Susheela Sharma

Augmented Bridge Spinal Fixation: A New Concept for Addressing Pedicle Screw Pullout via a Steerable Drilling Robot and Flexible Pedicle Screws

Jul 02, 2025Abstract:To address the screw loosening and pullout limitations of rigid pedicle screws in spinal fixation procedures, and to leverage our recently developed Concentric Tube Steerable Drilling Robot (CT-SDR) and Flexible Pedicle Screw (FPS), in this paper, we introduce the concept of Augmented Bridge Spinal Fixation (AB-SF). In this concept, two connecting J-shape tunnels are first drilled through pedicles of vertebra using the CT-SDR. Next, two FPSs are passed through this tunnel and bone cement is then injected through the cannulated region of the FPS to form an augmented bridge between two pedicles and reinforce strength of the fixated spine. To experimentally analyze and study the feasibility of AB-SF technique, we first used our robotic system (i.e., a CT-SDR integrated with a robotic arm) to create two different fixation scenarios in which two J-shape tunnels, forming a bridge, were drilled at different depth of a vertebral phantom. Next, we implanted two FPSs within the drilled tunnels and then successfully simulated the bone cement augmentation process.

Towards Design and Development of a Concentric Tube Steerable Drilling Robot for Creating S-shape Tunnels for Pelvic Fixation Procedures

Jul 02, 2025Abstract:Current pelvic fixation techniques rely on rigid drilling tools, which inherently constrain the placement of rigid medical screws in the complex anatomy of pelvis. These constraints prevent medical screws from following anatomically optimal pathways and force clinicians to fixate screws in linear trajectories. This suboptimal approach, combined with the unnatural placement of the excessively long screws, lead to complications such as screw misplacement, extended surgery times, and increased radiation exposure due to repeated X-ray images taken ensure to safety of procedure. To address these challenges, in this paper, we present the design and development of a unique 4 degree-of-freedom (DoF) pelvic concentric tube steerable drilling robot (pelvic CT-SDR). The pelvic CT-SDR is capable of creating long S-shaped drilling trajectories that follow the natural curvatures of the pelvic anatomy. The performance of the pelvic CT-SDR was thoroughly evaluated through several S-shape drilling experiments in simulated bone phantoms.

S3D: A Spatial Steerable Surgical Drilling Framework for Robotic Spinal Fixation Procedures

Jul 02, 2025

Abstract:In this paper, we introduce S3D: A Spatial Steerable Surgical Drilling Framework for Robotic Spinal Fixation Procedures. S3D is designed to enable realistic steerable drilling while accounting for the anatomical constraints associated with vertebral access in spinal fixation (SF) procedures. To achieve this, we first enhanced our previously designed concentric tube Steerable Drilling Robot (CT-SDR) to facilitate steerable drilling across all vertebral levels of the spinal column. Additionally, we propose a four-Phase calibration, registration, and navigation procedure to perform realistic SF procedures on a spine holder phantom by integrating the CT-SDR with a seven-degree-of-freedom robotic manipulator. The functionality of this framework is validated through planar and out-of-plane steerable drilling experiments in vertebral phantoms.

From Monocular Vision to Autonomous Action: Guiding Tumor Resection via 3D Reconstruction

Mar 20, 2025Abstract:Surgical automation requires precise guidance and understanding of the scene. Current methods in the literature rely on bulky depth cameras to create maps of the anatomy, however this does not translate well to space-limited clinical applications. Monocular cameras are small and allow minimally invasive surgeries in tight spaces but additional processing is required to generate 3D scene understanding. We propose a 3D mapping pipeline that uses only RGB images to create segmented point clouds of the target anatomy. To ensure the most precise reconstruction, we compare different structure from motion algorithms' performance on mapping the central airway obstructions, and test the pipeline on a downstream task of tumor resection. In several metrics, including post-procedure tissue model evaluation, our pipeline performs comparably to RGB-D cameras and, in some cases, even surpasses their performance. These promising results demonstrate that automation guidance can be achieved in minimally invasive procedures with monocular cameras. This study is a step toward the complete autonomy of surgical robots.

Towards the Feasibility Analysis and Additive Manufacturing of a Novel Flexible Pedicle Screw for Spinal Fixation Procedures

Sep 16, 2024Abstract:In this paper, we explore the feasibility of developing a novel flexible pedicle screw (FPS) for enhanced spinal fixation of osteoporotic vertebrae. Vital for spinal fracture treatment, pedicle screws have been around since the early 20th century and have undergone multiple iterations to enhance internal spinal fixation. However, spinal fixation treatments tend to be problematic for osteoporotic patients due to multiple inopportune variables. The inherent rigid nature of the pedicle screw, along with the forced linear trajectory of the screw path, frequently leads to the placement of these screws in highly osteoporotic regions of the bone. This results in eventual screw slippage and causing neurological and respiratory problems for the patient. To address this problem, we focus on developing a novel FPS that is structurally capable of safely bending to fit curved trajectories drilled by a steerable drilling robot and bypass highly osteoporotic regions of the vertebral body. Afterwards, we simulate its morphability capabilities using finite element analysis (FEA). We then additively manufacture the FPS using stainless steel (SS) 316L alloy through direct metal laser sintering (DMLS). Finally, the fabricated FPS is experimentally evaluated for its bending performance and compared with the FEA results for verification. Results demonstrate the feasibility of additive manufacturing of FPS using DMLS approach and agreement of the developed FEA with the experiments.

Towards an Autonomous Minimally Invasive Spinal Fixation Surgery Using a Concentric Tube Steerable Drilling Robot

May 29, 2024

Abstract:Towards performing a realistic autonomous minimally invasive spinal fixation procedure, in this paper, we introduce a unique robotic drilling system utilizing a concentric tube steerable drilling robot (CT-SDR) integrated with a seven degree-of-freedom robotic manipulator. The CT-SDR in integration with the robotic arm enables creating precise J-shape trajectories enabling access to the areas within the vertebral body that currently are not accessible utilizing existing rigid instruments. To ensure safety and accuracy of the autonomous drilling procedure, we also performed required calibration procedures. The performance of the proposed robotic system and the calibration steps were thoroughly evaluated by performing various drilling experiments on simulated Sawbone samples.

A Patient-Specific Framework for Autonomous Spinal Fixation via a Steerable Drilling Robot

May 27, 2024

Abstract:In this paper, with the goal of enhancing the minimally invasive spinal fixation procedure in osteoporotic patients, we propose a first-of-its-kind image-guided robotic framework for performing an autonomous and patient-specific procedure using a unique concentric tube steerable drilling robot (CT-SDR). Particularly, leveraging a CT-SDR, we introduce the concept of J-shape drilling based on a pre-operative trajectory planned in CT scan of a patient followed by appropriate calibration, registration, and navigation steps to safely execute this trajectory in real-time using our unique robotic setup. To thoroughly evaluate the performance of our framework, we performed several experiments on two different vertebral phantoms designed based on CT scan of real patients.

Towards Biomechanical Evaluation of a Transformative Additively Manufactured Flexible Pedicle Screw for Robotic Spinal Fixation

May 27, 2024

Abstract:Vital for spinal fracture treatment, pedicle screw fixation is the gold standard for spinal fixation procedures. Nevertheless, due to the screw pullout and loosening issues, this surgery often fails to be effective for patients suffering from osteoporosis (i.e., having low bone mineral density). These failures can be attributed to the rigidity of existing drilling instruments and pedicle screws forcing clinicians to place these implants into the osteoporotic regions of the vertebral body. To address this critical issue, we have developed a steerable drilling robotic system and evaluated its performance in drilling various J- and U-shape trajectories. Complementary to this robotic system, in this paper, we propose design, additive manufacturing, and biomechanical evaluation of a transformative flexible pedicle screw (FPS) that can be placed in pre-drilled straight and curved trajectories. To evaluate the performance of the proposed flexible implant, we designed and fabricated two different types of FPSs using the direct metal laser sintering (DMLS) process. Utilizing our unique experimental setup and ASTM standards, we then performed various pullout experiments on these FPSs to evaluate and analyze their biomechanical performance implanted in straight trajectories.

Spatial Spinal Fixation: A Transformative Approach Using a Unique Robot-Assisted Steerable Drilling System and Flexible Pedicle Screw

May 27, 2024

Abstract:Spinal fixation procedures are currently limited by the rigidity of the existing instruments and pedicle screws leading to fixation failures and rigid pedicle screw pull out. Leveraging our recently developed Concentric Tube Steerable Drilling Robot (CT-SDR) in integration with a robotic manipulator, to address the aforementioned issue, here we introduce the transformative concept of Spatial Spinal Fixation (SSF) using a unique Flexible Pedicle Screw (FPS). The proposed SSF procedure enables planar and out-of-plane placement of the FPS throughout the full volume of the vertebral body. In other words, not only does our fixation system provide the option of drilling in-plane and out-of-plane trajectories, it also enables implanting the FPS inside linear (represented by an I-shape) and/or non-linear (represented by J-shape) trajectories. To thoroughly evaluate the functionality of our proposed robotic system and the SSF procedure, we have performed various experiments by drilling different I-J and J-J drilling trajectory pairs into our custom-designed L3 vertebral phantoms and analyzed the accuracy of the procedure using various metrics.

Towards Biomechanics-Aware Design of a Steerable Drilling Robot for Spinal Fixation Procedures with Flexible Pedicle Screws

May 24, 2023

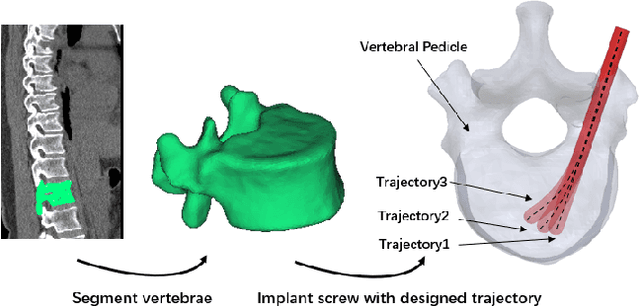

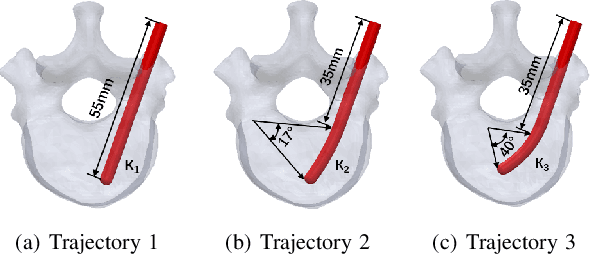

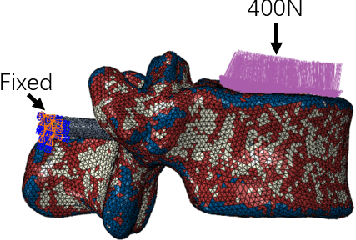

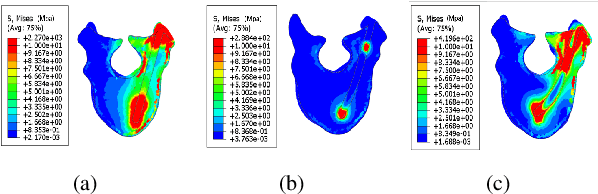

Abstract:Towards reducing the failure rate of spinal fixation surgical procedures in osteoporotic patients, we propose a unique biomechanically-aware framework for the design of a novel concentric tube steerable drilling robot (CT-SDR). The proposed framework leverages a patient-specific finite element (FE) biomechanics model developed based on Quantitative Computed Tomography (QCT) scans of the patient's vertebra to calculate a biomechanically-optimal and feasible drilling and implantation trajectory. The FE output is then used as a design requirement for the design and evaluation of the CT-SDR. Providing a balance between the necessary flexibility to create curved optimal trajectories obtained by the FE module with the required strength to not buckle during drilling through a hard simulated bone material, we showed that the CT-SDR can reliably recreate this drilling trajectory with errors between 1.7-2.2%

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge