Camilo Charron

LS2N, UR2, LS2N - équipe PACCE

A Novel Skill Modeling Approach: Integrating Vergnaud's Scheme with Cognitive Architectures

Sep 16, 2025Abstract:Human-machine interaction is increasingly important in industry, and this trend will only intensify with the rise of Industry 5.0. Human operators have skills that need to be adapted when using machines to achieve the best results. It is crucial to highlight the operator's skills and understand how they use and adapt them [18]. A rigorous description of these skills is necessary to compare performance with and without robot assistance. Predicate logic, used by Vergnaud within Piaget's scheme concept, offers a promising approach. However, this theory doesn't account for cognitive system constraints, such as the timing of actions, the limitation of cognitive resources, the parallelization of tasks, or the activation of automatic gestures contrary to optimal knowledge. Integrating these constraints is essential for representing agent skills understanding skill transfer between biological and mechanical structures. Cognitive architectures models [2] address these needs by describing cognitive structure and can be combined with the scheme for mutual benefit. Welding provides a relevant case study, as it highlights the challenges faced by operators, even highly skilled ones. Welding's complexity stems from the need for constant skill adaptation to variable parameters like part position and process. This adaptation is crucial, as weld quality, a key factor, is only assessed afterward via destructive testing. Thus, the welder is confronted with a complex perception-decision-action cycle, where the evaluation of the impact of his actions is delayed and where errors are definitive. This dynamic underscores the importance of understanding and modeling the skills of operators.

Improving Welding Robotization via Operator Skill Identification, Modeling, and Human-Machine Collaboration: Experimental Protocol Implementation

Feb 22, 2024Abstract:The industry of the future, also known as Industry 5.0, aims to modernize production tools, digitize workshops, and cultivate the invaluable human capital within the company. Industry 5.0 can't be done without fostering a workforce that is not only technologically adept but also has enhanced skills and knowledge. Specifically, collaborative robotics plays a key role in automating strenuous or repetitive tasks, enabling human cognitive functions to contribute to quality and innovation. In manual manufacturing, however, some of these tasks remain challenging to automate without sacrificing quality. In certain situations, these tasks require operators to dynamically organize their mental, perceptual, and gestural activities. In other words, skills that are not yet adequately explained and digitally modeled to allow a machine in an industrial context to reproduce them, even in an approximate manner. Some tasks in welding serve as a perfect example. Drawing from the knowledge of cognitive and developmental psychology, professional didactics, and collaborative robotics research, our work aims to find a way to digitally model manual manufacturing skills to enhance the automation of tasks that are still challenging to robotize. Using welding as an example, we seek to develop, test, and deploy a methodology transferable to other domains. The purpose of this article is to present the experimental setup used to achieve these objectives.

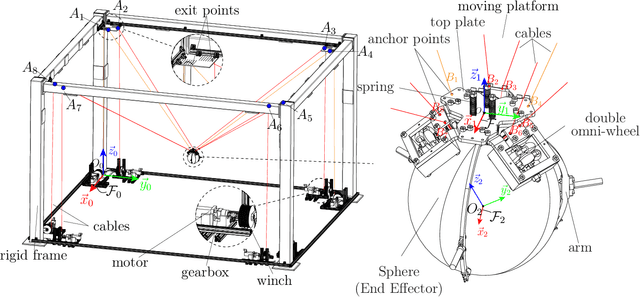

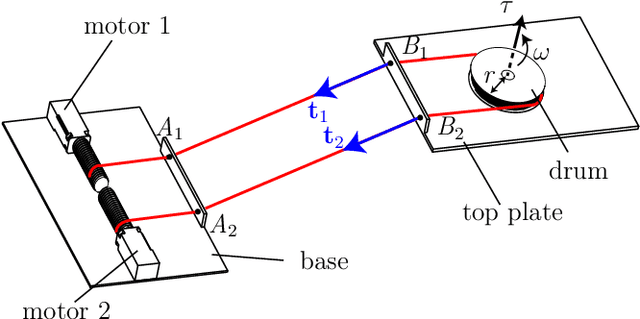

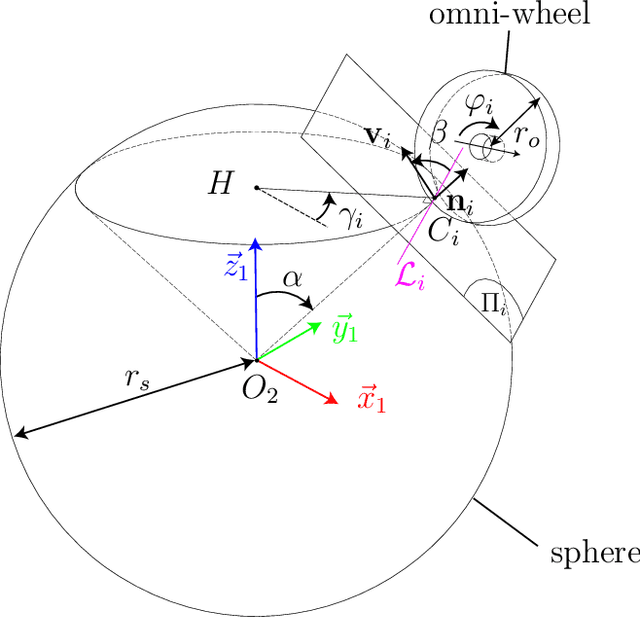

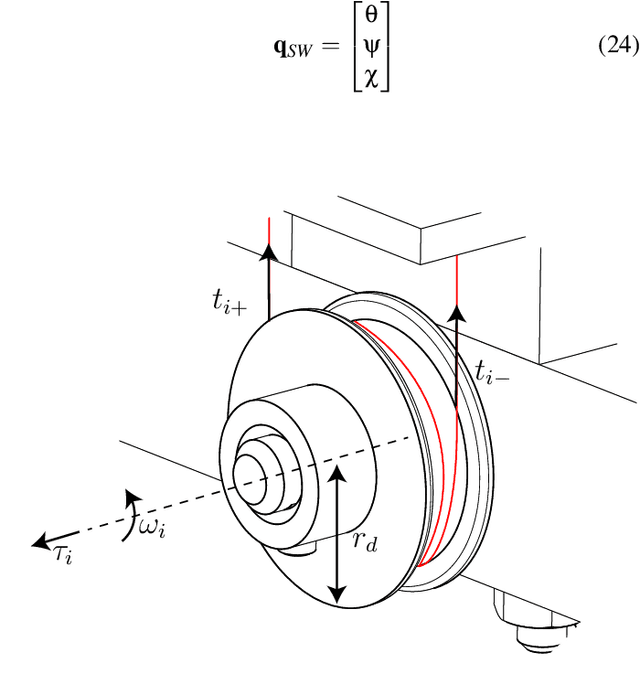

A Cable-Driven Parallel Robot with Full-Circle End-Effector Rotations

Jan 04, 2021

Abstract:Cable-Driven Parallel Robots (CDPRs) offer high payload capacities, large translational workspace and high dynamic performances. The rigid base frame of the CDPR is connected in parallel to the moving platform using cables. However, their orientation workspace is usually limited due to cable/cable and cable/moving platform collisions. This paper deals with the design, modelling and prototyping of a hybrid robot. This robot, which is composed of a CDPR mounted in series with a Parallel Spherical Wrist (PSW), has both a large translational workspace and an unlimited orientation workspace. It should be noted that the six degrees of freedom (DOF) motions of the moving platform of the CDPR, namely, the base of the PSW, and the three-DOF motion of the PSW are actuated by means of eight actuators fixed to the base. As a consequence, the overall system is underactuated and its total mass and inertia in motion is reduced.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge