Mahla Nejati

Pallet Detection And Localisation From Synthetic Data

Mar 29, 2025Abstract:The global warehousing industry is experiencing rapid growth, with the market size projected to grow at an annual rate of 8.1% from 2024 to 2030 [Grand View Research, 2021]. This expansion has led to a surge in demand for efficient pallet detection and localisation systems. While automation can significantly streamline warehouse operations, the development of such systems often requires extensive manual data annotation, with an average of 35 seconds per image, for a typical computer vision project. This paper presents a novel approach to enhance pallet detection and localisation using purely synthetic data and geometric features derived from their side faces. By implementing a domain randomisation engine in Unity, the need for time-consuming manual annotation is eliminated while achieving high-performance results. The proposed method demonstrates a pallet detection performance of 0.995 mAP50 for single pallets on a real-world dataset. Additionally, an average position accuracy of less than 4.2 cm and an average rotation accuracy of 8.2{\deg} were achieved for pallets within a 5-meter range, with the pallet positioned head-on.

Detection of Spider Mites on Labrador Beans through Machine Learning Approaches Using Custom Datasets

Feb 12, 2024

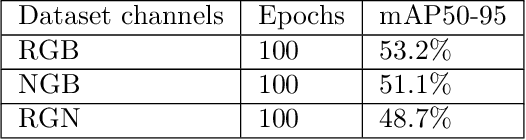

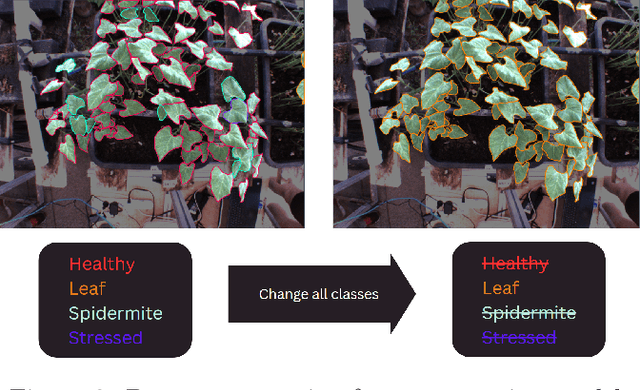

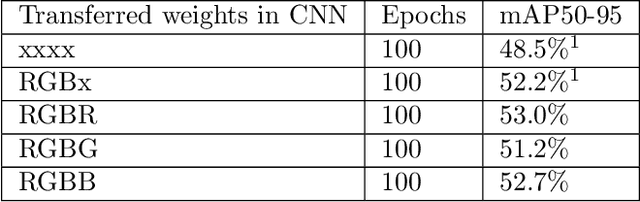

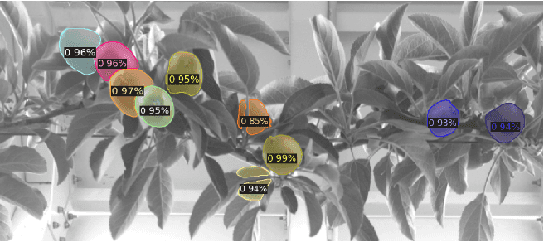

Abstract:Amidst growing food production demands, early plant disease detection is essential to safeguard crops; this study proposes a visual machine learning approach for plant disease detection, harnessing RGB and NIR data collected in real-world conditions through a JAI FS-1600D-10GE camera to build an RGBN dataset. A two-stage early plant disease detection model with YOLOv8 and a sequential CNN was used to train on a dataset with partial labels, which showed a 3.6% increase in mAP compared to a single-stage end-to-end segmentation model. The sequential CNN model achieved 90.62% validation accuracy utilising RGBN data. An average of 6.25% validation accuracy increase is found using RGBN in classification compared to RGB using ResNet15 and the sequential CNN models. Further research and dataset improvements are needed to meet food production demands.

Does ChatGPT and Whisper Make Humanoid Robots More Relatable?

Feb 11, 2024Abstract:Humanoid robots are designed to be relatable to humans for applications such as customer support and helpdesk services. However, many such systems, including Softbank's Pepper, fall short because they fail to communicate effectively with humans. The advent of Large Language Models (LLMs) shows the potential to solve the communication barrier for humanoid robotics. This paper outlines the comparison of different Automatic Speech Recognition (ASR) APIs, the integration of Whisper ASR and ChatGPT with the Pepper robot and the evaluation of the system (Pepper-GPT) tested by 15 human users. The comparison result shows that, compared to the Google ASR and Google Cloud ASR, the Whisper ASR performed best as its average Word Error Rate (1.716%) and processing time (2.639 s) are both the lowest. The participants' usability investigations show that 60% of the participants thought the performance of the Pepper-GPT was "excellent", while the rest rated this system as "good" in the subsequent experiments. It is proved that while some problems still need to be overcome, such as the robot's multilingual ability and facial tracking capacity, users generally responded positively to the system, feeling like talking to an actual human.

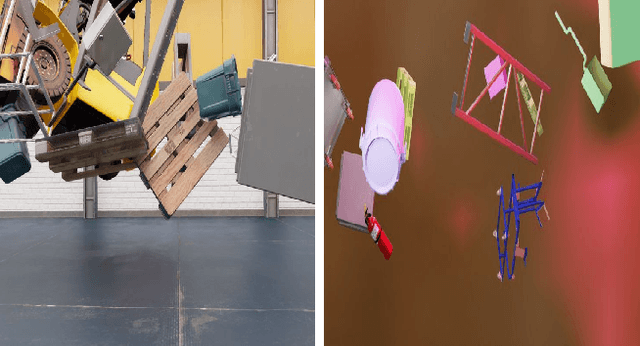

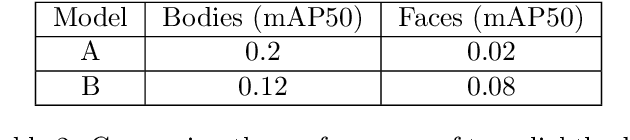

Improving Pallet Detection Using Synthetic Data

Feb 11, 2024

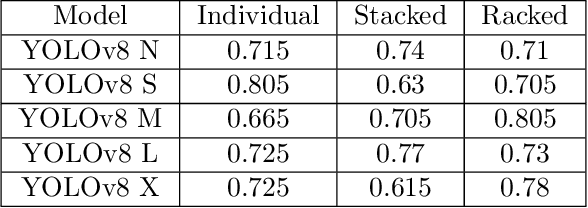

Abstract:The use of synthetic data in machine learning saves a significant amount of time when implementing an effective object detector. However, there is limited research in this domain. This study aims to improve upon previously applied implementations in the task of instance segmentation of pallets in a warehouse environment. This study proposes using synthetically generated domain-randomised data as well as data generated through Unity to achieve this. This study achieved performance improvements on the stacked and racked pallet categories by 69% and 50% mAP50, respectively when being evaluated on real data. Additionally, it was found that there was a considerable impact on the performance of a model when it was evaluated against images in a darker environment, dropping as low as 3% mAP50 when being evaluated on images with an 80% brightness reduction. This study also created a two-stage detector that used YOLOv8 and SAM, but this proved to have unstable performance. The use of domain-randomised data proved to have negligible performance improvements when compared to the Unity-generated data.

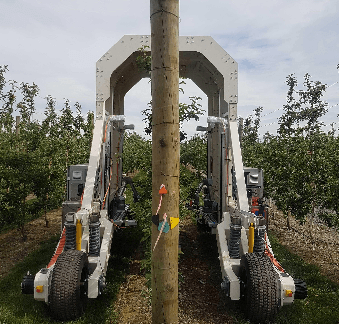

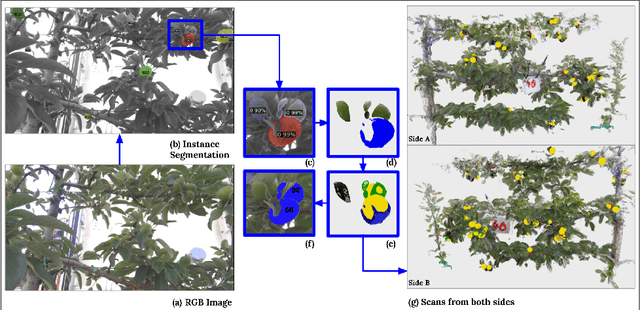

Seeing the Fruit for the Leaves: Robotically Mapping Apple Fruitlets in a Commercial Orchard

Aug 15, 2023

Abstract:Aotearoa New Zealand has a strong and growing apple industry but struggles to access workers to complete skilled, seasonal tasks such as thinning. To ensure effective thinning and make informed decisions on a per-tree basis, it is crucial to accurately measure the crop load of individual apple trees. However, this task poses challenges due to the dense foliage that hides the fruitlets within the tree structure. In this paper, we introduce the vision system of an automated apple fruitlet thinning robot, developed to tackle the labor shortage issue. This paper presents the initial design, implementation,and evaluation specifics of the system. The platform straddles the 3.4 m tall 2D apple canopy structures to create an accurate map of the fruitlets on each tree. We show that this platform can measure the fruitlet load on an apple tree by scanning through both sides of the branch. The requirement of an overarching platform was justified since two-sided scans had a higher counting accuracy of 81.17 % than one-sided scans at 73.7 %. The system was also demonstrated to produce size estimates within 5.9% RMSE of their true size.

Visual based Tomato Size Measurement System for an Indoor Farming Environment

Apr 12, 2023

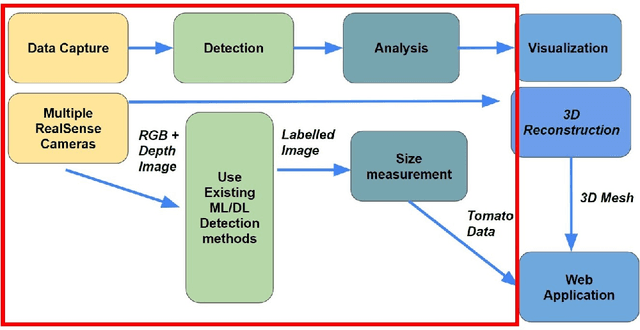

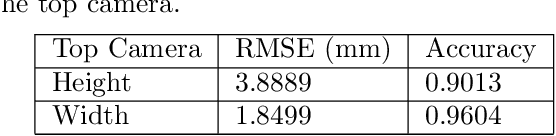

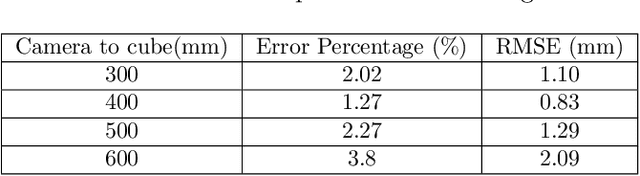

Abstract:As technology progresses, smart automated systems will serve an increasingly important role in the agricultural industry. Current existing vision systems for yield estimation face difficulties in occlusion and scalability as they utilize a camera system that is large and expensive, which are unsuitable for orchard environments. To overcome these problems, this paper presents a size measurement method combining a machine learning model and depth images captured from three low cost RGBD cameras to detect and measure the height and width of tomatoes. The performance of the presented system is evaluated on a lab environment with real tomato fruits and fake leaves to simulate occlusion in the real farm environment. To improve accuracy by addressing fruit occlusion, our three-camera system was able to achieve a height measurement accuracy of 0.9114 and a width accuracy of 0.9443.

Look how they have grown: Non-destructive Leaf Detection and Size Estimation of Tomato Plants for 3D Growth Monitoring

Apr 07, 2023

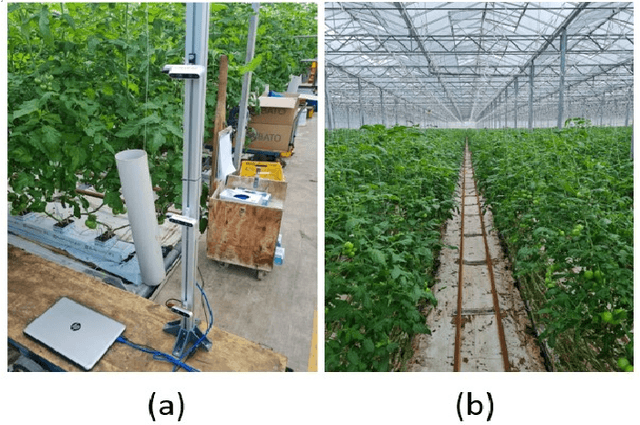

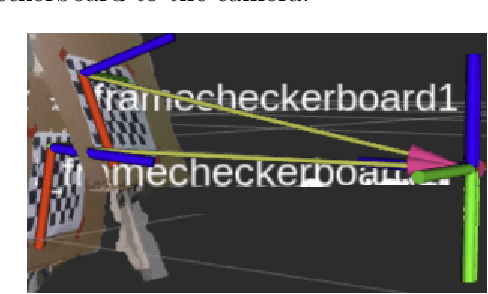

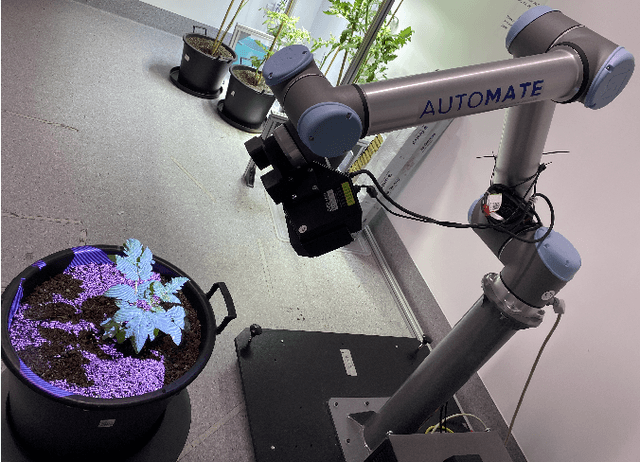

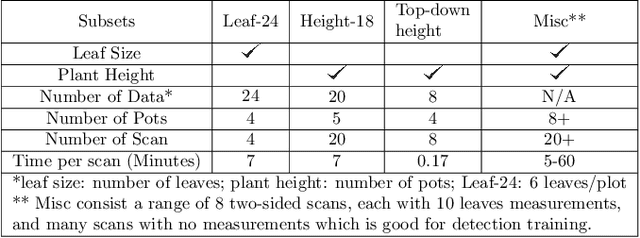

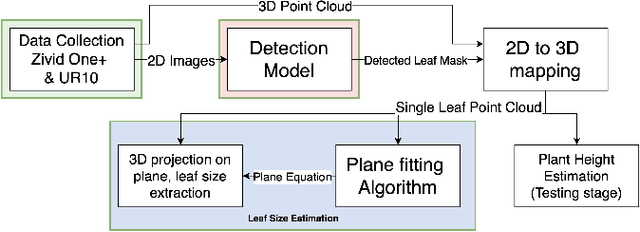

Abstract:Smart farming is a growing field as technology advances. Plant characteristics are crucial indicators for monitoring plant growth. Research has been done to estimate characteristics like leaf area index, leaf disease, and plant height. However, few methods have been applied to non-destructive measurements of leaf size. In this paper, an automated non-destructive imaged-based measuring system is presented, which uses 2D and 3D data obtained using a Zivid 3D camera, creating 3D virtual representations (digital twins) of the tomato plants. Leaves are detected from corresponding 2D RGB images and mapped to their 3D point cloud using the detected leaf masks, which then pass the leaf point cloud to the plane fitting algorithm to extract the leaf size to provide data for growth monitoring. The performance of the measurement platform has been measured through a comprehensive trial on real-world tomato plants with quantified performance metrics compared to ground truth measurements. Three tomato leaf and height datasets (including 50+ 3D point cloud files of tomato plants) were collected and open-sourced in this project. The proposed leaf size estimation method demonstrates an RMSE value of 4.47mm and an R^2 value of 0.87. The overall measurement system (leaf detection and size estimation algorithms combine) delivers an RMSE value of 8.13mm and an R^2 value of 0.899.

* 10 Pages, 10 Figures

Pallet Detection from Synthetic Data Using Game Engines

Apr 07, 2023Abstract:This research sets out to assess the viability of using game engines to generate synthetic training data for machine learning in the context of pallet segmentation. Using synthetic data has been proven in prior research to be a viable means of training neural networks and saves hours of manual labour due to the reduced need for manual image annotation. Machine vision for pallet detection can benefit from synthetic data as the industry increases the development of autonomous warehousing technologies. As per our methodology, we developed a tool capable of automatically generating large amounts of annotated training data from 3D models at pixel-perfect accuracy and a much faster rate than manual approaches. Regarding image segmentation, a Mask R-CNN pipeline was used, which achieved an AP50 of 86% for individual pallets.

* 9 Pages, 10 Figures

Seeing the Fruit for the Leaves: Towards Automated Apple Fruitlet Thinning

Feb 20, 2023

Abstract:Following a global trend, the lack of reliable access to skilled labour is causing critical issues for the effective management of apple orchards. One of the primary challenges is maintaining skilled human operators capable of making precise fruitlet thinning decisions. Thinning requires accurately measuring the true crop load for individual apple trees to provide optimal thinning decisions on an individual basis. A challenging task due to the dense foliage obscuring the fruitlets within the tree structure. This paper presents the initial design, implementation, and evaluation details of the vision system for an automatic apple fruitlet thinning robot to meet this need. The platform consists of a UR5 robotic arm and stereo cameras which enable it to look around the leaves to map the precise number and size of the fruitlets on the apple branches. We show that this platform can measure the fruitlet load on the apple tree to with 84% accuracy in a real-world commercial apple orchard while being 87% precise.

Kiwifruit detection in challenging conditions

Jun 21, 2020

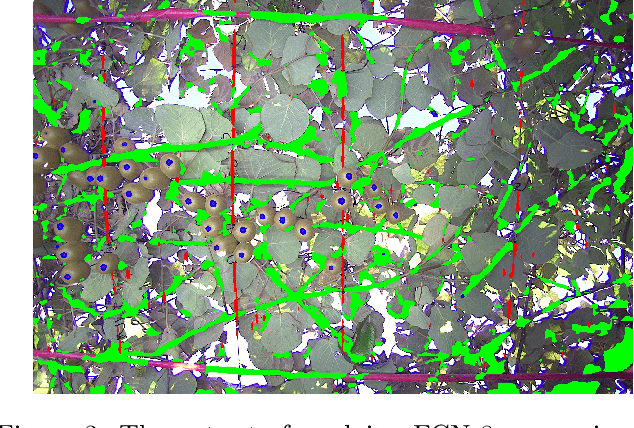

Abstract:Accurate and reliable kiwifruit detection is one of the biggest challenges in developing a selective fruit harvesting robot. The vision system of an orchard robot faces difficulties such as dynamic lighting conditions and fruit occlusions. This paper presents a semantic segmentation approach with two novel image prepossessing techniques designed to detect kiwifruit under the harsh lighting conditions found in the canopy. The performance of the presented system is evaluated on a 3D real-world image set of kiwifruit under different lighting conditions (typical, glare, and overexposed). Alone the semantic segmentation approach achieves an F1_score of 0.82 on the typical lighting image set, but struggles with harsh lighting with an F1_score of 0.13. Utilising the prepossessing techniques the vision system under harsh lighting improves to an F1_score 0.42. To address the fruit occlusion challenge, the overall approach was found to be capable of detecting 87.0% of non-occluded and 30.0% of occluded kiwifruit across all lighting conditions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge