Xuewen Zhang

Fellow IEEE

Inference Compute-Optimal Video Vision Language Models

May 24, 2025Abstract:This work investigates the optimal allocation of inference compute across three key scaling factors in video vision language models: language model size, frame count, and the number of visual tokens per frame. While prior works typically focuses on optimizing model efficiency or improving performance without considering resource constraints, we instead identify optimal model configuration under fixed inference compute budgets. We conduct large-scale training sweeps and careful parametric modeling of task performance to identify the inference compute-optimal frontier. Our experiments reveal how task performance depends on scaling factors and finetuning data size, as well as how changes in data size shift the compute-optimal frontier. These findings translate to practical tips for selecting these scaling factors.

CompCap: Improving Multimodal Large Language Models with Composite Captions

Dec 06, 2024

Abstract:How well can Multimodal Large Language Models (MLLMs) understand composite images? Composite images (CIs) are synthetic visuals created by merging multiple visual elements, such as charts, posters, or screenshots, rather than being captured directly by a camera. While CIs are prevalent in real-world applications, recent MLLM developments have primarily focused on interpreting natural images (NIs). Our research reveals that current MLLMs face significant challenges in accurately understanding CIs, often struggling to extract information or perform complex reasoning based on these images. We find that existing training data for CIs are mostly formatted for question-answer tasks (e.g., in datasets like ChartQA and ScienceQA), while high-quality image-caption datasets, critical for robust vision-language alignment, are only available for NIs. To bridge this gap, we introduce Composite Captions (CompCap), a flexible framework that leverages Large Language Models (LLMs) and automation tools to synthesize CIs with accurate and detailed captions. Using CompCap, we curate CompCap-118K, a dataset containing 118K image-caption pairs across six CI types. We validate the effectiveness of CompCap-118K by supervised fine-tuning MLLMs of three sizes: xGen-MM-inst.-4B and LLaVA-NeXT-Vicuna-7B/13B. Empirical results show that CompCap-118K significantly enhances MLLMs' understanding of CIs, yielding average gains of 1.7%, 2.0%, and 2.9% across eleven benchmarks, respectively.

Time-Series Regeneration with Convolutional Recurrent Generative Adversarial Network for Remaining Useful Life Estimation

Jan 11, 2021

Abstract:For health prognostic task, ever-increasing efforts have been focused on machine learning-based methods, which are capable of yielding accurate remaining useful life (RUL) estimation for industrial equipment or components without exploring the degradation mechanism. A prerequisite ensuring the success of these methods depends on a wealth of run-to-failure data, however, run-to-failure data may be insufficient in practice. That is, conducting a substantial amount of destructive experiments not only is high costs, but also may cause catastrophic consequences. Out of this consideration, an enhanced RUL framework focusing on data self-generation is put forward for both non-cyclic and cyclic degradation patterns for the first time. It is designed to enrich data from a data-driven way, generating realistic-like time-series to enhance current RUL methods. First, high-quality data generation is ensured through the proposed convolutional recurrent generative adversarial network (CR-GAN), which adopts a two-channel fusion convolutional recurrent neural network. Next, a hierarchical framework is proposed to combine generated data into current RUL estimation methods. Finally, the efficacy of the proposed method is verified through both non-cyclic and cyclic degradation systems. With the enhanced RUL framework, an aero-engine system following non-cyclic degradation has been tested using three typical RUL models. State-of-art RUL estimation results are achieved by enhancing capsule network with generated time-series. Specifically, estimation errors evaluated by the index score function have been reduced by 21.77%, and 32.67% for the two employed operating conditions, respectively. Besides, the estimation error is reduced to zero for the Lithium-ion battery system, which presents cyclic degradation.

Deep Learning Based Defect Detection for Solder Joints on Industrial X-Ray Circuit Board Images

Aug 06, 2020

Abstract:Quality control is of vital importance during electronics production. As the methods of producing electronic circuits improve, there is an increasing chance of solder defects during assembling the printed circuit board (PCB). Many technologies have been incorporated for inspecting failed soldering, such as X-ray imaging, optical imaging, and thermal imaging. With some advanced algorithms, the new technologies are expected to control the production quality based on the digital images. However, current algorithms sometimes are not accurate enough to meet the quality control. Specialists are needed to do a follow-up checking. For automated X-ray inspection, joint of interest on the X-ray image is located by region of interest (ROI) and inspected by some algorithms. Some incorrect ROIs deteriorate the inspection algorithm. The high dimension of X-ray images and the varying sizes of image dimensions also challenge the inspection algorithms. On the other hand, recent advances on deep learning shed light on image-based tasks and are competitive to human levels. In this paper, deep learning is incorporated in X-ray imaging based quality control during PCB quality inspection. Two artificial intelligence (AI) based models are proposed and compared for joint defect detection. The noised ROI problem and the varying sizes of imaging dimension problem are addressed. The efficacy of the proposed methods are verified through experimenting on a real-world 3D X-ray dataset. By incorporating the proposed methods, specialist inspection workload is largely saved.

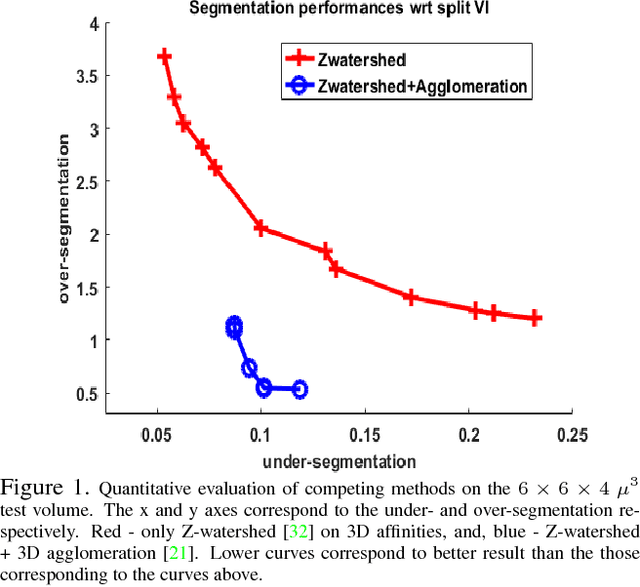

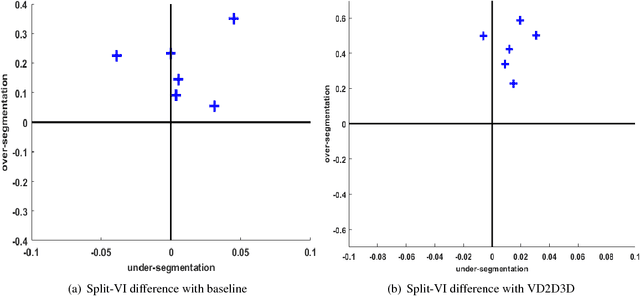

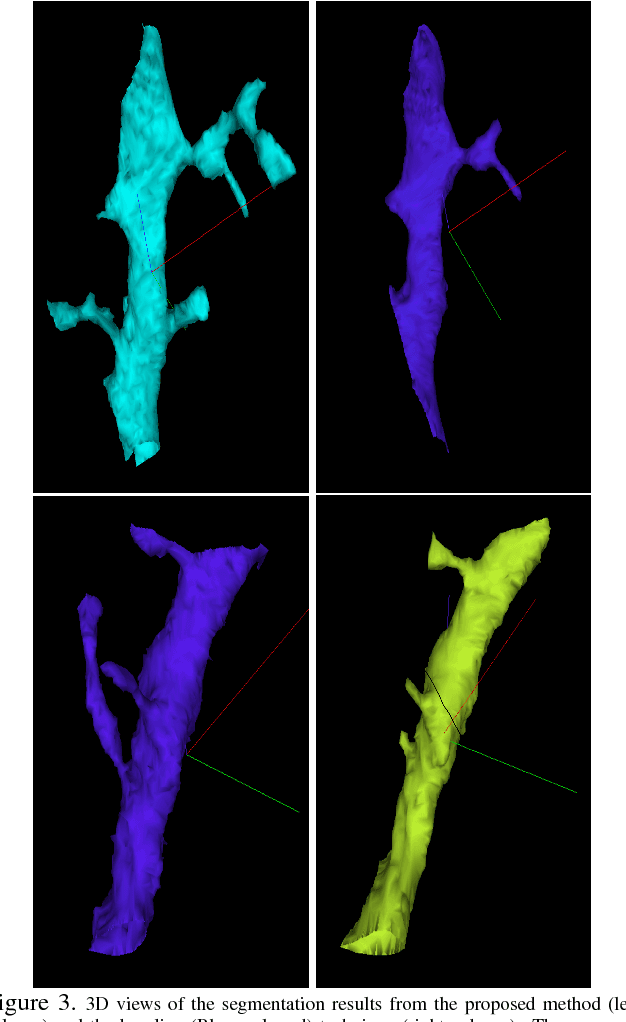

Anisotropic EM Segmentation by 3D Affinity Learning and Agglomeration

Aug 03, 2018

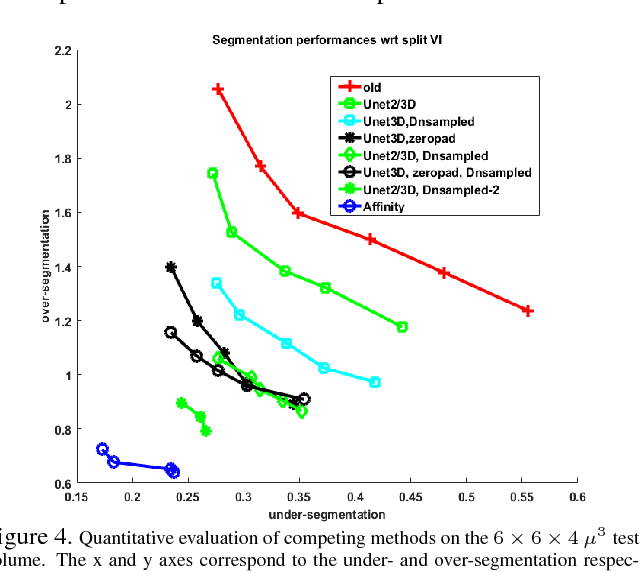

Abstract:The field of connectomics has recently produced neuron wiring diagrams from relatively large brain regions from multiple animals. Most of these neural reconstructions were computed from isotropic (e.g., FIBSEM) or near isotropic (e.g., SBEM) data. In spite of the remarkable progress on algorithms in recent years, automatic dense reconstruction from anisotropic data remains a challenge for the connectomics community. One significant hurdle in the segmentation of anisotropic data is the difficulty in generating a suitable initial over-segmentation. In this study, we present a segmentation method for anisotropic EM data that agglomerates a 3D over-segmentation computed from the 3D affinity prediction. A 3D U-net is trained to predict 3D affinities by the MALIS approach. Experiments on multiple datasets demonstrates the strength and robustness of the proposed method for anisotropic EM segmentation.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge