Markus P. Nemitz

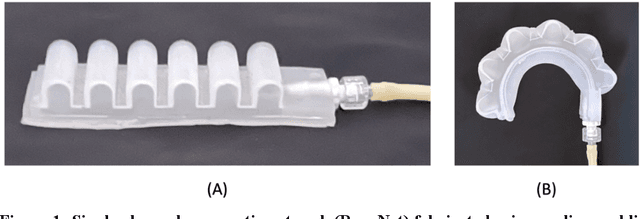

Vision-based FDM Printing for Fabricating Airtight Soft Actuators

Dec 02, 2023

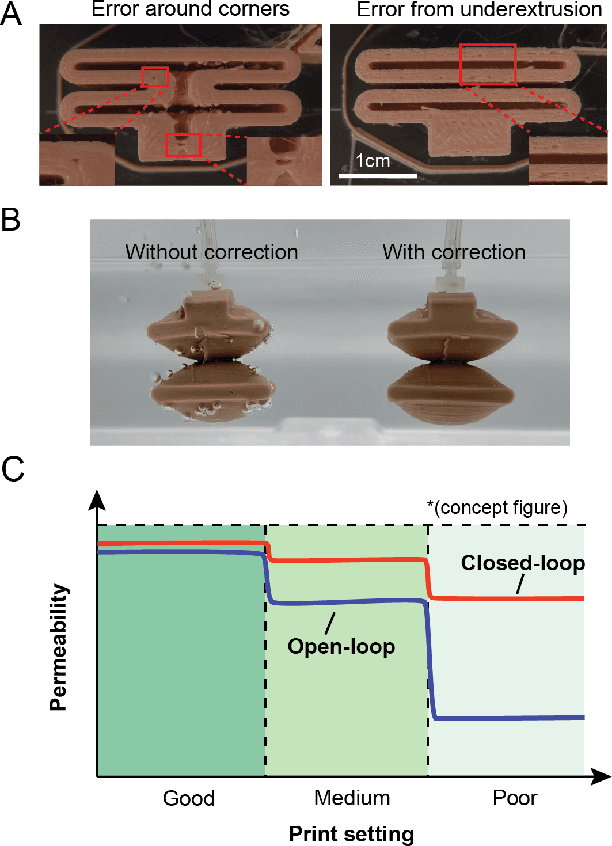

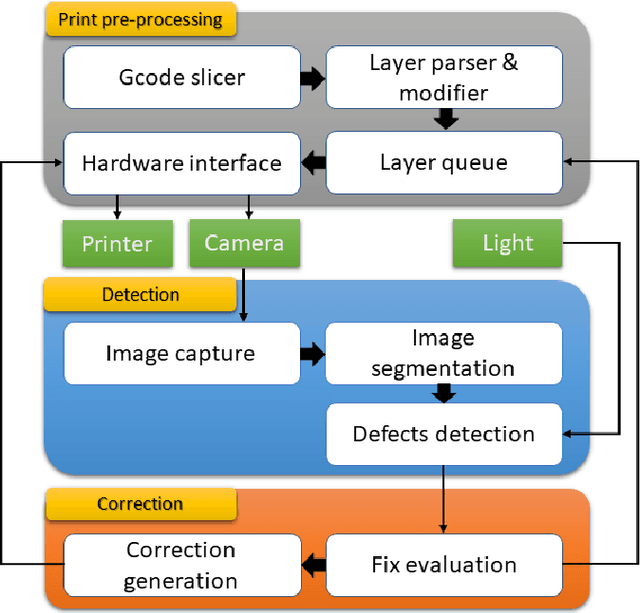

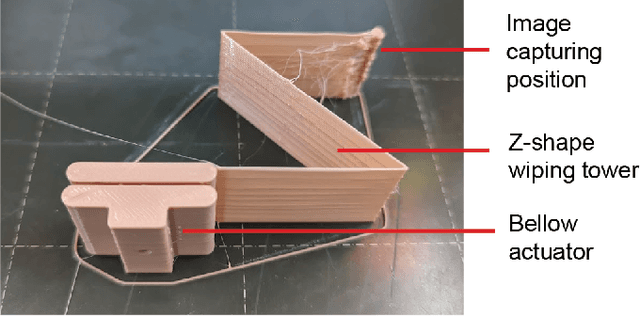

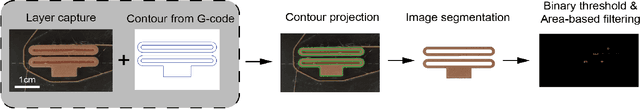

Abstract:Pneumatic soft robots are typically fabricated by molding, a manual fabrication process that requires skilled labor. Additive manufacturing has the potential to break this limitation and speed up the fabrication process but struggles with consistently producing high-quality prints. We propose a low-cost approach to improve the print quality of desktop fused deposition modeling by adding a webcam to the printer to monitor the printing process and detect and correct defects such as holes or gaps. We demonstrate that our approach improves the air-tightness of printed pneumatic actuators without fine-tuning printing parameters. Our approach presents a new option for robustly fabricating airtight, soft robotic actuators.

STREAM: Software Tool for Routing Efficiently Advanced Macrofluidics

Dec 02, 2023Abstract:The current fabrication and assembly of fluidic circuits for soft robots relies heavily on manual processes; as the complexity of fluidic circuits increases, manual assembly becomes increasingly arduous, error-prone, and timeconsuming. We introduce a software tool that generates printable fluidic networks automatically. We provide a library of fluidic logic elements that are easily 3D printed from thermoplastic polyurethanes using Fused Deposition Modeling only. Our software tool and component library allow the development of arbitrary soft digital circuits. We demonstrate a variable frequency ring oscillator and a full adder. The simplicity of our approach using FDM printers only, democratizes fluidic circuit implementation beyond specialized laboratories. Our software is available on GitHub (https://github.com/roboticmaterialsgroup/FluidLogic).

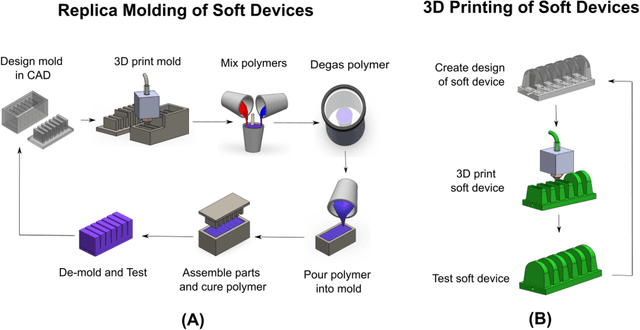

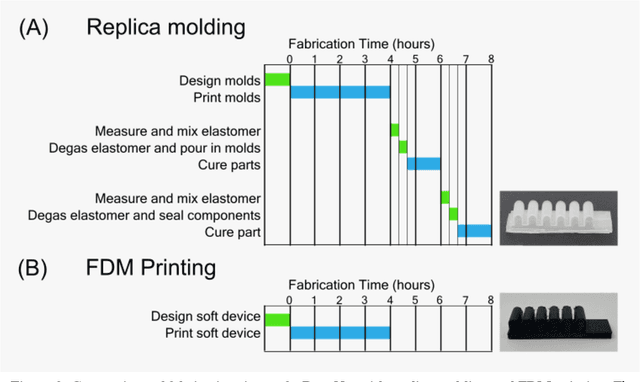

FDM Printing: a Fabrication Method for Fluidic Soft Circuits?

Dec 02, 2023Abstract:Existing fluidic soft logic gates for the control of soft robots either rely on extensive manual fabrication processes or expensive printing techniques. In our work, we explore Fused Deposition Modeling for creating fully 3D printed fluidic logic gates. We print a soft bistable valve from thermoplastic polyurethane using a desktop FDM printer. We introduce a new printing nozzle for extruding tubing. Our fabrication strategy reduces the production time of soft bistable valves from 27 hours with replica molding to 3 hours with a FDM printer. Our rapid and cost-effective fabrication process for fluidic logic gates seeks to democratize fluidic circuitry for the control of soft robots.

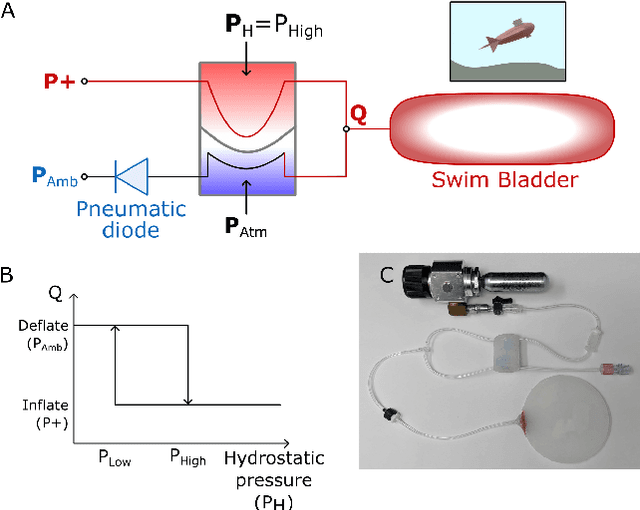

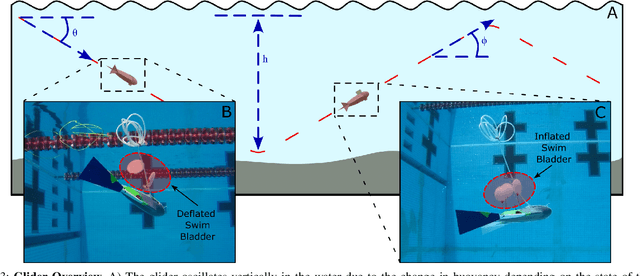

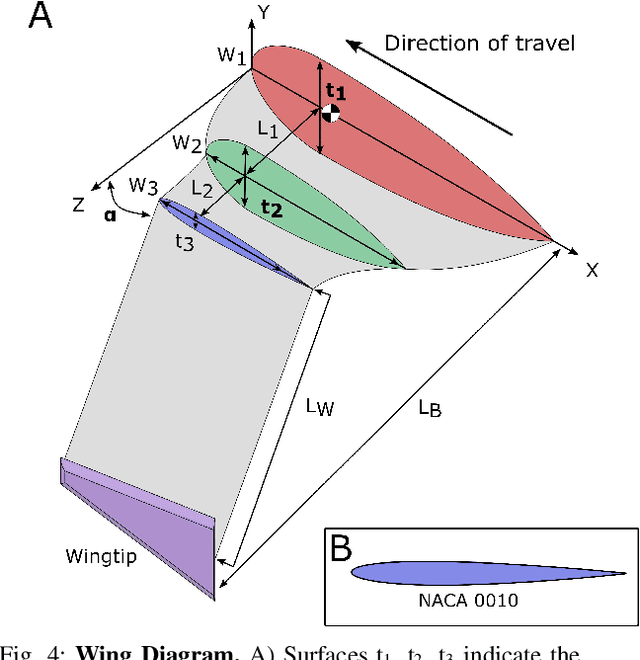

Soft Fluidic Closed-Loop Controller for Untethered Underwater Gliders

Mar 15, 2023

Abstract:Soft underwater robots typically explore bioinspired designs at the expense of power efficiency when compared to traditional underwater robots, which limits their practical use in real-world applications. We leverage a fluidic closed-loop controller to actuate a passive underwater glider. A soft hydrostatic pressure sensor is configured as a bangbang controller actuating a swim bladder made from silicone balloons. Our underwater glider oscillates between the water surface and 4 m depth while traveling 15 m translational. The fluidic underwater glider demonstrates a power efficiency of 28 mW/m. This work demonstrates a low-cost and power-efficient underwater glider and non-electronic controller. Due to its simple design, low cost, and ease of fabrication using FDM printing and soft lithography, it serves as a starting point for the exploration of non-electronic underwater soft robots.

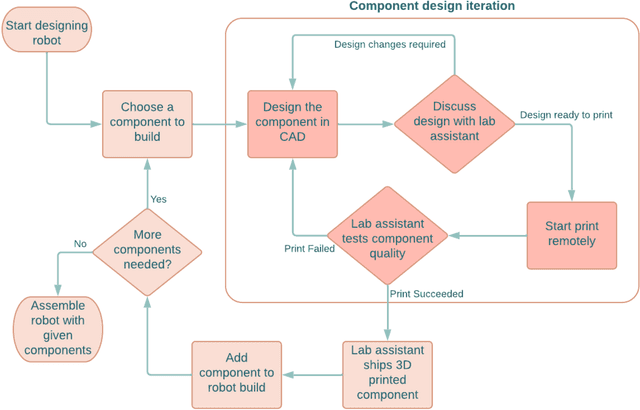

Printable Flexible Robots for Remote Learning

Jul 15, 2022

Abstract:The COVID-19 pandemic has revealed the importance of digital fabrication to enable online learning, which remains a challenge for robotics courses. We introduce a teaching methodology that allows students to participate remotely in a hands-on robotics course involving the design and fabrication of robots. Our methodology employs 3D printing techniques with flexible filaments to create innovative soft robots; robots are made from flexible, as opposed to rigid, materials. Students design flexible robotic components such as actuators, sensors, and controllers using CAD software, upload their designs to a remote 3D printing station, monitor the print with a web camera, and inspect the components with lab staff before being mailed for testing and assembly. At the end of the course, students will have iterated through several designs and created fluidically-driven soft robots. Our remote teaching methodology enables educators to utilize 3D printing resources to teach soft robotics and cultivate creativity among students to design novel and innovative robots. Our methodology seeks to democratize robotics engineering by decoupling hands-on learning experiences from expensive equipment in the learning environment.

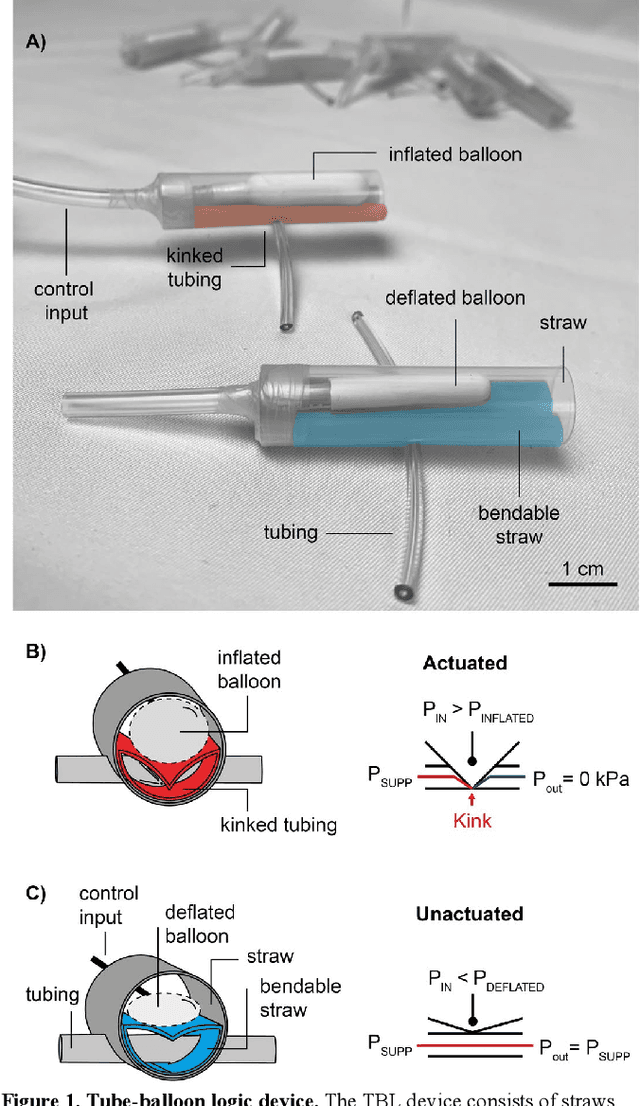

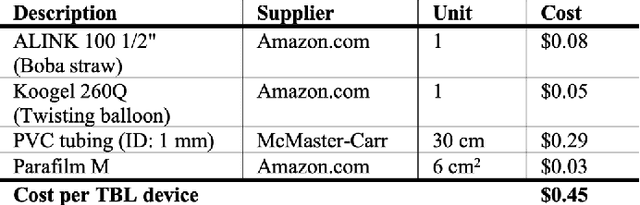

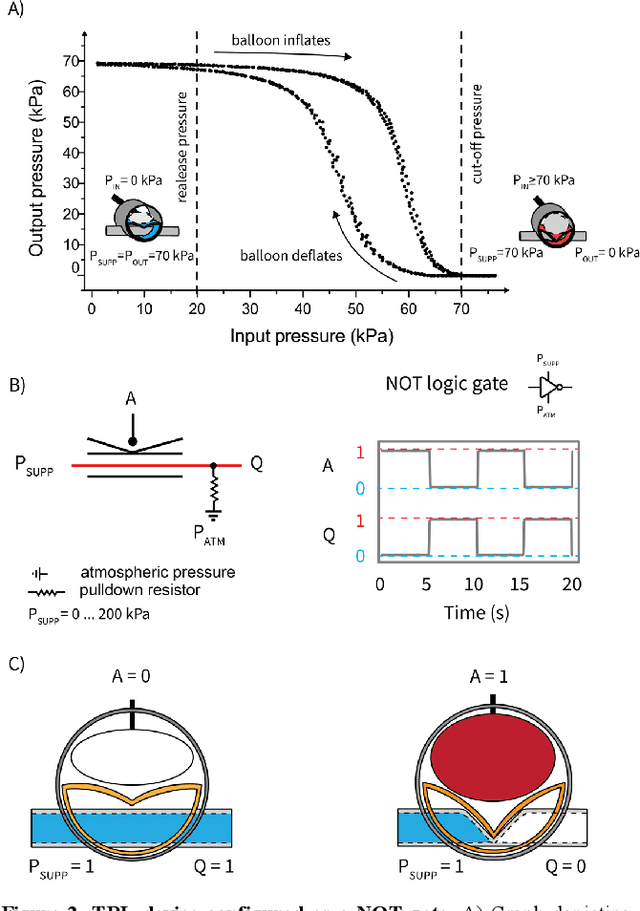

Tube-Balloon Logic for the Exploration of Fluidic Control Elements

Feb 08, 2022

Abstract:The control of pneumatically driven soft robots typically requires electronics. Microcontrollers are connected to power electronics that switch valves and pumps on and off. As a recent alternative, fluidic control methods have been introduced, in which soft digital logic gates permit multiple actuation states to be achieved in soft systems. Such systems have demonstrated autonomous behaviors without the use of electronics. However, fluidic controllers have required complex fabrication processes. To democratize the exploration of fluidic controllers, we developed tube-balloon logic circuitry, which consists of logic gates made from straws and balloons. Each tube-balloon logic device takes a novice five minutes to fabricate and costs $0.45. Tube-balloon logic devices can also operate at pressures of up to 200 kPa and oscillate at frequencies of up to 15 Hz. We configure the tube-balloon logic device as NOT-, NAND-, and NOR-gates and assemble them into a three-ring oscillator to demonstrate a vibrating sieve that separates sugar from rice. Because tube-balloon logic devices are low-cost, easy to fabricate, and their operating principle is simple, they are well suited for exploring fundamental concepts of fluidic control schemes while encouraging design inquiry for pneumatically driven soft robots

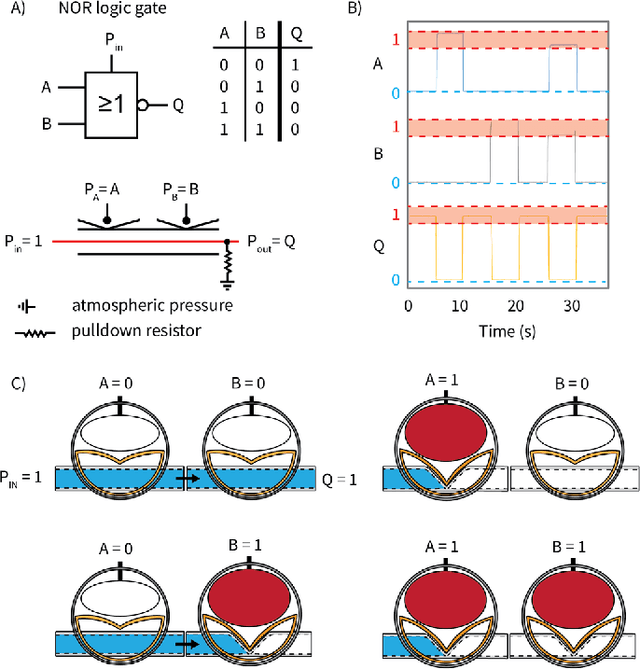

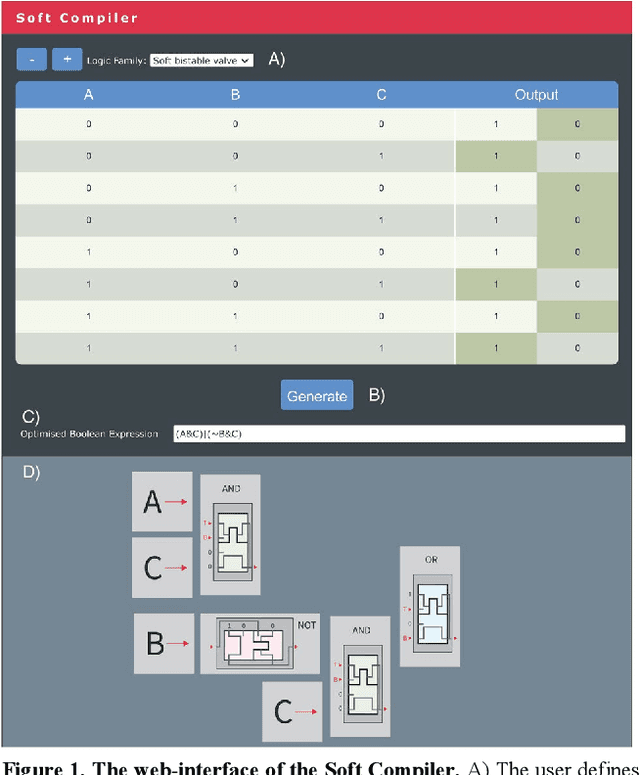

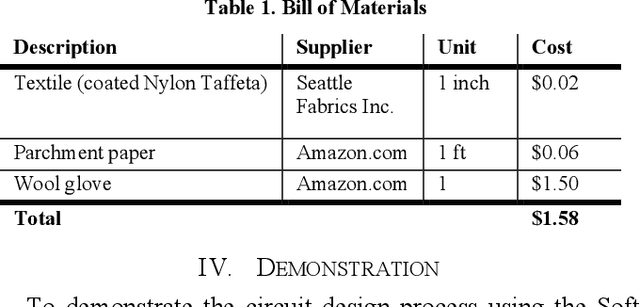

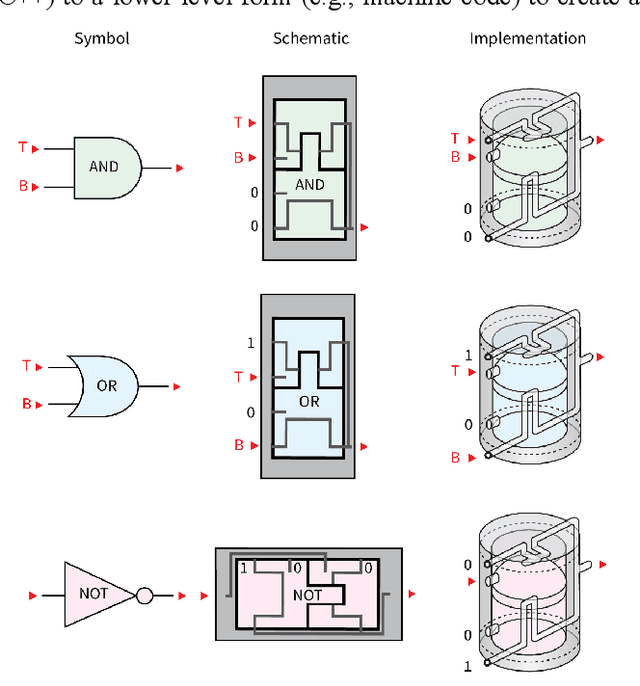

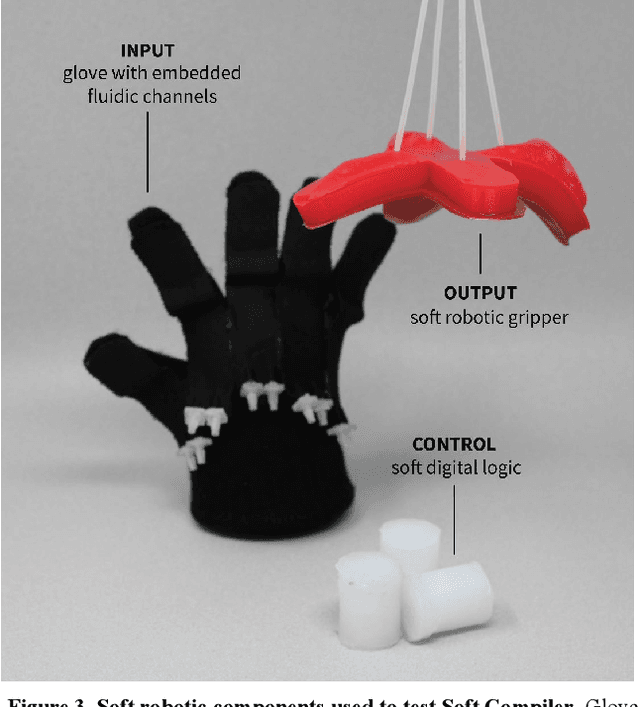

The Soft Compiler: A Web-Based Tool for the Design of Modular Pneumatic Circuits for Soft Robots

Feb 08, 2022

Abstract:Developing soft circuits from individual soft logic gates poses a unique challenge: with increasing numbers of logic gates, the design and implementation of circuits leads to inefficiencies due to mathematically unoptimized circuits and wiring mistakes during assembly. It is therefore practically important to introduce design tools that support the development of soft circuits. We developed a web-based graphical user interface, the Soft Compiler, that accepts a user-defined robot behavior as a truth table to generate a mathematically optimized circuit diagram that guides the assembly of a soft fluidic circuit. We describe the design and experimental verification of three soft circuits of increasing complexity, using the Soft Compiler as a design tool and a novel pneumatic glove as an input interface. In one example, we reduce the size of a soft circuit from the original 11 logic gates to 4 logic gates while maintaining circuit functionality. The Soft Compiler is a web-based design tool for fluidic, soft circuits and published under open-source MIT License.

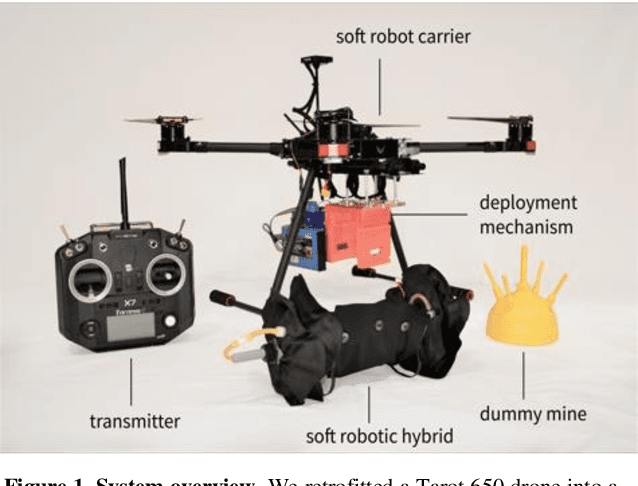

Air-Releasable Soft Robots for Explosive Ordnance Disposal

Feb 07, 2022

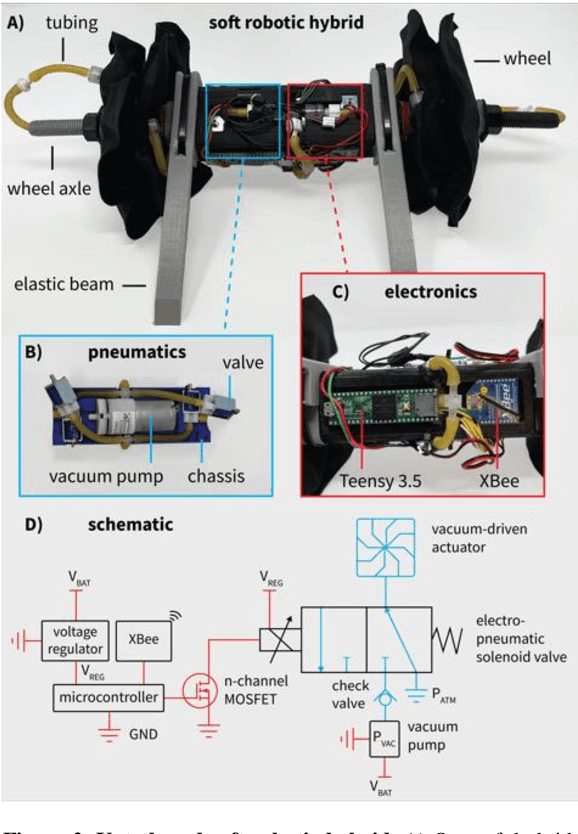

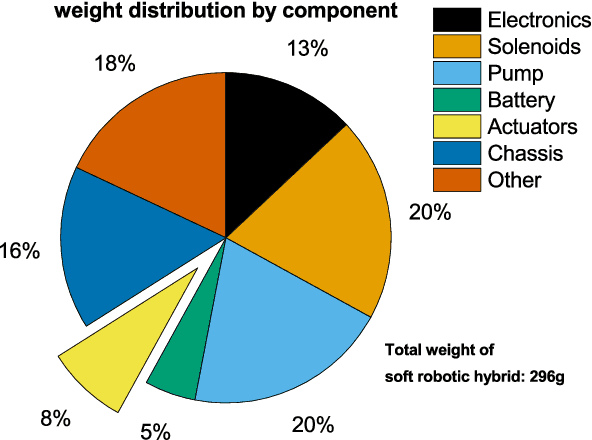

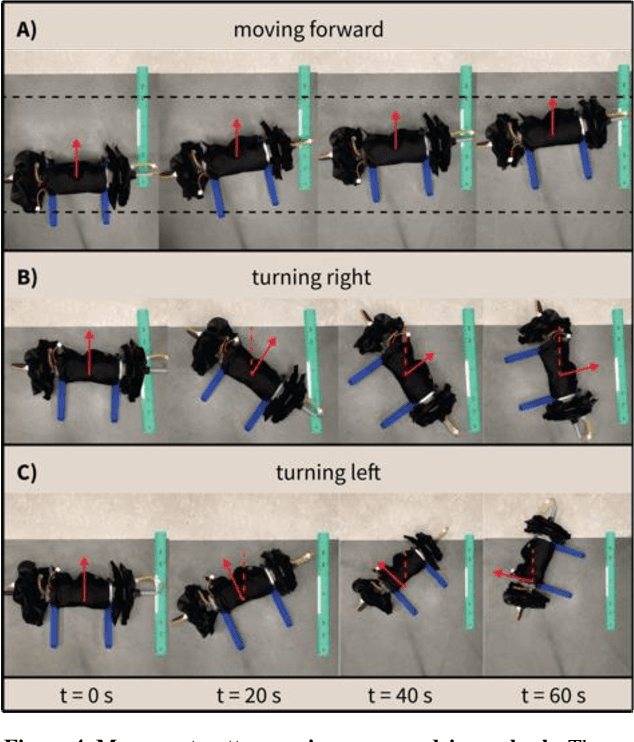

Abstract:The demining of landmines using drones is challenging; air-releasable payloads are typically non-intelligent (e.g., water balloons or explosives) and deploying them at even low altitudes (~6 meter) is inherently inaccurate due to complex deployment trajectories and constrained visual awareness by the drone pilot. Soft robotics offers a unique approach for aerial demining, namely due to the robust, low-cost, and lightweight designs of soft robots. Instead of non-intelligent payloads, here, we propose the use of air-releasable soft robots for demining. We developed a full system consisting of an unmanned aerial vehicle retrofitted to a soft robot carrier including a custom-made deployment mechanism, and an air-releasable, lightweight (296 g), untethered soft hybrid robot with integrated electronics that incorporates a new type of a vacuum-based flasher roller actuator system. We demonstrate a deployment cycle in which the drone drops the soft robotic hybrid from an altitude of 4.5 m meters and after which the robot approaches a dummy landmine. By deploying soft robots at points of interest, we can transition soft robotic technologies from the laboratory to real-world environments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge