Keisuke Koyama

A Dual-Arm Robot that Manipulates Heavy Plates Cooperatively with a Vacuum Lifter

Mar 20, 2022

Abstract:A vacuum lifter is widely used to hold and pick up large, heavy, and flat objects. Conventionally, when using a vacuum lifter, a human worker watches the state of a running vacuum lifter and adjusts the object's pose to maintain balance. In this work, we propose using a dual-arm robot to replace the human workers and develop planning and control methods for a dual-arm robot to raise a heavy plate with the help of a vacuum lifter. The methods help the robot determine its actions by considering the vacuum lifer's suction position and suction force limits. The essence of the methods is two-fold. First, we build a Manipulation State Graph (MSG) to store the weighted logical relations of various plate contact states and robot/vacuum lifter configurations, and search the graph to plan efficient and low-cost robot manipulation sequences. Second, we develop a velocity-based impedance controller to coordinate the robot and the vacuum lifter when lifting an object. With its help, a robot can follow the vacuum lifter's motion and realize compliant robot-vacuum lifter collaboration. The proposed planning and control methods are investigated using real-world experiments. The results show that a robot can effectively and flexibly work together with a vacuum lifter to manipulate large and heavy plate-like objects with the methods' support.

Proximity Perception in Human-Centered Robotics: A Survey on Sensing Systems and Applications

Aug 17, 2021

Abstract:Proximity perception is a technology that has the potential to play an essential role in the future of robotics. It can fulfill the promise of safe, robust, and autonomous systems in industry and everyday life, alongside humans, as well as in remote locations in space and underwater. In this survey paper, we cover the developments of this field from the early days up to the present, with a focus on human-centered robotics. Here, proximity sensors are typically deployed in two scenarios: first, on the exterior of manipulator arms to support safety and interaction functionality, and second, on the inside of grippers or hands to support grasping and exploration. Starting from this observation, we propose a categorization for the approaches found in the literature. To provide a basis for understanding these approaches, we devote effort to present the technologies and different measuring principles that were developed over the years, also providing a summary in form of a table. Then, we show the diversity of applications that have been presented in the literature. Finally, we give an overview of the most important trends that will shape the future of this domain.

A Topological Solution of Entanglement for Complex-shaped Parts in Robotic Bin-picking

Jun 02, 2021

Abstract:This paper addresses the problem of picking up only one object at a time avoiding any entanglement in bin-picking. To cope with a difficult case where the complex-shaped objects are heavily entangled together, we propose a topology-based method that can generate non-tangle grasp positions on a single depth image. The core technique is entanglement map, which is a feature map to measure the entanglement possibilities obtained from the input image. We use the entanglement map to select probable regions containing graspable objects. The optimum grasping pose is detected from the selected regions considering the collision between robot hand and objects. Experimental results show that our analytic method provides a more comprehensive and intuitive observation of entanglement and exceeds previous learning-based work in success rates. Especially, our topology-based method does not rely on any object models or time-consuming training process, so that it can be easily adapted to more complex bin-picking scenes.

Controlling Pivoting Gait using Graph Model Predictive Control

Apr 19, 2021

Abstract:Pivoting gait is efficient for manipulating a big and heavy object with relatively small manipulating force, in which a robot iteratively tilts the object, rotates it around the vertex, and then puts it down to the floor. However, pivoting gait can easily fail even with a small external disturbance due to its instability in nature. To cope with this problem, we propose a controller to robustly control the object motion during the pivoting gait by introducing two gait modes, i.e., one is the double-support mode, which can manipulate a relatively light object with faster speed, and the other is the quadruple-support mode, which can manipulate a relatively heavy object with lower speed. To control the pivoting gait, a graph model predictive control is applied taking into account of these two gait modes. By adaptively switching the gait mode according to the applied external disturbance, a robot can stably perform the pivoting gait even if the external disturbance is applied to the object.

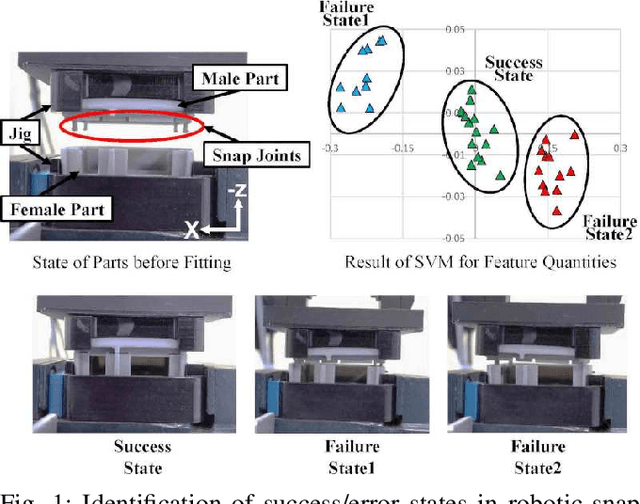

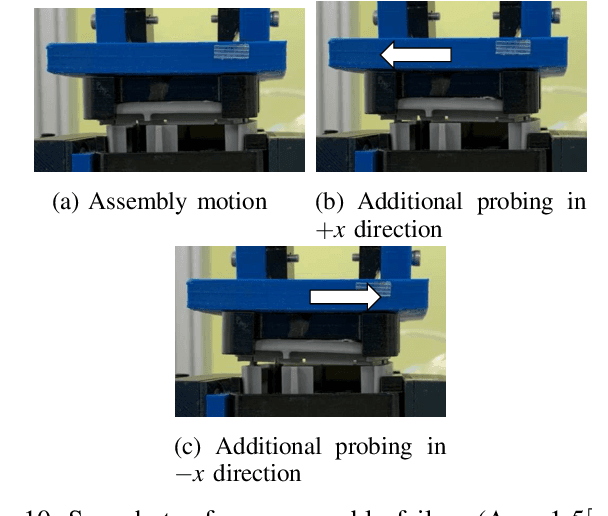

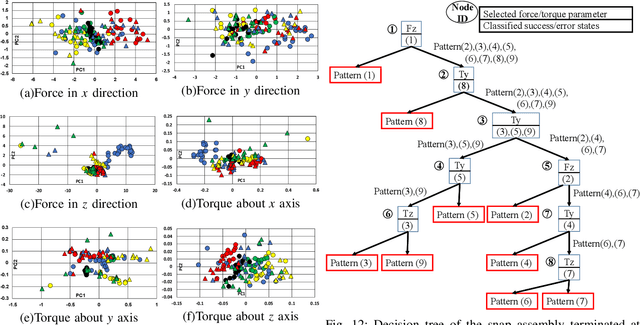

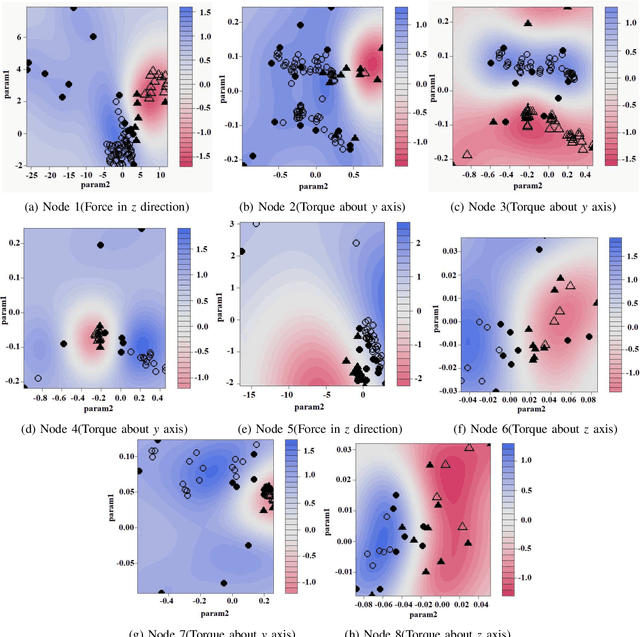

Error Identification and Recovery in Robotic Snap Assembly

Mar 24, 2021

Abstract:Existing methods for predicting robotic snap joint assembly cannot predict failures before their occurrence. To address this limitation, this paper proposes a method for predicting error states before the occurence of error, thereby enabling timely recovery. Robotic snap joint assembly requires precise positioning; therefore, even a slight offset between parts can lead to assembly failure. To correctly predict error states, we apply functional principal component analysis (fPCA) to 6D force/torque profiles that are terminated before the occurence of an error. The error state is identified by applying a feature vector to a decision tree, wherein the support vector machine (SVM) is employed at each node. If the estimation accuracy is low, we perform additional probing to more correctly identify the error state. Finally, after identifying the error state, a robot performs the error recovery motion based on the identified error state. Through the experimental results of assembling plastic parts with four snap joints, we show that the error states can be correctly estimated and a robot can recover from the identified error state.

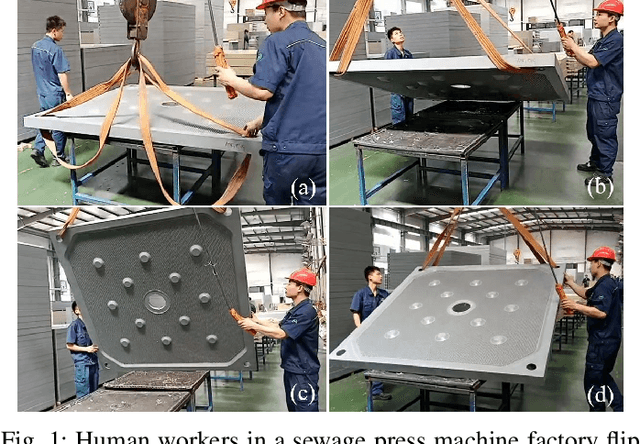

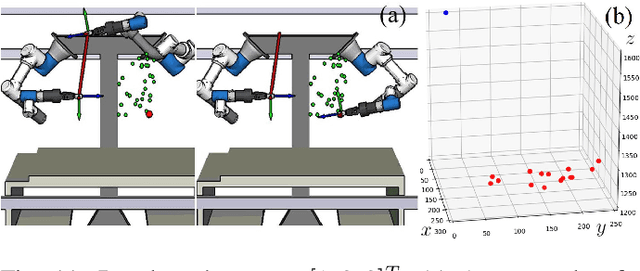

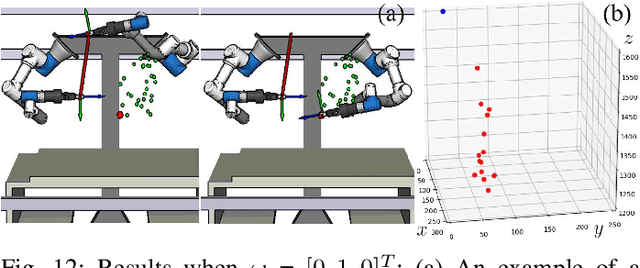

A Dual-arm Robot that Autonomously Lifts Up and Tumbles Heavy Plates Using Crane Pulley Blocks

Jan 23, 2021

Abstract:This paper develops a planner that plans the action sequences and motion for a dual-arm robot to lift up and flip heavy plates using crane pulley blocks. The problem is motivated by the low payload of modern collaborative robots. Instead of directly manipulating heavy plates that collaborative robots cannot afford, the paper develops a planner for collaborative robots to operate crane pulley blocks. The planner assumes a target plate is pre-attached to the crane hook. It optimizes dual-arm action sequences and plans the robot's dual-arm motion that pulls the rope of the crane pulley blocks to lift up the plate. The crane pulley blocks reduce the payload that each robotic arm needs to bear. When the plate is lifted up to a satisfying pose, the planner plans a pushing motion for one of the robot arms to tumble over the plate while considering force and moment constraints. The article presents the technical details of the planner and several experiments and analysis carried out using a dual-arm robot made by two Universal Robots UR3 arms. The influence of various parameters and optimization goals are investigated and compared in depth. The results show that the proposed planner is flexible and efficient.

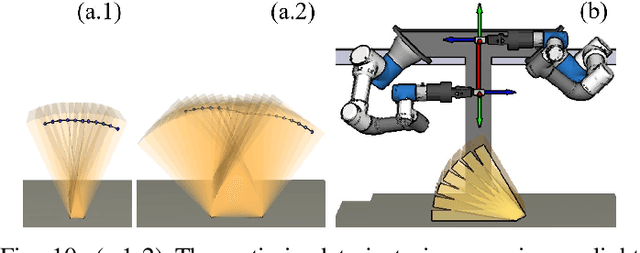

Multi-Pen Robust Robotic 3D Drawing Using Closed-Loop Planning

Oct 01, 2020

Abstract:This paper develops a flexible and robust robotic system for autonomous drawing on 3D surfaces. The system takes 2D drawing strokes and a 3D target surface (mesh or point clouds) as input. It maps the 2D strokes onto the 3D surface and generates a robot motion to draw the mapped strokes using visual recognition, grasp pose reasoning, and motion planning. The system is flexible compared to conventional robotic drawing systems as we do not fix drawing tools to the end of a robot arm. Instead, a robot selects drawing tools using a vision system and holds drawing tools for painting using its hand. Meanwhile, with the flexibility, the system has high robustness thanks to the following crafts: First, a high-quality mapping method is developed to minimize deformation in the strokes. Second, visual detection is used to re-estimate the drawing tool's pose before executing each drawing motion. Third, force control is employed to avoid noisy visual detection and calibration, and ensure a firm touch between the pen tip and a target surface. Fourth, error detection and recovery are implemented to deal with unexpected problems. The planning and executions are performed in a closed-loop manner until the strokes are successfully drawn. We evaluate the system and analyze the necessity of the various crafts using different real-word tasks. The results show that the proposed system is flexible and robust to generate a robot motion from picking and placing the pens to successfully drawing 3D strokes on given surfaces.

Four-Arm Collaboration: Two Dual-Arm Robots Work Together to Maneuver Tethered Tools

Sep 29, 2020

Abstract:In this paper, we present a planner for a master dual-arm robot to manipulate tethered tools with an assistant dual-arm robot's help. The assistant robot provides assistance to the master robot by manipulating the tool cable and avoiding collisions. The provided assistance allows the master robot to perform tool placements on the robot workspace table to regrasp the tool, which would typically fail since the tool cable tension may change the tool positions. It also allows the master robot to perform tool handovers, which would normally cause entanglements or collisions with the cable and the environment without the assistance. Simulations and real-world experiments are performed to validate the proposed planner.

A Mechanical Screwing Tool for 2-Finger Parallel Grippers -- Design, Optimization, and Manipulation Policies

Jun 18, 2020

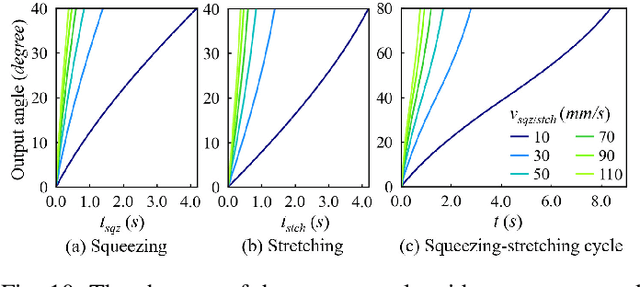

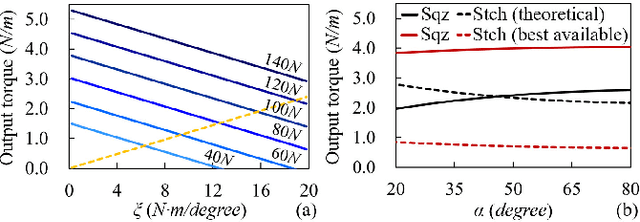

Abstract:This paper develops a mechanical tool as well as its manipulation policies for 2-finger parallel robotic grippers. It primarily focuses on a mechanism that converts the gripping motion of 2-finger parallel grippers into a continuous rotation to realize tasks like fastening screws. The essential structure of the tool comprises a Scissor-Like Element (SLE) mechanism and a double-ratchet mechanism. They together convert repeated linear motion into continuous rotating motion. At the joints of the SLE mechanism, elastic elements are attached to provide resisting force for holding the tool as well as for producing torque output when a gripper releases the tool. The tool is entirely mechanical, allowing robots to use the tool without any peripherals and power supply. The paper presents the details of the tool design, optimizes its dimensions and effective stroke lengths, and studies the contacts and forces to achieve stable grasping and screwing. Besides the design, the paper develops manipulation policies for the tool. The policies include visual recognition, picking-up and manipulation, and exchanging tooltips. The developed tool produces clockwise rotation at the front end and counter-clockwise rotation at the back end. Various tooltips can be installed at both two ends. Robots may employ the developed manipulation policies to exchange the tooltips and rotating directions following the needs of specific fastening or loosening tasks. Robots can also reorient the tool using pick-and-place or handover, and move the tool to work poses using the policies. The designed tool, together with the developed manipulation policies, are analyzed and verified in several real-world applications. The tool is small, cordless, convenient, and has good robustness and adaptability.

Functionally Divided Manipulation Synergy for Controlling Multi-fingered Hands

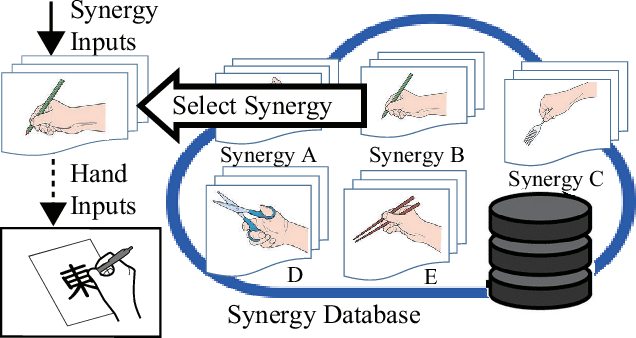

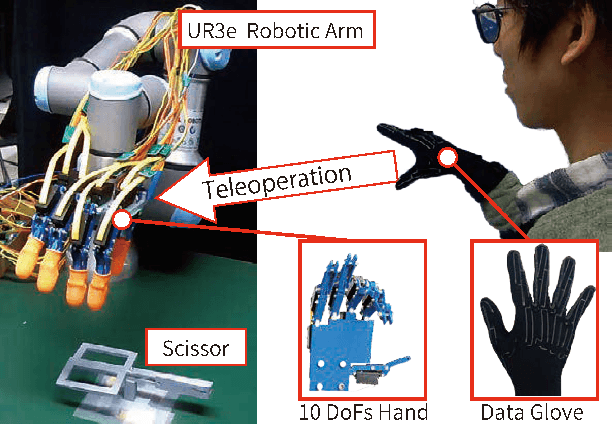

Mar 26, 2020

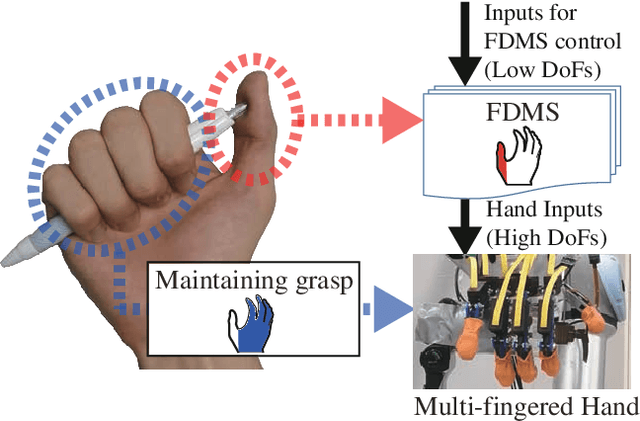

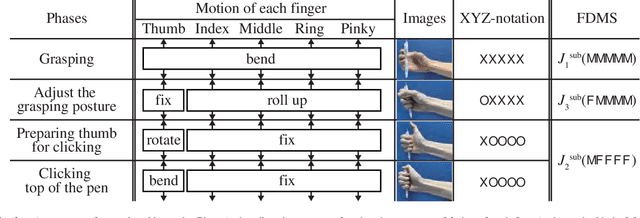

Abstract:Synergy supplies a practical approach for expressing various postures of a multi-fingered hand. However, a conventional synergy defined for reproducing grasping postures cannot perform general-purpose tasks expected for a multi-fingered hand. Locking the position of particular fingers is essential for a multi-fingered hand to manipulate an object. When using conventional synergy based control to manipulate an object, which requires locking some fingers, the coordination of joints is heavily restricted, decreasing the dexterity of the hand. We propose a functionally divided manipulation synergy (FDMS) method, which provides a synergy-based control to achieves both dimensionality reduction and in-hand manipulation. In FDMS, first, we define the function of each finger of the hand as either "manipulation" or "fixed." Then, we apply synergy control only to the fingers having the manipulation function, so that dexterous manipulations can be realized with few control inputs. The effectiveness of our proposed approach is experimentally verified.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge