Stéphane Caro

LS2N, CNRS, LS2N - équipe RoMas

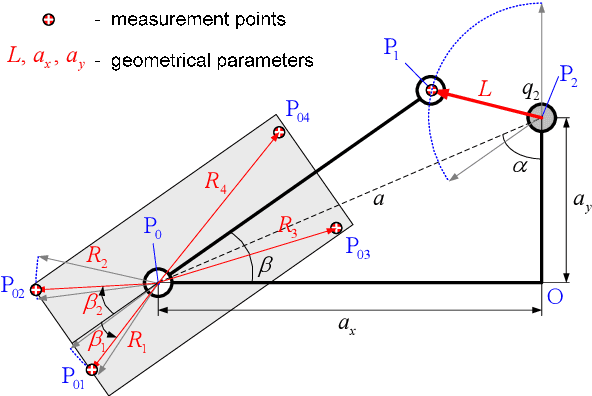

Kinetostatic Optimization for Kinematic Redundancy Planning of Nimbl'Bot Robot

Mar 29, 2023

Abstract:<jats:title>Abstract</jats:title> <jats:p>In manufacturing industry, Computer Numerical Control (CNC) machines are often preferred over Industrial Serial Robots (ISR) for machining tasks. Indeed, CNC machines offer high positioning accuracy, which leads to slight dimensional deviation on the final product. However, these machines have a restricted workspace generating limitations in the machining work. Conversely, ISR are typically characterized by a larger workspace. ISR have already shown satisfactory performance in tasks like polishing, grinding and deburring. This paper proposes a kinematic redundant robot composed of a novel two degrees-of-freedom mechanism with a closed-loop kinematic chain. After describing a task priority inverse kinematic control framework used for joint trajectory planning exploiting the robot kinematic redundancy, the paper analyses the kinetostatic performance of this robot depending on the considered control tasks. Moreover, two kinetostatic tasks are introduced and employed to improve the robot performance. Simulation results show how the robot better performs when the optimization tasks are active.</jats:p>

A Cable-Driven Parallel Robot with Full-Circle End-Effector Rotations

Jan 04, 2021

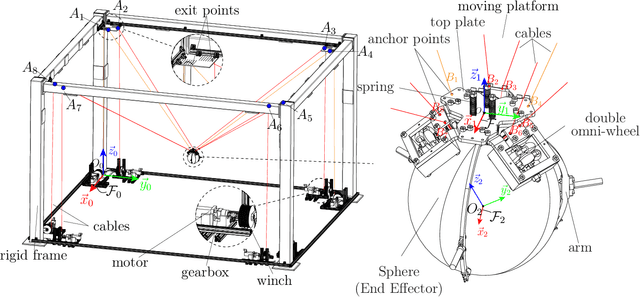

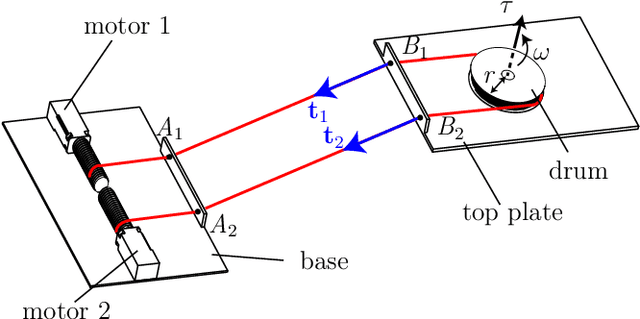

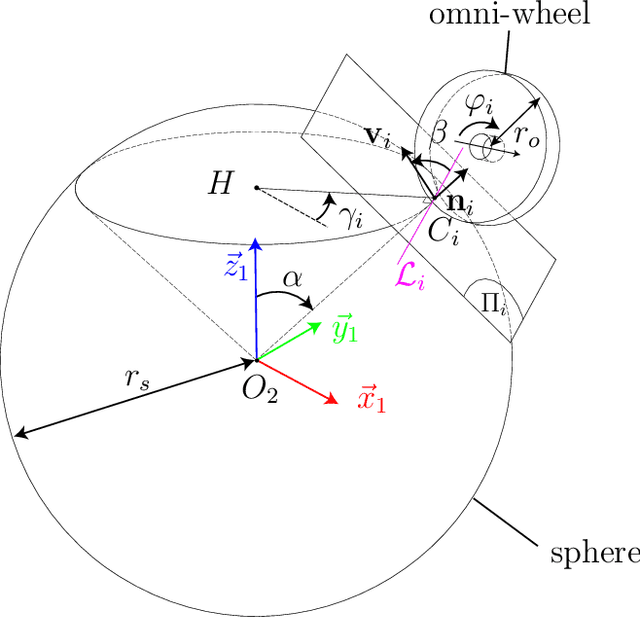

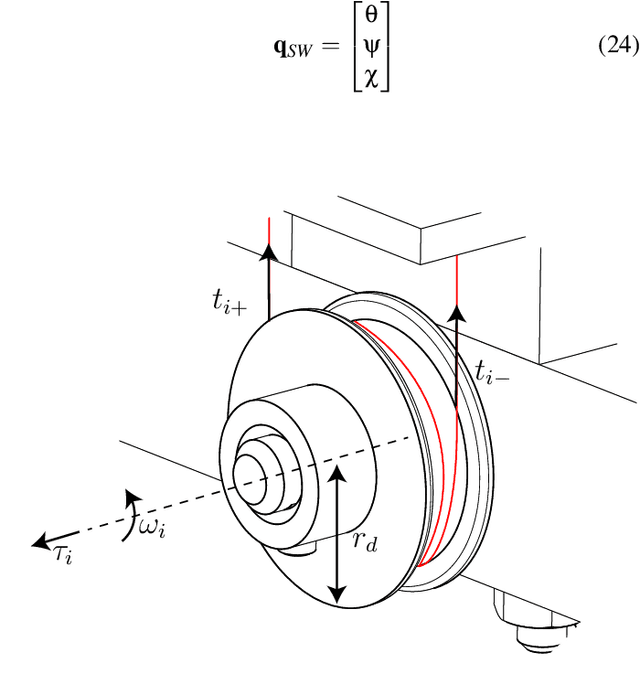

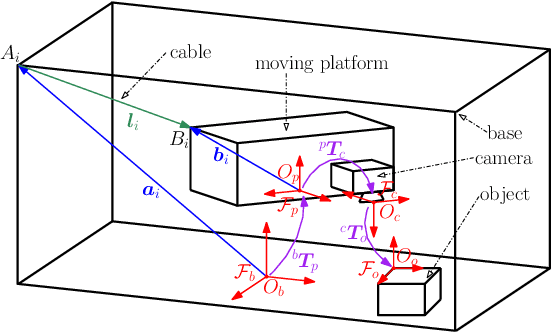

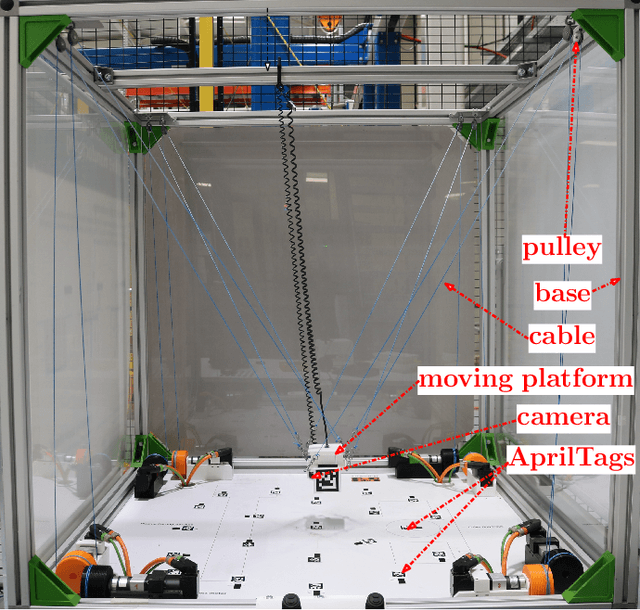

Abstract:Cable-Driven Parallel Robots (CDPRs) offer high payload capacities, large translational workspace and high dynamic performances. The rigid base frame of the CDPR is connected in parallel to the moving platform using cables. However, their orientation workspace is usually limited due to cable/cable and cable/moving platform collisions. This paper deals with the design, modelling and prototyping of a hybrid robot. This robot, which is composed of a CDPR mounted in series with a Parallel Spherical Wrist (PSW), has both a large translational workspace and an unlimited orientation workspace. It should be noted that the six degrees of freedom (DOF) motions of the moving platform of the CDPR, namely, the base of the PSW, and the three-DOF motion of the PSW are actuated by means of eight actuators fixed to the base. As a consequence, the overall system is underactuated and its total mass and inertia in motion is reduced.

Robust 2 1/2D Visual Servoing of a Cable-Driven Parallel Robot Thanks to Trajectory Tracking

Jan 16, 2020

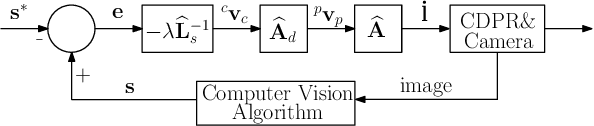

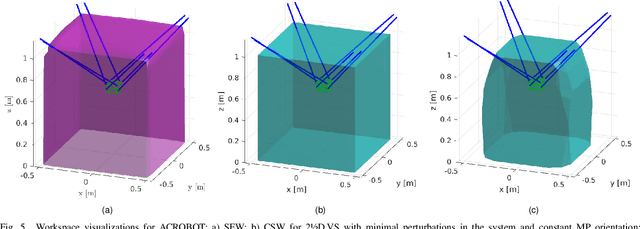

Abstract:Cable-Driven Parallel Robots (CDPRs) are a kind of parallel robots that have cables instead of rigid links. Implementing vision-based control on CDPRs leads to a good final accuracy despite modeling errors and other perturbations in the system. However, unlike final accuracy, the trajectory to the goal can be affected by the perturbations in the system. This paper proposes the use of trajectory tracking to improve the robustness of 2 1/2 D visual servoing control of CDPRs. Lyapunov stability analysis is performed and, as a result, a novel workspace, named control stability workspace, is defined. This workspace defines the set of moving-platform poses where the robot is able to execute its task while being stable. The improvement of robustness is clearly shown in experimental validation.

Design and Control of a Variable Aerial Cable Towed System

Jan 08, 2020

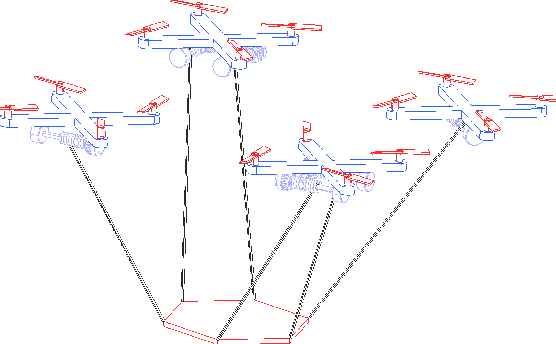

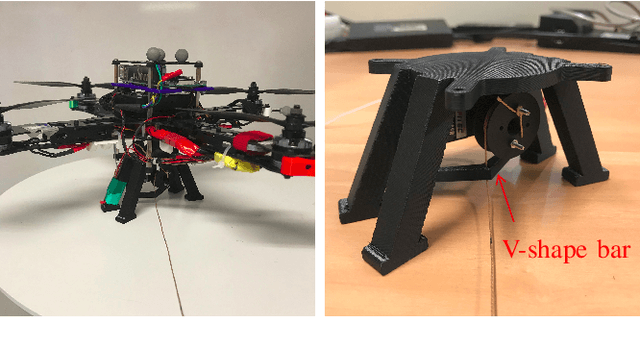

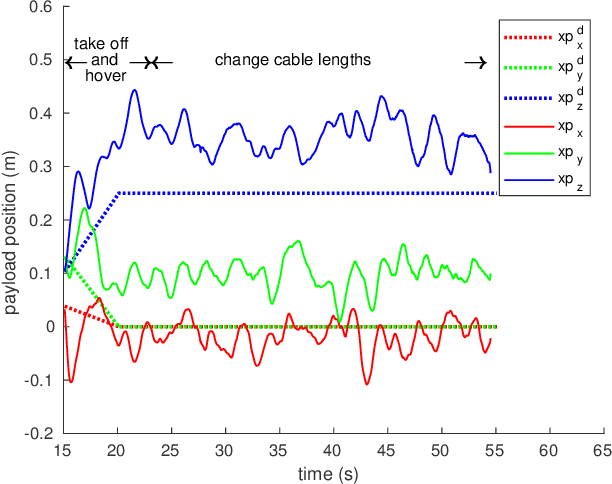

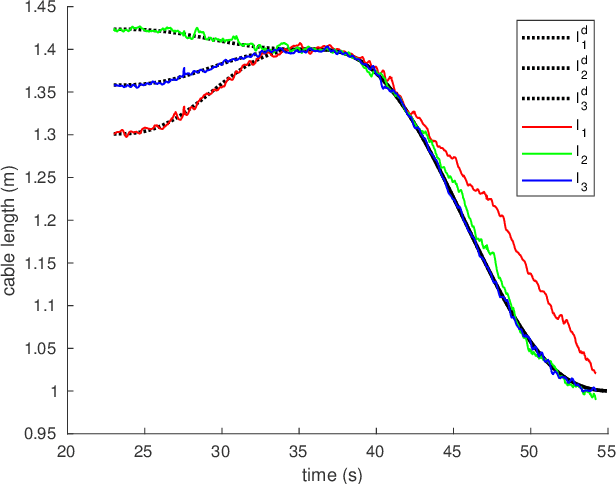

Abstract:Aerial Cable Towed Systems (ACTS) are composed of several Unmanned Aerial Vehicles (UAVs) connected to a payload by cables. Compared to towing objects from individual aerial vehicles, an ACTS has significant advantages such as heavier payload capacity, modularity, and full control of the payload pose. They are however generally large with limited ability to meet geometric constraints while avoiding collisions between UAVs. This paper presents the modelling, performance analysis, design, and a proposed controller for a novel ACTS with variable cable lengths, named Variable Aerial Cable Towed System (VACTS).Winches are embedded on the UAVs for actuating the cable lengths similar to a Cable-Driven Parallel Robot to increase the versatility of the ACTS. The general geometric, kinematic and dynamic models of the VACTS are derived, followed by the development of a centralized feedback linearization controller. The design is based on a wrench analysis of the VACTS, without constraining the cables to pass through the UAV center of mass, as in current works. Additionally, the performance of the VACTS and ACTS are compared showing that the added versatility comes at the cost of payload and configuration flexibility. A prototype confirms the feasibility of the system.

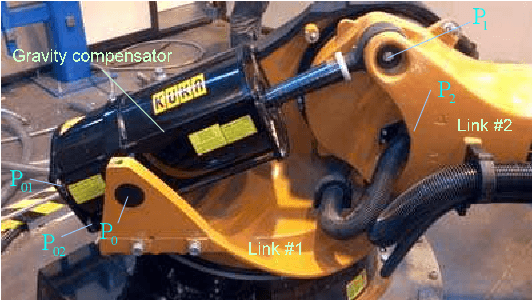

Accuracy Improvement of Robot-Based Milling Using an Enhanced Manipulator Model

Sep 22, 2014

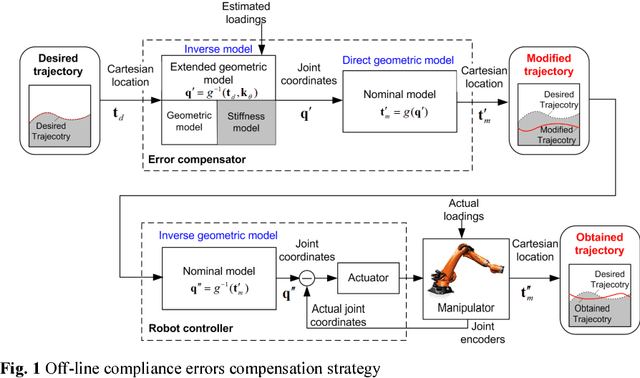

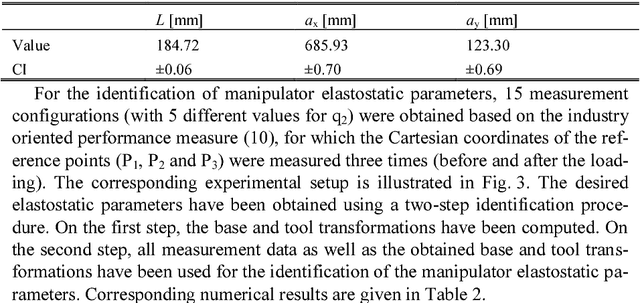

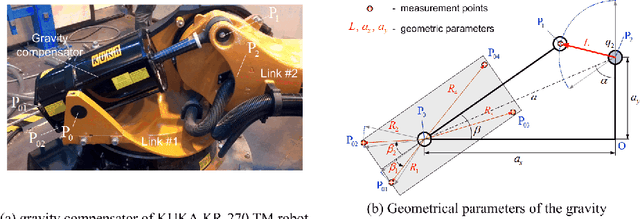

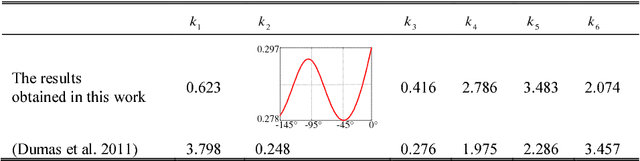

Abstract:The paper is devoted to the accuracy improvement of robot-based milling by using an enhanced manipulator model that takes into account both geometric and elastostatic factors. Particular attention is paid to the model parameters identification accuracy. In contrast to other works, the proposed approach takes into account impact of the gravity compensator and link weights on the manipulator elastostatic properties. In order to improve the identification accuracy, the industry oriented performance measure is used to define optimal measurement configurations and an enhanced partial pose measurement method is applied for the identification of the model parameters. The advantages of the developed approach are confirmed by experimental results that deal with the elastostatic calibration of a heavy industrial robot used for milling. The achieved accuracy improvement factor is about 2.4.

Sensitivity Analysis of the Orthoglide, a 3-DOF Translational Parallel Kinematic Machine

Dec 04, 2013

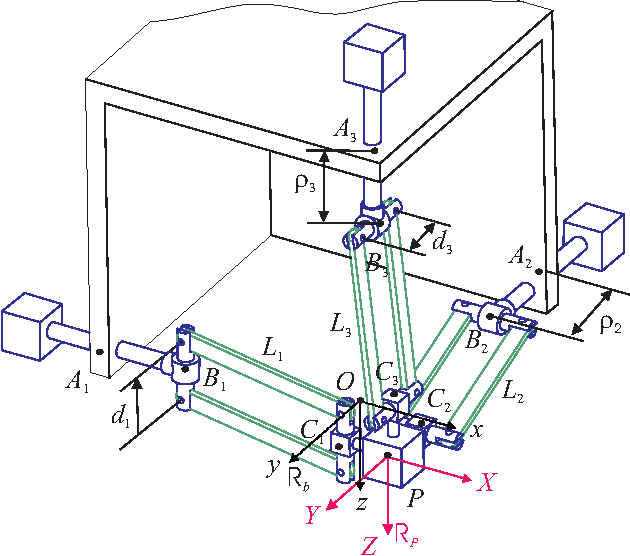

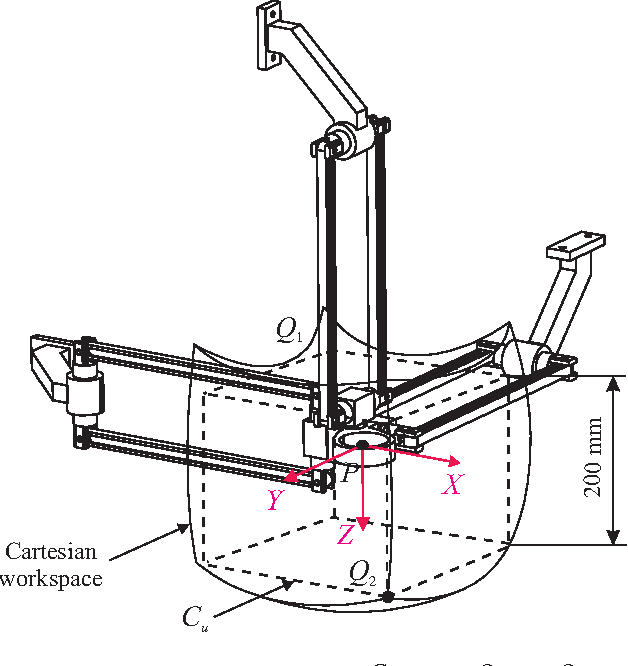

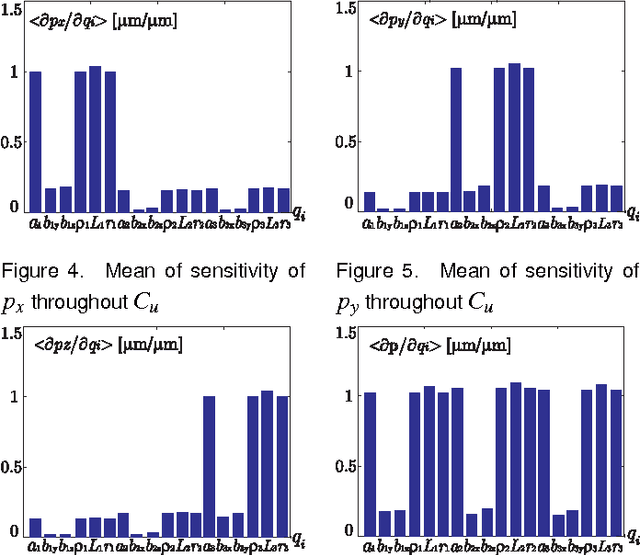

Abstract:This paper presents a sensitivity analysis of the Orthoglide, a 3-DOF translational Parallel Kinematic Machine. Two complementary methods are developed to analyze its sensitivity to its dimensional and angular variations. First, a linkage kinematic analysis method is used to have a rough idea of the influence of the dimensional variations on the location of the end-effector. Besides, this method shows that variations in the design parameters of the same type from one leg to the other have the same influence on the end-effector. However, this method does not take into account the variations in the parallelograms. Thus, a differential vector method is used to study the influence of the dimensional and angular variations in the parts of the manipulator on the position and orientation of the end-effector, and particularly the influence of the variations in the parallelograms. It turns out that the kinematic isotropic configuration of the manipulator is the least sensitive one to its dimensional and angular variations. On the contrary, the closest configurations to its kinematic singular configurations are the most sensitive ones to geometrical variations.

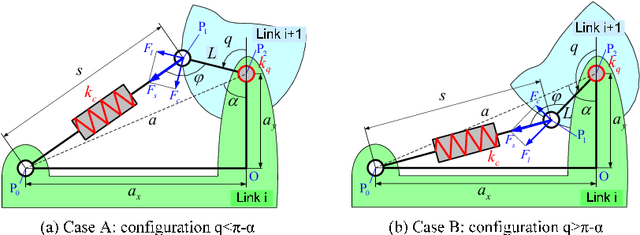

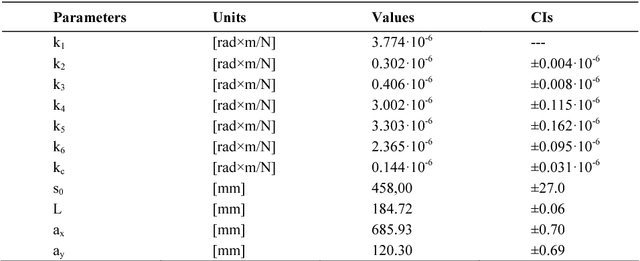

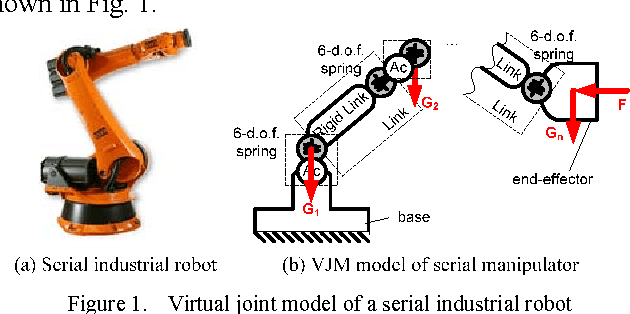

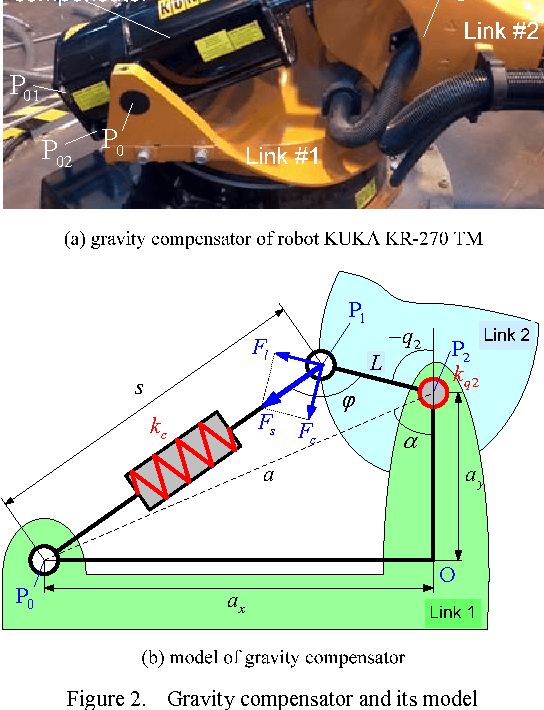

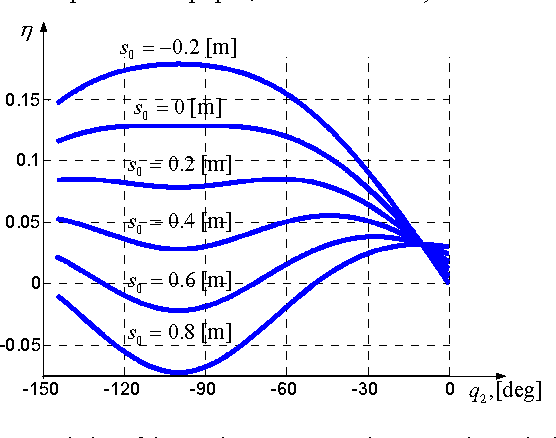

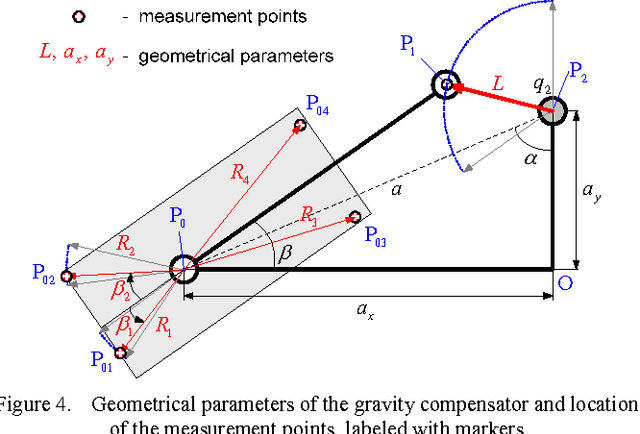

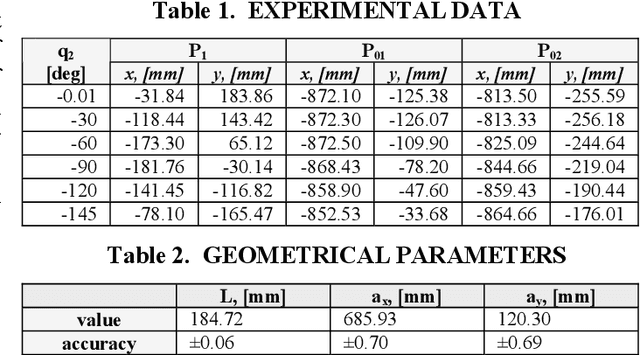

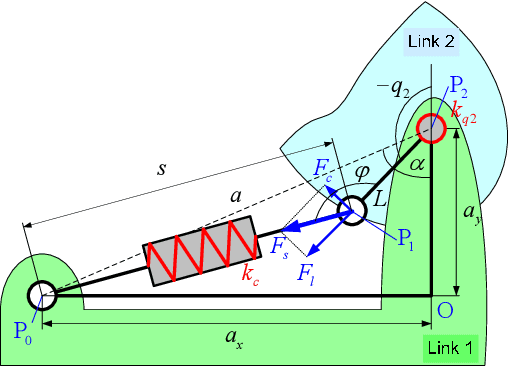

Stiffness modeling of robotic manipulator with gravity compensator

Nov 26, 2013

Abstract:The paper focuses on the stiffness modeling of robotic manipulators with gravity compensators. The main attention is paid to the development of the stiffness model of a spring-based compensator located between sequential links of a serial structure. The derived model allows us to describe the compensator as an equivalent non-linear virtual spring integrated in the corresponding actuated joint. The obtained results have been efficiently applied to the stiffness modeling of a heavy industrial robot of the Kuka family.

Identification of geometrical and elastostatic parameters of heavy industrial robots

Nov 26, 2013

Abstract:The paper focuses on the stiffness modeling of heavy industrial robots with gravity compensators. The main attention is paid to the identification of geometrical and elastostatic parameters and calibration accuracy. To reduce impact of the measurement errors, the set of manipulator configurations for calibration experiments is optimized with respect to the proposed performance measure related to the end-effector position accuracy. Experimental results are presented that illustrate the advantages of the developed technique.

* arXiv admin note: substantial text overlap with arXiv:1311.6674

Advanced robot calibration using partial pose measurements

Nov 26, 2013

Abstract:The paper focuses on the calibration of serial industrial robots using partial pose measurements. In contrast to other works, the developed advanced robot calibration technique is suitable for geometrical and elastostatic calibration. The main attention is paid to the model parameters identification accuracy. To reduce the impact of measurement errors, it is proposed to use directly position measurements of several points instead of computing orientation of the end-effector. The proposed approach allows us to avoid the problem of non-homogeneity of the least-square objective, which arises in the classical identification technique with the full-pose information. The developed technique does not require any normalization and can be efficiently applied both for geometric and elastostatic identification. The advantages of a new approach are confirmed by comparison analysis that deals with the efficiency evaluation of different identification strategies. The obtained results have been successfully applied to the elastostatic parameters identification of the industrial robot employed in a machining work-cell for aerospace industry.

Modelling of the gravity compensators in robotic manufacturing cells

Nov 26, 2013

Abstract:The paper deals with the modeling and identification of the gravity compensators used in heavy industrial robots. The main attention is paid to the geometrical parameters identification and calibration accuracy. To reduce impact of the measurement errors, the design of calibration experiments is used. The advantages of the developed technique are illustrated by experimental results

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge