Dingchen Wang

Continuous-Time Digital Twin with Analogue Memristive Neural Ordinary Differential Equation Solver

Jun 12, 2024Abstract:Digital twins, the cornerstone of Industry 4.0, replicate real-world entities through computer models, revolutionising fields such as manufacturing management and industrial automation. Recent advances in machine learning provide data-driven methods for developing digital twins using discrete-time data and finite-depth models on digital computers. However, this approach fails to capture the underlying continuous dynamics and struggles with modelling complex system behaviour. Additionally, the architecture of digital computers, with separate storage and processing units, necessitates frequent data transfers and Analogue-Digital (A/D) conversion, thereby significantly increasing both time and energy costs. Here, we introduce a memristive neural ordinary differential equation (ODE) solver for digital twins, which is capable of capturing continuous-time dynamics and facilitates the modelling of complex systems using an infinite-depth model. By integrating storage and computation within analogue memristor arrays, we circumvent the von Neumann bottleneck, thus enhancing both speed and energy efficiency. We experimentally validate our approach by developing a digital twin of the HP memristor, which accurately extrapolates its nonlinear dynamics, achieving a 4.2-fold projected speedup and a 41.4-fold projected decrease in energy consumption compared to state-of-the-art digital hardware, while maintaining an acceptable error margin. Additionally, we demonstrate scalability through experimentally grounded simulations of Lorenz96 dynamics, exhibiting projected performance improvements of 12.6-fold in speed and 189.7-fold in energy efficiency relative to traditional digital approaches. By harnessing the capabilities of fully analogue computing, our breakthrough accelerates the development of digital twins, offering an efficient and rapid solution to meet the demands of Industry 4.0.

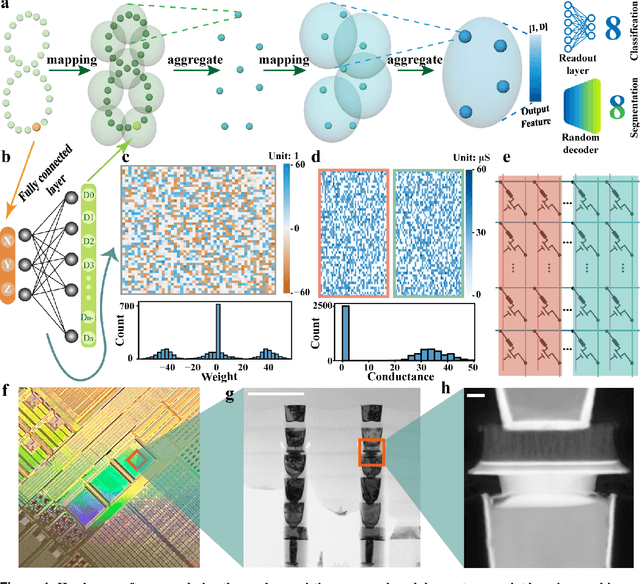

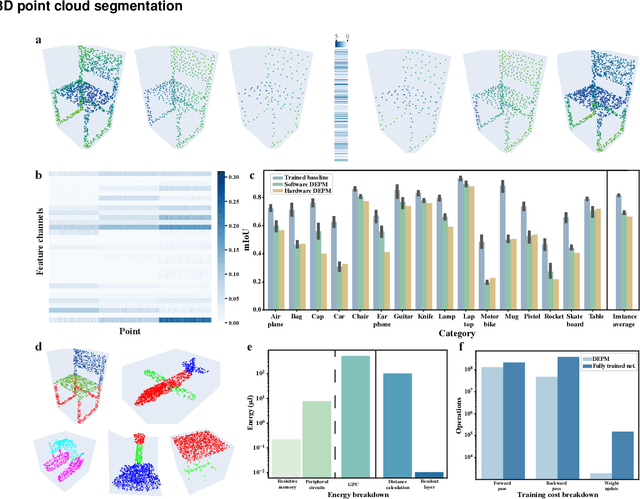

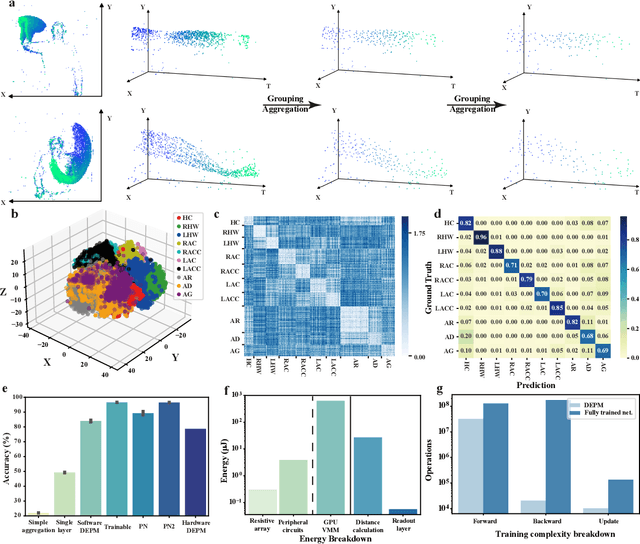

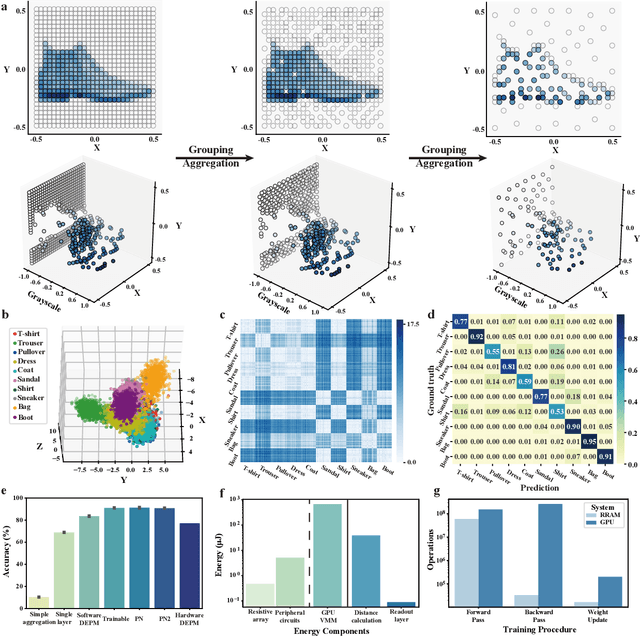

Random resistive memory-based deep extreme point learning machine for unified visual processing

Dec 14, 2023

Abstract:Visual sensors, including 3D LiDAR, neuromorphic DVS sensors, and conventional frame cameras, are increasingly integrated into edge-side intelligent machines. Realizing intensive multi-sensory data analysis directly on edge intelligent machines is crucial for numerous emerging edge applications, such as augmented and virtual reality and unmanned aerial vehicles, which necessitates unified data representation, unprecedented hardware energy efficiency and rapid model training. However, multi-sensory data are intrinsically heterogeneous, causing significant complexity in the system development for edge-side intelligent machines. In addition, the performance of conventional digital hardware is limited by the physically separated processing and memory units, known as the von Neumann bottleneck, and the physical limit of transistor scaling, which contributes to the slowdown of Moore's law. These limitations are further intensified by the tedious training of models with ever-increasing sizes. We propose a novel hardware-software co-design, random resistive memory-based deep extreme point learning machine (DEPLM), that offers efficient unified point set analysis. We show the system's versatility across various data modalities and two different learning tasks. Compared to a conventional digital hardware-based system, our co-design system achieves huge energy efficiency improvements and training cost reduction when compared to conventional systems. Our random resistive memory-based deep extreme point learning machine may pave the way for energy-efficient and training-friendly edge AI across various data modalities and tasks.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge