Hai-Tao Zhang

Coordinated Guiding Vector Field Design for Ordering-Flexible Multi-Robot Surface Navigation

Jan 25, 2024

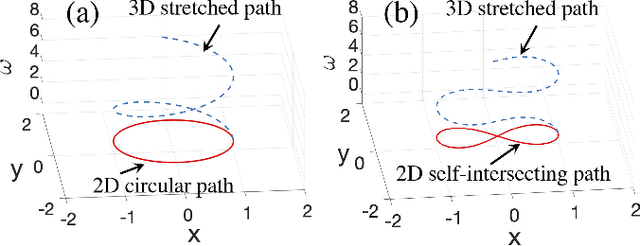

Abstract:We design a distributed coordinated guiding vector field (CGVF) for a group of robots to achieve ordering-flexible motion coordination while maneuvering on a desired two-dimensional (2D) surface. The CGVF is characterized by three terms, i.e., a convergence term to drive the robots to converge to the desired surface, a propagation term to provide a traversing direction for maneuvering on the desired surface, and a coordinated term to achieve the surface motion coordination with an arbitrary ordering of the robotic group. By setting the surface parameters as additional virtual coordinates, the proposed approach eliminates the potential singularity of the CGVF and enables both the global convergence to the desired surface and the maneuvering on the surface from all possible initial conditions. The ordering-flexible surface motion coordination is realized by each robot to share with its neighbors only two virtual coordinates, i.e. that of a given target and that of its own, which reduces the communication and computation cost in multi-robot surface navigation. Finally, the effectiveness of the CGVF is substantiated by extensive numerical simulations.

Coordinated Navigation Control of Cross-Domain Unmanned Systems via Guiding Vector Fields

Dec 18, 2023

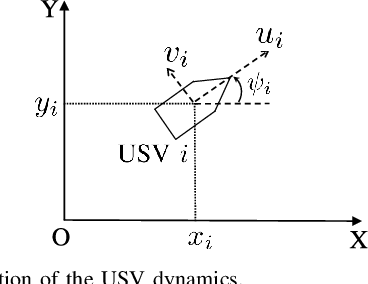

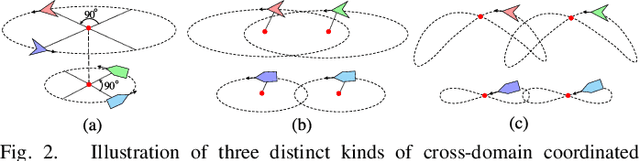

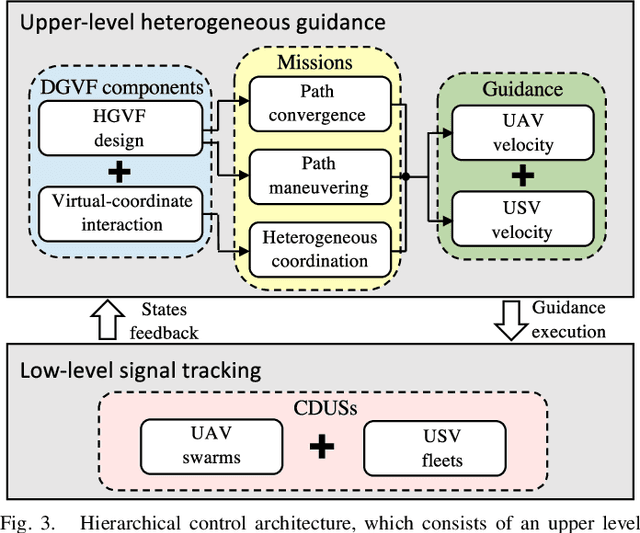

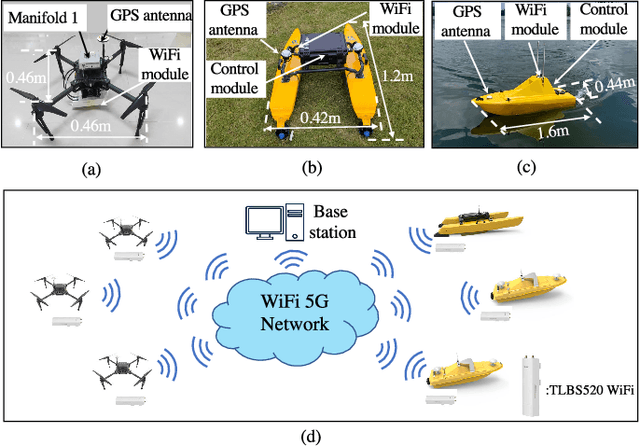

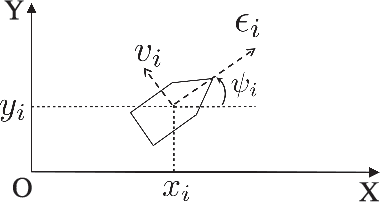

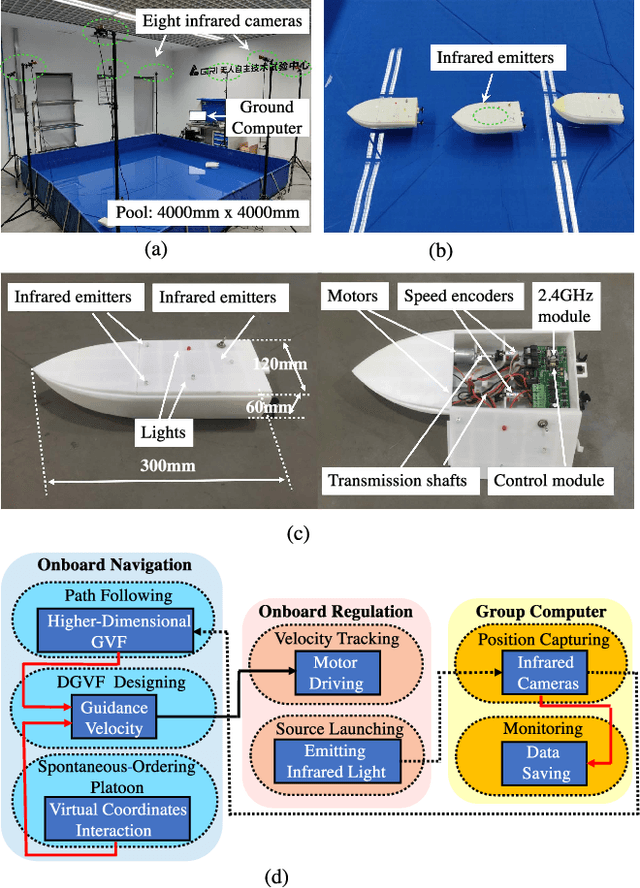

Abstract:This paper proposes a distributed guiding-vector-field (DGVF) controller for cross-domain unmanned systems (CDUSs) consisting of heterogeneous unmanned aerial vehicles (UAVs) and unmanned surface vehicles (USVs), to achieve coordinated navigation whereas maneuvering along their prescribed paths. In particular, the DGVF controller provides a hierarchical architecture of an upper-level heterogeneous guidance velocity controller and a lower-level signal tracking regulator. Therein, the upper-level controller is to govern multiple heterogeneous USVs and UAVs to approach and maneuver along the prescribed paths and coordinate the formation simultaneously, whereas the low-level regulator is to track the corresponding desired guidance signals provided by the upper-level module. Significantly, the heterogeneous coordination among neighboring UAVs and USVs is achieved merely by the lightweight communication of a scalar (i.e., the additional virtual coordinate), which substantially decreases the communication and computational costs. Sufficient conditions assuring asymptotical convergence of the closed-loop system are derived in presence of the exponentially vanishing tracking errors. Finally, real-lake experiments are conducted on a self-established cross-domain heterogeneous platform consisting of three M-100 UAVs, two HUSTER-16 USVs, a HUSTER-12C USV, and a WiFi 5G wireless communication station to verify the effectiveness of the present DGVF controller.

* 14 pages

Spontaneous-Ordering Platoon Control for Multirobot Path Navigation Using Guiding Vector Fields

Nov 02, 2023

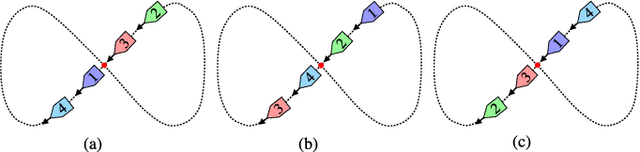

Abstract:In this paper, we propose a distributed guiding-vector-field (DGVF) algorithm for a team of robots to form a spontaneous-ordering platoon moving along a predefined desired path in the n-dimensional Euclidean space. Particularly, by adding a path parameter as an additional virtual coordinate to each robot, the DGVF algorithm can eliminate the singular points where the vector fields vanish, and govern robots to approach a closed and even self-intersecting desired path. Then, the interactions among neighboring robots and a virtual target robot through their virtual coordinates enable the realization of the desired platoon; in particular, relative parametric displacements can be achieved with arbitrary ordering sequences. Rigorous analysis is provided to guarantee the global convergence to the spontaneous-ordering platoon on the common desired path from any initial positions. 2D experiments using three HUSTER-0.3 unmanned surface vessels (USVs) are conducted to validate the practical effectiveness of the proposed DGVF algorithm, and 3D numerical simulations are presented to demonstrate its effectiveness and robustness when tackling higher-dimensional multi-robot path-navigation missions and some robots breakdown.

BoostTree and BoostForest for Ensemble Learning

Mar 21, 2020

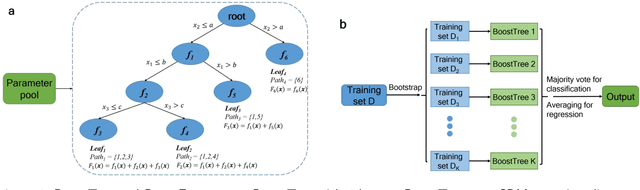

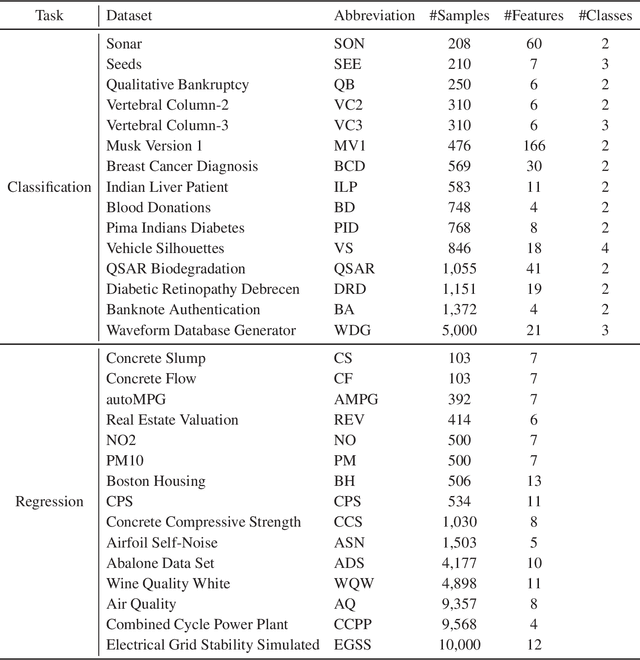

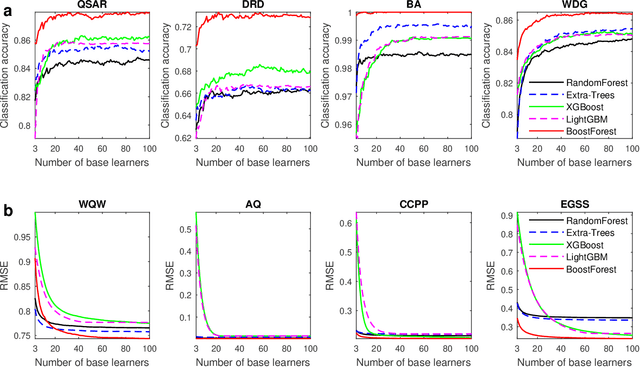

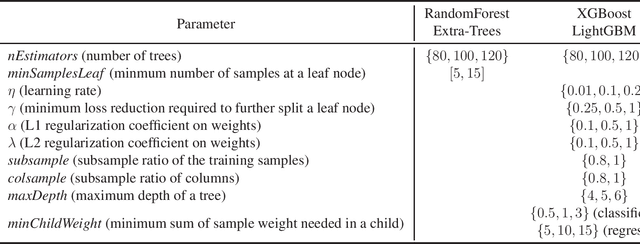

Abstract:Bootstrap aggregation (Bagging) and boosting are two popular ensemble learning approaches, which combine multiple base learners to generate a composite learner. This article proposes BoostForest, which is an ensemble learning approach using BoostTree as base learners and can be used for both classification and regression. BoostTree constructs a tree by gradient boosting, which trains a linear or nonlinear model at each node. When a new sample comes in, BoostTree first sorts it down to a leaf, then computes the final prediction by summing up the outputs of all models along the path from the root node to that leaf. BoostTree achieves high randomness (diversity) by sampling its parameters randomly from a parameter pool, and selecting a subset of features randomly at node splitting. BoostForest further increases the randomness by bootstrapping the training data in constructing different BoostTrees. BoostForest is compared with four classical ensemble learning approaches on 30 classification and regression datasets, demonstrating that it can generate more accurate and more robust composite learners.

Artificial Intelligent Diagnosis and Monitoring in Manufacturing

Dec 17, 2018

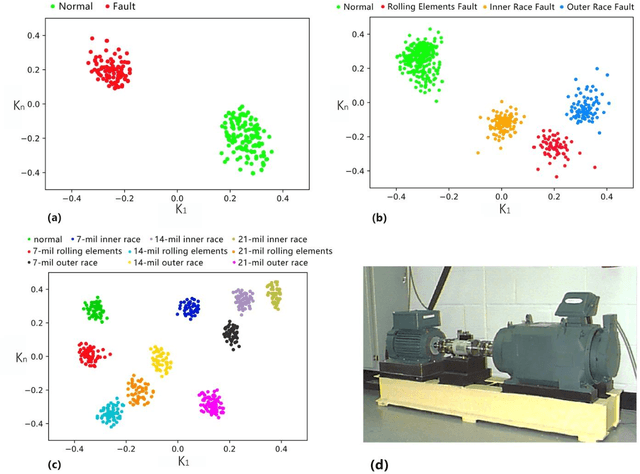

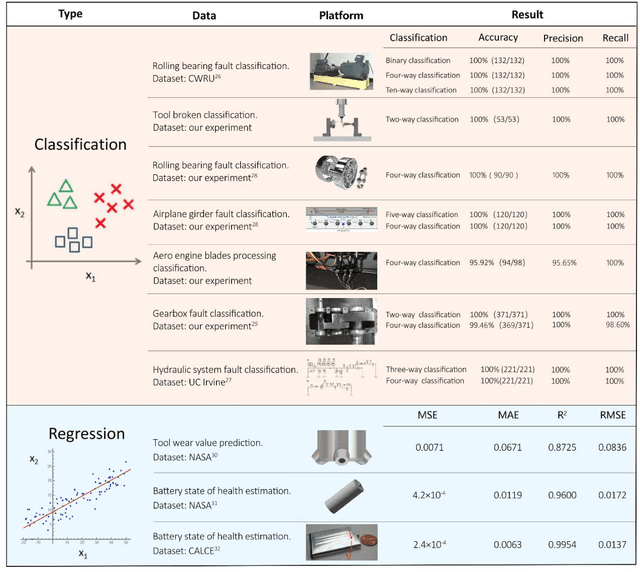

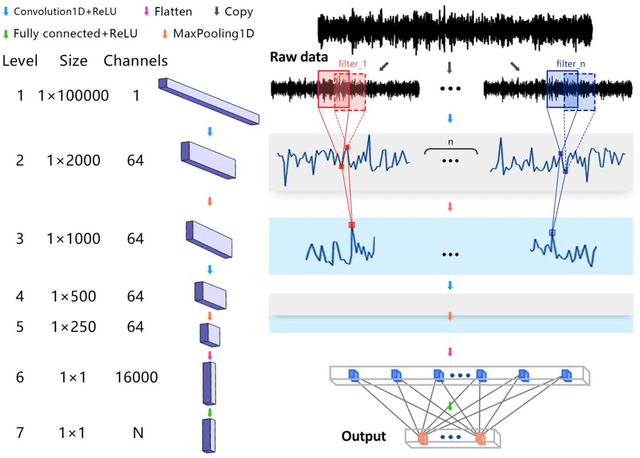

Abstract:The manufacturing sector is heavily influenced by artificial intelligence-based technologies with the extraordinary increases in computational power and data volumes. It has been reported that 35% of US manufacturers are currently collecting data from sensors for manufacturing processes enhancement. Nevertheless, many are still struggling to achieve the 'Industry 4.0', which aims to achieve nearly 50% reduction in maintenance cost and total machine downtime by proper health management. For increasing productivity and reducing operating costs, a central challenge lies in the detection of faults or wearing parts in machining operations. Here we propose a data-driven, end-to-end framework for monitoring of manufacturing systems. This framework, derived from deep learning techniques, evaluates fused sensory measurements to detect and even predict faults and wearing conditions. This work exploits the predictive power of deep learning to extract hidden degradation features from noisy data. We demonstrate the proposed framework on several representative experimental manufacturing datasets drawn from a wide variety of applications, ranging from mechanical to electrical systems. Results reveal that the framework performs well in all benchmark applications examined and can be applied in diverse contexts, indicating its potential for use as a critical corner stone in smart manufacturing.

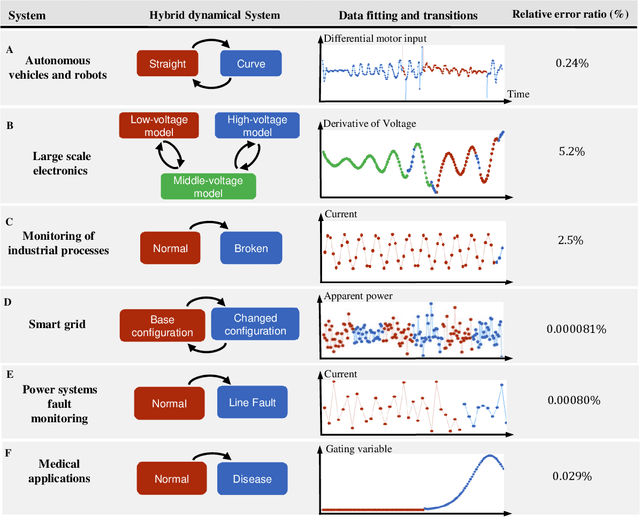

Data-driven Discovery of Cyber-Physical Systems

Oct 01, 2018

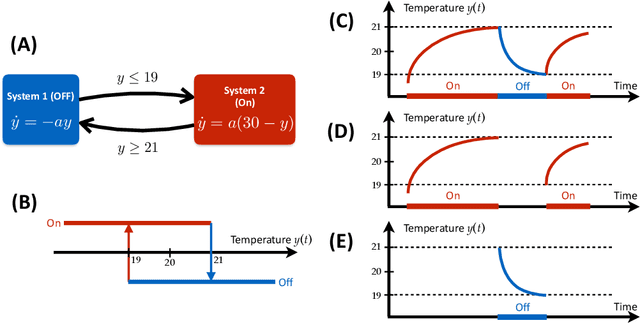

Abstract:Cyber-physical systems (CPSs) embed software into the physical world. They appear in a wide range of applications such as smart grids, robotics, intelligent manufacture and medical monitoring. CPSs have proved resistant to modeling due to their intrinsic complexity arising from the combination of physical components and cyber components and the interaction between them. This study proposes a general framework for reverse engineering CPSs directly from data. The method involves the identification of physical systems as well as the inference of transition logic. It has been applied successfully to a number of real-world examples ranging from mechanical and electrical systems to medical applications. The novel framework seeks to enable researchers to make predictions concerning the trajectory of CPSs based on the discovered model. Such information has been proven essential for the assessment of the performance of CPS, the design of failure-proof CPS and the creation of design guidelines for new CPSs.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge