Samuel Lensgraf

Multi-modal Perception Dataset of In-water Objects for Autonomous Surface Vehicles

Apr 29, 2024

Abstract:This paper introduces the first publicly accessible multi-modal perception dataset for autonomous maritime navigation, focusing on in-water obstacles within the aquatic environment to enhance situational awareness for Autonomous Surface Vehicles (ASVs). This dataset, consisting of diverse objects encountered under varying environmental conditions, aims to bridge the research gap in marine robotics by providing a multi-modal, annotated, and ego-centric perception dataset, for object detection and classification. We also show the applicability of the proposed dataset's framework using deep learning-based open-source perception algorithms that have shown success. We expect that our dataset will contribute to development of the marine autonomy pipeline and marine (field) robotics. Please note this is a work-in-progress paper about our on-going research that we plan to release in full via future publication.

Improving the perception of visual fiducial markers in the field using Adaptive Active Exposure Control

Apr 18, 2024

Abstract:Accurate localization is fundamental for autonomous underwater vehicles (AUVs) to carry out precise tasks, such as manipulation and construction. Vision-based solutions using fiducial marker are promising, but extremely challenging underwater because of harsh lighting condition underwater. This paper introduces a gradient-based active camera exposure control method to tackle sharp lighting variations during image acquisition, which can establish better foundation for subsequent image enhancement procedures. Considering a typical scenario for underwater operations where visual tags are used, we proposed several experiments comparing our method with other state-of-the-art exposure control method including Active Exposure Control (AEC) and Gradient-based Exposure Control (GEC). Results show a significant improvement in the accuracy of robot localization. This method is an important component that can be used in visual-based state estimation pipeline to improve the overall localization accuracy.

Scalable underwater assembly with reconfigurable visual fiducials

Oct 30, 2023

Abstract:We present a scalable combined localization infrastructure deployment and task planning algorithm for underwater assembly. Infrastructure is autonomously modified to suit the needs of manipulation tasks based on an uncertainty model on the infrastructure's positional accuracy. Our uncertainty model can be combined with the noise characteristics from multiple devices. For the task planning problem, we propose a layer-based clustering approach that completes the manipulation tasks one cluster at a time. We employ movable visual fiducial markers as infrastructure and an autonomous underwater vehicle (AUV) for manipulation tasks. The proposed task planning algorithm is computationally simple, and we implement it on AUV without any offline computation requirements. Combined hardware experiments and simulations over large datasets show that the proposed technique is scalable to large areas.

Buoyancy enabled autonomous underwater construction with cement blocks

May 09, 2023Abstract:We present the first free-floating autonomous underwater construction system capable of using active ballasting to transport cement building blocks efficiently. It is the first free-floating autonomous construction robot to use a paired set of resources: compressed air for buoyancy and a battery for thrusters. In construction trials, our system built structures of up to 12 components and weighing up to 100Kg (75Kg in water). Our system achieves this performance by combining a novel one-degree-of-freedom manipulator, a novel two-component cement block construction system that corrects errors in placement, and a simple active ballasting system combined with compliant placement and grasp behaviors. The passive error correcting components of the system minimize the required complexity in sensing and control. We also explore the problem of buoyancy allocation for building structures at scale by defining a convex program which allocates buoyancy to minimize the predicted energy cost for transporting blocks.

Toward Optimal FDM Toolpath Planning with Monte Carlo Tree Search

Feb 05, 2020

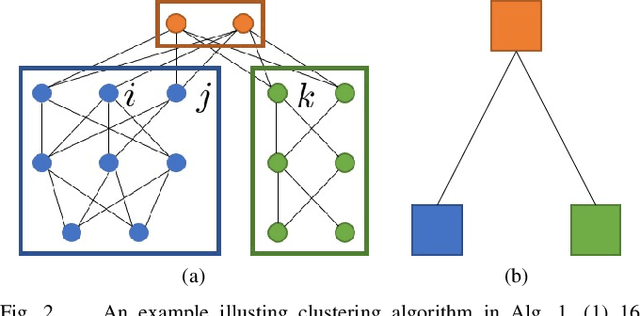

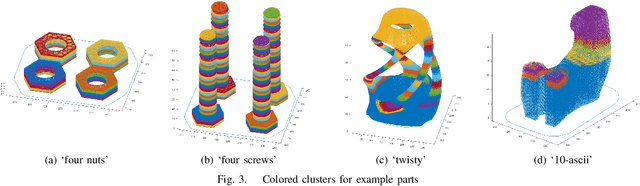

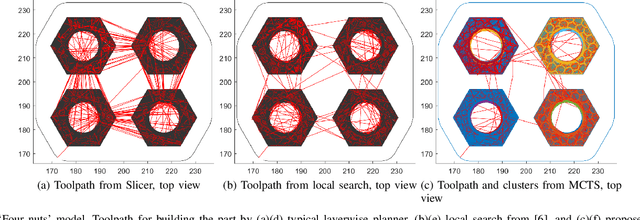

Abstract:The most widely used methods for toolpath planning in fused deposition 3D printing slice the input model into successive 2D layers in order to construct the toolpath. Unfortunately slicing-based methods can incur a substantial amount of wasted motion (i.e., the extruder is moving while not printing), particularly when features of the model are spatially separated. In recent years we have introduced a new paradigm that characterizes the space of feasible toolpaths using a dependency graph on the input model, along with several algorithms to search this space for toolpaths that optimize objective functions such as wasted motion or print time. A natural question that arises is, under what circumstances can we efficiently compute an optimal toolpath? In this paper, we give an algorithm for computing fused deposition modeling (FDM) toolpaths that utilizes Monte Carlo Tree Search (MCTS), a powerful general-purpose method for navigating large search spaces that is guaranteed to converge to the optimal solution. Under reasonable assumptions on printer geometry that allow us to compress the dependency graph, our MCTS-based algorithm converges to find the optimal toolpath. We validate our algorithm on a dataset of 75 models and show it performs on par with our previous best local search-based algorithm in terms of toolpath quality. In prior work we speculated that the performance of local search was near optimal, and we examine in detail the properties of the models and MCTS executions that lead to better or worse results than local search.

PuzzleFlex: kinematic motion of chains with loose joints

Jun 20, 2019

Abstract:This paper presents a method of computing free motions of a planar assembly of rigid bodies connected by loose joints. Joints are modeled using local distance constraints, which are then linearized with respect to configuration space velocities, yielding a linear programming formulation that allows analysis of systems with thousands of rigid bodies. Potential applications include analysis of collections of modular robots, structural stability perturbation analysis, tolerance analysis for mechanical systems,and formation control of mobile robots.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge