Tetsuyou Watanabe

Single-Motor Robotic Gripper with Multi-Surface Fingers for Variable Grasping Configurations

Mar 24, 2024

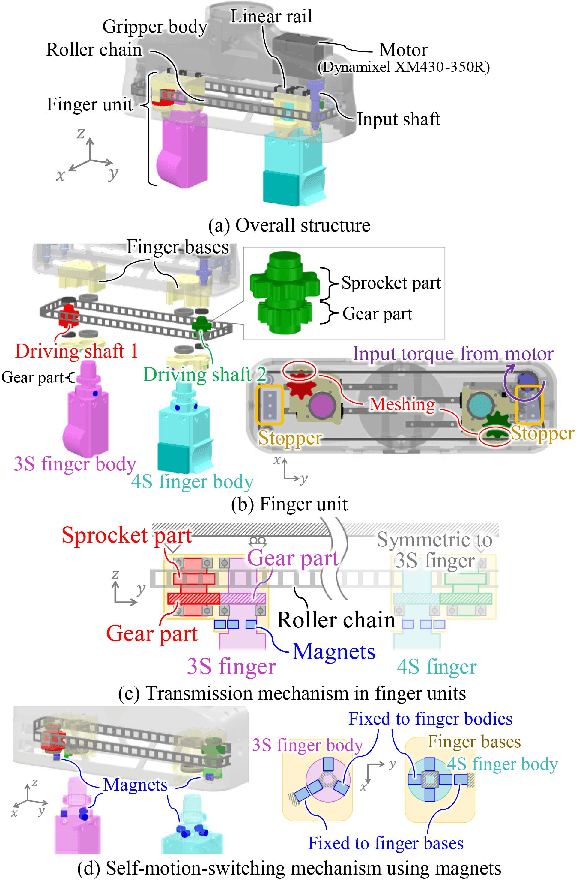

Abstract:This study proposes a novel robotic gripper with variable grasping configurations for grasping various objects. The fingers of the developed gripper incorporate multiple different surfaces. The gripper possesses the function of altering the finger surfaces facing a target object by rotating the fingers in its longitudinal direction. In the proposed design equipped with two fingers, the two fingers incorporate three and four surfaces, respectively, resulting in the nine available grasping configurations by the combination of these finger surfaces. The developed gripper is equipped with the functions of opening/closing its fingers for grasping and rotating its fingers to alter the grasping configuration -all achieved with a single motor. To enable the two motions using a single motor, this study introduces a self-motion switching mechanism utilizing magnets. This mechanism automatically transitions between gripper motions based on the direction of the motor rotation when the gripper is fully opened. In this state, rotating the motor towards closing initiates the finger closing action, while further opening the fingers from the fully opened state activates the finger rotation. This letter presents the gripper design, the mechanics of the self-motion switching mechanism, the control method, and the grasping configuration selection strategy. The performance of the gripper is experimentally demonstrated.

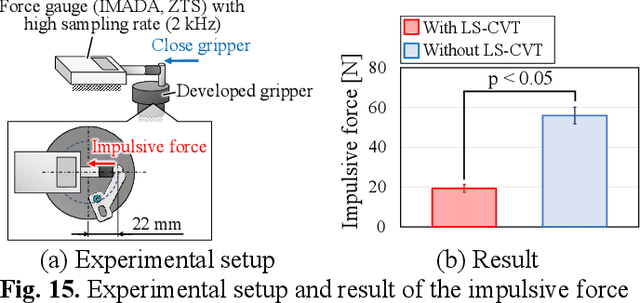

Lightweight High-Speed and High-Force Gripper for Assembly

Oct 26, 2023

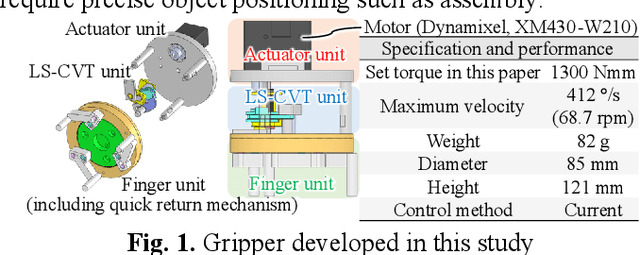

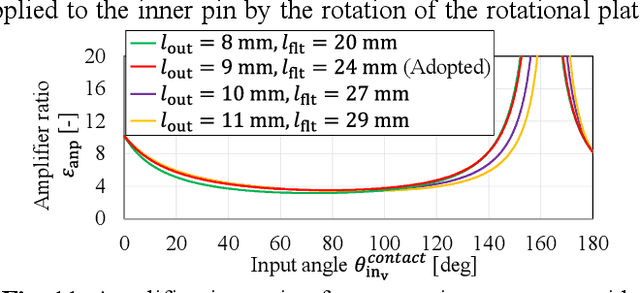

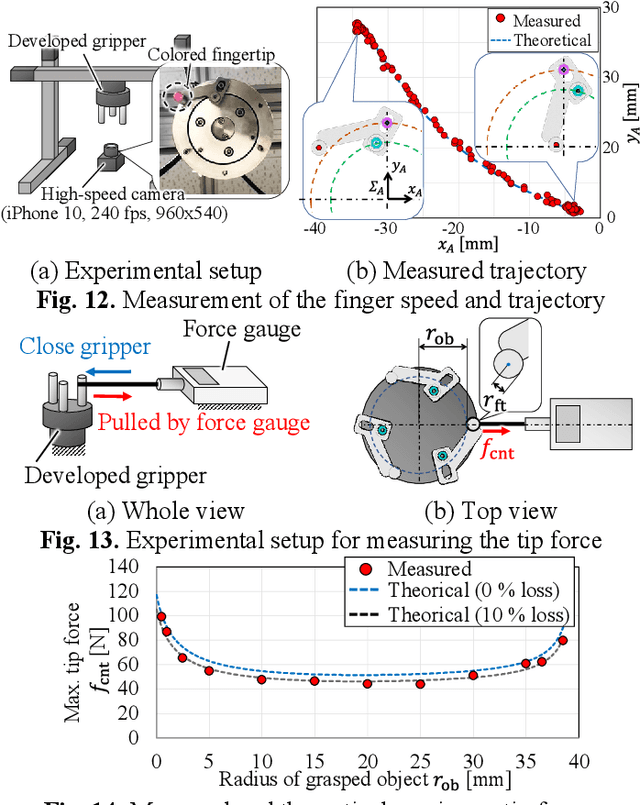

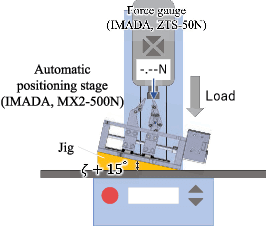

Abstract:This paper presents a novel industrial robotic gripper with a high grasping speed (maximum: 1396 mm/s), high tip force (maximum: 80 N) for grasping, large motion range, and lightweight design (0.3 kg). To realize these features, the high-speed section of the quick-return mechanism and load-sensitive continuously variable transmission mechanism are installed in the gripper. The gripper is also equipped with a self-centering function. The high grasping speed and self-centering function improve the cycle time in robotic operations. In addition, the high tip force is advantageous for stably grasping and assembling heavy objects. Moreover, the design of the gripper reduce the gripper's proportion of the manipulator's payload, thus increasing the weight of the object that can be grasped. The gripper performance was validated through kinematic and static analyses as well as experimental evaluations. This paper also presents the analysis of the self-centering function of the developed gripper.

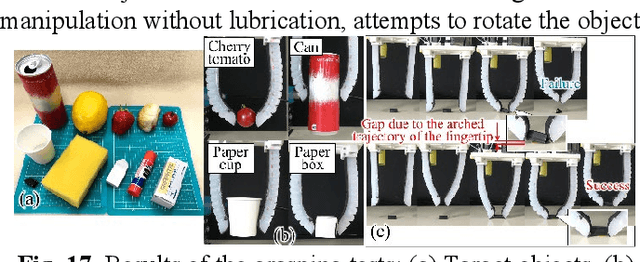

Single-Motor Robotic Gripper With Three Functional Modes for Grasping in Confined Spaces

Oct 26, 2023Abstract:This study proposes a novel robotic gripper driven by a single motor. The main task is to pick up objects in confined spaces. For this purpose, the developed gripper has three operating modes: grasping, finger-bending, and pull-in modes. Using these three modes, the developed gripper can rotate and translate a grasped object, i.e., can perform in-hand manipulation. This in-hand manipulation is effective for grasping in extremely confined spaces, such as the inside of a box in a shelf, to avoid interference between the grasped object and obstacles. To achieve the three modes using a single motor, the developed gripper is equipped with two novel self-motion switching mechanisms. These mechanisms switch their motions automatically when the motion being generated is prevented. An analysis of the mechanism and control methodology used to achieve the desired behavior are presented. Furthermore, the validity of the analysis and methodology are experimentally demonstrated. The gripper performance is also evaluated through the grasping tests.

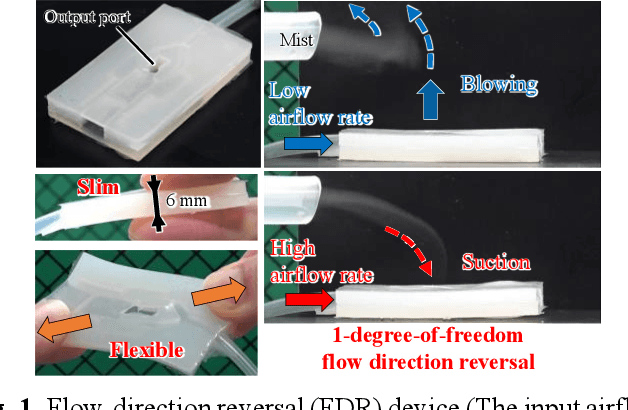

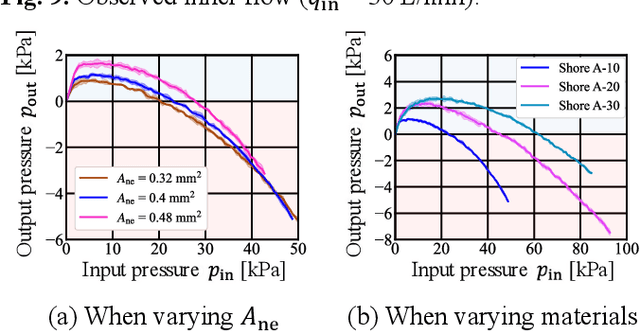

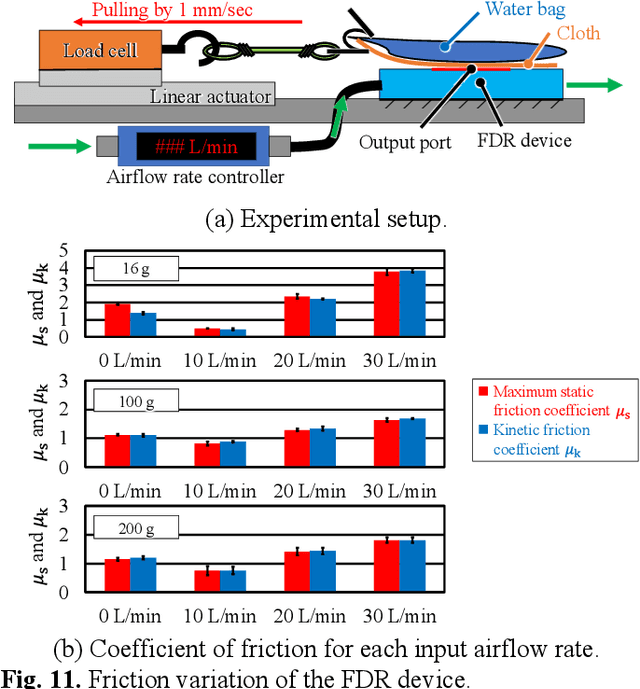

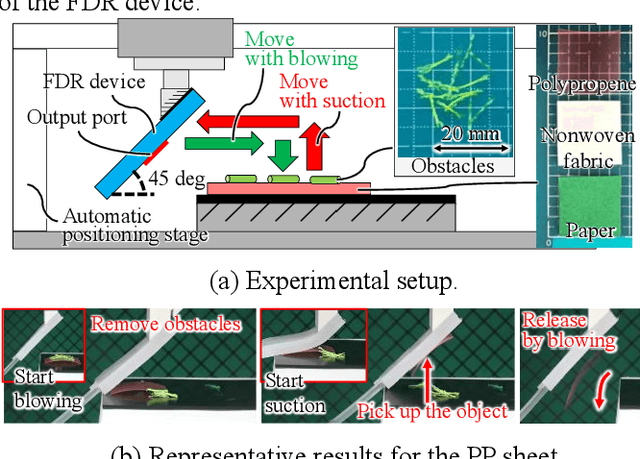

Flexible and slim device switching air blowing and suction by a single airflow control

Mar 08, 2023

Abstract:This study proposes a soft robotic device with a slim and flexible body that switches between air blowing and suction with a single airflow control. Suction is achieved by jet flow entraining surrounding air, and blowing is achieved by blocking and reversing jet flow. The thin and flexible flap gate enables the switching. Air flow is blocked while the gate is closed and passes through while the gate is open. The opening and closing of the flap gate are controlled by the expansion of the inflatable chambers installed near the gate. The extent of expansion is determined by the upstream static pressure. Therefore, the gate can be controlled by the input airflow rate. The dimensions of the flap gate are introduced as a design parameter, and we show that the parameter contributes to the blowing and suction capacities. We also experimentally demonstrate that the proposed device is available for a variable friction system and an end effector for picking up a thin object covered with dust.

High-payload and self-adaptive robotic hand with 1-degree-of-freedom translation/rotation switching mechanism

Mar 08, 2023Abstract:This study proposes a novel robotic hand that can achieve self-adaptive grasping and a large payload (over 20 kg) with a single actuator. Accordingly, two novel mechanisms, an actuation system with self-motion switching and a self-adaptive finger with a self-locking mechanism, are installed in a 1-degree-of-freedom robotic hand. The actuation system switches the output motion from translational to rotational according to the applied external load. The finger is bent by inserting a flexible shaft inside it. Its bending posture can conform to the shape of the object owing to the flexible shaft, and the posture is fixed by a self-locking mechanism, which can be released by the rotational motion of the actuation system. This study presents a mechanical analysis of these mechanisms to achieve the desired behavior. The analysis was validated experimentally, and a robotic hand with these mechanisms were evaluated using grasping tests.

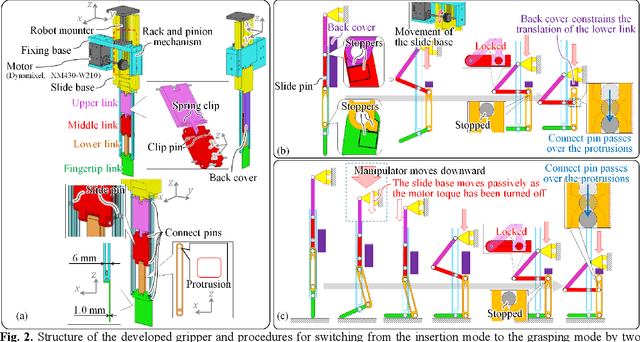

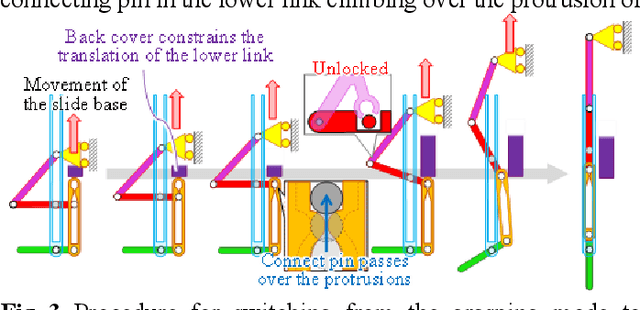

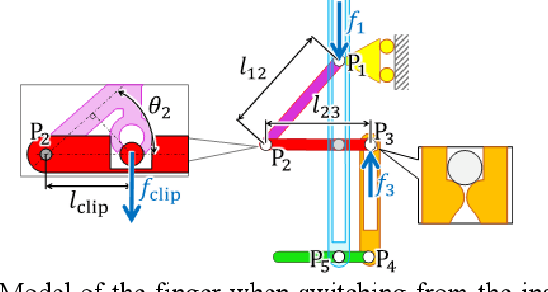

Single-Fingered Reconfigurable Robotic Gripper With a Folding Mechanism for Narrow Working Spaces

Nov 22, 2022

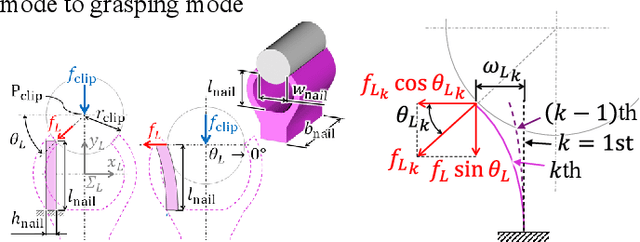

Abstract:This letter proposes a novel single-fingered reconfigurable robotic gripper for grasping objects in narrow working spaces. The finger of the developed gripper realizes two configurations, namely, the insertion and grasping modes, using only a single motor. In the insertion mode, the finger assumes a thin shape such that it can insert its tip into a narrow space. The grasping mode of the finger is activated through a folding mechanism. Mode switching can be achieved in two ways: switching the mode actively by a motor, or combining passive rotation of the fingertip through contact with the support surface and active motorized construction of the claw. The latter approach is effective when it is unclear how much finger insertion is required for a specific task. The structure provides a simple control scheme. The performance of the proposed robotic gripper design and control methodology was experimentally evaluated. The minimum width of the insertion space required to grasp an object is 4 mm (1 mm, when using a strategy).

* This study was presented at IROS 2022

1-degree-of-freedom Robotic Gripper With Infinite Self-Twist Function

Nov 10, 2022Abstract:This study proposed a novel robotic gripper that can achieve grasping and infinite wrist twisting motions using a single actuator. The gripper is equipped with a differential gear mechanism that allows switching between the grasping and twisting motions according to the magnitude of the tip force applied to the finger. The grasping motion is activated when the tip force is below a set value, and the wrist twisting motion is activated when the tip force exceeds this value. "Twist grasping," a special grasping mode that allows the wrapping of a flexible thin object around the fingers of the gripper, can be achieved by the twisting motion. Twist grasping is effective for handling objects with flexible thin parts, such as laminated packaging pouches, that are difficult to grasp using conventional antipodal grasping. In this study, the gripper design is presented, and twist grasping is analyzed. The gripper performance is experimentally validated.

Sensing and Control of Friction Mode for Contact Area Variable Surfaces

Nov 09, 2022Abstract:Robotic hands with soft surfaces can perform stable grasping, but the high friction of the soft surfaces makes it difficult to release objects, or to perform operations that require sliding. To solve this issue, we previously developed a contact area variable surface (CAVS), whose friction changed according to the load. However, only our fundamental results were previously presented, with detailed analyses not provided. In this study, we first investigated the CAVS friction anisotropy, and demonstrated that the longitudinal direction exhibited a larger ratio of friction change. Next, we proposed a sensible CAVS, capable of providing a variable-friction mechanism, and tested its sensing and control systems in operations requiring switching between sliding and stable-grasping modes. Friction sensing was performed using an embedded camera, and we developed a gripper using the sensible CAVS, considering the CAVS friction anisotropy. In CAVS, the low-friction mode corresponds to a small grasping force, while the high-friction mode corresponds to a greater grasping force. Therefore, by controlling only the friction mode, the gripper mode can be set to either the sliding or stable-grasping mode. Based on this feature, a methodology for controlling the contact mode was constructed. We demonstrated a manipulation involving sliding and stable grasping, and thus verified the efficacy of the developed sensible CAVS.

Soft robotic hand with finger-bending/friction-reduction switching mechanism through 1-degree-of-freedom flow control

Mar 28, 2022

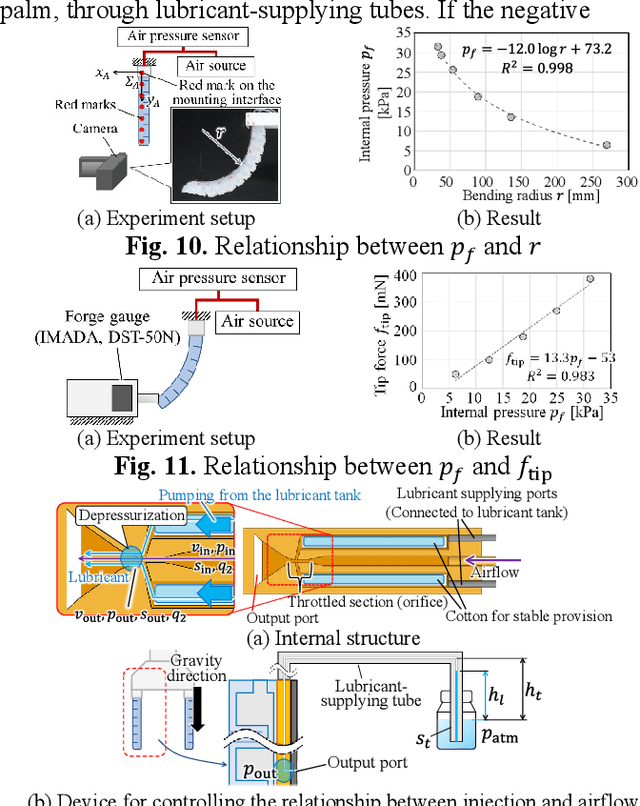

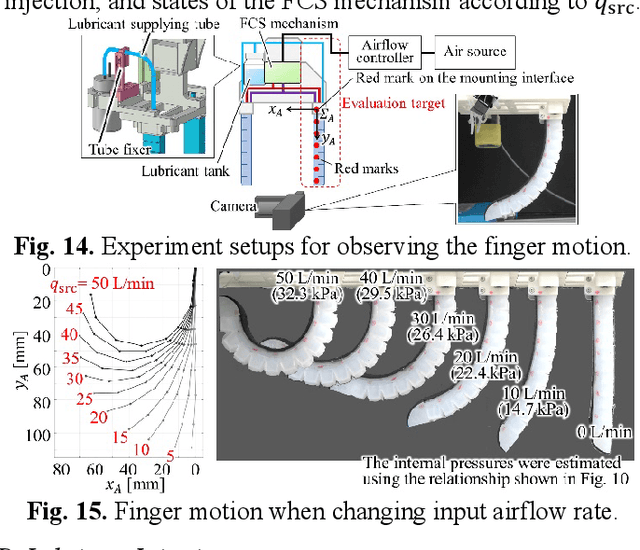

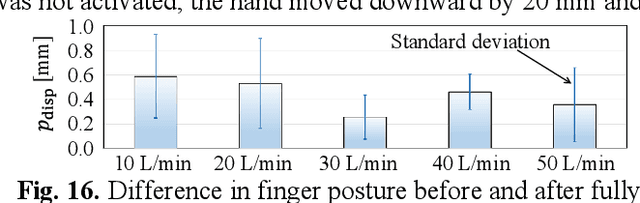

Abstract:This paper proposes a novel pneumatic soft robotic hand that incorporates a mechanism that can switch the airflow path using a single airflow control. The developed hand can control the finger motion and operate the surface friction variable mechanism. In the friction variable mechanism, a lubricant is injected onto the high-friction finger surface to reduce surface friction. To inject the lubrication using a positive-pressure airflow, the Venturi effect is applied. The design and evaluation of the airflow-path switching and friction variable mechanisms are described. Moreover, the entire design of a soft robotic hand equipped with these mechanisms is presented. The performance was validated through grasping, placing, and manipulation tests.

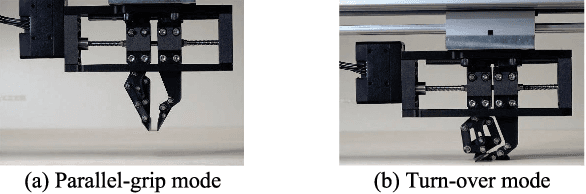

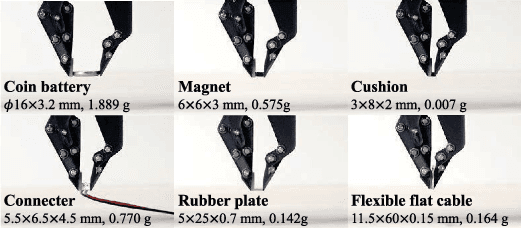

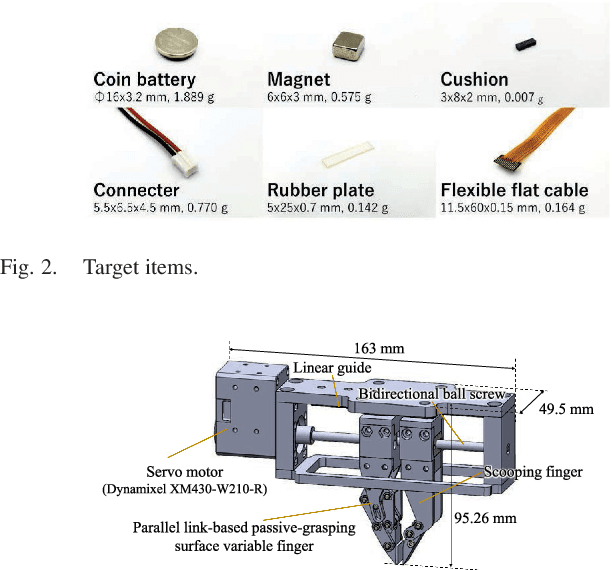

Variable-Grasping-Mode Gripper With Different Finger Structures For Grasping Small-Sized Items

Jun 18, 2021

Abstract:This letter presents a novel small gripper capable of grasping various types of small-sized items from flat surfaces for the assembly of small devices. Using a single actuator, the proposed gripper realizes two grasping modes: parallel-grip and turn-over modes. The gripper's mode can be switched via contact with a flat surface, such as a table. Handling thin thicknesses and light weights are the key challenges faced in attempts to grasp small-sized items. Although parallel grippers are effective in handling small items, there is a limit to the thinness of objects that can be grasped by parallel grippers. Accordingly, the turn-over mode was adopted to grasp items that exceeded this threshold. In the turn-over mode, one finger lifts the item, while another finger holds the item from above to keep it from flicking out. The proposed gripper is capable of picking up several types of items from a table, including thin (0.05 mm) and lightweight (0.007 g) items.

* 8 pages, 12 figures

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge