Rajesh Sinha

Domain-Independent Disperse and Pick method for Robotic Grasping

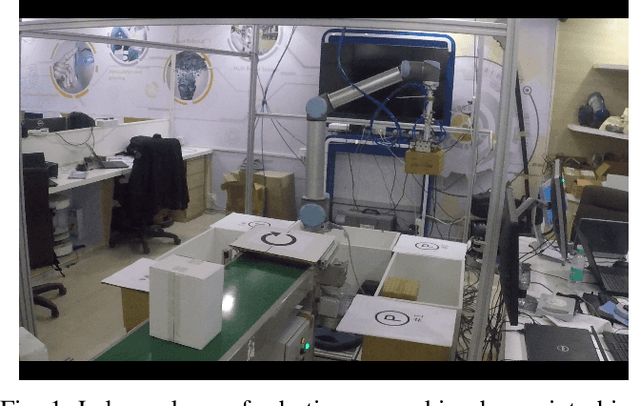

Dec 19, 2023Abstract:Picking unseen objects from clutter is a difficult problem because of the variability in objects (shape, size, and material) and occlusion due to clutter. As a result, it becomes difficult for grasping methods to segment the objects properly and they fail to singulate the object to be picked. This may result in grasp failure or picking of multiple objects together in a single attempt. A push-to-move action by the robot will be beneficial to disperse the objects in the workspace and thus assist the grasping and vision algorithm. We propose a disperse and pick method for domain-independent robotic grasping in a highly cluttered heap of objects. The novel contribution of our framework is the introduction of a heuristic clutter removal method that does not require deep learning and can work on unseen objects. At each iteration of the algorithm, the robot either performs a push-to-move action or a grasp action based on the estimated clutter profile. For grasp planning, we present an improved and adaptive version of a recent domain-independent grasping method. The efficacy of the integrated system is demonstrated in simulation as well as in the real-world.

* Published at 2022 International Joint Conference on Neural Networks (IJCNN)

A generalized algorithm and framework for online 3-dimensional bin packing in an automated sorting center

Nov 01, 2021

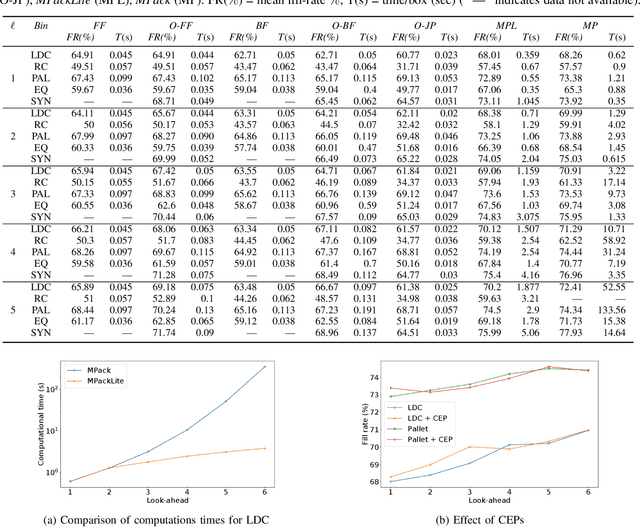

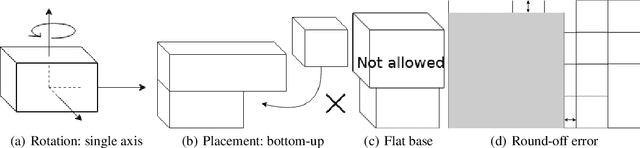

Abstract:Online 3-dimensional bin packing problem (O3D-BPP) is getting renewed prominence due to the industrial automation brought by Industry 4.0. However, due to limited attention in the past and its challenging nature, a good approximate algorithm is in scarcity as compared to 1D or 2D problems. This paper considers real-time O$3$D-BPP of cuboidal boxes with partial information (look-ahead) in an automated robotic sorting center. We present two rolling-horizon mixed-integer linear programming (MILP) cum-heuristic based algorithms: MPack (for bench-marking) and MPackLite (for real-time deployment). Additionally, we present a framework OPack that adapts and improves the performance of BP heuristics by utilizing information in an online setting with a look-ahead. We then perform a comparative analysis of BP heuristics (with and without OPack), MPack, and MPackLite on synthetic and industry provided data with increasing look-ahead. MPackLite and the baseline heuristics perform within bounds of robot operations and thus, can be used in real-time.

A Generalized Reinforcement Learning Algorithm for Online 3D Bin-Packing

Jul 01, 2020

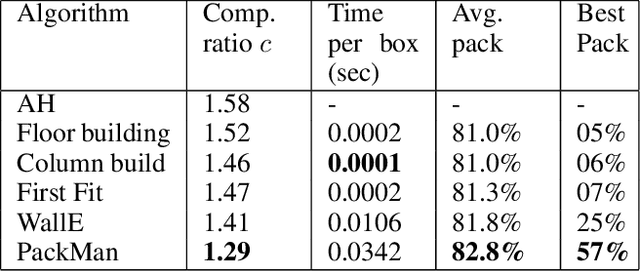

Abstract:We propose a Deep Reinforcement Learning (Deep RL) algorithm for solving the online 3D bin packing problem for an arbitrary number of bins and any bin size. The focus is on producing decisions that can be physically implemented by a robotic loading arm, a laboratory prototype used for testing the concept. The problem considered in this paper is novel in two ways. First, unlike the traditional 3D bin packing problem, we assume that the entire set of objects to be packed is not known a priori. Instead, a fixed number of upcoming objects is visible to the loading system, and they must be loaded in the order of arrival. Second, the goal is not to move objects from one point to another via a feasible path, but to find a location and orientation for each object that maximises the overall packing efficiency of the bin(s). Finally, the learnt model is designed to work with problem instances of arbitrary size without retraining. Simulation results show that the RL-based method outperforms state-of-the-art online bin packing heuristics in terms of empirical competitive ratio and volume efficiency.

Managing a Fleet of Autonomous Mobile Robots using Cloud Robotics Platform

Jun 27, 2017

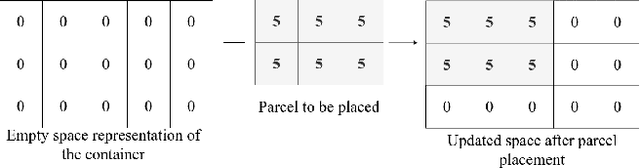

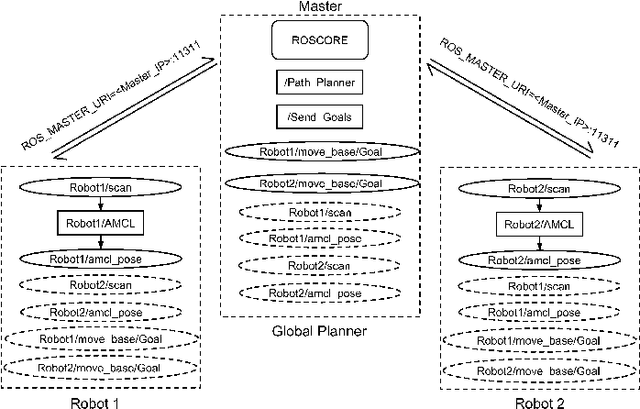

Abstract:In this paper, we provide details of implementing a system for managing a fleet of autonomous mobile robots (AMR) operating in a factory or a warehouse premise. While the robots are themselves autonomous in its motion and obstacle avoidance capability, the target destination for each robot is provided by a global planner. The global planner and the ground vehicles (robots) constitute a multi agent system (MAS) which communicate with each other over a wireless network. Three different approaches are explored for implementation. The first two approaches make use of the distributed computing based Networked Robotics architecture and communication framework of Robot Operating System (ROS) itself while the third approach uses Rapyuta Cloud Robotics framework for this implementation. The comparative performance of these approaches are analyzed through simulation as well as real world experiment with actual robots. These analyses provide an in-depth understanding of the inner working of the Cloud Robotics Platform in contrast to the usual ROS framework. The insight gained through this exercise will be valuable for students as well as practicing engineers interested in implementing similar systems else where. In the process, we also identify few critical limitations of the current Rapyuta platform and provide suggestions to overcome them.

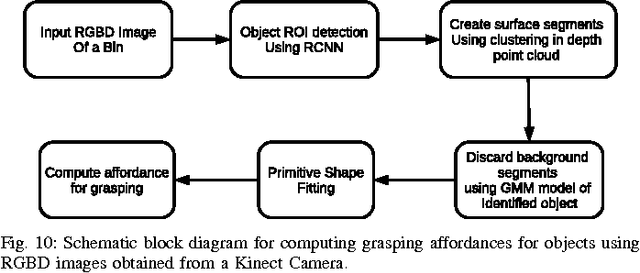

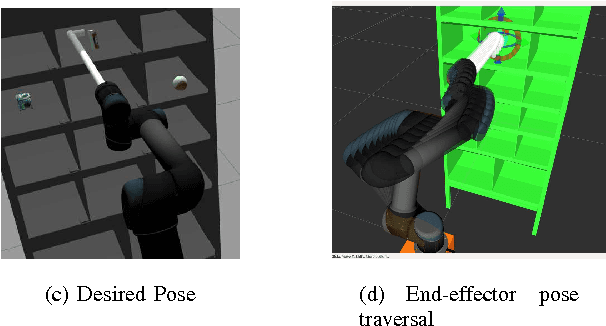

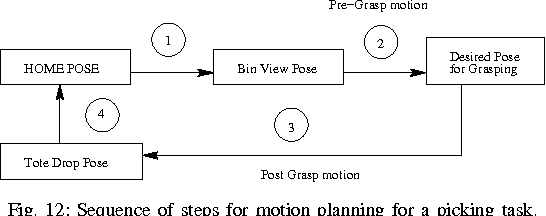

Design and Development of an automated Robotic Pick & Stow System for an e-Commerce Warehouse

Mar 07, 2017

Abstract:In this paper, we provide details of a robotic system that can automate the task of picking and stowing objects from and to a rack in an e-commerce fulfillment warehouse. The system primarily comprises of four main modules: (1) Perception module responsible for recognizing query objects and localizing them in the 3-dimensional robot workspace; (2) Planning module generates necessary paths that the robot end- effector has to take for reaching the objects in the rack or in the tote; (3) Calibration module that defines the physical workspace for the robot visible through the on-board vision system; and (4) Gripping and suction system for picking and stowing different kinds of objects. The perception module uses a faster region-based Convolutional Neural Network (R-CNN) to recognize objects. We designed a novel two finger gripper that incorporates pneumatic valve based suction effect to enhance its ability to pick different kinds of objects. The system was developed by IITK-TCS team for participation in the Amazon Picking Challenge 2016 event. The team secured a fifth place in the stowing task in the event. The purpose of this article is to share our experiences with students and practicing engineers and enable them to build similar systems. The overall efficacy of the system is demonstrated through several simulation as well as real-world experiments with actual robots.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge