Ali Alabbas

Industry 6.0: New Generation of Industry driven by Generative AI and Swarm of Heterogeneous Robots

Sep 16, 2024

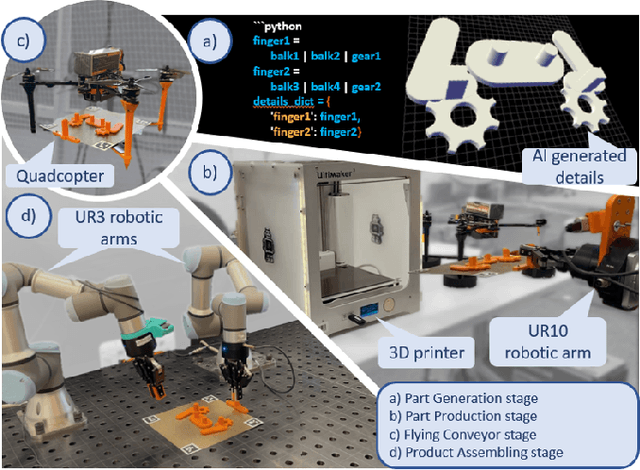

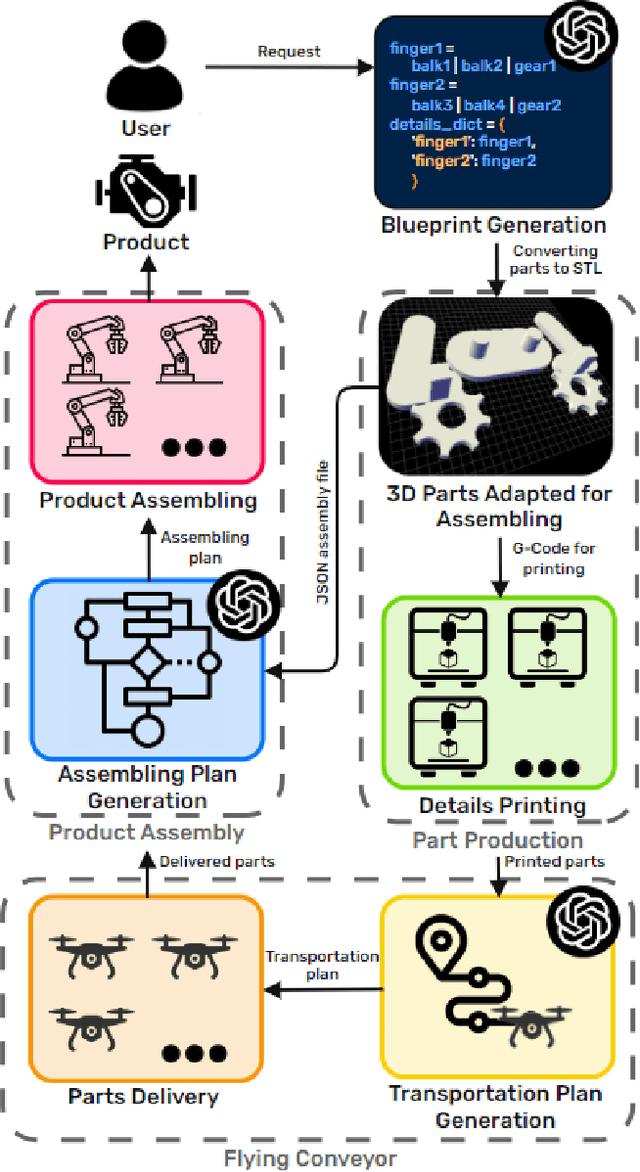

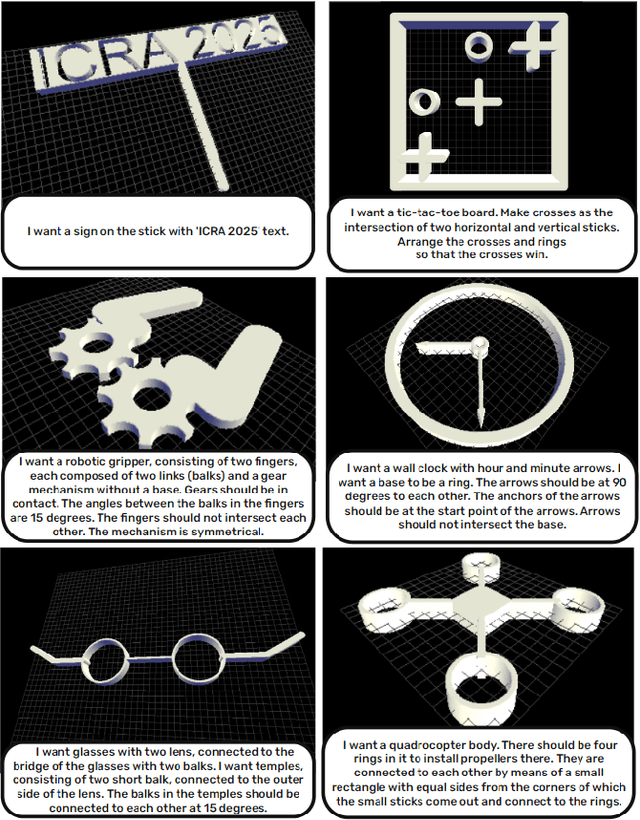

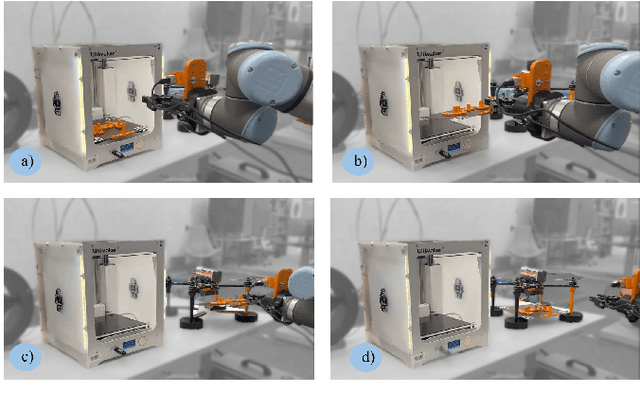

Abstract:This paper presents the concept of Industry 6.0, introducing the world's first fully automated production system that autonomously handles the entire product design and manufacturing process based on user-provided natural language descriptions. By leveraging generative AI, the system automates critical aspects of production, including product blueprint design, component manufacturing, logistics, and assembly. A heterogeneous swarm of robots, each equipped with individual AI through integration with Large Language Models (LLMs), orchestrates the production process. The robotic system includes manipulator arms, delivery drones, and 3D printers capable of generating assembly blueprints. The system was evaluated using commercial and open-source LLMs, functioning through APIs and local deployment. A user study demonstrated that the system reduces the average production time to 119.10 minutes, significantly outperforming a team of expert human developers, who averaged 528.64 minutes (an improvement factor of 4.4). Furthermore, in the product blueprinting stage, the system surpassed human CAD operators by an unprecedented factor of 47, completing the task in 0.5 minutes compared to 23.5 minutes. This breakthrough represents a major leap towards fully autonomous manufacturing.

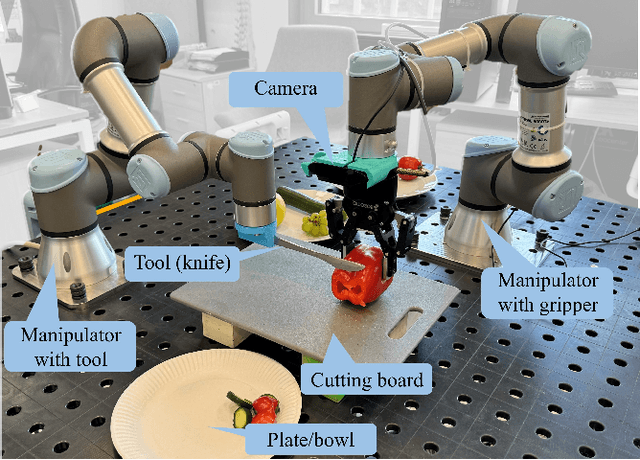

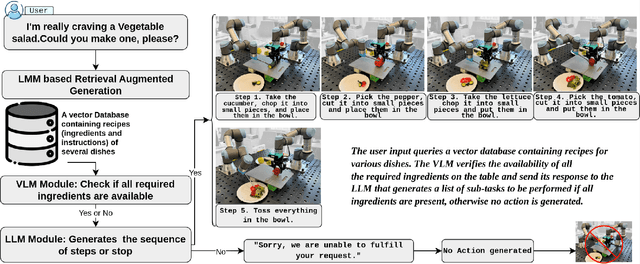

Bi-VLA: Vision-Language-Action Model-Based System for Bimanual Robotic Dexterous Manipulations

May 09, 2024

Abstract:This research introduces the Bi-VLA (Vision-Language-Action) model, a novel system designed for bimanual robotic dexterous manipulations that seamlessly integrate vision, language understanding, and physical action. The system's functionality was evaluated through a set of household tasks, including the preparation of a desired salad upon human request. Bi-VLA demonstrates the ability to interpret complex human instructions, perceive and understand the visual context of ingredients, and execute precise bimanual actions to assemble the requested salad. Through a series of experiments, we evaluate the system's performance in terms of accuracy, efficiency, and adaptability to various salad recipes and human preferences. Our results indicate a high success rate of 100% in generating the correct executable code by the Language module from the user-requested tasks. The Vision Module achieved a success rate of 96.06% in detecting specific ingredients and an 83.4% success rate in detecting a list of multiple ingredients.

MoveTouch: Robotic Motion Capturing System with Wearable Tactile Display to Achieve Safe HRI

May 08, 2024

Abstract:The collaborative robot market is flourishing as there is a trend towards simplification, modularity, and increased flexibility on the production line. But when humans and robots are collaborating in a shared environment, the safety of humans should be a priority. We introduce a novel wearable robotic system to enhance safety during Human Robot Interaction (HRI). The proposed wearable robot is designed to hold a fiducial marker and maintain its visibility to the tracking system, which, in turn, localizes the user's hand with good accuracy and low latency and provides haptic feedback on the user's wrist. The haptic feedback guides the user's hand movement during collaborative tasks in order to increase safety and enhance collaboration efficiency. A user study was conducted to assess the recognition and discriminability of ten designed haptic patterns applied to the volar and dorsal parts of the user's wrist. As a result, four patterns with a high recognition rate were chosen to be incorporated into our system. A second experiment was carried out to evaluate the system integration into real-world collaborative tasks.

CognitiveOS: Large Multimodal Model based System to Endow Any Type of Robot with Generative AI

Jan 29, 2024

Abstract:This paper introduces CognitiveOS, a disruptive system based on multiple transformer-based models, endowing robots of various types with cognitive abilities not only for communication with humans but also for task resolution through physical interaction with the environment. The system operates smoothly on different robotic platforms without extra tuning. It autonomously makes decisions for task execution by analyzing the environment and using information from its long-term memory. The system underwent testing on various platforms, including quadruped robots and manipulator robots, showcasing its capability to formulate behavioral plans even for robots whose behavioral examples were absent in the training dataset. Experimental results revealed the system's high performance in advanced task comprehension and adaptability, emphasizing its potential for real-world applications. The chapters of this paper describe the key components of the system and the dataset structure. The dataset for fine-tuning step generation model is provided at the following link: link coming soon

ArUcoGlide: a Novel Wearable Robot for Position Tracking and Haptic Feedback to Increase Safety During Human-Robot Interaction

Jul 17, 2023Abstract:The current capabilities of robotic systems make human collaboration necessary to accomplish complex tasks effectively. In this work, we are introducing a framework to ensure safety in a human-robot collaborative environment. The system is composed of a wearable 2-DOF robot, a low-cost and easy-to-install tracking system, and a collision avoidance algorithm based on the Artificial Potential Field (APF). The wearable robot is designed to hold a fiducial marker and maintain its visibility to the tracking system, which, in turn, localizes the user's hand with good accuracy and low latency and provides haptic feedback to the user. The system is designed to enhance the performance of collaborative tasks while ensuring user safety. Three experiments were carried out to evaluate the performance of the proposed system. The first one evaluated the accuracy of the tracking system. The second experiment analyzed human-robot behavior during an imminent collision. The third experiment evaluated the system in a collaborative activity in a shared working environment. The results show that the implementation of the introduced system reduces the operation time by 16% and increases the average distance between the user's hand and the robot by 5 cm.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge