6N-DoF Pose Tracking for Tensegrity Robots

Paper and Code

May 29, 2022

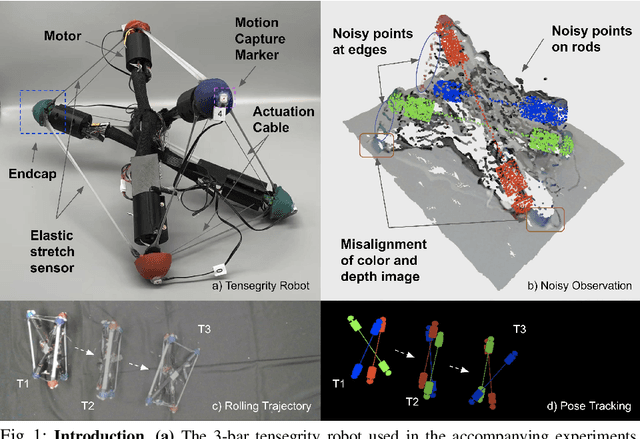

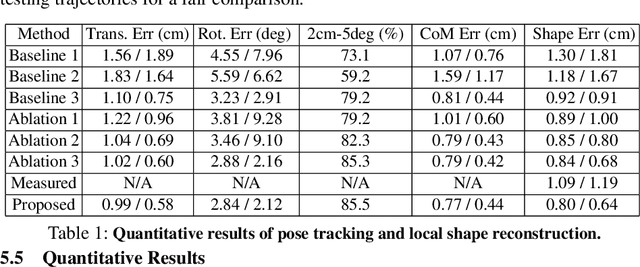

Tensegrity robots, which are composed of rigid compressive elements (rods) and flexible tensile elements (e.g., cables), have a variety of advantages, including flexibility, light weight, and resistance to mechanical impact. Nevertheless, the hybrid soft-rigid nature of these robots also complicates the ability to localize and track their state. This work aims to address what has been recognized as a grand challenge in this domain, i.e., the pose tracking of tensegrity robots through a markerless, vision-based method, as well as novel, onboard sensors that can measure the length of the robot's cables. In particular, an iterative optimization process is proposed to estimate the 6-DoF poses of each rigid element of a tensegrity robot from an RGB-D video as well as endcap distance measurements from the cable sensors. To ensure the pose estimates of rigid elements are physically feasible, i.e., they are not resulting in collisions between rods or with the environment, physical constraints are introduced during the optimization. Real-world experiments are performed with a 3-bar tensegrity robot, which performs locomotion gaits. Given ground truth data from a motion capture system, the proposed method achieves less than 1 cm translation error and 3 degrees rotation error, which significantly outperforms alternatives. At the same time, the approach can provide pose estimates throughout the robot's motion, while motion capture often fails due to occlusions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge