Weibang Bai

P-FABRIK: A General Intuitive and Robust Inverse Kinematics Method for Parallel Mechanisms Using FABRIK Approach

Dec 28, 2025Abstract:Traditional geometric inverse kinematics methods for parallel mechanisms rely on specific spatial geometry constraints. However, their application to redundant parallel mechanisms is challenged due to the increased constraint complexity. Moreover, it will output no solutions and cause unpredictable control problems when the target pose lies outside its workspace. To tackle these challenging issues, this work proposes P-FABRIK, a general, intuitive, and robust inverse kinematics method to find one feasible solution for diverse parallel mechanisms based on the FABRIK algorithm. By decomposing the general parallel mechanism into multiple serial sub-chains using a new topological decomposition strategy, the end targets of each sub-chain can be subsequently revised to calculate the inverse kinematics solutions iteratively. Multiple case studies involving planar, standard, and redundant parallel mechanisms demonstrated the proposed method's generality across diverse parallel mechanisms. Furthermore, numerical simulation studies verified its efficacy and computational efficiency, as well as its robustness ability to handle out-of-workspace targets.

A Novel Robotic Variable Stiffness Mechanism Based on Helically Wound Structured Electrostatic Layer Jamming

Dec 25, 2025Abstract:This paper introduces a novel variable stiffness mechanism termed Helically Wound Structured Electrostatic Layer Jamming (HWS-ELJ) and systematically investigates its potential applications in variable stiffness robotic finger design. The proposed method utilizes electrostatic attraction to enhance interlayer friction, thereby suppressing relative sliding and enabling tunable stiffness. Compared with conventional planar ELJ, the helical configuration of HWS-ELJ provides exponentially increasing stiffness adjustment with winding angle, achieving significantly greater stiffness enhancement for the same electrode contact area while reducing the required footprint under equivalent stiffness conditions. Considering the practical advantage of voltage-based control, a series of experimental tests under different initial force conditions were conducted to evaluate the stiffness modulation characteristics of HWS-ELJ. The results demonstrated its rational design and efficacy, with outcomes following the deduced theoretical trends. Furthermore, a robotic finger prototype integrating HWS-ELJ was developed, demonstrating voltage-driven stiffness modulation and confirming the feasibility of the proposed robotic variable stiffness mechanism.

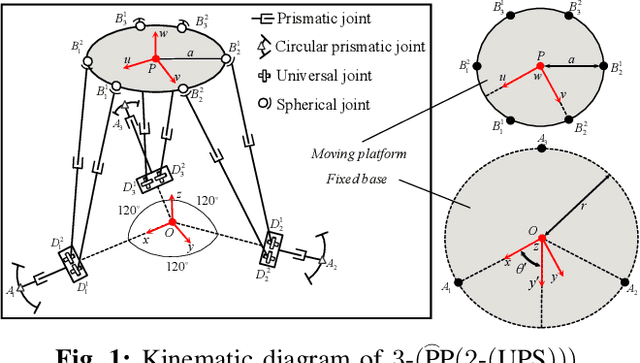

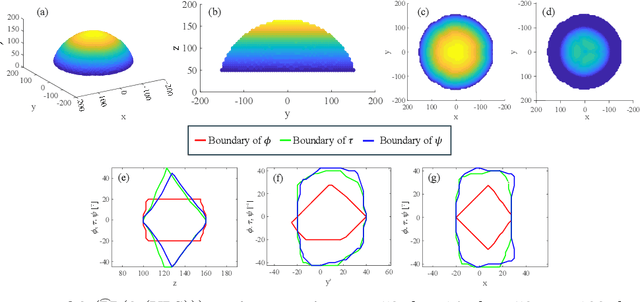

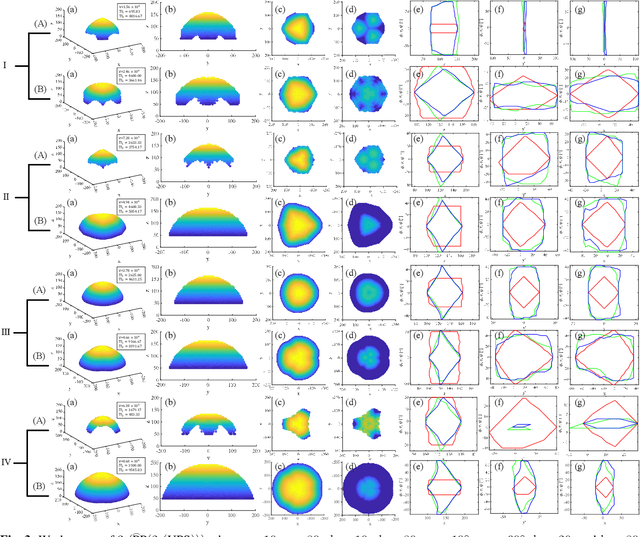

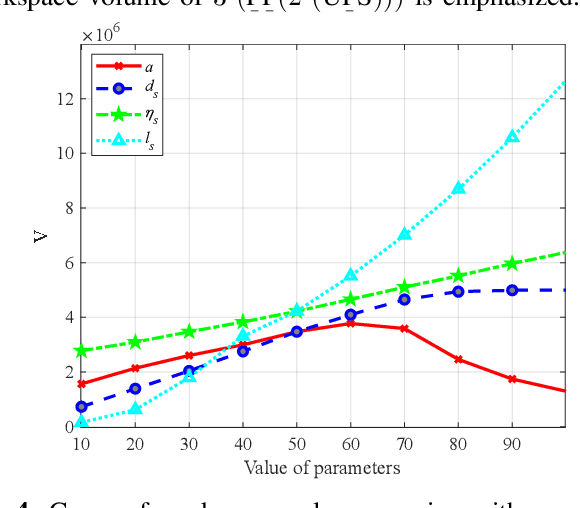

Geometric Parameter Optimization of a Novel 3-(PP(2-(UPS))) Redundant Parallel Mechanism based on Workspace Determination

Dec 16, 2025

Abstract:Redundant parallel robots are normally employed in scenarios requiring good precision, high load capability, and large workspace compared to traditional parallel mechanisms. However, the elementary robotic configuration and geometric parameter optimization are still quite challenging. This paper proposes a novel 3-(PP(2-(UPS))) redundant parallel mechanism, with good generalizability first, and further investigates the kinematic optimization issue by analyzing and investigating how its key geometric parameters influence the volume, shape, boundary completeness, and orientation capabilities of its workspace. The torsional capability index TI_1 and tilting capability index TI_2 are defined to evaluate the orientation performance of the mechanism. Numerical simulation studies are completed to indicate the analysis, providing reasonable but essential references for the parameter optimization of 3-(PP(2-(UPS))) and other similar redundant parallel mechanisms.

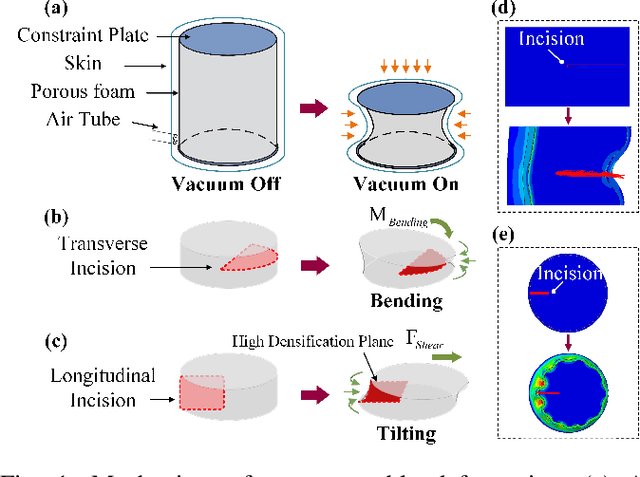

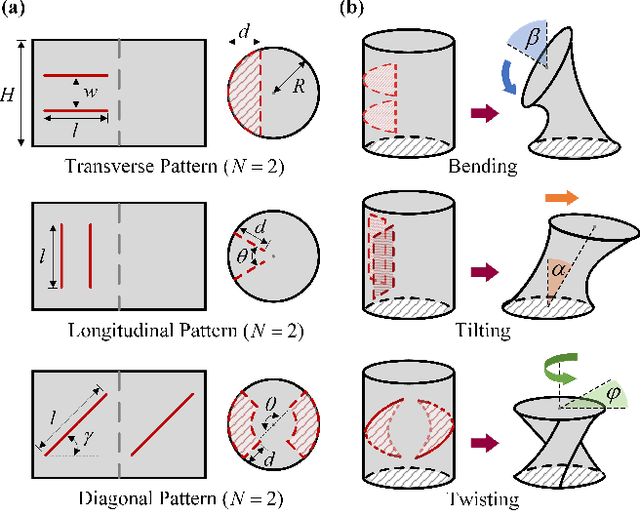

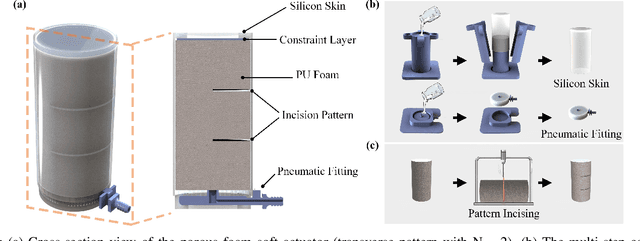

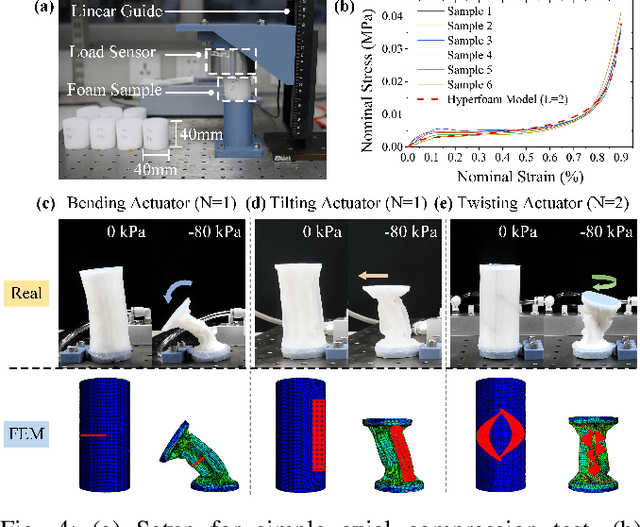

Programmable Deformation Design of Porous Soft Actuator through Volumetric-Pattern-Induced Anisotropy

Dec 13, 2025

Abstract:Conventional soft pneumatic actuators, typically based on hollow elastomeric chambers, often suffer from small structural support and require costly geometry-specific redesigns for multimodal functionality. Porous materials such as foam, filled into chambers, can provide structural stability for the actuators. However, methods to achieve programmable deformation by tailoring the porous body itself remain underexplored. In this paper, a novel design method is presented to realize soft porous actuators with programmable deformation by incising specific patterns into the porous foam body. This approach introduces localized structural anisotropy of the foam guiding the material's deformation under a global vacuum input. Furthermore, three fundamental patterns on a cylindrical foam substrate are discussed: transverse for bending, longitudinal for tilting, and diagonal for twisting. A computational model is built with Finite Element Analysis (FEA), to investigate the mechanism of the incision-patterning method. Experiments demonstrate that with a potential optimal design of the pattern array number N, actuators can achieve bending up to $80^{\circ}$ (N=2), tilting of $18^{\circ}$ (N=1), and twisting of $115^{\circ}$ (N=8). The versatility of our approach is demonstrated via pattern transferability, scalability, and mold-less rapid prototyping of complex designs. As a comprehensive application, we translate the human hand crease map into a functional incision pattern, creating a bio-inspired soft robot hand capable of human-like adaptive grasping. Our work provides a new, efficient, and scalable paradigm for the design of multi-functional soft porous robots.

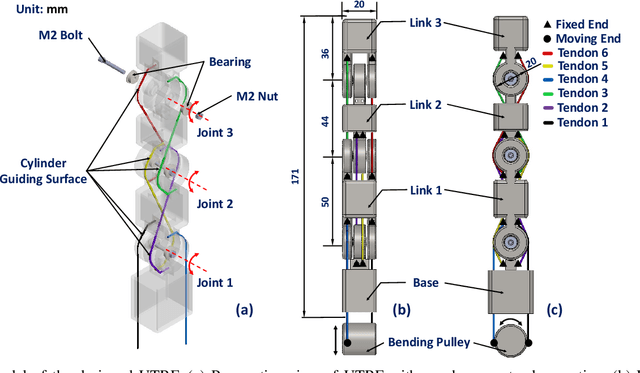

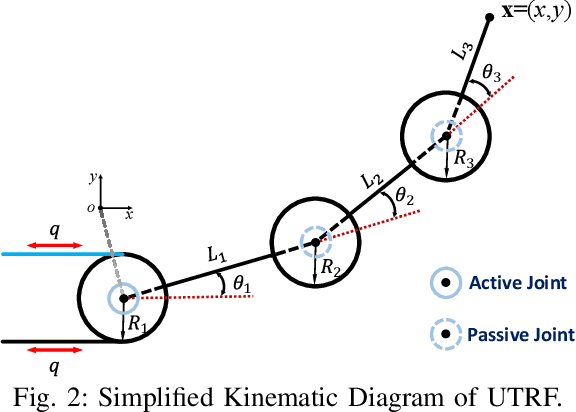

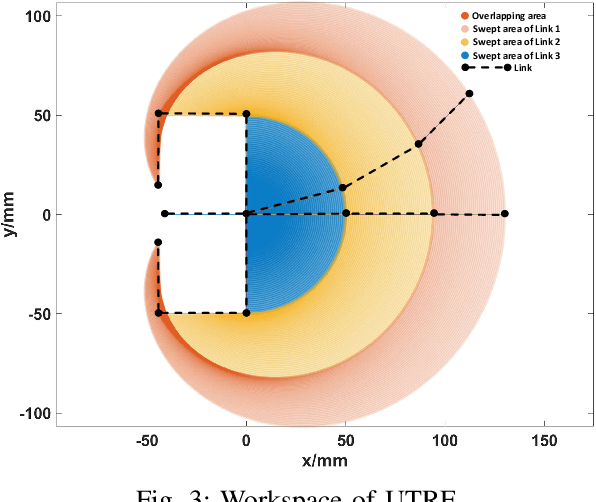

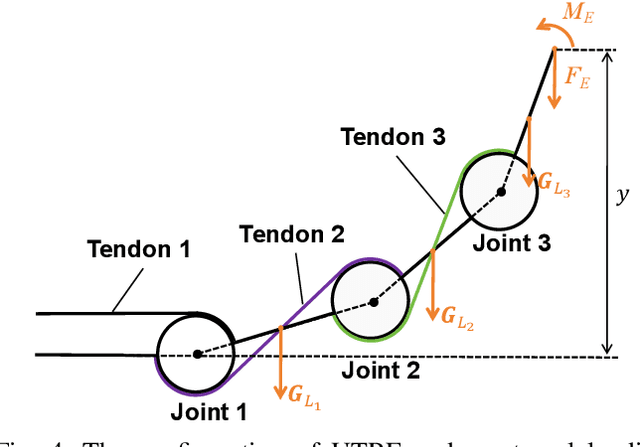

Design and Validation of an Under-actuated Robotic Finger with Synchronous Tendon Routing

Dec 11, 2025

Abstract:Tendon-driven under-actuated robotic fingers provide advantages for dexterous manipulation through reduced actuator requirements and simplified mechanical design. However, achieving both high load capacity and adaptive compliance in a compact form remains challenging. This paper presents an under-actuated tendon-driven robotic finger (UTRF) featuring a synchronous tendon routing that mechanically couples all joints with fixed angular velocity ratios, enabling the entire finger to be actuated by a single actuator. This approach significantly reduces the number of actuators required in multi-finger hands, resulting in a lighter and more compact structure without sacrificing stiffness or compliance. The kinematic and static models of the finger are derived, incorporating tendon elasticity to predict structural stiffness. A single-finger prototype was fabricated and tested under static loading, showing an average deflection prediction error of 1.0 mm (0.322% of total finger length) and a measured stiffness of 1.2x10^3 N/m under a 3 kg tip load. Integration into a five-finger robotic hand (UTRF-RoboHand) demonstrates effective object manipulation across diverse scenarios, confirming that the proposed routing achieves predictable stiffness and reliable grasping performance with a minimal actuator count.

CS3D: An Efficient Facial Expression Recognition via Event Vision

Dec 10, 2025Abstract:Responsive and accurate facial expression recognition is crucial to human-robot interaction for daily service robots. Nowadays, event cameras are becoming more widely adopted as they surpass RGB cameras in capturing facial expression changes due to their high temporal resolution, low latency, computational efficiency, and robustness in low-light conditions. Despite these advantages, event-based approaches still encounter practical challenges, particularly in adopting mainstream deep learning models. Traditional deep learning methods for facial expression analysis are energy-intensive, making them difficult to deploy on edge computing devices and thereby increasing costs, especially for high-frequency, dynamic, event vision-based approaches. To address this challenging issue, we proposed the CS3D framework by decomposing the Convolutional 3D method to reduce the computational complexity and energy consumption. Additionally, by utilizing soft spiking neurons and a spatial-temporal attention mechanism, the ability to retain information is enhanced, thus improving the accuracy of facial expression detection. Experimental results indicate that our proposed CS3D method attains higher accuracy on multiple datasets compared to architectures such as the RNN, Transformer, and C3D, while the energy consumption of the CS3D method is just 21.97\% of the original C3D required on the same device.

Map Imagination Like Blind Humans: Group Diffusion Model for Robotic Map Generation

Dec 22, 2024Abstract:Can robots imagine or generate maps like humans do, especially when only limited information can be perceived like blind people? To address this challenging task, we propose a novel group diffusion model (GDM) based architecture for robots to generate point cloud maps with very limited input information.Inspired from the blind humans' natural capability of imagining or generating mental maps, the proposed method can generate maps without visual perception data or depth data. With additional limited super-sparse spatial positioning data, like the extra contact-based positioning information the blind individuals can obtain, the map generation quality can be improved even more.Experiments on public datasets are conducted, and the results indicate that our method can generate reasonable maps solely based on path data, and produce even more refined maps upon incorporating exiguous LiDAR data.Compared to conventional mapping approaches, our novel method significantly mitigates sensor dependency, enabling the robots to imagine and generate elementary maps without heavy onboard sensory devices.

Learning Quadrupedal Robot Locomotion for Narrow Pipe Inspection

Dec 18, 2024

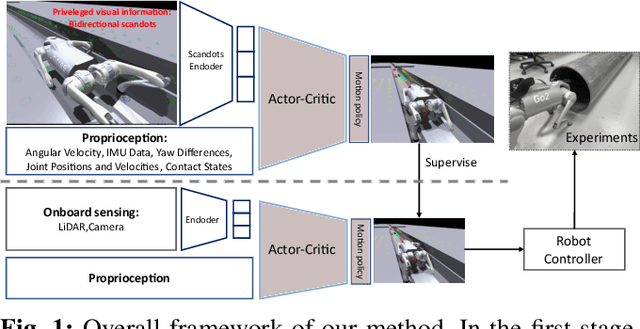

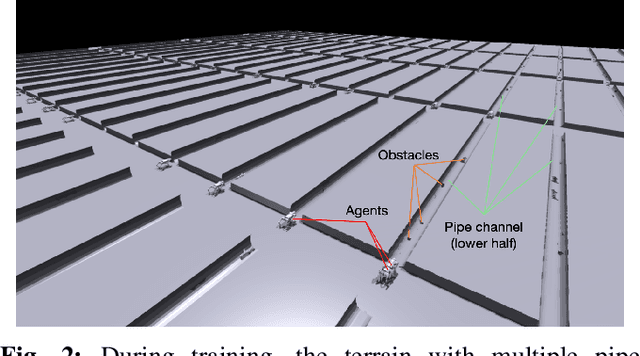

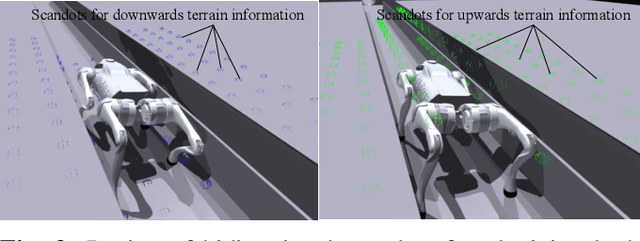

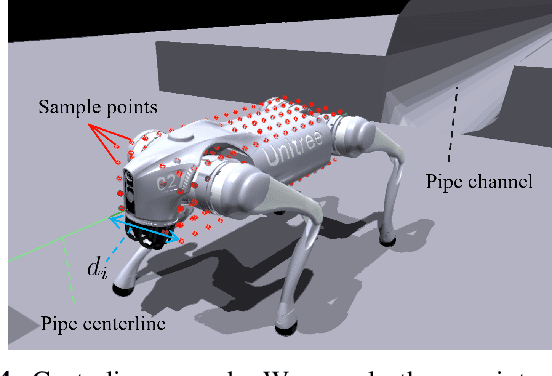

Abstract:Various pipes are extensively used in both industrial settings and daily life, but the pipe inspection especially those with narrow sizes are still very challenging with tremendous time and manufacturing consumed. Quadrupedal robots, inspired from patrol dogs, can be a substitution of traditional solutions but always suffer from navigation and locomotion difficulties. In this paper, we introduce a Reinforcement Learning (RL) based method to train a policy enabling the quadrupedal robots to cross narrow pipes adaptively. A new privileged visual information and a new reward function are defined to tackle the problems. Experiments on both simulation and real world scenarios were completed, demonstrated that the proposed method can achieve the pipe-crossing task even with unexpected obstacles inside.

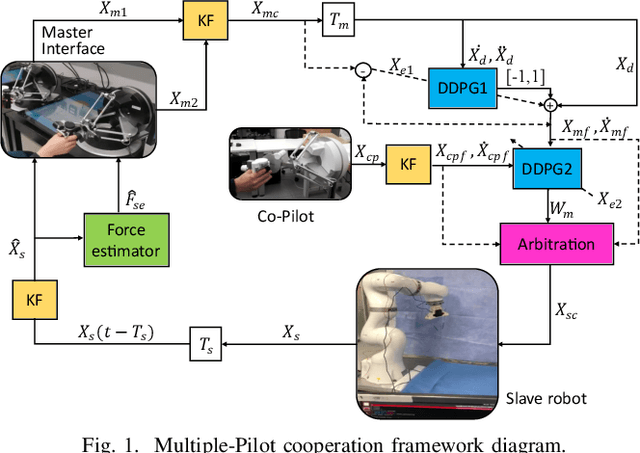

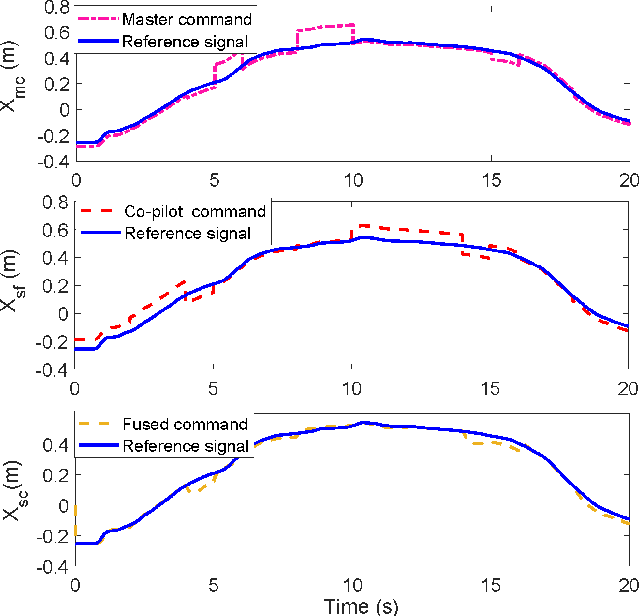

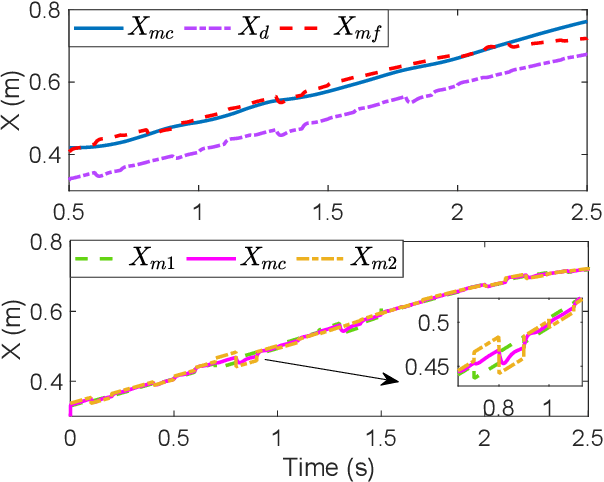

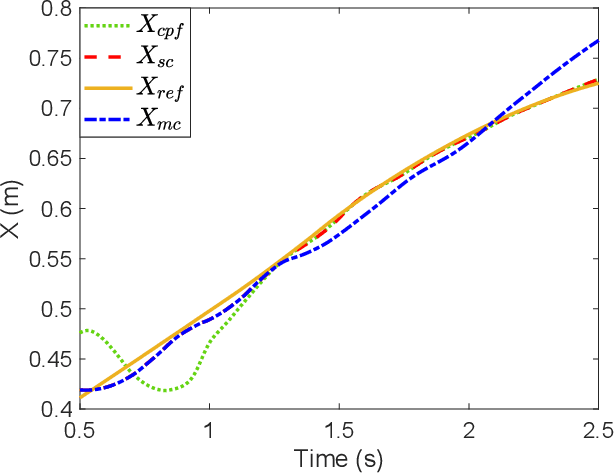

Multiple-Pilot Collaboration for Advanced Remote Intervention using Reinforcement Learning

Sep 27, 2021

Abstract:The traditional master-slave teleoperation relies on human expertise without correction mechanisms, resulting in excessive physical and mental workloads. To address these issues, a co-pilot-in-the-loop control framework is investigated for cooperative teleoperation. A deep deterministic policy gradient(DDPG) based agent is realised to effectively restore the master operators' intents without prior knowledge on time delay. The proposed framework allows for introducing an operator (i.e., co-pilot) to generate commands at the slave side, whose weights are optimally assigned online through DDPG-based arbitration, thereby enhancing the command robustness in the case of possible human operational errors. With the help of interval type-2(IT2) Takagi-Sugeno (T-S) fuzzy identification, force feedback can be reconstructed at the master side without a sense of delay, thus ensuring the telepresence performance in the force-sensor-free scenarios. Two experimental applications validate the effectiveness of the proposed framework.

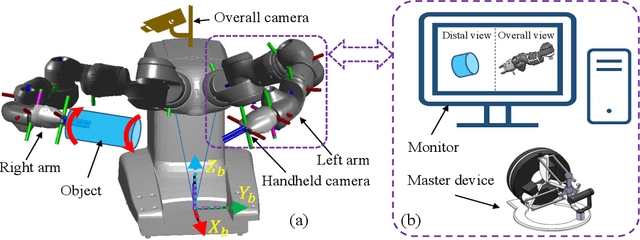

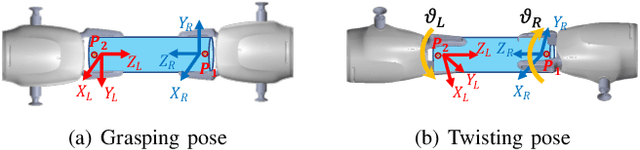

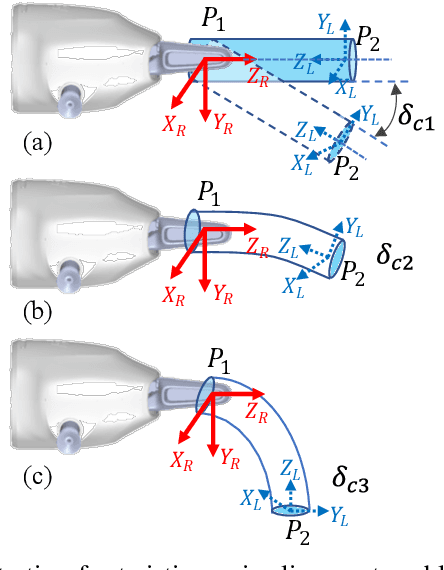

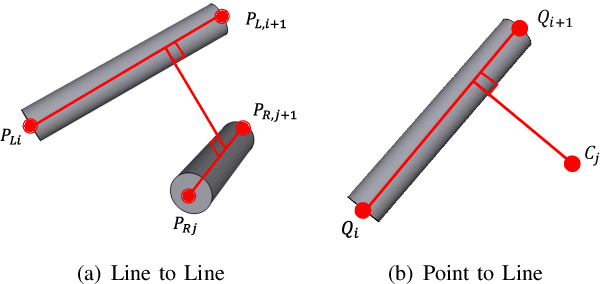

Dual-arm Coordinated Manipulation for Object Twisting with Human Intelligence

Aug 26, 2021

Abstract:Robotic dual-arm twisting is a common but very challenging task in both industrial production and daily services, as it often requires dexterous collaboration, a large scale of end-effector rotating, and good adaptivity for object manipulation. Meanwhile, safety and efficiency are preliminary concerns for robotic dual-arm coordinated manipulation. Thus, the normally adopted fully automated task execution approaches based on environmental perception and motion planning techniques are still inadequate and problematic for the arduous twisting tasks. To this end, this paper presents a novel strategy of the dual-arm coordinated control for twisting manipulation based on the combination of optimized motion planning for one arm and real-time telecontrol with human intelligence for the other. The analysis and simulation results showed it can achieve collision and singularity free for dual arms with enhanced dexterity, safety, and efficiency.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge