Joran Booth

Real2Sim2Real Transfer for Control of Cable-driven Robots via a Differentiable Physics Engine

Sep 20, 2022

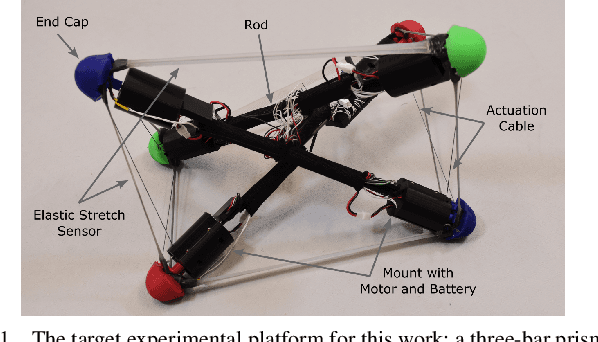

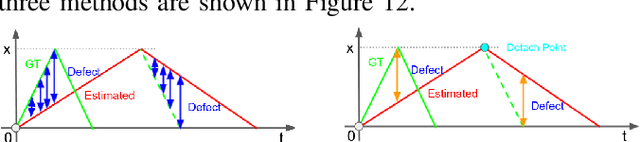

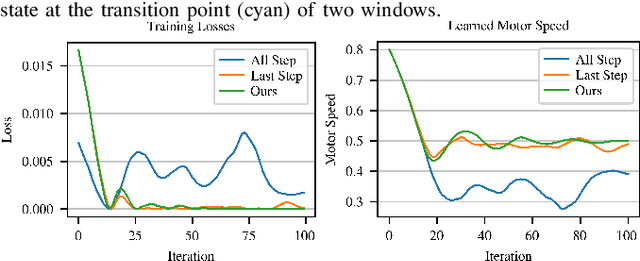

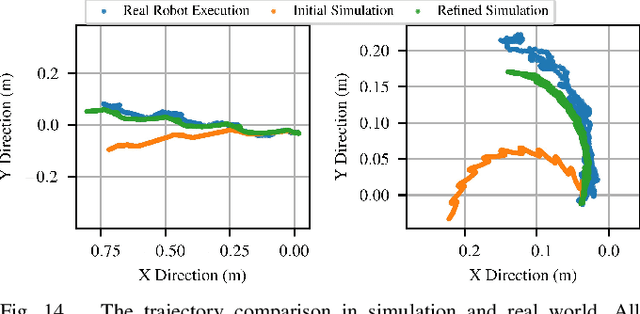

Abstract:Tensegrity robots, composed of rigid rods and flexible cables, exhibit high strength-to-weight ratios and extreme deformations, enabling them to navigate unstructured terrain and even survive harsh impacts. However, they are hard to control due to their high dimensionality, complex dynamics, and coupled architecture. Physics-based simulation is one avenue for developing locomotion policies that can then be transferred to real robots, but modeling tensegrity robots is a complex task, so simulations experience a substantial sim2real gap. To address this issue, this paper describes a Real2Sim2Real strategy for tensegrity robots. This strategy is based on a differential physics engine that can be trained given limited data from a real robot (i.e. offline measurements and one random trajectory) and achieve a high enough accuracy to discover transferable locomotion policies. Beyond the overall pipeline, key contributions of this work include computing non-zero gradients at contact points, a loss function, and a trajectory segmentation technique that avoid conflicts in gradient evaluation during training. The proposed pipeline is demonstrated and evaluated on a real 3-bar tensegrity robot.

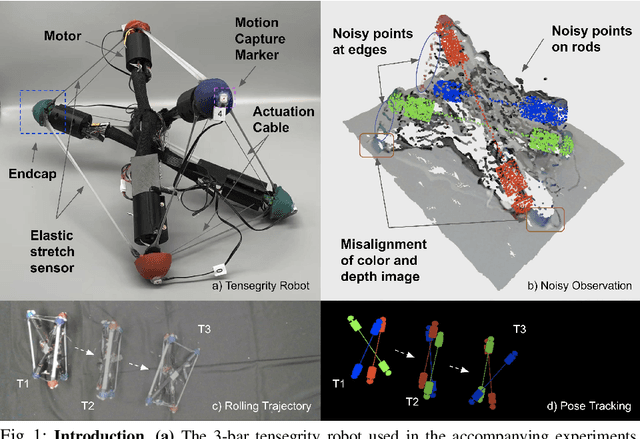

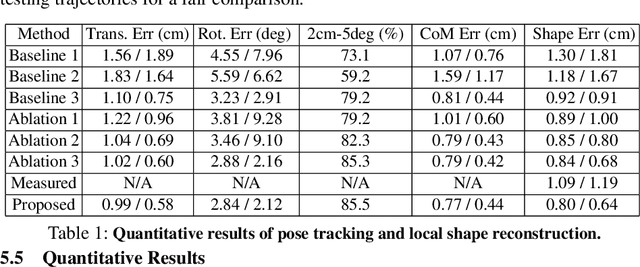

6N-DoF Pose Tracking for Tensegrity Robots

May 29, 2022

Abstract:Tensegrity robots, which are composed of rigid compressive elements (rods) and flexible tensile elements (e.g., cables), have a variety of advantages, including flexibility, light weight, and resistance to mechanical impact. Nevertheless, the hybrid soft-rigid nature of these robots also complicates the ability to localize and track their state. This work aims to address what has been recognized as a grand challenge in this domain, i.e., the pose tracking of tensegrity robots through a markerless, vision-based method, as well as novel, onboard sensors that can measure the length of the robot's cables. In particular, an iterative optimization process is proposed to estimate the 6-DoF poses of each rigid element of a tensegrity robot from an RGB-D video as well as endcap distance measurements from the cable sensors. To ensure the pose estimates of rigid elements are physically feasible, i.e., they are not resulting in collisions between rods or with the environment, physical constraints are introduced during the optimization. Real-world experiments are performed with a 3-bar tensegrity robot, which performs locomotion gaits. Given ground truth data from a motion capture system, the proposed method achieves less than 1 cm translation error and 3 degrees rotation error, which significantly outperforms alternatives. At the same time, the approach can provide pose estimates throughout the robot's motion, while motion capture often fails due to occlusions.

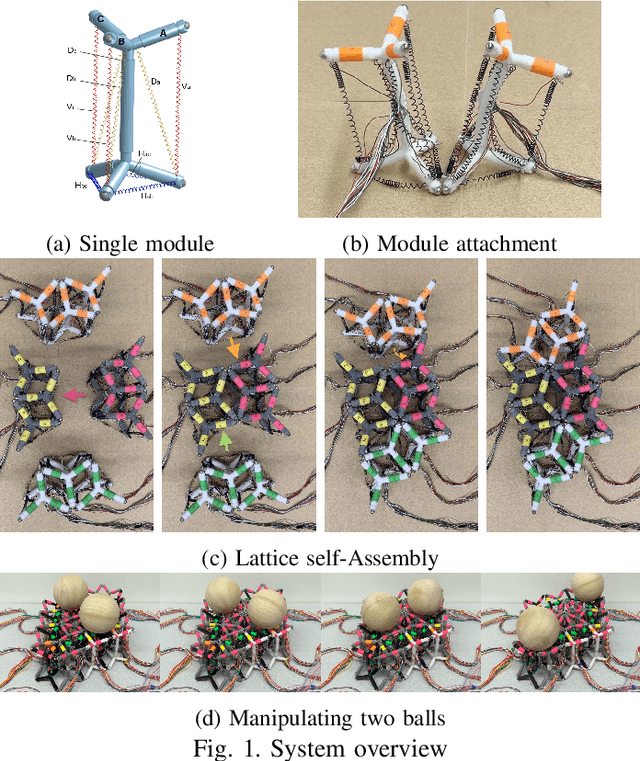

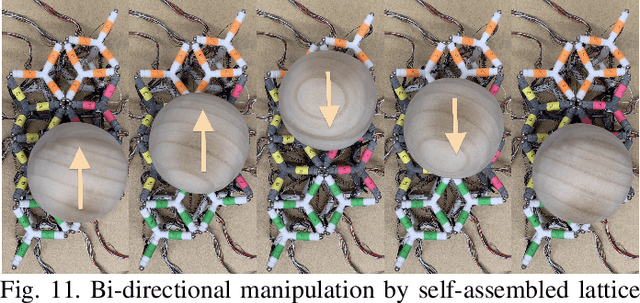

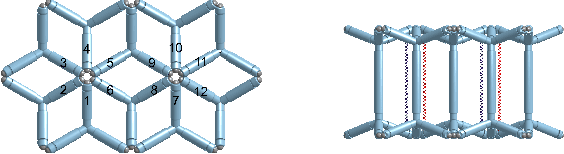

Soft Lattice Modules that Behave Independently and Collectively

Oct 21, 2021

Abstract:Natural systems integrate the work of many sub-units (cells) toward a large-scale unified goal (morphological and behavioral), which can counteract the effects of unexpected experiences, damage, or simply changes in tasks demands. In this paper, we exploit the opportunities presented by soft, modular, and tensegrity robots to introduce soft lattice modules that parallel the sub-units seen in biological systems. The soft lattice modules are comprised of 3D printed plastic "skeletons", linear contracting shape memory alloy spring actuators, and permanent magnets that enable adhesion between modules. The soft lattice modules are capable of independent locomotion, and can also join with other modules to achieve collective, self-assembled, larger scale tasks such as collective locomotion and moving an object across the surface of the lattice assembly. This work represents a preliminary step toward soft modular systems capable of independent and collective behaviors, and provide a platform for future studies on distributed control.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge