Tokuo Tsuji

Casting manipulation of unknown string by robot arm

Jan 30, 2024

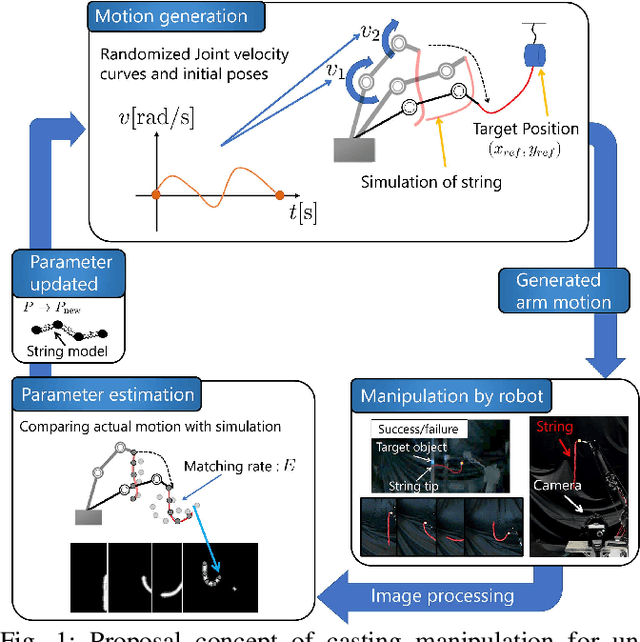

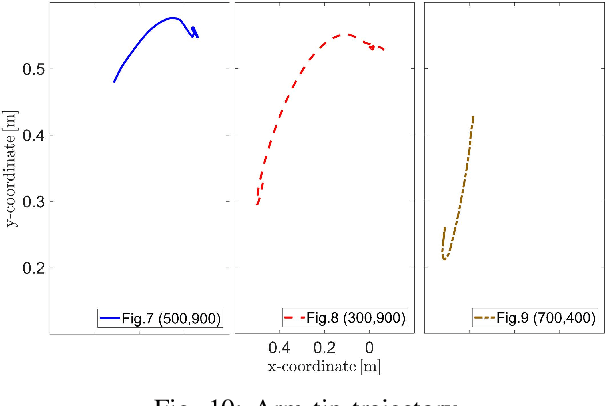

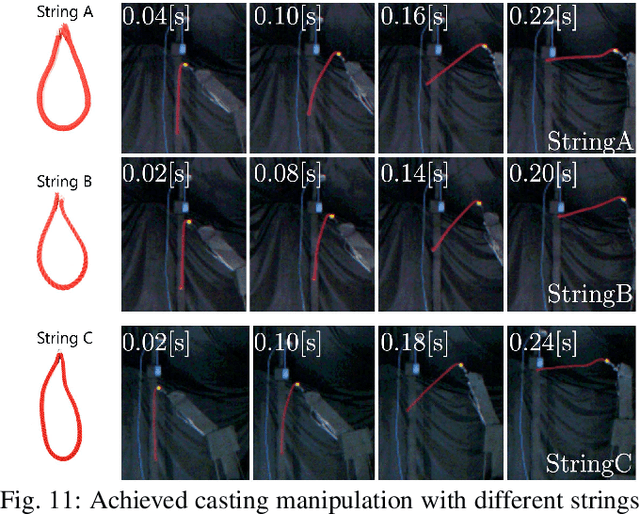

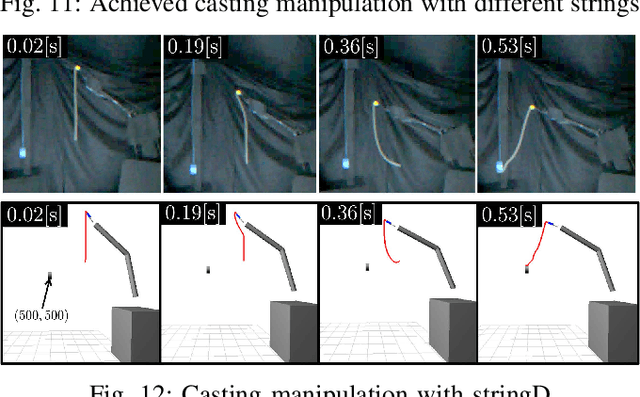

Abstract:Casting manipulation has been studied to expand the robot's movable range. In this manipulation, the robot throws and reaches the end effector to a distant target. Usually, a special casting manipulator, which consists of rigid arm links and specific flexible linear objects, is constructed for an effective casting manipulation. However, the special manipulator cannot perform normal manipulations, such as picking and placing, grasping, and operating objects. We propose that the normal robot arm, which can perform normal tasks, picks up an unknown string in the surrounding environment and realizes casting manipulation with it. As the properties of the string are not provided in advance, it is crucial how to reflect it in casting manipulation. This is realized by the motion generation of the robot arm with the simulation of string movement, actual string manipulation by the robot arm, and string parameter estimation from the actual string movement. After repeating these three steps, the simulated string movement approximates the actual to realize casting manipulation with the unknown string. We confirmed the effectiveness of the proposed method through experiments. The try of this study will lead to enhancement of the performance of home service robot, exploration robot, rescue robot and entertainment robot.

* Accepted to IROS 2021

Lightweight High-Speed and High-Force Gripper for Assembly

Oct 26, 2023

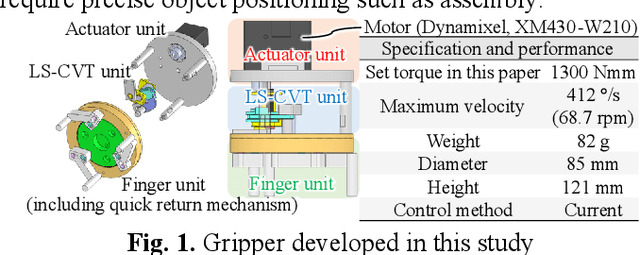

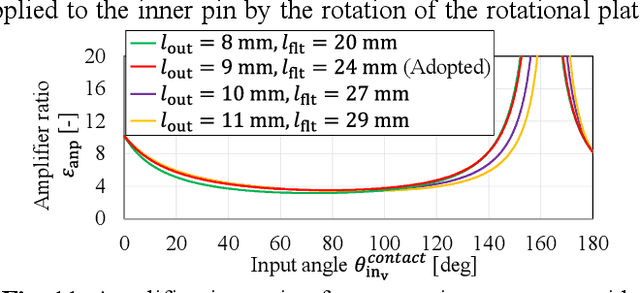

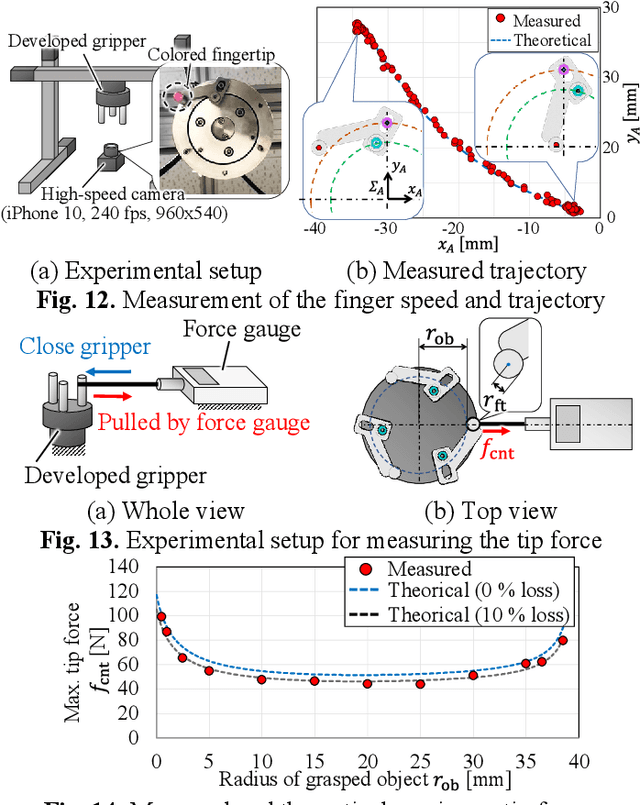

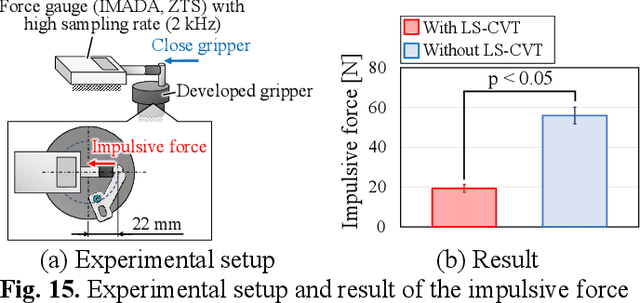

Abstract:This paper presents a novel industrial robotic gripper with a high grasping speed (maximum: 1396 mm/s), high tip force (maximum: 80 N) for grasping, large motion range, and lightweight design (0.3 kg). To realize these features, the high-speed section of the quick-return mechanism and load-sensitive continuously variable transmission mechanism are installed in the gripper. The gripper is also equipped with a self-centering function. The high grasping speed and self-centering function improve the cycle time in robotic operations. In addition, the high tip force is advantageous for stably grasping and assembling heavy objects. Moreover, the design of the gripper reduce the gripper's proportion of the manipulator's payload, thus increasing the weight of the object that can be grasped. The gripper performance was validated through kinematic and static analyses as well as experimental evaluations. This paper also presents the analysis of the self-centering function of the developed gripper.

1-degree-of-freedom Robotic Gripper With Infinite Self-Twist Function

Nov 10, 2022Abstract:This study proposed a novel robotic gripper that can achieve grasping and infinite wrist twisting motions using a single actuator. The gripper is equipped with a differential gear mechanism that allows switching between the grasping and twisting motions according to the magnitude of the tip force applied to the finger. The grasping motion is activated when the tip force is below a set value, and the wrist twisting motion is activated when the tip force exceeds this value. "Twist grasping," a special grasping mode that allows the wrapping of a flexible thin object around the fingers of the gripper, can be achieved by the twisting motion. Twist grasping is effective for handling objects with flexible thin parts, such as laminated packaging pouches, that are difficult to grasp using conventional antipodal grasping. In this study, the gripper design is presented, and twist grasping is analyzed. The gripper performance is experimentally validated.

Sensing and Control of Friction Mode for Contact Area Variable Surfaces

Nov 09, 2022Abstract:Robotic hands with soft surfaces can perform stable grasping, but the high friction of the soft surfaces makes it difficult to release objects, or to perform operations that require sliding. To solve this issue, we previously developed a contact area variable surface (CAVS), whose friction changed according to the load. However, only our fundamental results were previously presented, with detailed analyses not provided. In this study, we first investigated the CAVS friction anisotropy, and demonstrated that the longitudinal direction exhibited a larger ratio of friction change. Next, we proposed a sensible CAVS, capable of providing a variable-friction mechanism, and tested its sensing and control systems in operations requiring switching between sliding and stable-grasping modes. Friction sensing was performed using an embedded camera, and we developed a gripper using the sensible CAVS, considering the CAVS friction anisotropy. In CAVS, the low-friction mode corresponds to a small grasping force, while the high-friction mode corresponds to a greater grasping force. Therefore, by controlling only the friction mode, the gripper mode can be set to either the sliding or stable-grasping mode. Based on this feature, a methodology for controlling the contact mode was constructed. We demonstrated a manipulation involving sliding and stable grasping, and thus verified the efficacy of the developed sensible CAVS.

Soft robotic hand with finger-bending/friction-reduction switching mechanism through 1-degree-of-freedom flow control

Mar 28, 2022

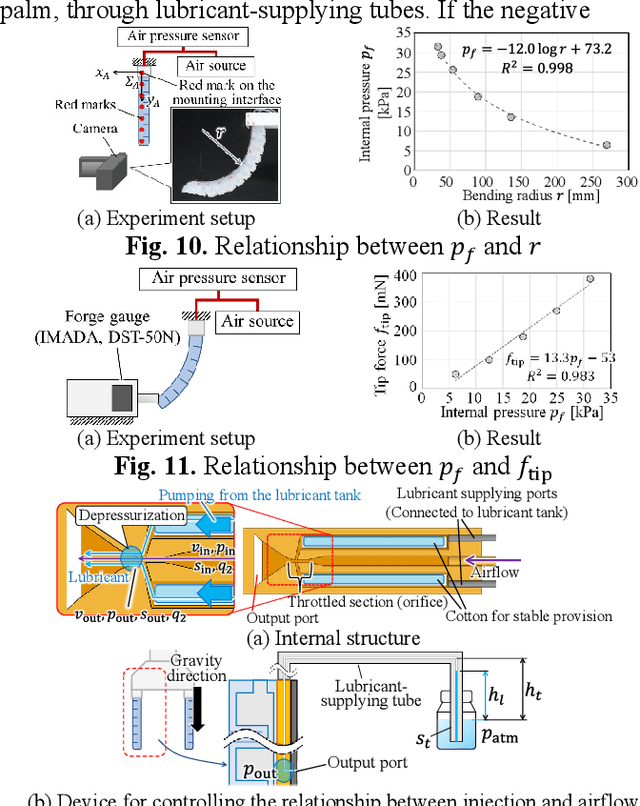

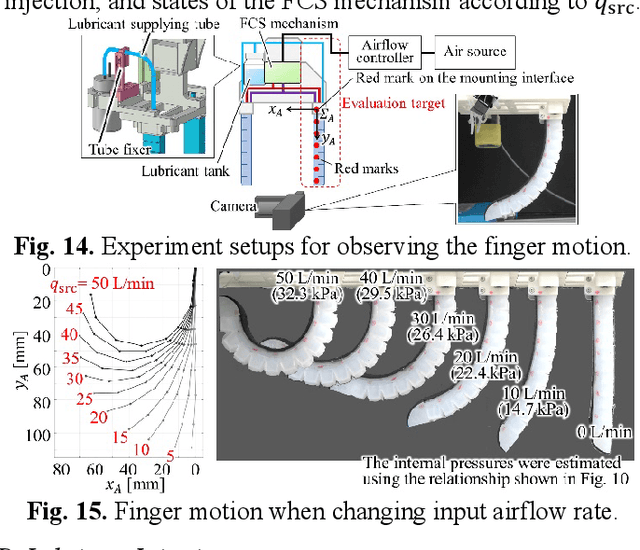

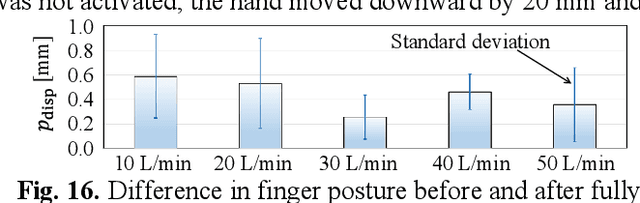

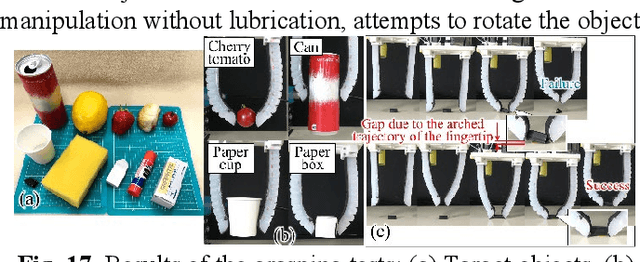

Abstract:This paper proposes a novel pneumatic soft robotic hand that incorporates a mechanism that can switch the airflow path using a single airflow control. The developed hand can control the finger motion and operate the surface friction variable mechanism. In the friction variable mechanism, a lubricant is injected onto the high-friction finger surface to reduce surface friction. To inject the lubrication using a positive-pressure airflow, the Venturi effect is applied. The design and evaluation of the airflow-path switching and friction variable mechanisms are described. Moreover, the entire design of a soft robotic hand equipped with these mechanisms is presented. The performance was validated through grasping, placing, and manipulation tests.

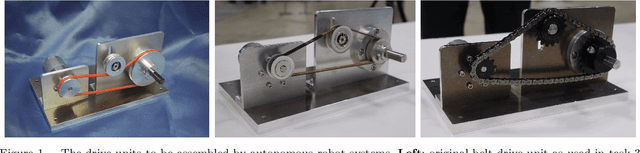

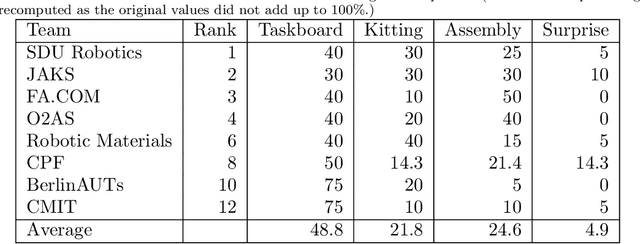

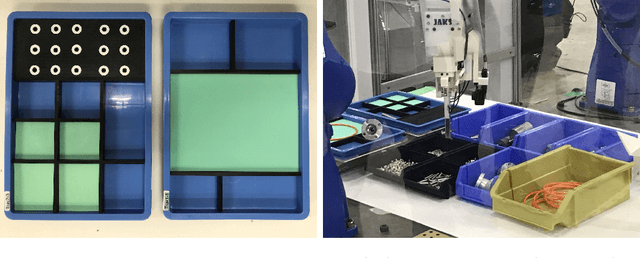

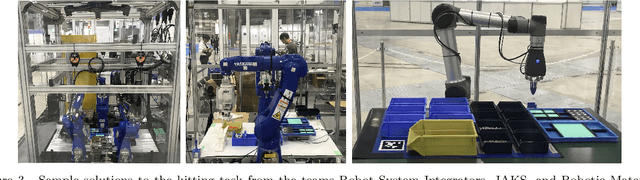

Robots Assembling Machines: Learning from the World Robot Summit 2018 Assembly Challenge

Nov 14, 2019

Abstract:The Industrial Assembly Challenge at the World Robot Summit was held in 2018 to showcase the state-of-the-art of autonomous manufacturing systems. The challenge included various tasks, such as bin picking, kitting, and assembly of standard industrial parts into 2D and 3D assemblies. Some of the tasks were only revealed at the competition itself, representing the challenge of "level 5" automation, i. e., programming and setting up an autonomous assembly system in less than one day. We conducted a survey among the teams that participated in the challenge and investigated aspects such as team composition, development costs, system setups as well as the teams' strategies and approaches. An analysis of the survey results reveals that the competitors have been in two camps: those constructing conventional robotic work cells with off-the-shelf tools, and teams who mostly relied on custom-made end effectors and novel software approaches in combination with collaborative robots. While both camps performed reasonably well, the winning team chose a middle ground in between, combining the efficiency of established play-back programming with the autonomy gained by CAD-based object detection and force control for assembly operations.

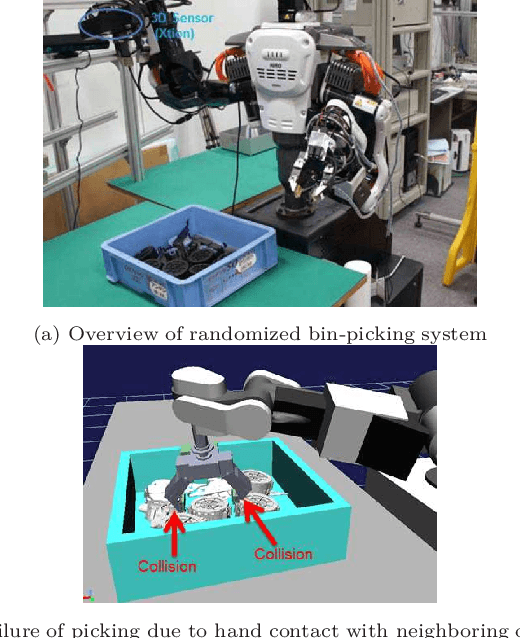

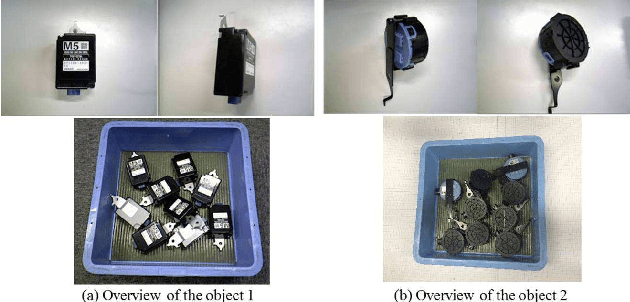

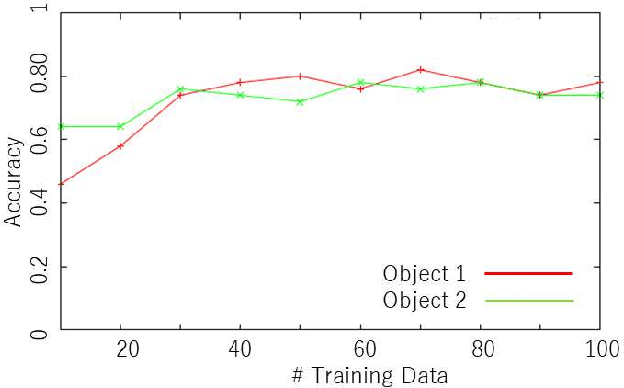

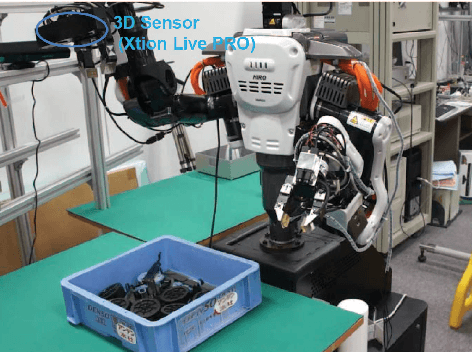

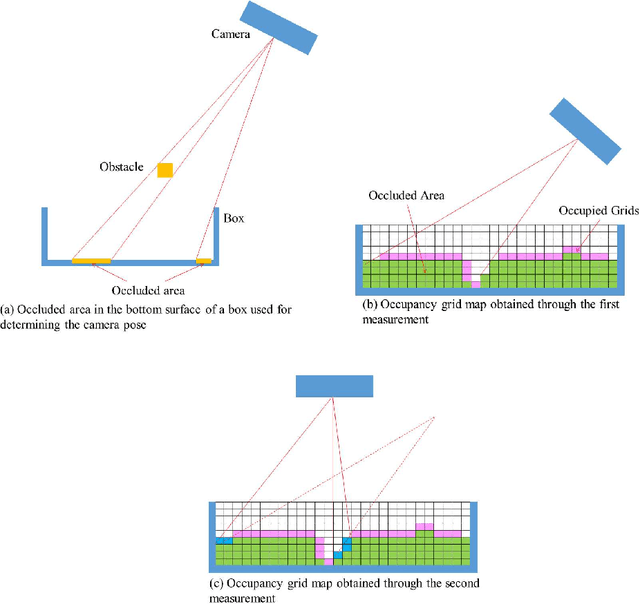

Experiments on Learning Based Industrial Bin-picking with Iterative Visual Recognition

May 22, 2018

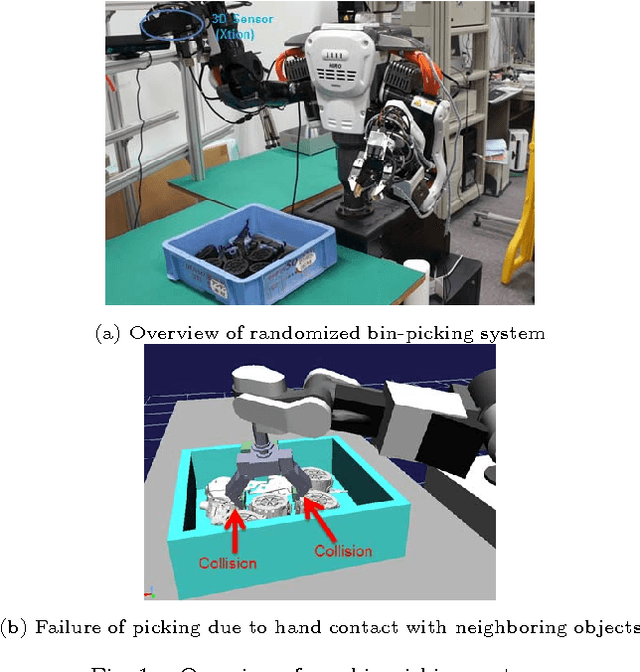

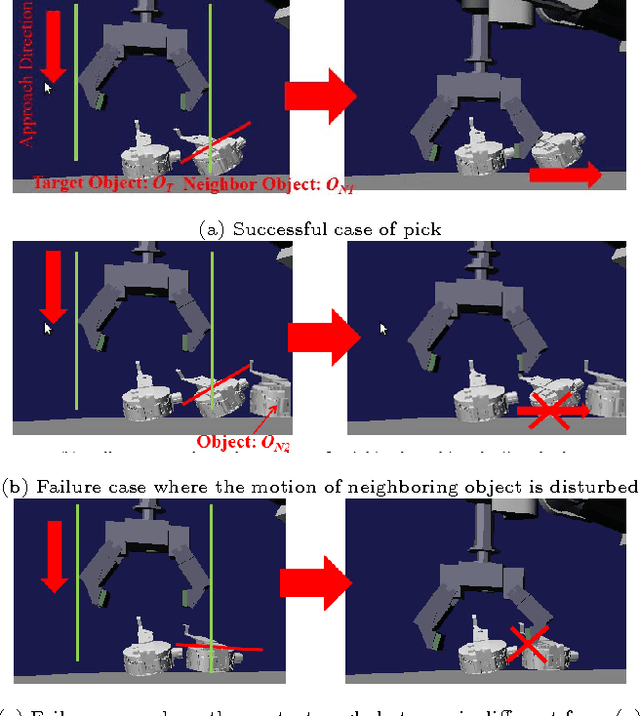

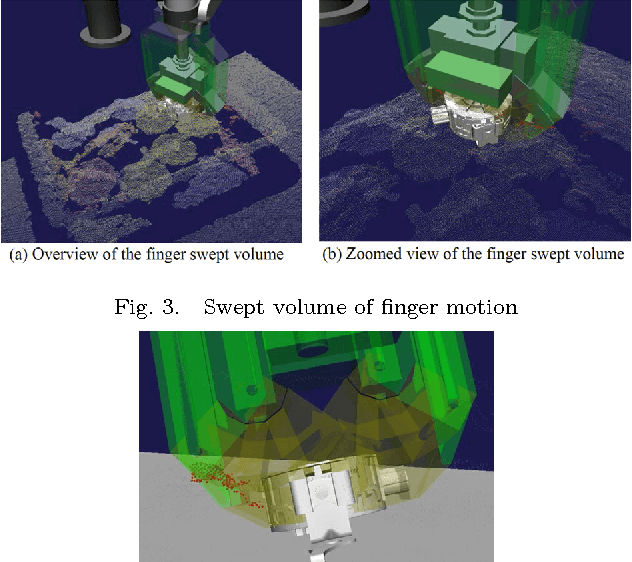

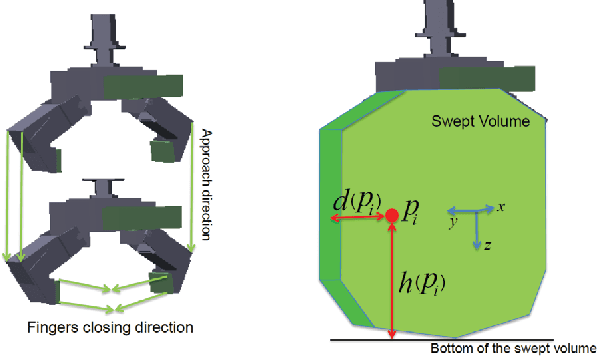

Abstract:This paper shows experimental results on learning based randomized bin-picking combined with iterative visual recognition. We use the random forest to predict whether or not a robot will successfully pick an object for given depth images of the pile taking the collision between a finger and a neighboring object into account. For the discriminator to be accurate, we consider estimating objects' poses by merging multiple depth images of the pile captured from different points of view by using a depth sensor attached at the wrist. We show that, even if a robot is predicted to fail in picking an object with a single depth image due to its large occluded area, it is finally predicted as success after merging multiple depth images. In addition, we show that the random forest can be trained with the small number of training data.

* This paper is to appear Industrial Robots: an International Journal

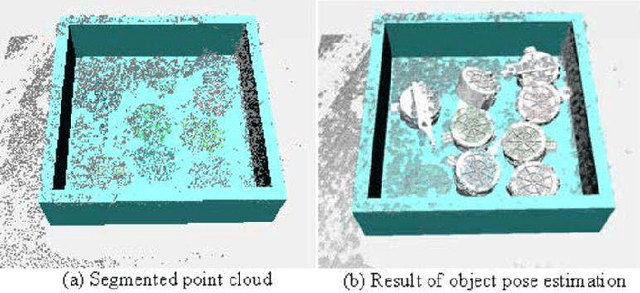

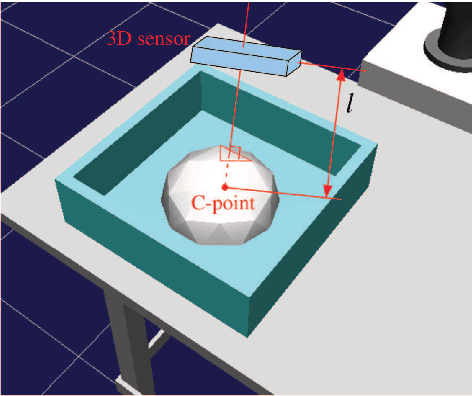

Iterative Visual Recognition for Learning Based Randomized Bin-Picking

Aug 01, 2016

Abstract:This paper proposes a iterative visual recognition system for learning based randomized bin-picking. Since the configuration on randomly stacked objects while executing the current picking trial is just partially different from the configuration while executing the previous picking trial, we consider detecting the poses of objects just by using a part of visual image taken at the current picking trial where it is different from the visual image taken at the previous picking trial. By using this method, we do not need to try to detect the poses of all objects included in the pile at every picking trial. Assuming the 3D vision sensor attached at the wrist of a manipulator, we first explain a method to determine the pose of a 3D vision sensor maximizing the visibility of randomly stacked objects. Then, we explain a method for detecting the poses of randomly stacked objects. Effectiveness of our proposed approach is confirmed by experiments using a dual-arm manipulator where a 3D vision sensor and the two-fingered hand attached at the right and the left wrists, respectively.

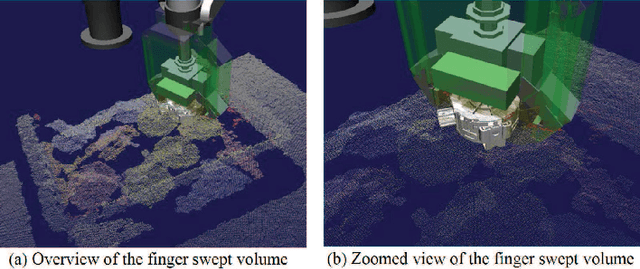

Initial Experiments on Learning-Based Randomized Bin-Picking Allowing Finger Contact with Neighboring Objects

Jul 11, 2016

Abstract:This paper proposes a novel method for randomized bin-picking based on learning. When a two-fingered gripper tries to pick an object from the pile, a finger often contacts a neighboring object. Even if a finger contacts a neighboring object, the target object will be successfully picked depending on the configuration of neighboring objects. In our proposed method, we use the visual information on neighboring objects to train the discriminator. Corresponding to a grasping posture of an object, the discriminator predicts whether or not the pick will be successful even if a finger contacts a neighboring object. We examine two learning algorithms, the linear support vector machine (SVM) and the random forest (RF) approaches. By using both methods, we demonstrate that the picking success rate is significantly higher than with conventional methods without learning.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge