Levent Burak Kara

FlowSSC: Universal Generative Monocular Semantic Scene Completion via One-Step Latent Diffusion

Jan 21, 2026Abstract:Semantic Scene Completion (SSC) from monocular RGB images is a fundamental yet challenging task due to the inherent ambiguity of inferring occluded 3D geometry from a single view. While feed-forward methods have made progress, they often struggle to generate plausible details in occluded regions and preserve the fundamental spatial relationships of objects. Such accurate generative reasoning capability for the entire 3D space is critical in real-world applications. In this paper, we present FlowSSC, the first generative framework applied directly to monocular semantic scene completion. FlowSSC treats the SSC task as a conditional generation problem and can seamlessly integrate with existing feed-forward SSC methods to significantly boost their performance. To achieve real-time inference without compromising quality, we introduce Shortcut Flow-matching that operates in a compact triplane latent space. Unlike standard diffusion models that require hundreds of steps, our method utilizes a shortcut mechanism to achieve high-fidelity generation in a single step, enabling practical deployment in autonomous systems. Extensive experiments on SemanticKITTI demonstrate that FlowSSC achieves state-of-the-art performance, significantly outperforming existing baselines.

FLARE: Fast Low-rank Attention Routing Engine

Aug 18, 2025

Abstract:The quadratic complexity of self-attention limits its applicability and scalability on large unstructured meshes. We introduce Fast Low-rank Attention Routing Engine (FLARE), a linear complexity self-attention mechanism that routes attention through fixed-length latent sequences. Each attention head performs global communication among $N$ tokens by projecting the input sequence onto a fixed length latent sequence of $M \ll N$ tokens using learnable query tokens. By routing attention through a bottleneck sequence, FLARE learns a low-rank form of attention that can be applied at $O(NM)$ cost. FLARE not only scales to unprecedented problem sizes, but also delivers superior accuracy compared to state-of-the-art neural PDE surrogates across diverse benchmarks. We also release a new additive manufacturing dataset to spur further research. Our code is available at https://github.com/vpuri3/FLARE.py.

Attention to Detail: Fine-Scale Feature Preservation-Oriented Geometric Pre-training for AI-Driven Surrogate Modeling

Apr 27, 2025

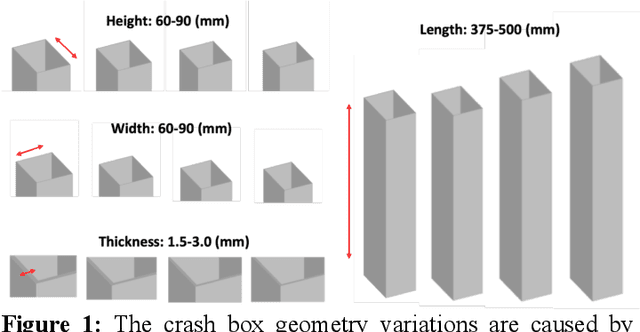

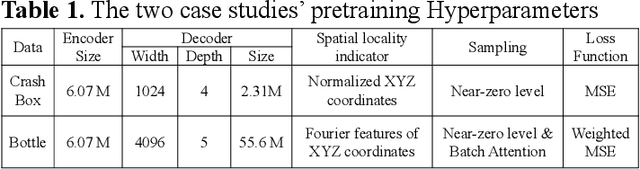

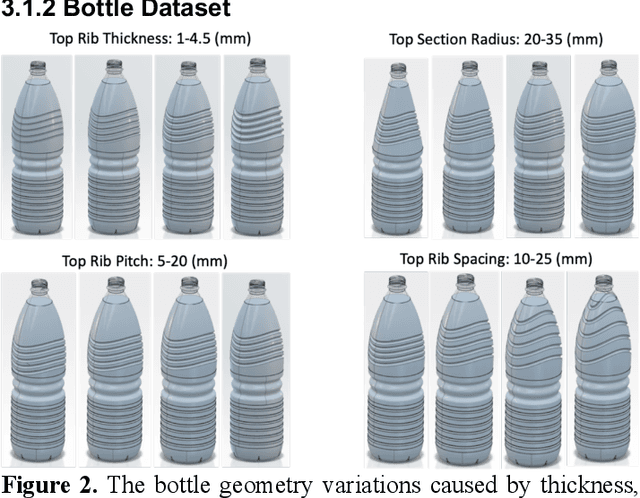

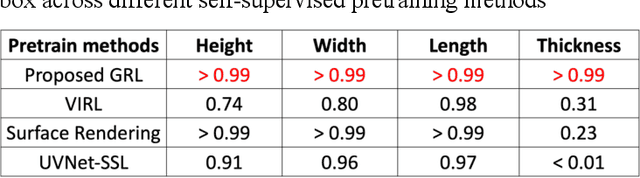

Abstract:AI-driven surrogate modeling has become an increasingly effective alternative to physics-based simulations for 3D design, analysis, and manufacturing. These models leverage data-driven methods to predict physical quantities traditionally requiring computationally expensive simulations. However, the scarcity of labeled CAD-to-simulation datasets has driven recent advancements in self-supervised and foundation models, where geometric representation learning is performed offline and later fine-tuned for specific downstream tasks. While these approaches have shown promise, their effectiveness is limited in applications requiring fine-scale geometric detail preservation. This work introduces a self-supervised geometric representation learning method designed to capture fine-scale geometric features from non-parametric 3D models. Unlike traditional end-to-end surrogate models, this approach decouples geometric feature extraction from downstream physics tasks, learning a latent space embedding guided by geometric reconstruction losses. Key elements include the essential use of near-zero level sampling and the innovative batch-adaptive attention-weighted loss function, which enhance the encoding of intricate design features. The proposed method is validated through case studies in structural mechanics, demonstrating strong performance in capturing design features and enabling accurate few-shot physics predictions. Comparisons with traditional parametric surrogate modeling highlight its potential to bridge the gap between geometric and physics-based representations, providing an effective solution for surrogate modeling in data-scarce scenarios.

MDDM: A Molecular Dynamics Diffusion Model to Predict Particle Self-Assembly

Jan 28, 2025

Abstract:The discovery and study of new material systems relies on molecular simulations that often come with significant computational expense. We propose MDDM, a Molecular Dynamics Diffusion Model, which is capable of predicting a valid output conformation for a given input pair potential function. After training MDDM on a large dataset of molecular dynamics self-assembly results, the proposed model can convert uniform noise into a meaningful output particle structure corresponding to an arbitrary input potential. The model's architecture has domain-specific properties built-in, such as satisfying periodic boundaries and being invariant to translation. The model significantly outperforms the baseline point-cloud diffusion model for both unconditional and conditional generation tasks.

Topology-Agnostic Graph U-Nets for Scalar Field Prediction on Unstructured Meshes

Oct 08, 2024

Abstract:Machine-learned surrogate models to accelerate lengthy computer simulations are becoming increasingly important as engineers look to streamline the product design cycle. In many cases, these approaches offer the ability to predict relevant quantities throughout a geometry, but place constraints on the form of the input data. In a world of diverse data types, a preferred approach would not restrict the input to a particular structure. In this paper, we propose Topology-Agnostic Graph U-Net (TAG U-Net), a graph convolutional network that can be trained to input any mesh or graph structure and output a prediction of a target scalar field at each node. The model constructs coarsened versions of each input graph and performs a set of convolution and pooling operations to predict the node-wise outputs on the original graph. By training on a diverse set of shapes, the model can make strong predictions, even for shapes unlike those seen during training. A 3-D additive manufacturing dataset is presented, containing Laser Powder Bed Fusion simulation results for thousands of parts. The model is demonstrated on this dataset, and it performs well, predicting both 2-D and 3-D scalar fields with a median R-squared > 0.85 on test geometries. Code and datasets are available online.

Scalar Field Prediction on Meshes Using Interpolated Multi-Resolution Convolutional Neural Networks

Oct 07, 2024Abstract:Scalar fields, such as stress or temperature fields, are often calculated in shape optimization and design problems in engineering. For complex problems where shapes have varying topology and cannot be parametrized, data-driven scalar field prediction can be faster than traditional finite element methods. However, current data-driven techniques to predict scalar fields are limited to a fixed grid domain, instead of arbitrary mesh structures. In this work, we propose a method to predict scalar fields on arbitrary meshes. It uses a convolutional neural network whose feature maps at multiple resolutions are interpolated to node positions before being fed into a multilayer perceptron to predict solutions to partial differential equations at mesh nodes. The model is trained on finite element von Mises stress fields, and once trained it can estimate stress values at each node on any input mesh. Two shape datasets are investigated, and the model has strong performance on both, with a median R-squared value of 0.91. We also demonstrate the model on a temperature field in a heat conduction problem, where its predictions have a median R-squared value of 0.99. Our method provides a potential flexible alternative to finite element analysis in engineering design contexts. Code and datasets are available online.

Multi-scale Topology Optimization using Neural Networks

Apr 11, 2024Abstract:A long-standing challenge is designing multi-scale structures with good connectivity between cells while optimizing each cell to reach close to the theoretical performance limit. We propose a new method for direct multi-scale topology optimization using neural networks. Our approach focuses on inverse homogenization that seamlessly maintains compatibility across neighboring microstructure cells. Our approach consists of a topology neural network that optimizes the microstructure shape and distribution across the design domain as a continuous field. Each microstructure cell is optimized based on a specified elasticity tensor that also accommodates in-plane rotations. The neural network takes as input the local coordinates within a cell to represent the density distribution within a cell, as well as the global coordinates of each cell to design spatially varying microstructure cells. As such, our approach models an n-dimensional multi-scale optimization problem as a 2n-dimensional inverse homogenization problem using neural networks. During the inverse homogenization of each unit cell, we extend the boundary of each cell by scaling the input coordinates such that the boundaries of neighboring cells are combined. Inverse homogenization on the combined cell improves connectivity. We demonstrate our method through the design and optimization of graded multi-scale structures.

Automating Style Analysis and Visualization With Explainable AI -- Case Studies on Brand Recognition

Jun 05, 2023Abstract:Incorporating style-related objectives into shape design has been centrally important to maximize product appeal. However, stylistic features such as aesthetics and semantic attributes are hard to codify even for experts. As such, algorithmic style capture and reuse have not fully benefited from automated data-driven methodologies due to the challenging nature of design describability. This paper proposes an AI-driven method to fully automate the discovery of brand-related features. Our approach introduces BIGNet, a two-tier Brand Identification Graph Neural Network (GNN) to classify and analyze scalar vector graphics (SVG). First, to tackle the scarcity of vectorized product images, this research proposes two data acquisition workflows: parametric modeling from small curve-based datasets, and vectorization from large pixel-based datasets. Secondly, this study constructs a novel hierarchical GNN architecture to learn from both SVG's curve-level and chunk-level parameters. In the first case study, BIGNet not only classifies phone brands but also captures brand-related features across multiple scales, such as the location of the lens, the height-width ratio, and the screen-frame gap, as confirmed by AI evaluation. In the second study, this paper showcases the generalizability of BIGNet learning from a vectorized car image dataset and validates the consistency and robustness of its predictions given four scenarios. The results match the difference commonly observed in luxury vs. economy brands in the automobile market. Finally, this paper also visualizes the activation maps generated from a convolutional neural network and shows BIGNet's advantage of being a more human-friendly, explainable, and explicit style-capturing agent. Code and dataset can be found on Github: 1. Phone case study: github.com/parksandrecfan/bignet-phone 2. Car case study: github.com/parksandrecfan/bignet-car

Topology Optimization using Neural Networks with Conditioning Field Initialization for Improved Efficiency

May 17, 2023Abstract:We propose conditioning field initialization for neural network based topology optimization. In this work, we focus on (1) improving upon existing neural network based topology optimization, (2) demonstrating that by using a prior initial field on the unoptimized domain, the efficiency of neural network based topology optimization can be further improved. Our approach consists of a topology neural network that is trained on a case by case basis to represent the geometry for a single topology optimization problem. It takes in domain coordinates as input to represent the density at each coordinate where the topology is represented by a continuous density field. The displacement is solved through a finite element solver. We employ the strain energy field calculated on the initial design domain as an additional conditioning field input to the neural network throughout the optimization. The addition of the strain energy field input improves the convergence speed compared to standalone neural network based topology optimization.

DMF-TONN: Direct Mesh-free Topology Optimization using Neural Networks

May 06, 2023

Abstract:We propose a direct mesh-free method for performing topology optimization by integrating a density field approximation neural network with a displacement field approximation neural network. We show that this direct integration approach can give comparable results to conventional topology optimization techniques, with an added advantage of enabling seamless integration with post-processing software, and a potential of topology optimization with objectives where meshing and Finite Element Analysis (FEA) may be expensive or not suitable. Our approach (DMF-TONN) takes in as inputs the boundary conditions and domain coordinates and finds the optimum density field for minimizing the loss function of compliance and volume fraction constraint violation. The mesh-free nature is enabled by a physics-informed displacement field approximation neural network to solve the linear elasticity partial differential equation and replace the FEA conventionally used for calculating the compliance. We show that using a suitable Fourier Features neural network architecture and hyperparameters, the density field approximation neural network can learn the weights to represent the optimal density field for the given domain and boundary conditions, by directly backpropagating the loss gradient through the displacement field approximation neural network, and unlike prior work there is no requirement of a sensitivity filter, optimality criterion method, or a separate training of density network in each topology optimization iteration.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge