Yier Wu

EM NANTES, IRCCyN

Accuracy Improvement of Robot-Based Milling Using an Enhanced Manipulator Model

Sep 22, 2014

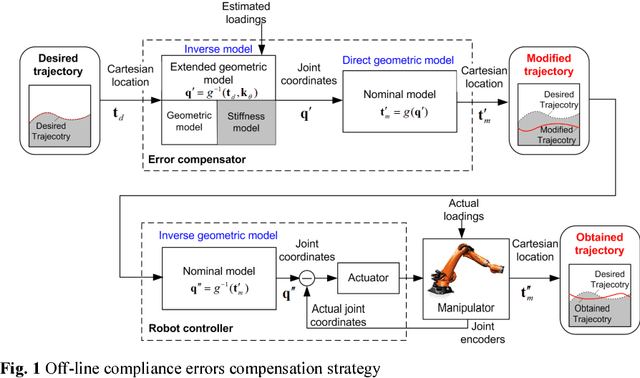

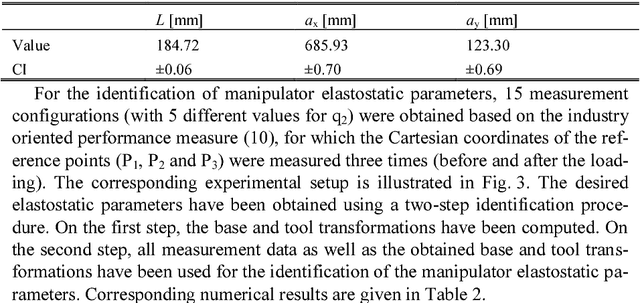

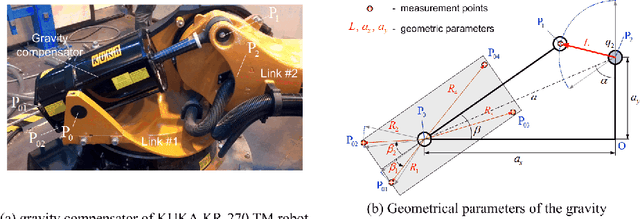

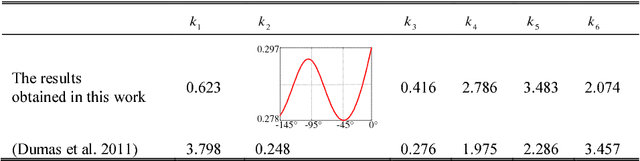

Abstract:The paper is devoted to the accuracy improvement of robot-based milling by using an enhanced manipulator model that takes into account both geometric and elastostatic factors. Particular attention is paid to the model parameters identification accuracy. In contrast to other works, the proposed approach takes into account impact of the gravity compensator and link weights on the manipulator elastostatic properties. In order to improve the identification accuracy, the industry oriented performance measure is used to define optimal measurement configurations and an enhanced partial pose measurement method is applied for the identification of the model parameters. The advantages of the developed approach are confirmed by experimental results that deal with the elastostatic calibration of a heavy industrial robot used for milling. The achieved accuracy improvement factor is about 2.4.

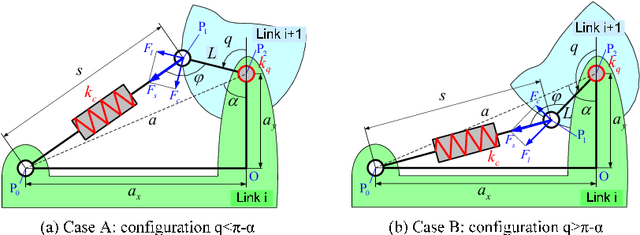

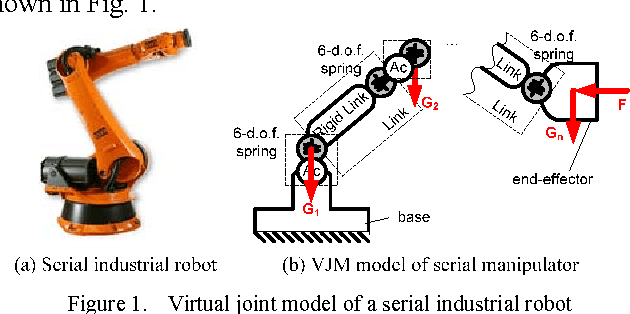

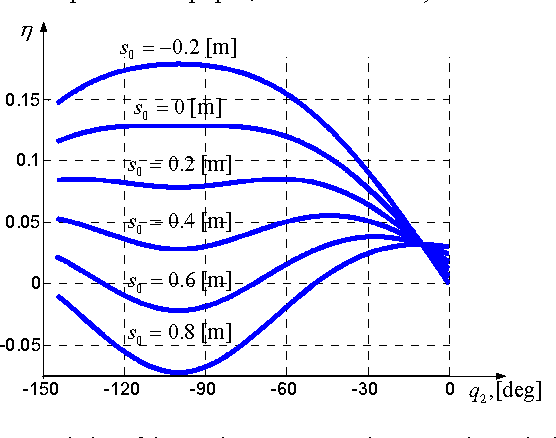

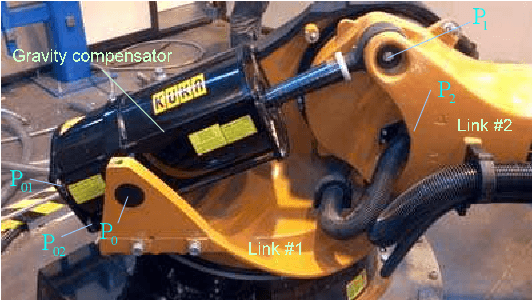

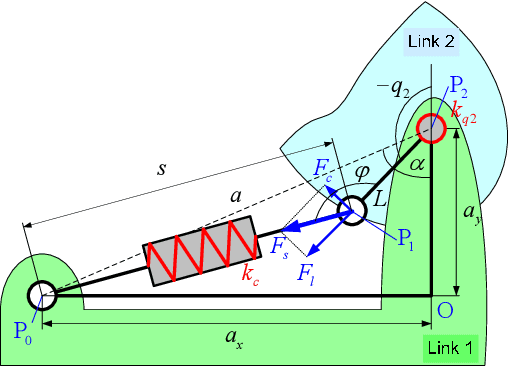

Stiffness modeling of robotic manipulator with gravity compensator

Nov 26, 2013

Abstract:The paper focuses on the stiffness modeling of robotic manipulators with gravity compensators. The main attention is paid to the development of the stiffness model of a spring-based compensator located between sequential links of a serial structure. The derived model allows us to describe the compensator as an equivalent non-linear virtual spring integrated in the corresponding actuated joint. The obtained results have been efficiently applied to the stiffness modeling of a heavy industrial robot of the Kuka family.

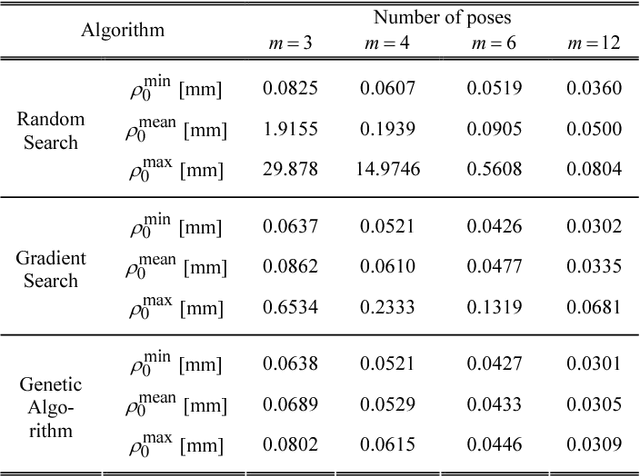

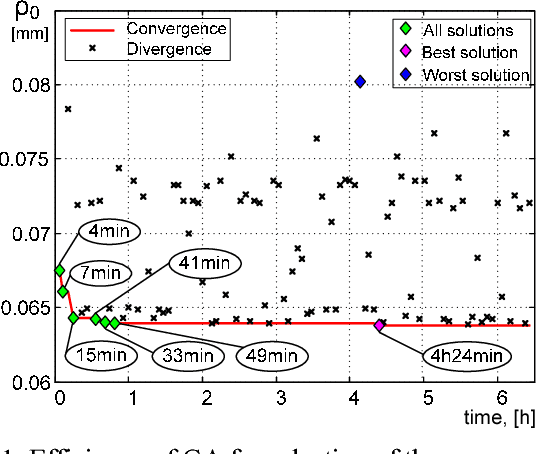

Identification of geometrical and elastostatic parameters of heavy industrial robots

Nov 26, 2013

Abstract:The paper focuses on the stiffness modeling of heavy industrial robots with gravity compensators. The main attention is paid to the identification of geometrical and elastostatic parameters and calibration accuracy. To reduce impact of the measurement errors, the set of manipulator configurations for calibration experiments is optimized with respect to the proposed performance measure related to the end-effector position accuracy. Experimental results are presented that illustrate the advantages of the developed technique.

* arXiv admin note: substantial text overlap with arXiv:1311.6674

Advanced robot calibration using partial pose measurements

Nov 26, 2013

Abstract:The paper focuses on the calibration of serial industrial robots using partial pose measurements. In contrast to other works, the developed advanced robot calibration technique is suitable for geometrical and elastostatic calibration. The main attention is paid to the model parameters identification accuracy. To reduce the impact of measurement errors, it is proposed to use directly position measurements of several points instead of computing orientation of the end-effector. The proposed approach allows us to avoid the problem of non-homogeneity of the least-square objective, which arises in the classical identification technique with the full-pose information. The developed technique does not require any normalization and can be efficiently applied both for geometric and elastostatic identification. The advantages of a new approach are confirmed by comparison analysis that deals with the efficiency evaluation of different identification strategies. The obtained results have been successfully applied to the elastostatic parameters identification of the industrial robot employed in a machining work-cell for aerospace industry.

Robust algorithm for calibration of robotic manipulator model

Nov 26, 2013

Abstract:The paper focuses on the robust identification of geometrical and elastostatic parameters of robotic manipulator. The main attention is paid to the efficiency improvement of the identification algorithm. To increase the identification accuracy, it is proposed to apply the weighted least square technique that employs a new algorithm for assigning of the weighting coefficients. The latter allows taking into account variation of the measurement system precision in different directions and throughout the robot workspace. The advantages of the proposed approach are illustrated by an application example that deals with the elasto-static calibration of industrial robot.

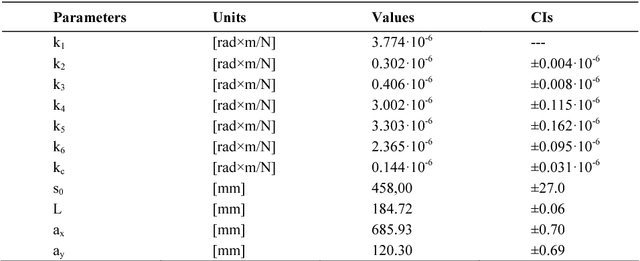

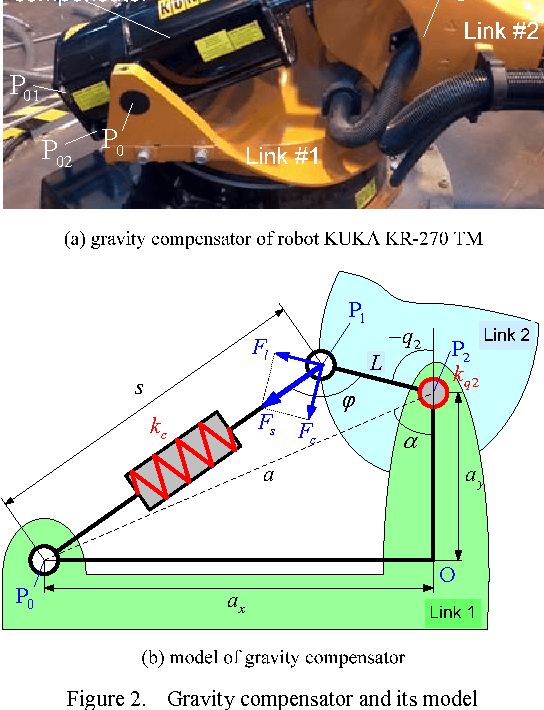

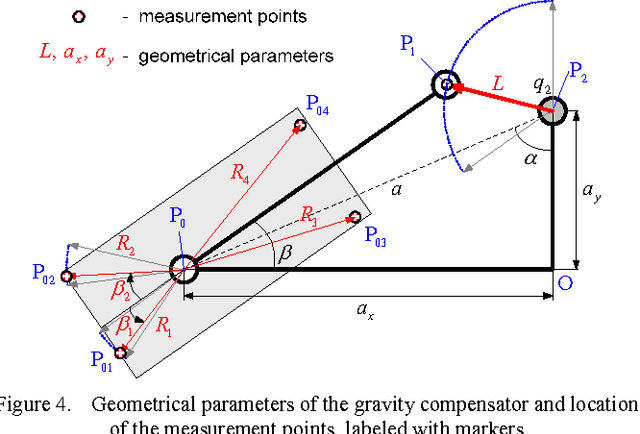

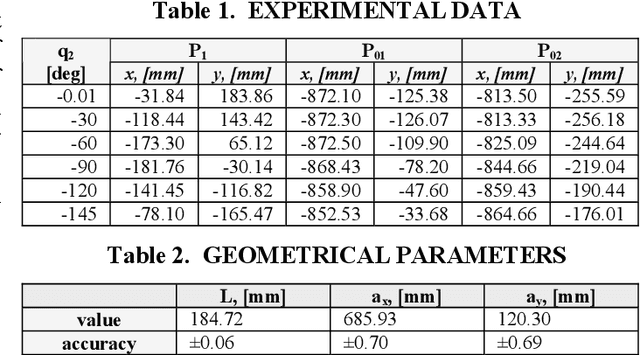

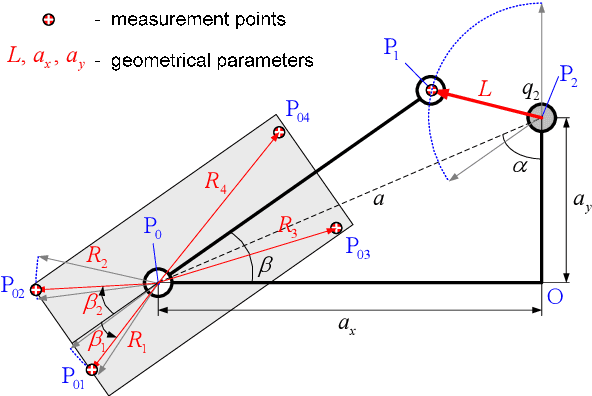

Modelling of the gravity compensators in robotic manufacturing cells

Nov 26, 2013

Abstract:The paper deals with the modeling and identification of the gravity compensators used in heavy industrial robots. The main attention is paid to the geometrical parameters identification and calibration accuracy. To reduce impact of the measurement errors, the design of calibration experiments is used. The advantages of the developed technique are illustrated by experimental results

Efficiency Improvement of Measurement Pose Selection Techniques in Robot Calibration

Nov 26, 2013

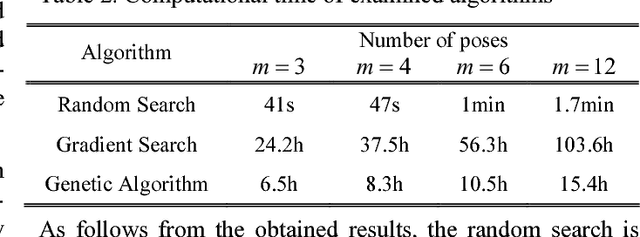

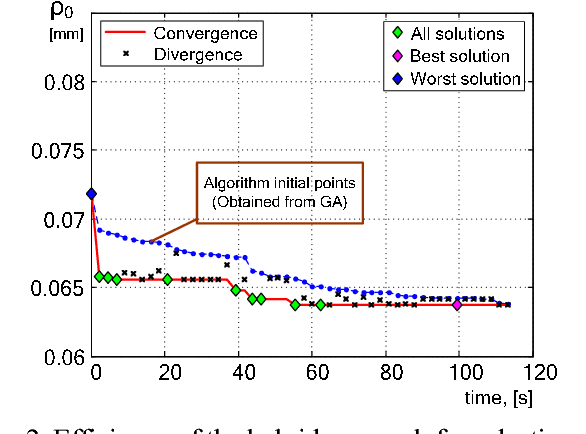

Abstract:The paper deals with the design of experiments for manipulator geometric and elastostatic calibration based on the test-pose approach. The main attention is paid to the efficiency improvement of numerical techniques employed in the selection of optimal measurement poses for calibration experiments. The advantages of the developed technique are illustrated by simulation examples that deal with the geometric calibration of the industrial robot of serial architecture.

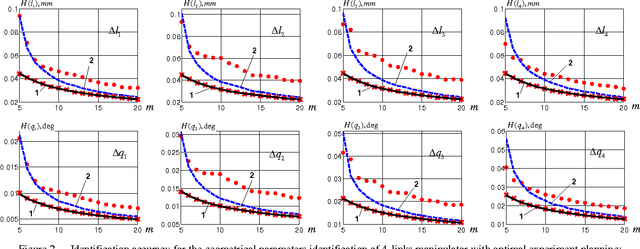

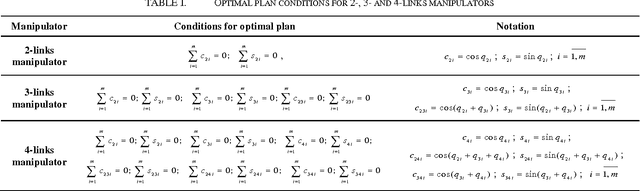

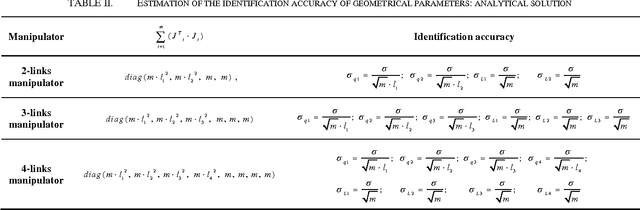

Design of Experiments for Calibration of Planar Anthropomorphic Manipulators

Dec 03, 2012

Abstract:The paper presents a novel technique for the design of optimal calibration experiments for a planar anthropomorphic manipulator with n degrees of freedom. Proposed approach for selection of manipulator configurations allows essentially improving calibration accuracy and reducing parameter identification errors. The results are illustrated by application examples that deal with typical anthropomorphic manipulators.

Industry-oriented Performance Measures for Design of Robot Calibration Experiment

Nov 25, 2012

Abstract:The paper focuses on the accuracy improvement of geometric and elasto-static calibration of industrial robots. It proposes industry-oriented performance measures for the calibration experiment design. They are based on the concept of manipulator test-pose and referred to the end-effector location accuracy after application of the error compensation algorithm, which implements the identified parameters. This approach allows the users to define optimal measurement configurations for robot calibration for given work piece location and machining forces/torques. These performance measures are suitable for comparing the calibration plans for both simple and complex trajectories to be performed. The advantages of the developed techniques are illustrated by an example that deals with machining using robotic manipulator.

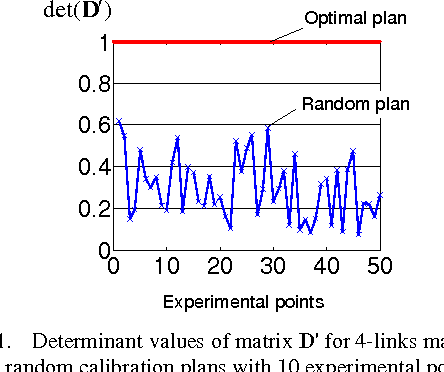

Optimization of measurement configurations for geometrical calibration of industrial robot

Nov 25, 2012

Abstract:The paper is devoted to the geometrical calibration of industrial robots employed in precise manufacturing. To identify geometric parameters, an advanced calibration technique is proposed that is based on the non-linear experiment design theory, which is adopted for this particular application. In contrast to previous works, the calibration experiment quality is evaluated using a concept of the user-defined test-pose. In the frame of this concept, the related optimization problem is formulated and numerical routines are developed, which allow user to generate optimal set of manipulator configurations for a given number of calibration experiments. The efficiency of the developed technique is illustrated by several examples.

* arXiv admin note: text overlap with arXiv:1211.6101

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge