Yijia Wu

Vision-based FDM Printing for Fabricating Airtight Soft Actuators

Dec 02, 2023

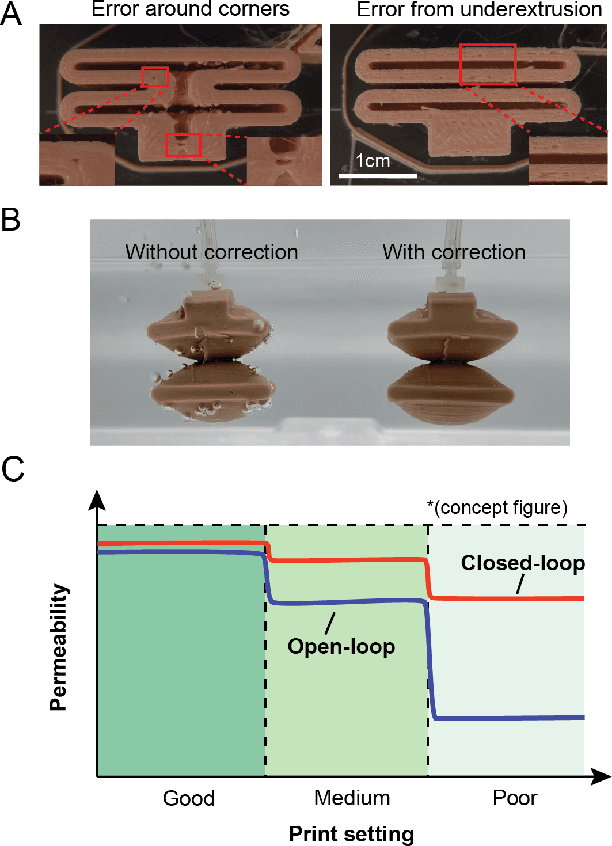

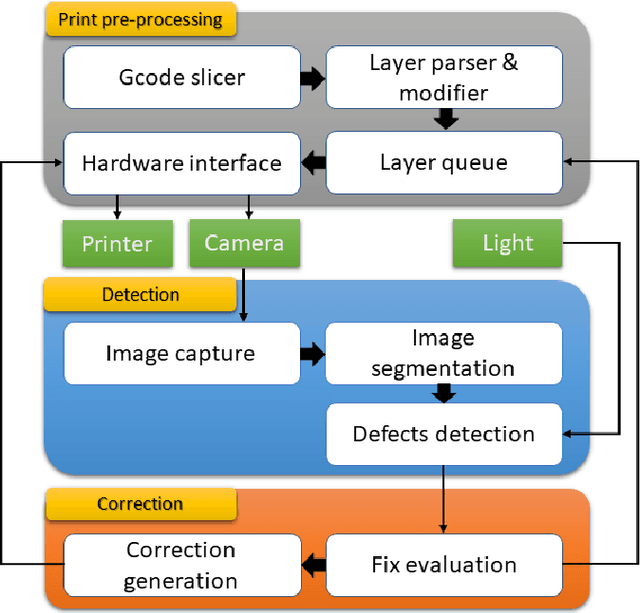

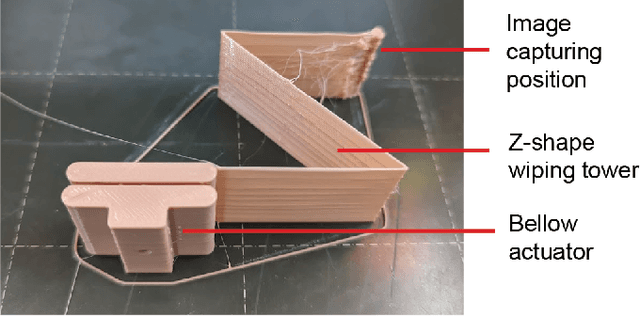

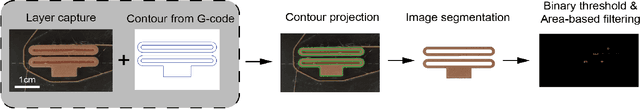

Abstract:Pneumatic soft robots are typically fabricated by molding, a manual fabrication process that requires skilled labor. Additive manufacturing has the potential to break this limitation and speed up the fabrication process but struggles with consistently producing high-quality prints. We propose a low-cost approach to improve the print quality of desktop fused deposition modeling by adding a webcam to the printer to monitor the printing process and detect and correct defects such as holes or gaps. We demonstrate that our approach improves the air-tightness of printed pneumatic actuators without fine-tuning printing parameters. Our approach presents a new option for robustly fabricating airtight, soft robotic actuators.

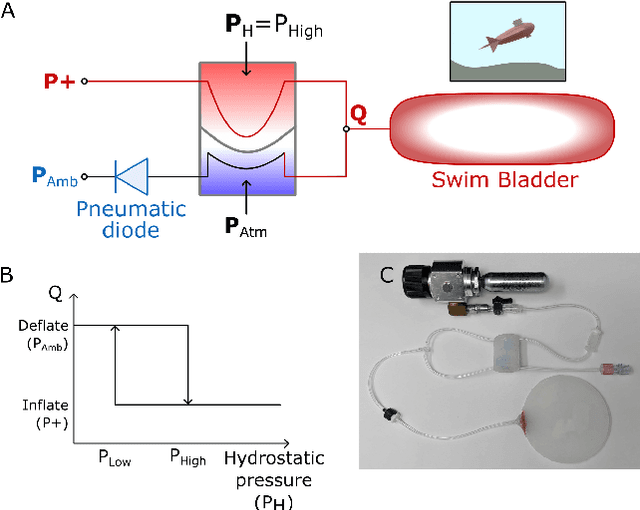

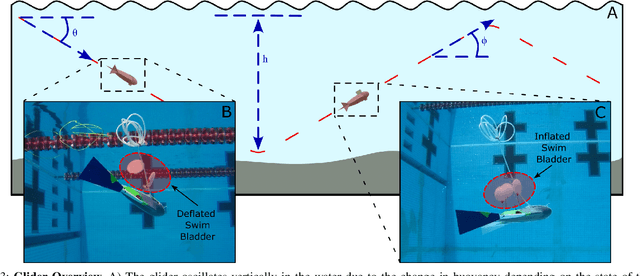

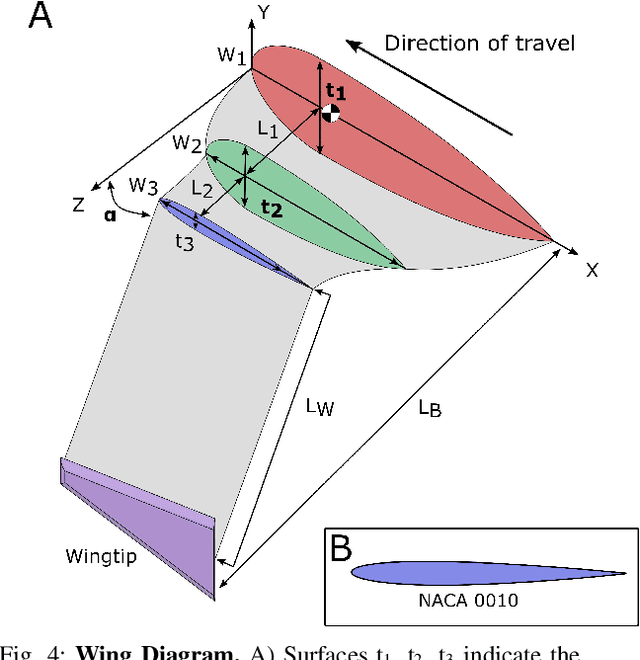

Soft Fluidic Closed-Loop Controller for Untethered Underwater Gliders

Mar 15, 2023

Abstract:Soft underwater robots typically explore bioinspired designs at the expense of power efficiency when compared to traditional underwater robots, which limits their practical use in real-world applications. We leverage a fluidic closed-loop controller to actuate a passive underwater glider. A soft hydrostatic pressure sensor is configured as a bangbang controller actuating a swim bladder made from silicone balloons. Our underwater glider oscillates between the water surface and 4 m depth while traveling 15 m translational. The fluidic underwater glider demonstrates a power efficiency of 28 mW/m. This work demonstrates a low-cost and power-efficient underwater glider and non-electronic controller. Due to its simple design, low cost, and ease of fabrication using FDM printing and soft lithography, it serves as a starting point for the exploration of non-electronic underwater soft robots.

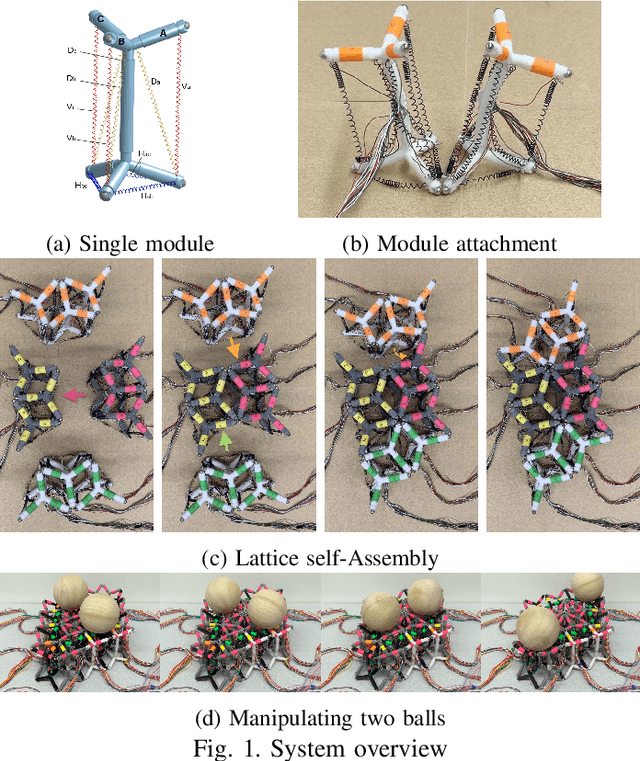

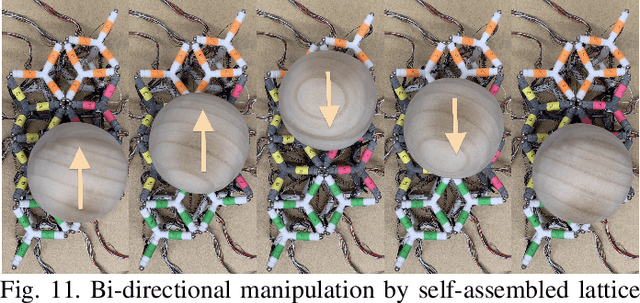

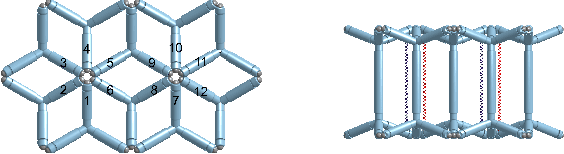

Soft Lattice Modules that Behave Independently and Collectively

Oct 21, 2021

Abstract:Natural systems integrate the work of many sub-units (cells) toward a large-scale unified goal (morphological and behavioral), which can counteract the effects of unexpected experiences, damage, or simply changes in tasks demands. In this paper, we exploit the opportunities presented by soft, modular, and tensegrity robots to introduce soft lattice modules that parallel the sub-units seen in biological systems. The soft lattice modules are comprised of 3D printed plastic "skeletons", linear contracting shape memory alloy spring actuators, and permanent magnets that enable adhesion between modules. The soft lattice modules are capable of independent locomotion, and can also join with other modules to achieve collective, self-assembled, larger scale tasks such as collective locomotion and moving an object across the surface of the lattice assembly. This work represents a preliminary step toward soft modular systems capable of independent and collective behaviors, and provide a platform for future studies on distributed control.

PuzzleFlex: kinematic motion of chains with loose joints

Jun 20, 2019

Abstract:This paper presents a method of computing free motions of a planar assembly of rigid bodies connected by loose joints. Joints are modeled using local distance constraints, which are then linearized with respect to configuration space velocities, yielding a linear programming formulation that allows analysis of systems with thousands of rigid bodies. Potential applications include analysis of collections of modular robots, structural stability perturbation analysis, tolerance analysis for mechanical systems,and formation control of mobile robots.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge