Thomas Buchner

ETH Zurich

Sensorized Soft Skin for Dexterous Robotic Hands

Apr 30, 2024

Abstract:Conventional industrial robots often use two-fingered grippers or suction cups to manipulate objects or interact with the world. Because of their simplified design, they are unable to reproduce the dexterity of human hands when manipulating a wide range of objects. While the control of humanoid hands evolved greatly, hardware platforms still lack capabilities, particularly in tactile sensing and providing soft contact surfaces. In this work, we present a method that equips the skeleton of a tendon-driven humanoid hand with a soft and sensorized tactile skin. Multi-material 3D printing allows us to iteratively approach a cast skin design which preserves the robot's dexterity in terms of range of motion and speed. We demonstrate that a soft skin enables firmer grasps and piezoresistive sensor integration enhances the hand's tactile sensing capabilities.

Replicating Human Anatomy with Vision Controlled Jetting -- A Pneumatic Musculoskeletal Hand and Forearm

Apr 29, 2024Abstract:The functional replication and actuation of complex structures inspired by nature is a longstanding goal for humanity. Creating such complex structures combining soft and rigid features and actuating them with artificial muscles would further our understanding of natural kinematic structures. We printed a biomimetic hand in a single print process comprised of a rigid skeleton, soft joint capsules, tendons, and printed touch sensors. We showed it's actuation using electric motors. In this work, we expand on this work by adding a forearm that is also closely modeled after the human anatomy and replacing the hand's motors with 22 independently controlled pneumatic artificial muscles (PAMs). Our thin, high-strain (up to 30.1%) PAMs match the performance of state-of-the-art artificial muscles at a lower cost. The system showcases human-like dexterity with independent finger movements, demonstrating successful grasping of various objects, ranging from a small, lightweight coin to a large can of 272g in weight. The performance evaluation, based on fingertip and grasping forces along with finger joint range of motion, highlights the system's potential.

Low Voltage Electrohydraulic Actuators for Untethered Robotics

Jun 01, 2023Abstract:Rigid robots can be precise in repetitive tasks but struggle in unstructured environments. Nature's versatility in such environments inspires researchers to develop biomimetic robots that incorporate compliant and contracting artificial muscles. Among the recently proposed artificial muscle technologies, electrohydraulic actuators are promising since they offer comparable performance to mammalian muscles in terms of speed and power density. However, they require high driving voltages and have safety concerns due to exposed electrodes. These high voltages lead to either bulky or inefficient driving electronics that make untethered, high-degree-of-freedom bio-inspired robots difficult to realize. Here, we present low voltage electrohydraulic actuators (LEAs) that match mammalian skeletal muscles in average power density (50.5 W/kg) and peak strain rate (971 percent/s) at a driving voltage of just 1100 V. This driving voltage is approx. 5 - 7 times lower compared to other electrohydraulic actuators using paraelectric dielectrics. Furthermore, LEAs are safe to touch, waterproof, and self-clearing, which makes them easy to implement in wearables and robotics. We characterize, model, and physically validate key performance metrics of the actuator and compare its performance to state-of-the-art electrohydraulic designs. Finally, we demonstrate the utility of our actuators on two muscle-based electrohydraulic robots: an untethered soft robotic swimmer and a robotic gripper. We foresee that LEAs can become a key building block for future highly-biomimetic untethered robots and wearables with many independent artificial muscles such as biomimetic hands, faces, or exoskeletons.

ViSE: Vision-Based 3D Real-Time Shape Estimation of Continuously Deformable Robots

Nov 09, 2022Abstract:The precise control of soft and continuum robots requires knowledge of their shape. The shape of these robots has, in contrast to classical rigid robots, infinite degrees of freedom. To partially reconstruct the shape, proprioceptive techniques use built-in sensors resulting in inaccurate results and increased fabrication complexity. Exteroceptive methods so far rely on placing reflective markers on all tracked components and triangulating their position using multiple motion-tracking cameras. Tracking systems are expensive and infeasible for deformable robots interacting with the environment due to marker occlusion and damage. Here, we present a regression approach for 3D shape estimation using a convolutional neural network. The proposed approach takes advantage of data-driven supervised learning and is capable of real-time marker-less shape estimation during inference. Two images of a robotic system are taken simultaneously at 25 Hz from two different perspectives, and are fed to the network, which returns for each pair the parameterized shape. The proposed approach outperforms marker-less state-of-the-art methods by a maximum of 4.4\% in estimation accuracy while at the same time being more robust and requiring no prior knowledge of the shape. The approach can be easily implemented due to only requiring two color cameras without depth and not needing an explicit calibration of the extrinsic parameters. Evaluations on two types of soft robotic arms and a soft robotic fish demonstrate our method's accuracy and versatility on highly deformable systems in real-time. The robust performance of the approach against different scene modifications (camera alignment and brightness) suggests its generalizability to a wider range of experimental setups, which will benefit downstream tasks such as robotic grasping and manipulation.

Planar Modeling and Sim-to-Real of a Tethered Multimaterial Soft Swimmer Driven by Peano-HASELs

Aug 02, 2022

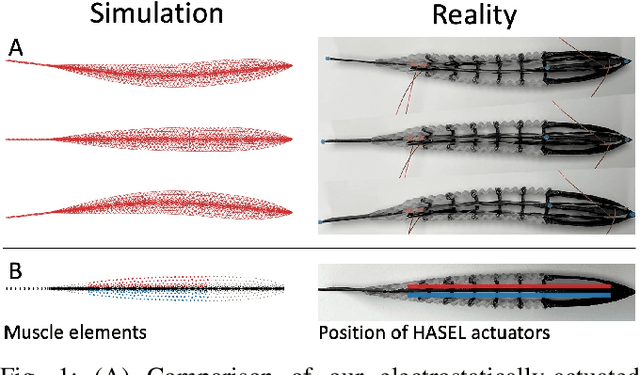

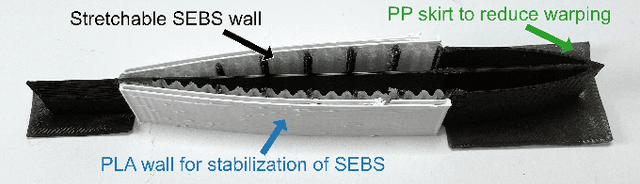

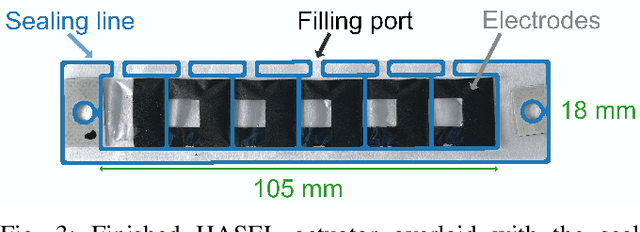

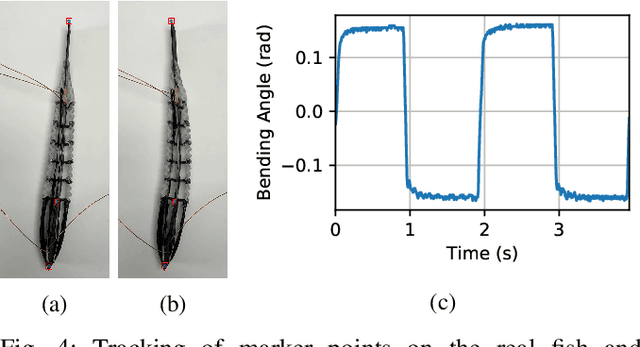

Abstract:Soft robotics has the potential to revolutionize robotic locomotion, in particular, soft robotic swimmers offer a minimally invasive and adaptive solution to explore and preserve our oceans. Unfortunately, current soft robotic swimmers are vastly inferior to evolved biological swimmers, especially in terms of controllability, efficiency, maneuverability, and longevity. Additionally, the tedious iterative fabrication and empirical testing required to design soft robots has hindered their optimization. In this work, we tackle this challenge by providing an efficient and straightforward pipeline for designing and fabricating soft robotic swimmers equipped with electrostatic actuation. We streamline the process to allow for rapid additive manufacturing, and show how a differentiable simulation can be used to match a simplified model to the real deformation of a robotic swimmer. We perform several experiments with the fabricated swimmer by varying the voltage and actuation frequency of the swimmer's antagonistic muscles. We show how the voltage and frequency vary the locomotion speed of the swimmer while moving in liquid oil and observe a clear optimum in forward swimming speed. The differentiable simulation model we propose has various downstream applications, such as control and shape optimization of the swimmer; optimization results can be directly mapped back to the real robot through our sim-to-real matching.

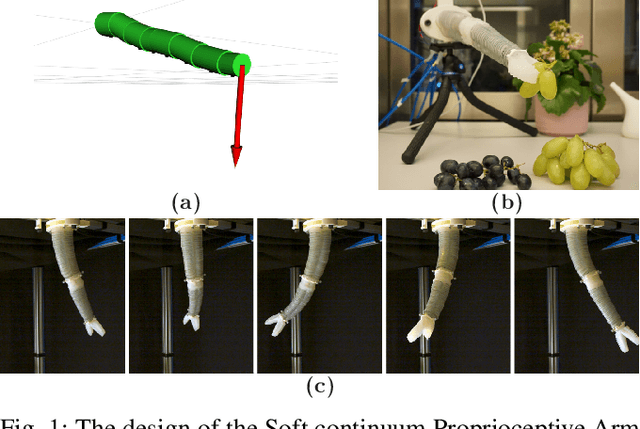

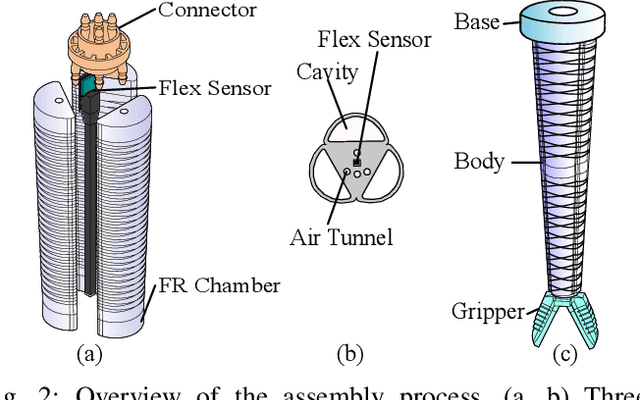

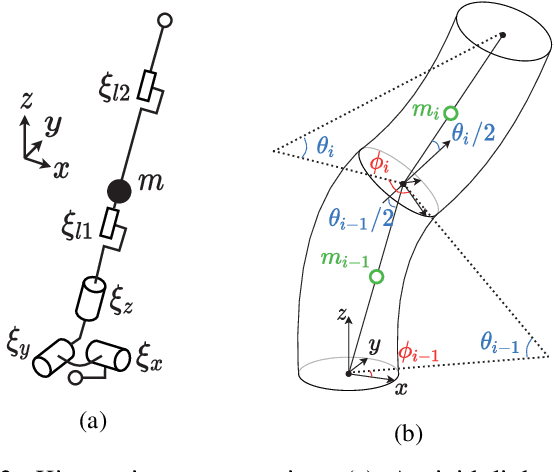

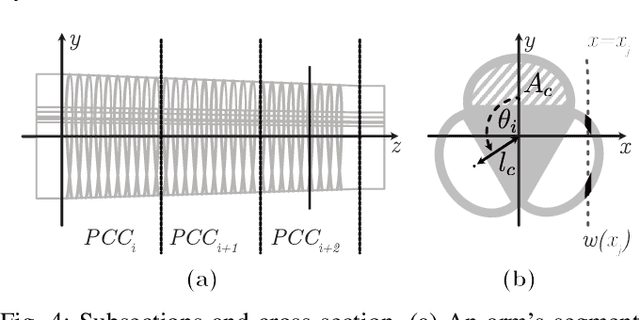

SoPrA: Fabrication & Dynamical Modeling of a Scalable Soft Continuum Robotic Arm with Integrated Proprioceptive Sensing

Mar 22, 2021

Abstract:Due to their inherent compliance, soft robots are more versatile than rigid linked robots when they interact with their environment, such as object manipulation or biomimetic motion, and considered the key element in introducing robots to everyday environments. Although various soft robotic actuators exist, past research has focused primarily on designing and analyzing single components. Limited effort has been made to combine each component to create an overall capable, integrated soft robot. Ideally, the behavior of such a robot can be accurately modeled, and its motion within an environment uses its proprioception, without requiring external sensors. This work presents a design and modeling process for a Soft continuum Proprioceptive Arm (SoPrA) actuated by pneumatics. The integrated design is suitable for an analytical model due to its internal capacitive flex sensor for proprioceptive measurements and its fiber-reinforced fluidic elastomer actuators. The proposed analytical dynamical model accounts for the inertial effects of the actuator's mass and the material properties, and predicts in real-time the soft robot's behavior. Our estimation method integrates the analytical model with proprioceptive sensors to calculate external forces, all without relying on an external motion capture system. SoPrA is validated in a series of experiments demonstrating the model's and sensor's accuracy in estimation. SoPrA will enable soft arm manipulation including force sensing while operating in obstructed environments that disallows exteroceptive measurements.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge