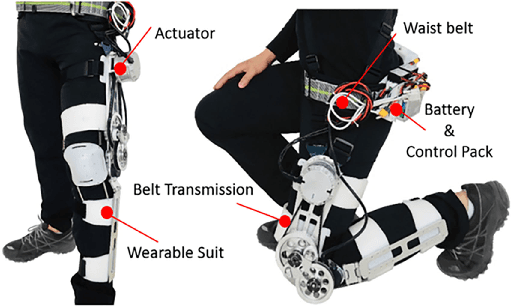

Design and Control of a Quasi-Direct Drive Soft Hybrid Knee Exoskeleton for Injury Prevention during Squatting

Feb 19, 2019

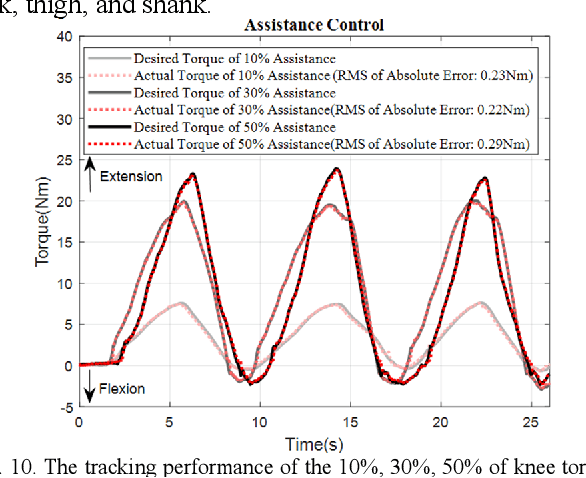

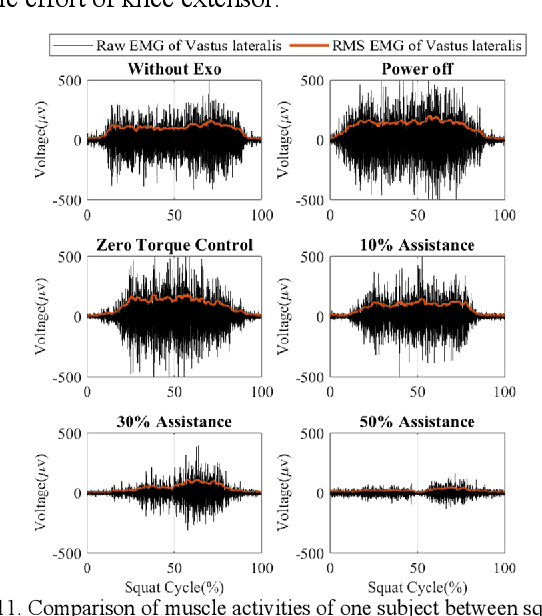

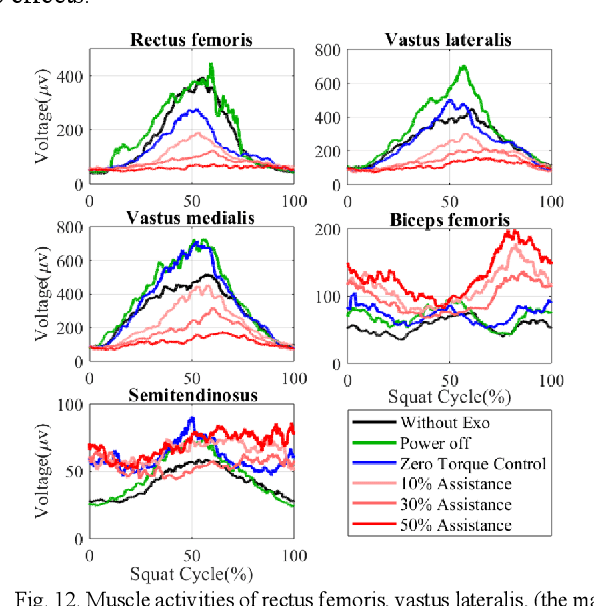

Abstract:This paper presents a new design approach of wearable robots that tackle the three barriers to mainstay practical use of exoskeletons, namely discomfort, weight of the device, and symbiotic control of the exoskeleton-human co-robot system. The hybrid exoskeleton approach, demonstrated in a soft knee industrial exoskeleton case, mitigates the discomfort of wearers as it aims to avoid the drawbacks of rigid exoskeletons and textile-based soft exosuits. Quasi-direct drive actuation using high-torque density motors minimizes the weight of the device and presents high backdrivability that does not restrict natural movement. We derive a biomechanics model that is generic to both squat and stoop lifting motion. The control algorithm symbiotically detects posture using compact inertial measurement unit (IMU) sensors to generate an assistive profile that is proportional to the biological torque generated from our model. Experimental results demonstrate that the robot exhibits 1.5 Nm torque when it is unpowered and 0.5 Nm torque with zero-torque tracking control. The efficacy of injury prevention is demonstrated with one healthy subject. Root mean square (RMS) error of torque tracking is less than 0.29 Nm (1.21% of 24 Nm peak torque) for 50% assistance of biological torque. Comparing to the squat without exoskeleton, the maximum amplitude of the knee extensor muscle activity (rectus femoris) measured by Electromyography (EMG) sensors is reduced by 30% with 50% assistance of biological torque.

Comfort-Centered Design of a Lightweight and Backdrivable Knee Exoskeleton

Feb 11, 2019

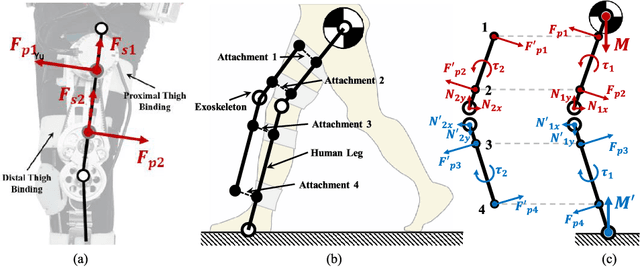

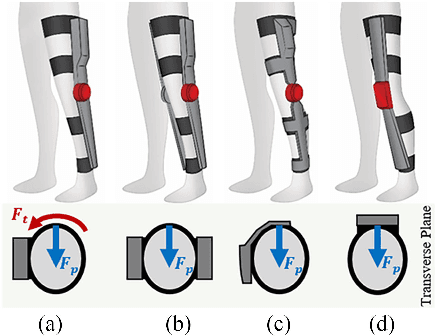

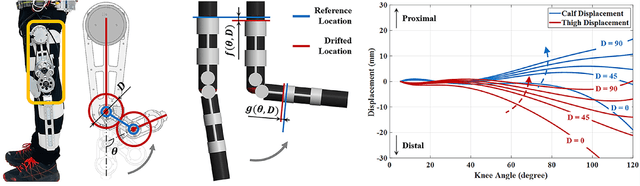

Abstract:This paper presents design principles for comfort-centered wearable robots and their application in a lightweight and backdrivable knee exoskeleton. The mitigation of discomfort is treated as mechanical design and control issues and three solutions are proposed in this paper: 1) a new wearable structure optimizes the strap attachment configuration and suit layout to ameliorate excessive shear forces of conventional wearable structure design; 2) rolling knee joint and double-hinge mechanisms reduce the misalignment in the sagittal and frontal plane, without increasing the mechanical complexity and inertia, respectively; 3) a low impedance mechanical transmission reduces the reflected inertia and damping of the actuator to human, thus the exoskeleton is highly-backdrivable. Kinematic simulations demonstrate that misalignment between the robot joint and knee joint can be reduced by 74% at maximum knee flexion. In experiments, the exoskeleton in the unpowered mode exhibits 1.03 Nm root mean square (RMS) low resistive torque. The torque control experiments demonstrate 0.31 Nm RMS torque tracking error in three human subjects.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge