Joao Ramos

Heavy lifting tasks via haptic teleoperation of a wheeled humanoid

May 26, 2025Abstract:Humanoid robots can support human workers in physically demanding environments by performing tasks that require whole-body coordination, such as lifting and transporting heavy objects.These tasks, which we refer to as Dynamic Mobile Manipulation (DMM), require the simultaneous control of locomotion, manipulation, and posture under dynamic interaction forces. This paper presents a teleoperation framework for DMM on a height-adjustable wheeled humanoid robot for carrying heavy payloads. A Human-Machine Interface (HMI) enables whole-body motion retargeting from the human pilot to the robot by capturing the motion of the human and applying haptic feedback. The pilot uses body motion to regulate robot posture and locomotion, while arm movements guide manipulation.Real time haptic feedback delivers end effector wrenches and balance related cues, closing the loop between human perception and robot environment interaction. We evaluate the different telelocomotion mappings that offer varying levels of balance assistance, allowing the pilot to either manually or automatically regulate the robot's lean in response to payload-induced disturbances. The system is validated in experiments involving dynamic lifting of barbells and boxes up to 2.5 kg (21% of robot mass), demonstrating coordinated whole-body control, height variation, and disturbance handling under pilot guidance. Video demo can be found at: https://youtu.be/jF270_bG1h8?feature=shared

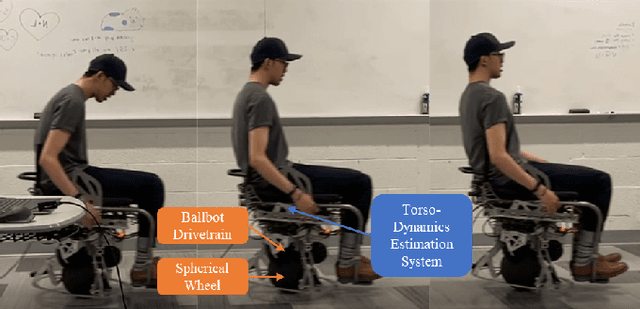

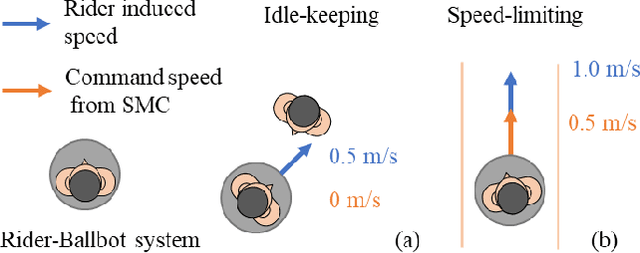

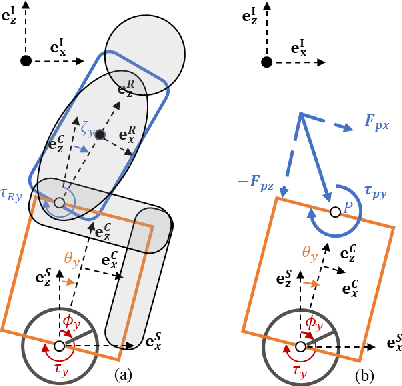

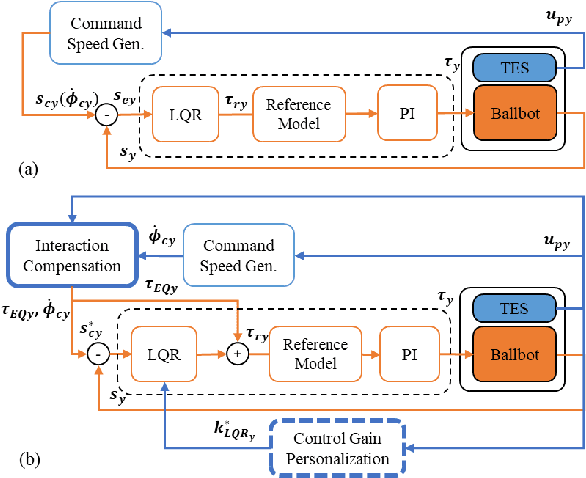

An Interactive Hands-Free Controller for a Riding Ballbot to Enable Simple Shared Control Tasks

Sep 27, 2024

Abstract:Our team developed a riding ballbot (called PURE) that is dynamically stable, omnidirectional, and driven by lean-to-steer control. A hands-free admittance control scheme (HACS) was previously integrated to allow riders with different torso functions to control the robot's movements via torso leaning and twisting. Such an interface requires motor coordination skills and could result in collisions with obstacles due to low proficiency. Hence, a shared controller (SC) that limits the speed of PURE could be helpful to ensure the safety of riders. However, the self-balancing dynamics of PURE could result in a weak control authority of its motion, in which the torso motion of the rider could easily result in poor tracking of the command speed dictated by the shared controller. Thus, we proposed an interactive hands-free admittance control scheme (iHACS), which added two modules to HACS to improve the speed-tracking performance of PURE: control gain personalization module and interaction compensation module. Human riding tests of simple tasks, idle-keeping and speed-limiting, were conducted to compare the performance of HACS and iHACS. Two manual wheelchair users and two able-bodied individuals participated in this study. They were instructed to use "adversarial" torso motions that would tax the SC's ability to keep the ballbot idling or below a set speed. In the idle-keeping tasks, iHACS demonstrated minimal translational motion and low command speed tracking RMSE, even with significant torso lean angles. During the speed-limiting task with command speed saturated at 0.5 m/s, the system achieved an average maximum speed of 1.1 m/s with iHACS, compared with that of over 1.9 m/s with HACS. These results suggest that iHACS can enhance PURE's control authority over the rider, which enables PURE to provide physical interactions back to the rider and results in a collaborative rider-robot synergy.

FSL-LVLM: Friction-Aware Safety Locomotion using Large Vision Language Model in Wheeled Robots

Sep 15, 2024

Abstract:Wheeled-legged robots offer significant mobility and versatility but face substantial challenges when operating on slippery terrains. Traditional model-based controllers for these robots assume no slipping. While reinforcement learning (RL) helps quadruped robots adapt to different surfaces, recovering from slips remains challenging, especially for systems with few contact points. Estimating the ground friction coefficient is another open challenge. In this paper, we propose a novel friction-aware safety locomotion framework that integrates Large Vision Language Models (LVLMs) with a RL policy. Our approach explicitly incorporates the estimated friction coefficient into the RL policy, enabling the robot to adapt its behavior in advance based on the surface type before reaching it. We introduce a Friction-From-Vision (FFV) module, which leverages LVLMs to estimate ground friction coefficients, eliminating the need for large datasets and extensive training. The framework was validated on a customized wheeled inverted pendulum, and experimental results demonstrate that our framework increases the success rate in completing driving tasks by adjusting speed according to terrain type, while achieving better tracking performance compared to baseline methods. Our framework can be simply integrated with any other RL policies.

Wheeled Humanoid Bilateral Teleoperation with Position-Force Control Modes for Dynamic Loco-Manipulation

Jul 16, 2024

Abstract:Remote-controlled humanoid robots can revolutionize manufacturing, construction, and healthcare industries by performing complex or dangerous manual tasks traditionally done by humans. We refer to these behaviors as Dynamic Loco-Manipulation (DLM). To successfully complete these tasks, humans control the position of their bodies and contact forces at their hands. To enable similar whole-body control in humanoids, we introduce loco-manipulation retargeting strategies with switched position and force control modes in a bilateral teleoperation framework. Our proposed locomotion mappings use the pitch and yaw of the operator's torso to control robot position or acceleration. The manipulation retargeting maps the operator's arm movements to the robot's arms for joint-position or impedance control of the end-effector. A Human-Machine Interface captures the teleoperator's motion and provides haptic feedback to their torso, enhancing their awareness of the robot's interactions with the environment. In this paper, we demonstrate two forms of DLM. First, we show the robot slotting heavy boxes (5-10.5 kg), weighing up to 83% of the robot's weight, into desired positions. Second, we show human-robot collaboration for carrying an object, where the robot and teleoperator take on leader and follower roles.

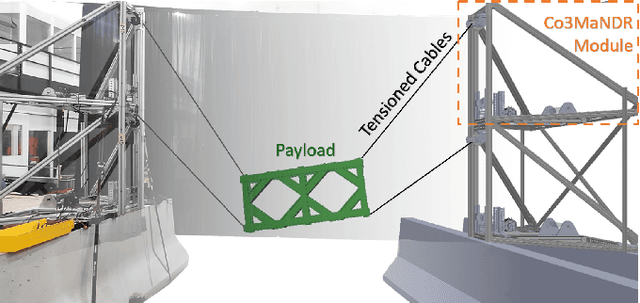

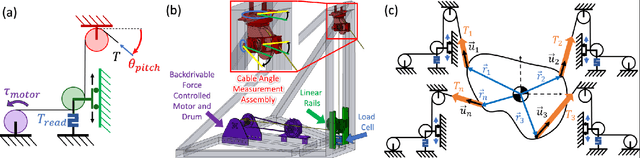

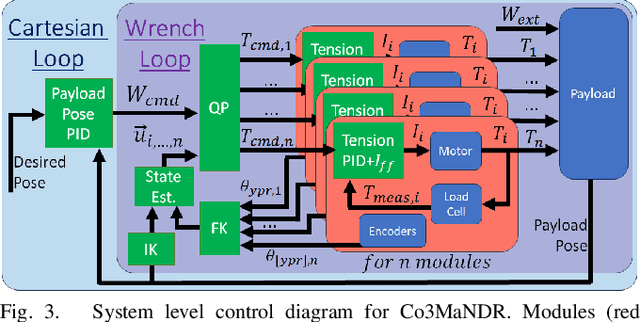

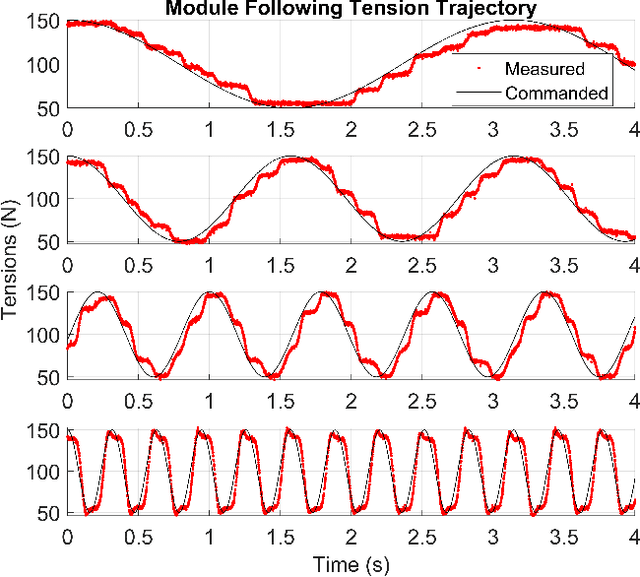

Cooperative Modular Manipulation with Numerous Cable-Driven Robots for Assistive Construction and Gap Crossing

Mar 19, 2024

Abstract:Soldiers in the field often need to cross negative obstacles, such as rivers or canyons, to reach goals or safety. Military gap crossing involves on-site temporary bridges construction. However, this procedure is conducted with dangerous, time and labor intensive operations, and specialized machinery. We envision a scalable robotic solution inspired by advancements in force-controlled and Cable Driven Parallel Robots (CDPRs); this solution can address the challenges inherent in this transportation problem, achieving fast, efficient, and safe deployment and field operations. We introduce the embodied vision in Co3MaNDR, a solution to the military gap crossing problem, a distributed robot consisting of several modules simultaneously pulling on a central payload, controlling the cables' tensions to achieve complex objectives, such as precise trajectory tracking or force amplification. Hardware experiments demonstrate teleoperation of a payload, trajectory following, and the sensing and amplification of operators' applied physical forces during slow operations. An operator was shown to manipulate a 27.2 kg (60 lb) payload with an average force utilization of 14.5\% of its weight. Results indicate that the system can be scaled up to heavier payloads without compromising performance or introducing superfluous complexity. This research lays a foundation to expand CDPR technology to uncoordinated and unstable mobile platforms in unknown environments.

Real-to-Sim Adaptation via High-Fidelity Simulation to Control a Wheeled-Humanoid Robot with Unknown Dynamics

Mar 16, 2024

Abstract:Model-based controllers using a linearized model around the system's equilibrium point is a common approach in the control of a wheeled humanoid due to their less computational load and ease of stability analysis. However, controlling a wheeled humanoid robot while it lifts an unknown object presents significant challenges, primarily due to the lack of knowledge in object dynamics. This paper presents a framework designed for predicting the new equilibrium point explicitly to control a wheeled-legged robot with unknown dynamics. We estimated the total mass and center of mass of the system from its response to initially unknown dynamics, then calculated the new equilibrium point accordingly. To avoid using additional sensors (e.g., force torque sensor) and reduce the effort of obtaining expensive real data, a data-driven approach is utilized with a novel real-to-sim adaptation. A more accurate nonlinear dynamics model, offering a closer representation of real-world physics, is injected into a rigid-body simulation for real-to-sim adaptation. The nonlinear dynamics model parameters were optimized using Particle Swarm Optimization. The efficacy of this framework was validated on a physical wheeled inverted pendulum, a simplified model of a wheeled-legged robot. The experimental results indicate that employing a more precise analytical model with optimized parameters significantly reduces the gap between simulation and reality, thus improving the efficiency of a model-based controller in controlling a wheeled robot with unknown dynamics.

Learning Inertial Parameter Identification of Unknown Object with Humanoid Robot using Sim-to-Real Adaptation

Sep 18, 2023

Abstract:Understanding the dynamics of unknown object is crucial for collaborative robots including humanoids to more safely and accurately interact with humans. Most relevant literature leverage a force/torque sensor, prior knowledge of object, vision system, and a long-horizon trajectory which are often impractical. Moreover, these methods often entail solving non-linear optimization problem, sometimes yielding physically inconsistent results. In this work, we propose a fast learningbased inertial parameter estimation as more practical manner. We acquire a reliable dataset in a high-fidelity simulation and train a time-series data-driven regression model (e.g., LSTM) to estimate the inertial parameter of unknown objects. We also introduce a novel sim-to-real adaptation method combining Robot System Identification and Gaussian Processes to directly transfer the trained model to real-world application. We demonstrate our method with a 4-DOF single manipulator of physical wheeled humanoid robot, SATYRR. Results show that our method can identify the inertial parameters of various unknown objects faster and more accurately than conventional methods.

Whole-Body Dynamic Telelocomotion: A Step-to-Step Dynamics Approach to Human Walking Reference Generation

Jul 21, 2023Abstract:Teleoperated humanoid robots hold significant potential as physical avatars for humans in hazardous and inaccessible environments, with the goal of channeling human intelligence and sensorimotor skills through these robotic counterparts. Precise coordination between humans and robots is crucial for accomplishing whole-body behaviors involving locomotion and manipulation. To progress successfully, dynamic synchronization between humans and humanoid robots must be achieved. This work enhances advancements in whole-body dynamic telelocomotion, addressing challenges in robustness. By embedding the hybrid and underactuated nature of bipedal walking into a virtual human walking interface, we achieve dynamically consistent walking gait generation. Additionally, we integrate a reactive robot controller into a whole-body dynamic telelocomotion framework. Thus, allowing the realization of telelocomotion behaviors on the full-body dynamics of a bipedal robot. Real-time telelocomotion simulation experiments validate the effectiveness of our methods, demonstrating that a trained human pilot can dynamically synchronize with a simulated bipedal robot, achieving sustained locomotion, controlling walking speeds within the range of 0.0 m/s to 0.3 m/s, and enabling backward walking for distances of up to 2.0 m. This research contributes to advancing teleoperated humanoid robots and paves the way for future developments in synchronized locomotion between humans and bipedal robots.

Control- & Task-Aware Optimal Design of Actuation System for Legged Robots using Binary Integer Linear Programming

Jul 21, 2023Abstract:Athletic robots demand a whole-body actuation system design that utilizes motors up to the boundaries of their performance. However, creating such robots poses challenges of integrating design principles and reasoning of practical design choices. This paper presents a design framework that guides designers to find optimal design choices to create an actuation system that can rapidly generate torques and velocities required to achieve a given set of tasks, by minimizing inertia and leveraging cooperation between actuators. The framework serves as an interactive tool for designers who are in charge of providing design rules and candidate components such as motors, reduction mechanism, and coupling mechanisms between actuators and joints. A binary integer linear optimization explores design combinations to find optimal components that can achieve a set of tasks. The framework is demonstrated with 200 optimal design studies of a biped with 5-degree-of-freedom (DoF) legs, focusing on the effect of achieving multiple tasks (walking, lifting), constraining the mass budget of all motors in the system and the use of coupling mechanisms. The result provides a comprehensive view of how design choices and rules affect reflected inertia, copper loss of motors, and force capability of optimal actuation systems.

Dynamic Mobile Manipulation via Whole-Body Bilateral Teleoperation of a Wheeled Humanoid

Jul 03, 2023

Abstract:Humanoid robots have the potential to help human workers by realizing physically demanding manipulation tasks such as moving large boxes within warehouses. We define such tasks as Dynamic Mobile Manipulation (DMM). This paper presents a framework for DMM via whole-body teleoperation, built upon three key contributions: Firstly, a teleoperation framework employing a Human Machine Interface (HMI) and a bi-wheeled humanoid, SATYRR, is proposed. Secondly, the study introduces a dynamic locomotion mapping, utilizing human-robot reduced order models, and a kinematic retargeting strategy for manipulation tasks. Additionally, the paper discusses the role of whole-body haptic feedback for wheeled humanoid control. Finally, the system's effectiveness and mappings for DMM are validated through locomanipulation experiments and heavy box pushing tasks. Here we show two forms of DMM: grasping a target moving at an average speed of 0.4 m/s, and pushing boxes weighing up to 105\% of the robot's weight. By simultaneously adjusting their pitch and using their arms, the pilot adjusts the robot pose to apply larger contact forces and move a heavy box at a constant velocity of 0.2 m/s.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge