Andras G. Kupcsik

The e-Bike Motor Assembly: Towards Advanced Robotic Manipulation for Flexible Manufacturing

Apr 20, 2023

Abstract:Robotic manipulation is currently undergoing a profound paradigm shift due to the increasing needs for flexible manufacturing systems, and at the same time, because of the advances in enabling technologies such as sensing, learning, optimization, and hardware. This demands for robots that can observe and reason about their workspace, and that are skillfull enough to complete various assembly processes in weakly-structured settings. Moreover, it remains a great challenge to enable operators for teaching robots on-site, while managing the inherent complexity of perception, control, motion planning and reaction to unexpected situations. Motivated by real-world industrial applications, this paper demonstrates the potential of such a paradigm shift in robotics on the industrial case of an e-Bike motor assembly. The paper presents a concept for teaching and programming adaptive robots on-site and demonstrates their potential for the named applications. The framework includes: (i) a method to teach perception systems onsite in a self-supervised manner, (ii) a general representation of object-centric motion skills and force-sensitive assembly skills, both learned from demonstration, (iii) a sequencing approach that exploits a human-designed plan to perform complex tasks, and (iv) a system solution for adapting and optimizing skills online. The aforementioned components are interfaced through a four-layer software architecture that makes our framework a tangible industrial technology. To demonstrate the generality of the proposed framework, we provide, in addition to the motivating e-Bike motor assembly, a further case study on dense box packing for logistics automation.

Learning Forceful Manipulation Skills from Multi-modal Human Demonstrations

Sep 09, 2021

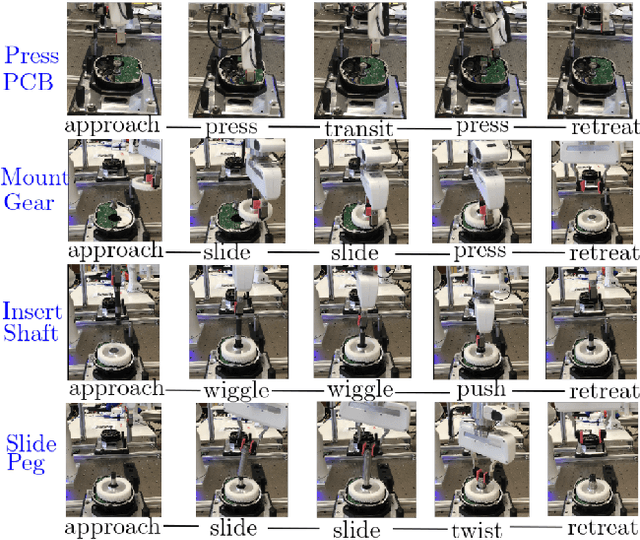

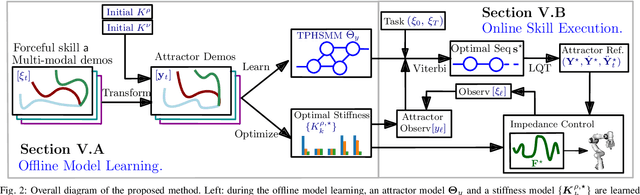

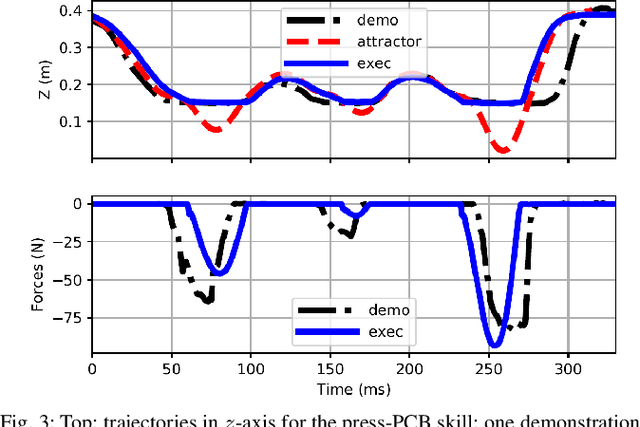

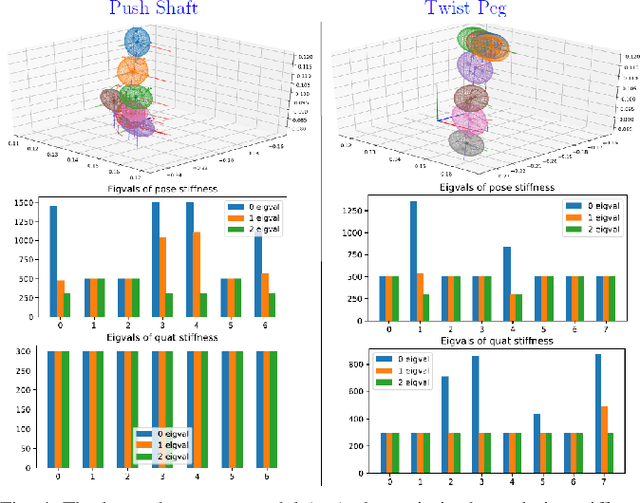

Abstract:Learning from Demonstration (LfD) provides an intuitive and fast approach to program robotic manipulators. Task parameterized representations allow easy adaptation to new scenes and online observations. However, this approach has been limited to pose-only demonstrations and thus only skills with spatial and temporal features. In this work, we extend the LfD framework to address forceful manipulation skills, which are of great importance for industrial processes such as assembly. For such skills, multi-modal demonstrations including robot end-effector poses, force and torque readings, and operation scene are essential. Our objective is to reproduce such skills reliably according to the demonstrated pose and force profiles within different scenes. The proposed method combines our previous work on task-parameterized optimization and attractor-based impedance control. The learned skill model consists of (i) the attractor model that unifies the pose and force features, and (ii) the stiffness model that optimizes the stiffness for different stages of the skill. Furthermore, an online execution algorithm is proposed to adapt the skill execution to real-time observations of robot poses, measured forces, and changed scenes. We validate this method rigorously on a 7-DoF robot arm over several steps of an E-bike motor assembly process, which require different types of forceful interaction such as insertion, sliding and twisting.

Learning and Sequencing of Object-Centric Manipulation Skills for Industrial Tasks

Aug 24, 2020

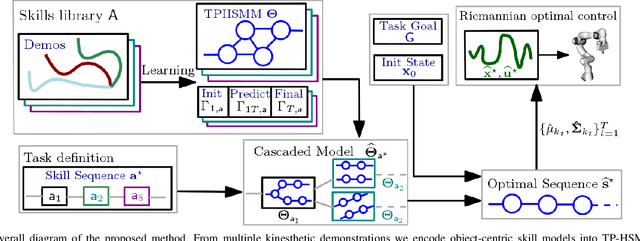

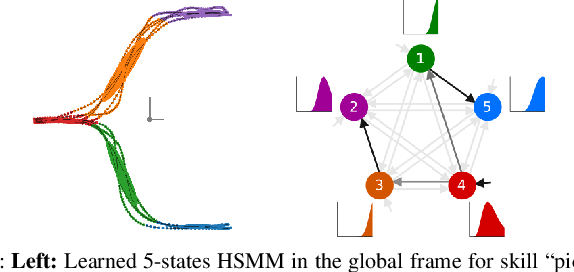

Abstract:Enabling robots to quickly learn manipulation skills is an important, yet challenging problem. Such manipulation skills should be flexible, e.g., be able adapt to the current workspace configuration. Furthermore, to accomplish complex manipulation tasks, robots should be able to sequence several skills and adapt them to changing situations. In this work, we propose a rapid robot skill-sequencing algorithm, where the skills are encoded by object-centric hidden semi-Markov models. The learned skill models can encode multimodal (temporal and spatial) trajectory distributions. This approach significantly reduces manual modeling efforts, while ensuring a high degree of flexibility and re-usability of learned skills. Given a task goal and a set of generic skills, our framework computes smooth transitions between skill instances. To compute the corresponding optimal end-effector trajectory in task space we rely on Riemannian optimal controller. We demonstrate this approach on a 7 DoF robot arm for industrial assembly tasks.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge