Rohit Menon

EvidMTL: Evidential Multi-Task Learning for Uncertainty-Aware Semantic Surface Mapping from Monocular RGB Images

Mar 06, 2025Abstract:For scene understanding in unstructured environments, an accurate and uncertainty-aware metric-semantic mapping is required to enable informed action selection by autonomous systems.Existing mapping methods often suffer from overconfident semantic predictions, and sparse and noisy depth sensing, leading to inconsistent map representations. In this paper, we therefore introduce EvidMTL, a multi-task learning framework that uses evidential heads for depth estimation and semantic segmentation, enabling uncertainty-aware inference from monocular RGB images. To enable uncertainty-calibrated evidential multi-task learning, we propose a novel evidential depth loss function that jointly optimizes the belief strength of the depth prediction in conjunction with evidential segmentation loss. Building on this, we present EvidKimera, an uncertainty-aware semantic surface mapping framework, which uses evidential depth and semantics prediction for improved 3D metric-semantic consistency. We train and evaluate EvidMTL on the NYUDepthV2 and assess its zero-shot performance on ScanNetV2, demonstrating superior uncertainty estimation compared to conventional approaches while maintaining comparable depth estimation and semantic segmentation. In zero-shot mapping tests on ScanNetV2, EvidKimera outperforms Kimera in semantic surface mapping accuracy and consistency, highlighting the benefits of uncertainty-aware mapping and underscoring its potential for real-world robotic applications.

GO-VMP: Global Optimization for View Motion Planning in Fruit Mapping

Mar 05, 2025Abstract:Automating labor-intensive tasks such as crop monitoring with robots is essential for enhancing production and conserving resources. However, autonomously monitoring horticulture crops remains challenging due to their complex structures, which often result in fruit occlusions. Existing view planning methods attempt to reduce occlusions but either struggle to achieve adequate coverage or incur high robot motion costs. We introduce a global optimization approach for view motion planning that aims to minimize robot motion costs while maximizing fruit coverage. To this end, we leverage coverage constraints derived from the set covering problem (SCP) within a shortest Hamiltonian path problem (SHPP) formulation. While both SCP and SHPP are well-established, their tailored integration enables a unified framework that computes a global view path with minimized motion while ensuring full coverage of selected targets. Given the NP-hard nature of the problem, we employ a region-prior-based selection of coverage targets and a sparse graph structure to achieve effective optimization outcomes within a limited time. Experiments in simulation demonstrate that our method detects more fruits, enhances surface coverage, and achieves higher volume accuracy than the motion-efficient baseline with a moderate increase in motion cost, while significantly reducing motion costs compared to the coverage-focused baseline. Real-world experiments further confirm the practical applicability of our approach.

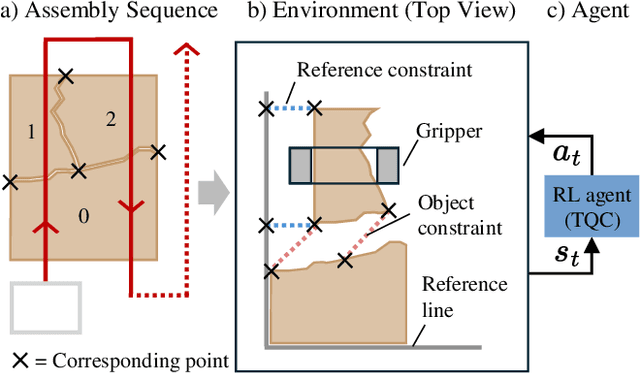

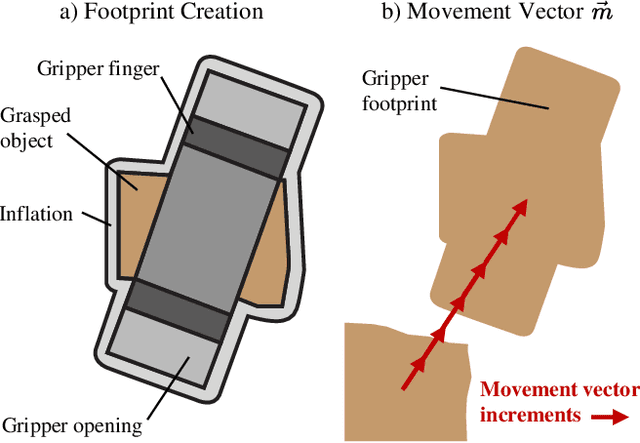

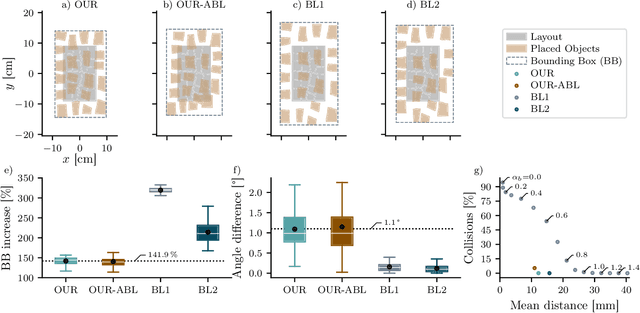

Constrained Object Placement Using Reinforcement Learning

Apr 16, 2024

Abstract:Close and precise placement of irregularly shaped objects requires a skilled robotic system. Particularly challenging is the manipulation of objects that have sensitive top surfaces and a fixed set of neighbors. To avoid damaging the surface, they have to be grasped from the side, and during placement, their neighbor relations have to be maintained. In this work, we train a reinforcement learning agent that generates smooth end-effector motions to place objects as close as possible next to each other. During the placement, our agent considers neighbor constraints defined in a given layout of the objects while trying to avoid collisions. Our approach learns to place compact object assemblies without the need for predefined spacing between objects as required by traditional methods. We thoroughly evaluated our approach using a two-finger gripper mounted to a robotic arm with six degrees of freedom. The results show that our agent outperforms two baseline approaches in terms of object assembly compactness, thereby reducing the needed space to place the objects according to the given neighbor constraints. On average, our approach reduces the distances between all placed objects by at least 60%, with fewer collisions at the same compactness compared to both baselines.

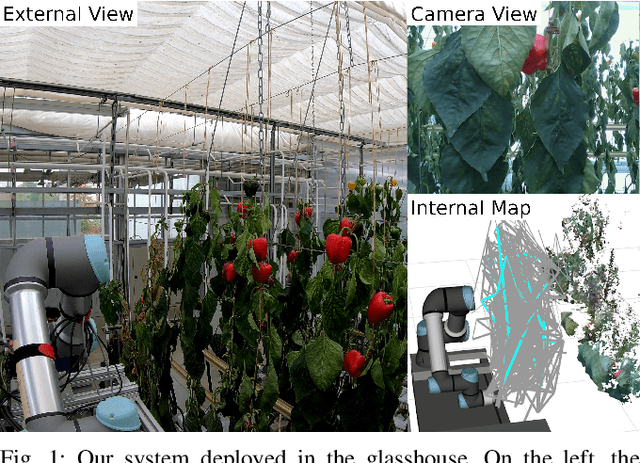

HortiBot: An Adaptive Multi-Arm System for Robotic Horticulture of Sweet Peppers

Mar 22, 2024Abstract:Horticultural tasks such as pruning and selective harvesting are labor intensive and horticultural staff are hard to find. Automating these tasks is challenging due to the semi-structured greenhouse workspaces, changing environmental conditions such as lighting, dense plant growth with many occlusions, and the need for gentle manipulation of non-rigid plant organs. In this work, we present the three-armed system HortiBot, with two arms for manipulation and a third arm as an articulated head for active perception using stereo cameras. Its perception system detects not only peppers, but also peduncles and stems in real time, and performs online data association to build a world model of pepper plants. Collision-aware online trajectory generation allows all three arms to safely track their respective targets for observation, grasping, and cutting. We integrated perception and manipulation to perform selective harvesting of peppers and evaluated the system in lab experiments. Using active perception coupled with end-effector force torque sensing for compliant manipulation, HortiBot achieves high success rates.

DawnIK: Decentralized Collision-Aware Inverse Kinematics Solver for Heterogeneous Multi-Arm Systems

Jul 24, 2023Abstract:Although inverse kinematics of serial manipulators is a well studied problem, challenges still exist in finding smooth feasible solutions that are also collision aware. Furthermore, with collaborative and service robots gaining traction, different robotic systems have to work in close proximity. This means that the current inverse kinematics approaches have to not only avoid collisions with themselves but also collisions with other robot arms. Therefore, we present a novel approach to compute inverse kinematics for serial manipulators that take into account different constraints while trying to reach a desired end-effector position and/or orientation that avoids collisions with themselves and other arms. Unlike other constraint based approaches, we neither perform expensive inverse Jacobian computations nor do we require arms with redundant degrees of freedom. Instead, we formulate different constraints as weighted cost functions to be optimized by a non-linear optimization solver. Our approach is superior to the state-of-the-art CollisionIK in terms of collision avoidance in the presence of multiple arms in confined spaces with no detected collisions at all in all the experimental scenarios. When the probability of collision is low, our approach shows better performance at trajectory tracking as well. Additionally, our approach is capable of simultaneous yet decentralized control of multiple arms for trajectory tracking in intersecting workspace without any collisions.

Graph-based View Motion Planning for Fruit Detection

Mar 06, 2023

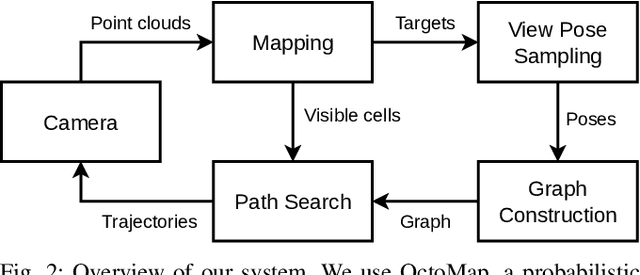

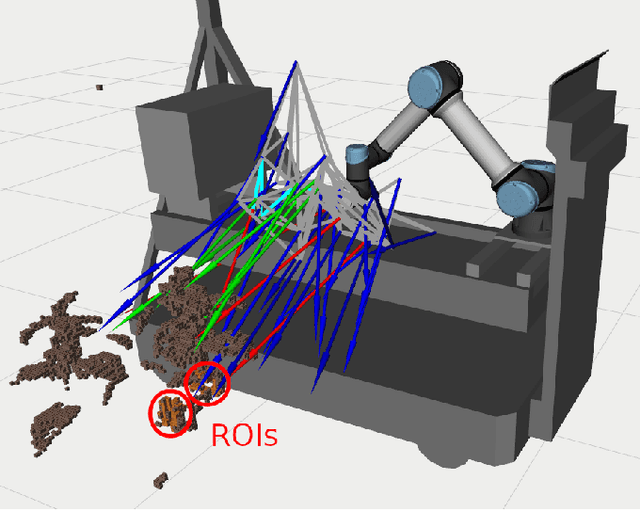

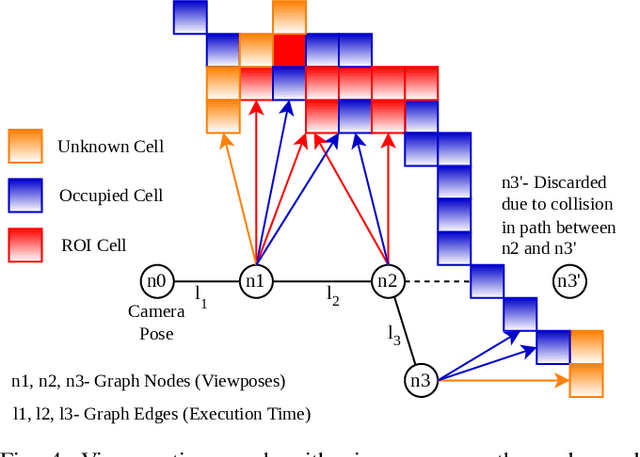

Abstract:Crop monitoring is crucial for maximizing agricultural productivity and efficiency. However, monitoring large and complex structures such as sweet pepper plants presents significant challenges, especially due to frequent occlusions of the fruits. Traditional next-best view planning can lead to unstructured and inefficient coverage of the crops. To address this, we propose a novel view motion planner that builds a graph network of viable view poses and trajectories between nearby poses, thereby considering robot motion constraints. The planner searches the graphs for view sequences with the highest accumulated information gain, allowing for efficient pepper plant monitoring while minimizing occlusions. The generated view poses aim at both sufficiently covering already detected and discovering new fruits. The graph and the corresponding best view pose sequence are computed with a limited horizon and are adaptively updated in fixed time intervals as the system gathers new information. We demonstrate the effectiveness of our approach through simulated and real-world experiments using a robotic arm equipped with an RGB-D camera and mounted on a trolley. As the experimental results show, our planner produces view pose sequences to systematically cover the crops and leads to increased fruit coverage when given a limited time in comparison to a state-of-the-art single next-best view planner.

Viewpoint Push Planning for Mapping of Unknown Confined Spaces

Mar 06, 2023Abstract:Viewpoint planning is an important task in any application where objects or scenes need to be viewed from different angles to achieve sufficient coverage. The mapping of confined spaces such as shelves is an especially challenging task since objects occlude each other and the scene can only be observed from the front, thus with limited possible viewpoints. In this paper, we propose a deep reinforcement learning framework that generates promising views aiming at reducing the map entropy. Additionally, the pipeline extends standard viewpoint planning by predicting adequate minimally invasive push actions to uncover occluded objects and increase the visible space. Using a 2.5D occupancy height map as state representation that can be efficiently updated, our system decides whether to plan a new viewpoint or perform a push. To learn feasible pushes, we use a neural network to sample push candidates on the map and have human experts manually label them to indicate whether the sampled push is a good action to perform. As simulated and real-world experimental results with a robotic arm show, our system is able to significantly increase the mapped space compared to different baselines, while the executed push actions highly benefit the viewpoint planner with only minor changes to the object configuration.

Reactive Correction of Object Placement Errors for Robotic Arrangement Tasks

Feb 15, 2023Abstract:When arranging objects with robotic arms, the quality of the end result strongly depends on the achievable placement accuracy. However, even the most advanced robotic systems are prone to positioning errors that can occur at different steps of the manipulation process. Ignoring such errors can lead to the partial or complete failure of the arrangement. In this paper, we present a novel approach to autonomously detect and correct misplaced objects by pushing them with a robotic arm. We thoroughly tested our approach both in simulation and on real hardware using a Robotiq two-finger gripper mounted on a UR5 robotic arm. In our evaluation, we demonstrate the successful compensation for different errors injected during the manipulation of regular shaped objects. Consequently, we achieve a highly reliable object placement accuracy in the millimeter range.

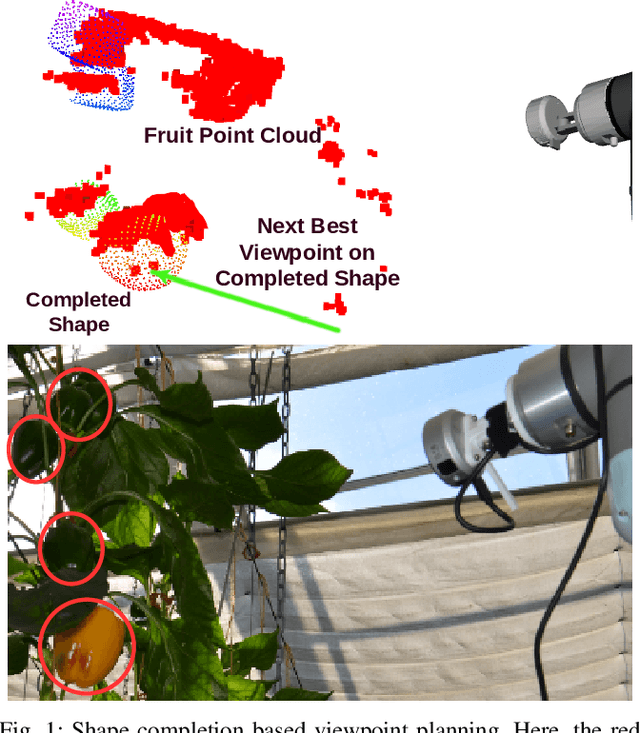

Viewpoint Planning based on Shape Completion for Fruit Mapping and Reconstruction

Sep 30, 2022

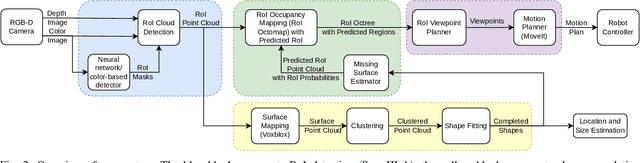

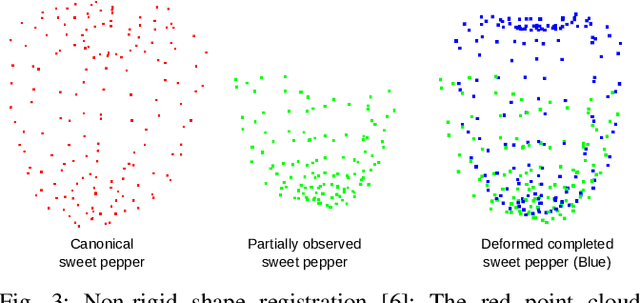

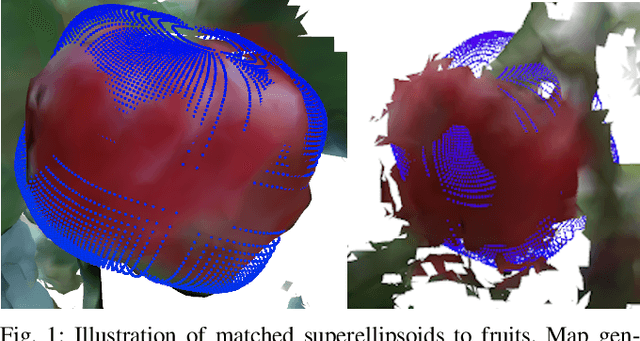

Abstract:Robotic systems in agriculture do not only enable increasing automation of farming activities but also represent new challenges for robotics due to the unstructured environment and the non-rigid structures of crops. Especially, active perception for fruit mapping and harvesting is a difficult task since occlusions frequently occur and image segmentation provides only limited accuracy on the actual shape of the fruits. In this paper, we present a viewpoint planning approach that explictly uses the shape prediction from collected data to guide the sensor to view as yet unobserved parts of the fruits. We developed a novel pipeline for continuous interaction between prediction and observation to maximize the information gain about sweet pepper fruits. We adapted two different shape prediction approaches, namely parametric superellipsoid fitting and model based non-rigid latent space registration, and integrated them into our Region of Interest (RoI) viewpoint planner. Additionally, we used a new concept of viewpoint dissimilarity to aid the planner to select good viewpoints and for shortening the planning times. Our simulation experiments with a UR5e arm equipped with a Realsense L515 sensor provide a quantitative demonstration of the efficacy of our iterative shape completion based viewpoint planning. In comparative experiments with a state-of-the-art viewpoint planner, we demonstrate improvement not only in the estimation of the fruit sizes, but also in their reconstruction. Finally, we show the viability of our approach for mapping sweet peppers with a real robotic system in a commercial glasshouse.

Fruit Mapping with Shape Completion for Autonomous Crop Monitoring

Mar 29, 2022

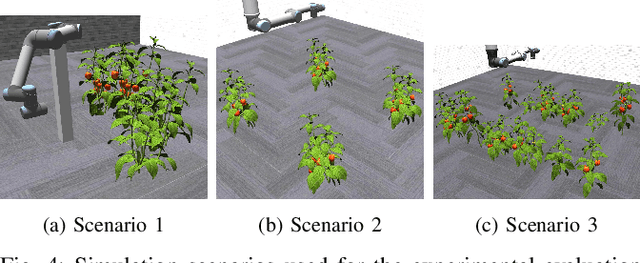

Abstract:Autonomous crop monitoring is a difficult task due to the complex structure of plants. Occlusions from leaves can make it impossible to obtain complete views about all fruits of, e.g., pepper plants. Therefore, accurately estimating the shape and volume of fruits from partial information is crucial to enable further advanced automation tasks such as yield estimation and automated fruit picking. In this paper, we present an approach for mapping fruits on plants and estimating their shape by matching superellipsoids. Our system segments fruits in images and uses their masks to generate point clouds of the fruits. To combine sequences of acquired point clouds, we utilize a real-time 3D mapping framework and build up a fruit map based on truncated signed distance fields. We cluster fruits from this map and use optimized superellipsoids for matching to obtain accurate shape estimates. In our experiments, we show in various simulated scenarios with a robotic arm equipped with an RGB-D camera that our approach can accurately estimate fruit volumes. Additionally, we provide qualitative results of estimated fruit shapes from data recorded in a commercial glasshouse environment.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge