Weiwei Wan

Osaka University

Replaceable Bit-based Gripper for Picking Cluttered Food Items

Jan 01, 2026Abstract:The food packaging industry goes through changes in food items and their weights quite rapidly. These items range from easy-to-pick, single-piece food items to flexible, long and cluttered ones. We propose a replaceable bit-based gripper system to tackle the challenge of weight-based handling of cluttered food items. The gripper features specialized food attachments(bits) that enhance its grasping capabilities, and a belt replacement system allows switching between different food items during packaging operations. It offers a wide range of control options, enabling it to grasp and drop specific weights of granular, cluttered, and entangled foods. We specifically designed bits for two flexible food items that differ in shape: ikura(salmon roe) and spaghetti. They represent the challenging categories of sticky, granular food and long, sticky, cluttered food, respectively. The gripper successfully picked up both spaghetti and ikura and demonstrated weight-specific dropping of these items with an accuracy over 80% and 95% respectively. The gripper system also exhibited quick switching between different bits, leading to the handling of a large range of food items.

Soft Regrasping Tool Inspired by Jamming Gripper

Sep 17, 2025

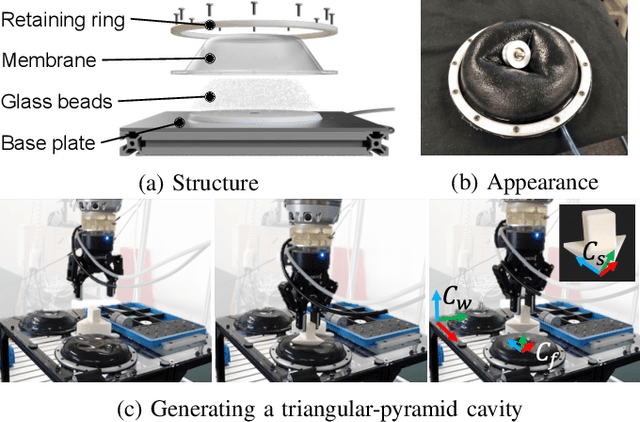

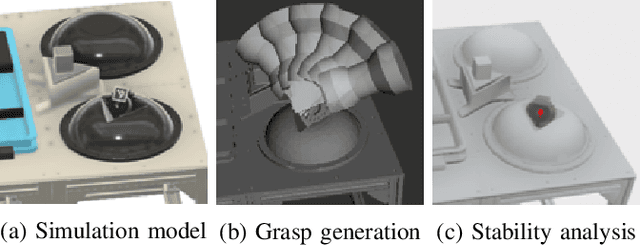

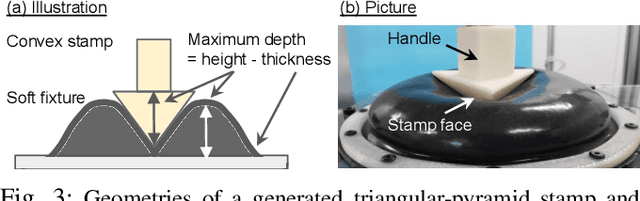

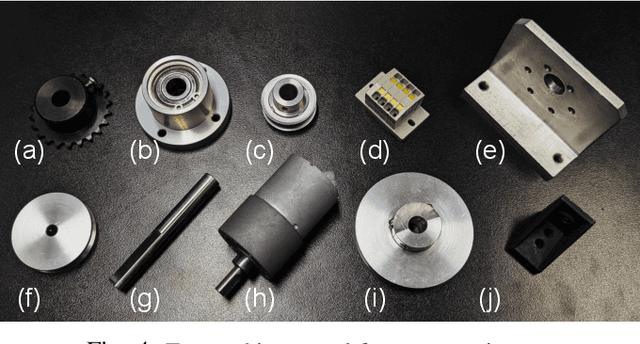

Abstract:Regrasping on fixtures is a promising approach to reduce pose uncertainty in robotic assembly, but conventional rigid fixtures lack adaptability and require dedicated designs for each part. To overcome this limitation, we propose a soft jig inspired by the jamming transition phenomenon, which can be continuously deformed to accommodate diverse object geometries. By pressing a triangular-pyramid-shaped tool into the membrane and evacuating the enclosed air, a stable cavity is formed as a placement space. We further optimize the stamping depth to balance placement stability and gripper accessibility. In soft-jig-based regrasping, the key challenge lies in optimizing the cavity size to achieve precise dropping; once the part is reliably placed, subsequent grasping can be performed with reduced uncertainty. Accordingly, we conducted drop experiments on ten mechanical parts of varying shapes, which achieved placement success rates exceeding 80% for most objects and above 90% for cylindrical ones, while failures were mainly caused by geometric constraints and membrane properties. These results demonstrate that the proposed jig enables general-purpose, accurate, and repeatable regrasping, while also clarifying its current limitations and future potential as a practical alternative to rigid fixtures in assembly automation.

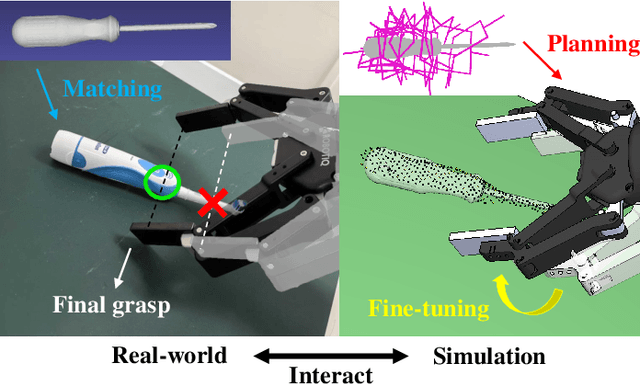

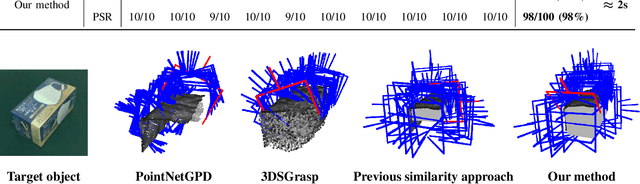

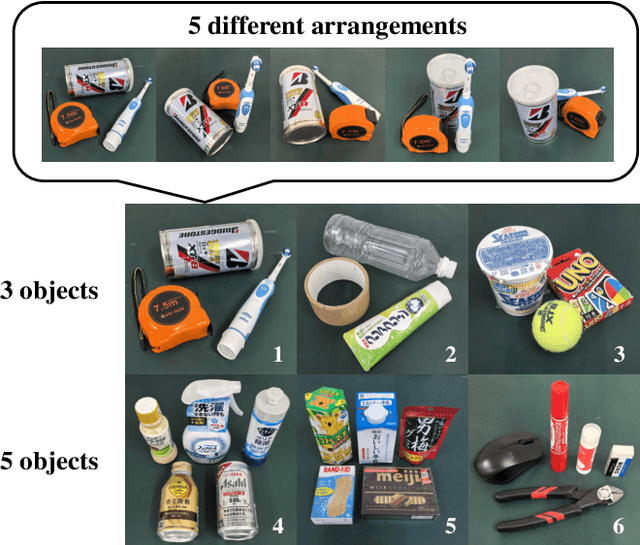

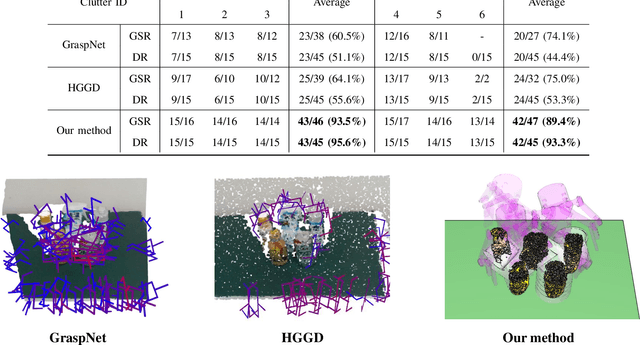

A Multi-Level Similarity Approach for Single-View Object Grasping: Matching, Planning, and Fine-Tuning

Jul 16, 2025

Abstract:Grasping unknown objects from a single view has remained a challenging topic in robotics due to the uncertainty of partial observation. Recent advances in large-scale models have led to benchmark solutions such as GraspNet-1Billion. However, such learning-based approaches still face a critical limitation in performance robustness for their sensitivity to sensing noise and environmental changes. To address this bottleneck in achieving highly generalized grasping, we abandon the traditional learning framework and introduce a new perspective: similarity matching, where similar known objects are utilized to guide the grasping of unknown target objects. We newly propose a method that robustly achieves unknown-object grasping from a single viewpoint through three key steps: 1) Leverage the visual features of the observed object to perform similarity matching with an existing database containing various object models, identifying potential candidates with high similarity; 2) Use the candidate models with pre-existing grasping knowledge to plan imitative grasps for the unknown target object; 3) Optimize the grasp quality through a local fine-tuning process. To address the uncertainty caused by partial and noisy observation, we propose a multi-level similarity matching framework that integrates semantic, geometric, and dimensional features for comprehensive evaluation. Especially, we introduce a novel point cloud geometric descriptor, the C-FPFH descriptor, which facilitates accurate similarity assessment between partial point clouds of observed objects and complete point clouds of database models. In addition, we incorporate the use of large language models, introduce the semi-oriented bounding box, and develop a novel point cloud registration approach based on plane detection to enhance matching accuracy under single-view conditions. Videos are available at https://youtu.be/qQDIELMhQmk.

Bimanual Regrasp Planning and Control for Eliminating Object Pose Uncertainty

Mar 28, 2025Abstract:Precisely grasping an object is a challenging task due to pose uncertainties. Conventional methods have used cameras and fixtures to reduce object uncertainty. They are effective but require intensive preparation, such as designing jigs based on the object geometry and calibrating cameras with high-precision tools fabricated using lasers. In this study, we propose a method to reduce the uncertainty of the position and orientation of a grasped object without using a fixture or a camera. Our method is based on the concept that the flat finger pads of a parallel gripper can reduce uncertainty along its opening/closing direction through flat surface contact. Three orthogonal grasps by parallel grippers with flat finger pads collectively constrain an object's position and orientation to a unique state. Guided by the concepts, we develop a regrasp planning and admittance control approach that sequentially finds and leverages three orthogonal grasps of two robotic arms to eliminate uncertainties in the object pose. We evaluated the proposed method on different initial object uncertainties and verified that the method has satisfactory repeatability accuracy. It outperforms an AR marker detection method implemented using cameras and laser jet printers under standard laboratory conditions.

IKSel: Selecting Good Seed Joint Values for Fast Numerical Inverse Kinematics Iterations

Mar 28, 2025

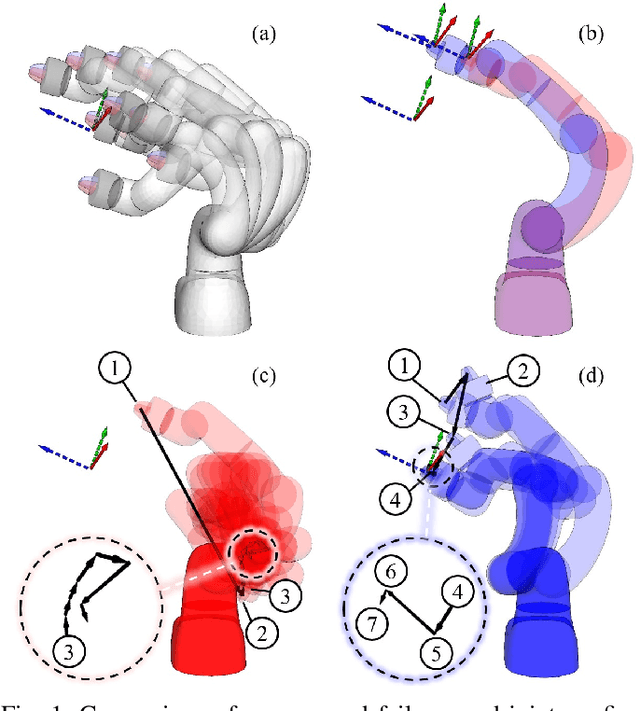

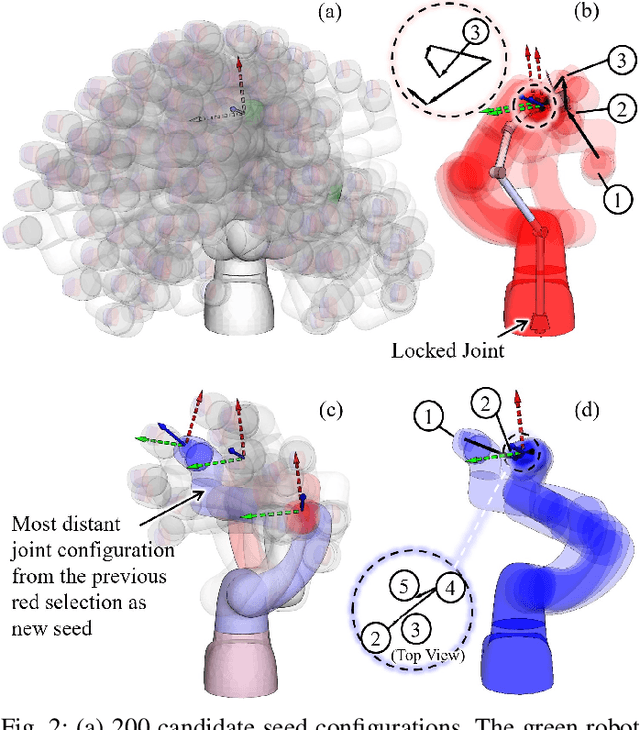

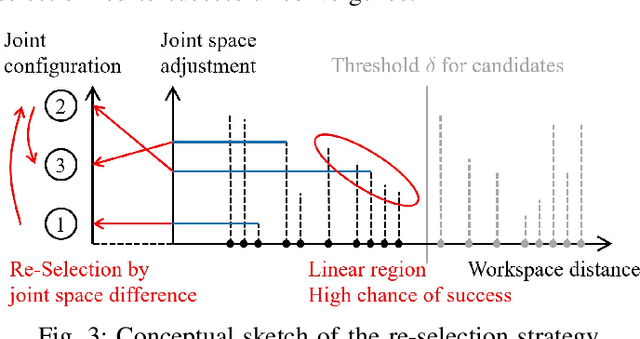

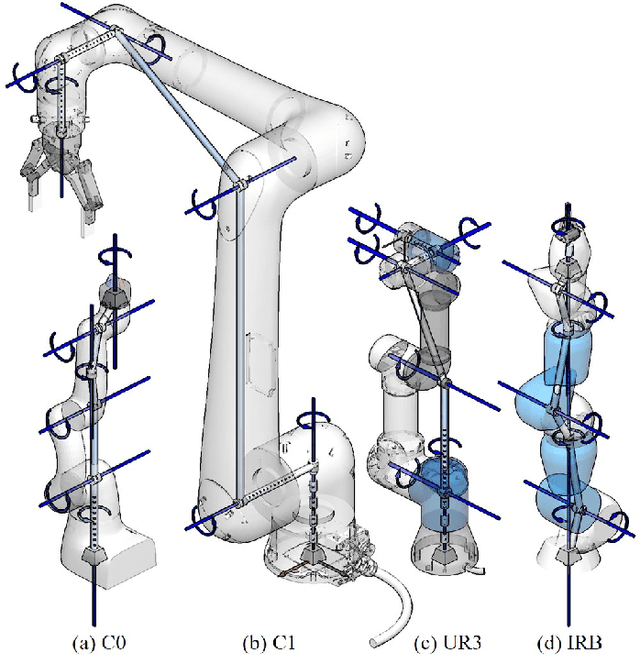

Abstract:This paper revisits the numerical inverse kinematics (IK) problem, leveraging modern computational resources and refining the seed selection process to develop a solver that is competitive with analytical-based methods. The proposed seed selection strategy consists of three key stages: (1) utilizing a K-Dimensional Tree (KDTree) to identify seed candidates based on workspace proximity, (2) sorting candidates by joint space adjustment and attempting numerical iterations with the one requiring minimal adjustment, and (3) re-selecting the most distant joint configurations for new attempts in case of failures. The joint space adjustment-based seed selection increases the likelihood of rapid convergence, while the re-attempt strategy effectively helps circumvent local minima and joint limit constraints. Comparison results with both traditional numerical solvers and learning-based methods demonstrate the strengths of the proposed approach in terms of success rate, time efficiency, and accuracy. Additionally, we conduct detailed ablation studies to analyze the effects of various parameters and solver settings, providing practical insights for customization and optimization. The proposed method consistently exhibits high success rates and computational efficiency. It is suitable for time-sensitive applications.

Cooking Task Planning using LLM and Verified by Graph Network

Mar 27, 2025

Abstract:Cooking tasks remain a challenging problem for robotics due to their complexity. Videos of people cooking are a valuable source of information for such task, but introduces a lot of variability in terms of how to translate this data to a robotic environment. This research aims to streamline this process, focusing on the task plan generation step, by using a Large Language Model (LLM)-based Task and Motion Planning (TAMP) framework to autonomously generate cooking task plans from videos with subtitles, and execute them. Conventional LLM-based task planning methods are not well-suited for interpreting the cooking video data due to uncertainty in the videos, and the risk of hallucination in its output. To address both of these problems, we explore using LLMs in combination with Functional Object-Oriented Networks (FOON), to validate the plan and provide feedback in case of failure. This combination can generate task sequences with manipulation motions that are logically correct and executable by a robot. We compare the execution of the generated plans for 5 cooking recipes from our approach against the plans generated by a few-shot LLM-only approach for a dual-arm robot setup. It could successfully execute 4 of the plans generated by our approach, whereas only 1 of the plans generated by solely using the LLM could be executed.

Robotic Paper Wrapping by Learning Force Control

Mar 19, 2025

Abstract:Robotic packaging using wrapping paper poses significant challenges due to the material's complex deformation properties. The packaging process itself involves multiple steps, primarily categorized as folding the paper or creating creases. Small deviations in the robot's arm trajectory or force vector can lead to tearing or wrinkling of the paper, exacerbated by the variability in material properties. This study introduces a novel framework that combines imitation learning and reinforcement learning to enable a robot to perform each step of the packaging process efficiently. The framework allows the robot to follow approximate trajectories of the tool-center point (TCP) based on human demonstrations while optimizing force control parameters to prevent tearing or wrinkling, even with variable wrapping paper materials. The proposed method was validated through ablation studies, which demonstrated successful task completion with a significant reduction in tear and wrinkle rates. Furthermore, the force control strategy proved to be adaptable across different wrapping paper materials and robust against variations in the size of the target object.

Robot Deformable Object Manipulation via NMPC-generated Demonstrations in Deep Reinforcement Learning

Feb 17, 2025Abstract:In this work, we conducted research on deformable object manipulation by robots based on demonstration-enhanced reinforcement learning (RL). To improve the learning efficiency of RL, we enhanced the utilization of demonstration data from multiple aspects and proposed the HGCR-DDPG algorithm. It uses a novel high-dimensional fuzzy approach for grasping-point selection, a refined behavior-cloning method to enhance data-driven learning in Rainbow-DDPG, and a sequential policy-learning strategy. Compared to the baseline algorithm (Rainbow-DDPG), our proposed HGCR-DDPG achieved 2.01 times the global average reward and reduced the global average standard deviation to 45% of that of the baseline algorithm. To reduce the human labor cost of demonstration collection, we proposed a low-cost demonstration collection method based on Nonlinear Model Predictive Control (NMPC). Simulation experiment results show that demonstrations collected through NMPC can be used to train HGCR-DDPG, achieving comparable results to those obtained with human demonstrations. To validate the feasibility of our proposed methods in real-world environments, we conducted physical experiments involving deformable object manipulation. We manipulated fabric to perform three tasks: diagonal folding, central axis folding, and flattening. The experimental results demonstrate that our proposed method achieved success rates of 83.3%, 80%, and 100% for these three tasks, respectively, validating the effectiveness of our approach. Compared to current large-model approaches for robot manipulation, the proposed algorithm is lightweight, requires fewer computational resources, and offers task-specific customization and efficient adaptability for specific tasks.

Learning to Group and Grasp Multiple Objects

Feb 12, 2025Abstract:Simultaneously grasping and transporting multiple objects can significantly enhance robotic work efficiency and has been a key research focus for decades. The primary challenge lies in determining how to push objects, group them, and execute simultaneous grasping for respective groups while considering object distribution and the hardware constraints of the robot. Traditional rule-based methods struggle to flexibly adapt to diverse scenarios. To address this challenge, this paper proposes an imitation learning-based approach. We collect a series of expert demonstrations through teleoperation and train a diffusion policy network, enabling the robot to dynamically generate action sequences for pushing, grouping, and grasping, thereby facilitating efficient multi-object grasping and transportation. We conducted experiments to evaluate the method under different training dataset sizes, varying object quantities, and real-world object scenarios. The results demonstrate that the proposed approach can effectively and adaptively generate multi-object grouping and grasping strategies. With the support of more training data, imitation learning is expected to be an effective approach for solving the multi-object grasping problem.

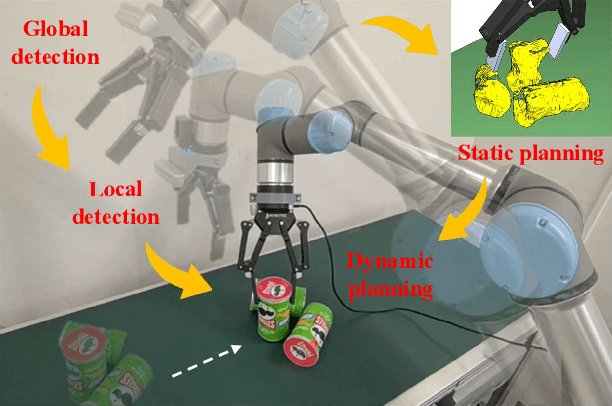

Adaptive Grasping of Moving Objects in Dense Clutter via Global-to-Local Detection and Static-to-Dynamic Planning

Feb 09, 2025

Abstract:Robotic grasping is facing a variety of real-world uncertainties caused by non-static object states, unknown object properties, and cluttered object arrangements. The difficulty of grasping increases with the presence of more uncertainties, where commonly used learning-based approaches struggle to perform consistently across varying conditions. In this study, we integrate the idea of similarity matching to tackle the challenge of grasping novel objects that are simultaneously in motion and densely cluttered using a single RGBD camera, where multiple uncertainties coexist. We achieve this by shifting visual detection from global to local states and operating grasp planning from static to dynamic scenes. Notably, we introduce optimization methods to enhance planning efficiency for this time-sensitive task. Our proposed system can adapt to various object types, arrangements and movement speeds without the need for extensive training, as demonstrated by real-world experiments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge