Christian Schlette

EcBot: Data-Driven Energy Consumption Open-Source MATLAB Library for Manipulators

Aug 08, 2025Abstract:Existing literature proposes models for estimating the electrical power of manipulators, yet two primary limitations prevail. First, most models are predominantly tested using traditional industrial robots. Second, these models often lack accuracy. To address these issues, we introduce an open source Matlab-based library designed to automatically generate \ac{ec} models for manipulators. The necessary inputs for the library are Denavit-Hartenberg parameters, link masses, and centers of mass. Additionally, our model is data-driven and requires real operational data, including joint positions, velocities, accelerations, electrical power, and corresponding timestamps. We validated our methodology by testing on four lightweight robots sourced from three distinct manufacturers: Universal Robots, Franka Emika, and Kinova. The model underwent testing, and the results demonstrated an RMSE ranging from 1.42 W to 2.80 W for the training dataset and from 1.45 W to 5.25 W for the testing dataset.

RobotGraffiti: An AR tool for semi-automated construction of workcell models to optimize robot deployment

Oct 01, 2024

Abstract:Improving robot deployment is a central step towards speeding up robot-based automation in manufacturing. A main challenge in robot deployment is how to best place the robot within the workcell. To tackle this challenge, we combine two knowledge sources: robotic knowledge of the system and workcell context awareness of the user, and intersect them with an Augmented Reality interface. RobotGraffiti is a unique tool that empowers the user in robot deployment tasks. One simply takes a 3D scan of the workcell with their mobile device, adds contextual data points that otherwise would be difficult to infer from the system, and receives a robot base position that satisfies the automation task. The proposed approach is an alternative to expensive and time-consuming digital twins, with a fast and easy-to-use tool that focuses on selected workcell features needed to run the placement optimization algorithm. The main contributions of this paper are the novel user interface for robot base placement data collection and a study comparing the traditional offline simulation with our proposed method. We showcase the method with a robot base placement solution and obtain up to 16 times reduction in time.

AR Training App for Energy Optimal Programming of Cobots

Oct 14, 2022

Abstract:Worldwide most factories aim for low-cost and fast production ignoring resources and energy consumption. But, high revenues have been accompanied by environmental degradation. The United Nations reacted to the ecological problem and proposed the Sustainable Development Goals, and one of them is Sustainable Production (Goal 12). In addition, the participation of lightweight robots, such as collaborative robots, in modern industrial production is increasing. The energy consumption of a single collaborative robot is not significant, however, the consumption of more and more cobots worldwide is representative. Consequently, our research focuses on strategies to reduce the energy consumption of lightweight robots aiming for sustainable production. Firstly, the energy consumption of the lightweight robot UR10e is assessed by a set of experiments. We analyzed the results of the experiments to describe the relationship between the energy consumption and the evaluation parameters, thus paving the way to optimization strategies. Next, we propose four strategies to reduce energy consumption: 1) optimal standby position, 2) optimal robot instruction, 3) optimal motion time, and 4) reduction of dissipative energy. The results show that cobots potentially reduce from 3\% up to 37\% of their energy consumption, depending on the optimization technique. To disseminate the results of our research, we developed an AR game in which the users learn how to energy-efficiently program cobots.

Robots Assembling Machines: Learning from the World Robot Summit 2018 Assembly Challenge

Nov 14, 2019

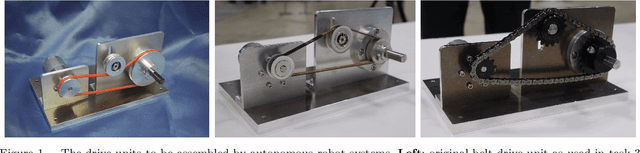

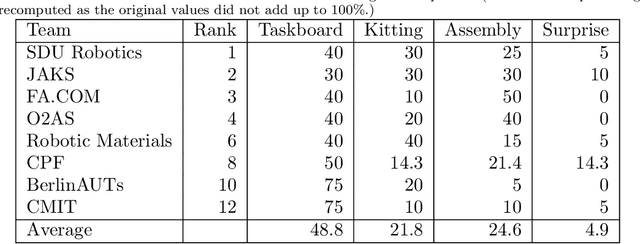

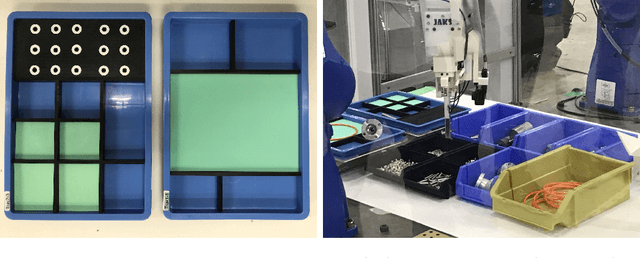

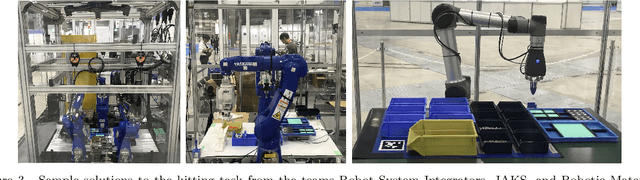

Abstract:The Industrial Assembly Challenge at the World Robot Summit was held in 2018 to showcase the state-of-the-art of autonomous manufacturing systems. The challenge included various tasks, such as bin picking, kitting, and assembly of standard industrial parts into 2D and 3D assemblies. Some of the tasks were only revealed at the competition itself, representing the challenge of "level 5" automation, i. e., programming and setting up an autonomous assembly system in less than one day. We conducted a survey among the teams that participated in the challenge and investigated aspects such as team composition, development costs, system setups as well as the teams' strategies and approaches. An analysis of the survey results reveals that the competitors have been in two camps: those constructing conventional robotic work cells with off-the-shelf tools, and teams who mostly relied on custom-made end effectors and novel software approaches in combination with collaborative robots. While both camps performed reasonably well, the winning team chose a middle ground in between, combining the efficiency of established play-back programming with the autonomy gained by CAD-based object detection and force control for assembly operations.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge