Yenan Chen

Disambiguate Gripper State in Grasp-Based Tasks: Pseudo-Tactile as Feedback Enables Pure Simulation Learning

Mar 31, 2025Abstract:Grasp-based manipulation tasks are fundamental to robots interacting with their environments, yet gripper state ambiguity significantly reduces the robustness of imitation learning policies for these tasks. Data-driven solutions face the challenge of high real-world data costs, while simulation data, despite its low costs, is limited by the sim-to-real gap. We identify the root cause of gripper state ambiguity as the lack of tactile feedback. To address this, we propose a novel approach employing pseudo-tactile as feedback, inspired by the idea of using a force-controlled gripper as a tactile sensor. This method enhances policy robustness without additional data collection and hardware involvement, while providing a noise-free binary gripper state observation for the policy and thus facilitating pure simulation learning to unleash the power of simulation. Experimental results across three real-world grasp-based tasks demonstrate the necessity, effectiveness, and efficiency of our approach.

Evolutionary Morphology Towards Overconstrained Locomotion via Large-Scale, Multi-Terrain Deep Reinforcement Learning

Jul 01, 2024

Abstract:While the animals' Fin-to-Limb evolution has been well-researched in biology, such morphological transformation remains under-adopted in the modern design of advanced robotic limbs. This paper investigates a novel class of overconstrained locomotion from a design and learning perspective inspired by evolutionary morphology, aiming to integrate the concept of `intelligent design under constraints' - hereafter referred to as constraint-driven design intelligence - in developing modern robotic limbs with superior energy efficiency. We propose a 3D-printable design of robotic limbs parametrically reconfigurable as a classical planar 4-bar linkage, an overconstrained Bennett linkage, and a spherical 4-bar linkage. These limbs adopt a co-axial actuation, identical to the modern legged robot platforms, with the added capability of upgrading into a wheel-legged system. Then, we implemented a large-scale, multi-terrain deep reinforcement learning framework to train these reconfigurable limbs for a comparative analysis of overconstrained locomotion in energy efficiency. Results show that the overconstrained limbs exhibit more efficient locomotion than planar limbs during forward and sideways walking over different terrains, including floors, slopes, and stairs, with or without random noises, by saving at least 22% mechanical energy in completing the traverse task, with the spherical limbs being the least efficient. It also achieves the highest average speed of 0.85 meters per second on flat terrain, which is 20% faster than the planar limbs. This study paves the path for an exciting direction for future research in overconstrained robotics leveraging evolutionary morphology and reconfigurable mechanism intelligence when combined with state-of-the-art methods in deep reinforcement learning.

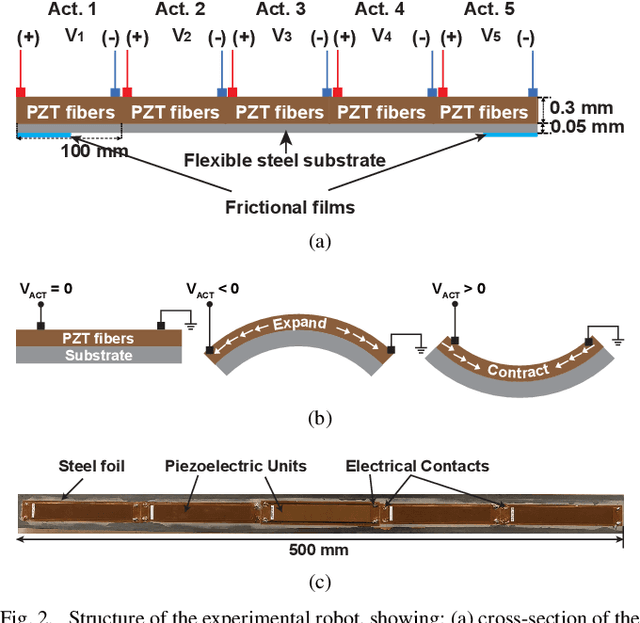

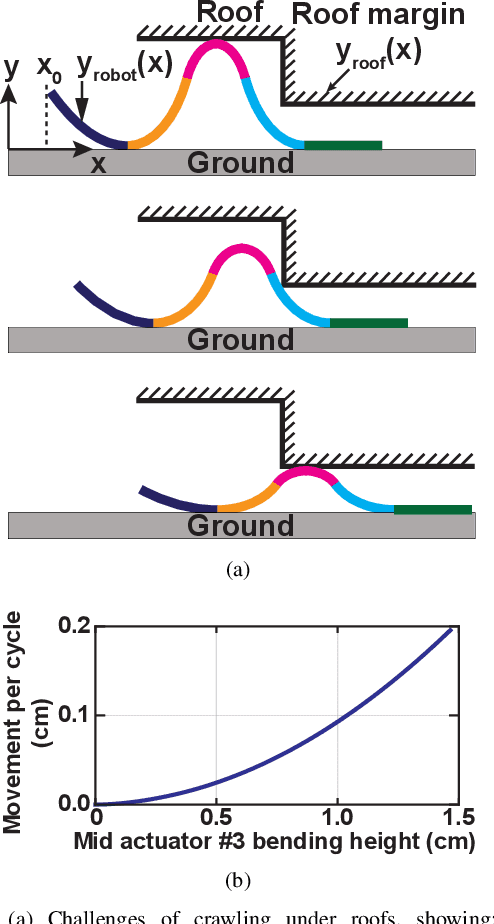

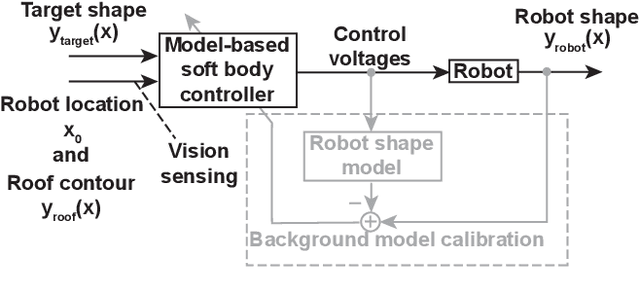

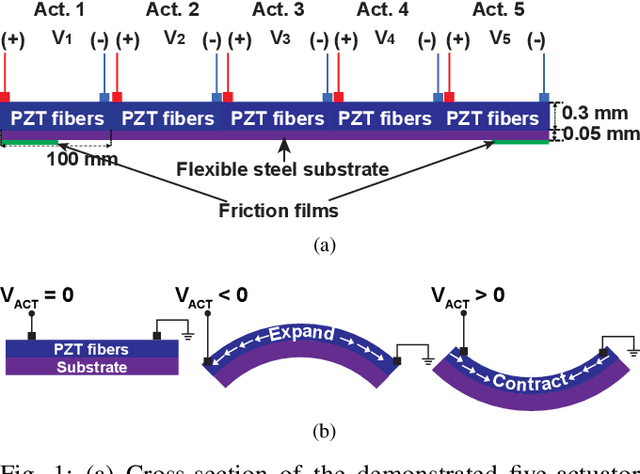

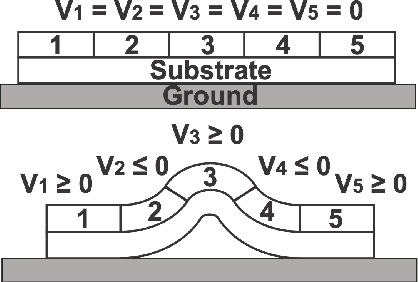

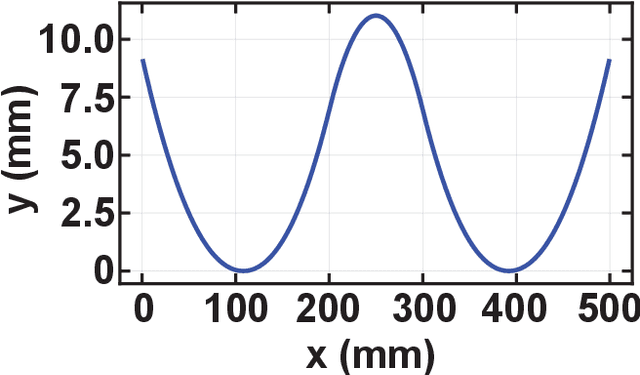

Model-Based Control of Planar Piezoelectric Inchworm Soft Robot for Crawling in Constrained Environments

Mar 29, 2022

Abstract:Soft robots have drawn significant attention recently for their ability to achieve rich shapes when interacting with complex environments. However, their elasticity and flexibility compared to rigid robots also pose significant challenges for precise and robust shape control in real-time. Motivated by their potential to operate in highly-constrained environments, as in search-and-rescue operations, this work addresses these challenges of soft robots by developing a model-based full-shape controller, validated and demonstrated by experiments. A five-actuator planar soft robot was constructed with planar piezoelectric layers bonded to a steel foil substrate, enabling inchworm-like motion. The controller uses a soft-body continuous model for shape planning and control, given target shapes and/or environmental constraints, such as crawling under overhead barriers or "roof" safety lines. An approach to background model calibrations is developed to address deviations of actual robot shape due to material parameter variations and drift. Full experimental shape control and optimal movement under a roof safety line are demonstrated, where the robot maximizes its speed within the overhead constraint. The mean-squared error between the measured and target shapes improves from ~0.05 cm$^{2}$ without calibration to ~0.01 cm$^{2}$ with calibration. Simulation-based validation is also performed with various different roof shapes.

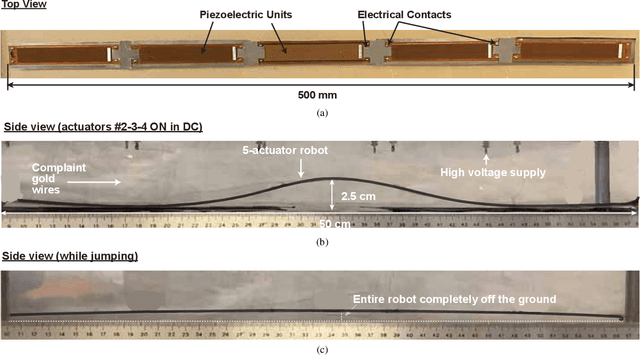

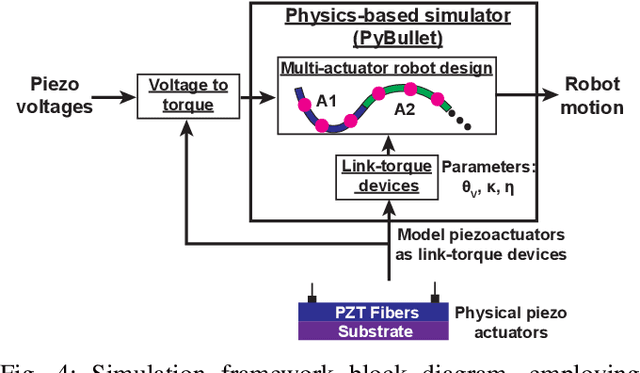

Scalable Simulation and Demonstration of Jumping Piezoelectric 2-D Soft Robots

Feb 28, 2022

Abstract:Soft robots have drawn great interest due to their ability to take on a rich range of shapes and motions, compared to traditional rigid robots. However, the motions, and underlying statics and dynamics, pose significant challenges to forming well-generalized and robust models necessary for robot design and control. In this work, we demonstrate a five-actuator soft robot capable of complex motions and develop a scalable simulation framework that reliably predicts robot motions. The simulation framework is validated by comparing its predictions to experimental results, based on a robot constructed from piezoelectric layers bonded to a steel-foil substrate. The simulation framework exploits the physics engine PyBullet, and employs discrete rigid-link elements connected by motors to model the actuators. We perform static and AC analyses to validate a single-unit actuator cantilever setup and observe close agreement between simulation and experiments for both the cases. The analyses are extended to the five-actuator robot, where simulations accurately predict the static and AC robot motions, including shapes for applied DC voltage inputs, nearly-static "inchworm" motion, and jumping (in vertical as well as vertical and horizontal directions). These motions exhibit complex non-linear behavior, with forward robot motion reaching ~1 cm/s. Our open-source code can be found at: https://github.com/zhiwuz/sfers.

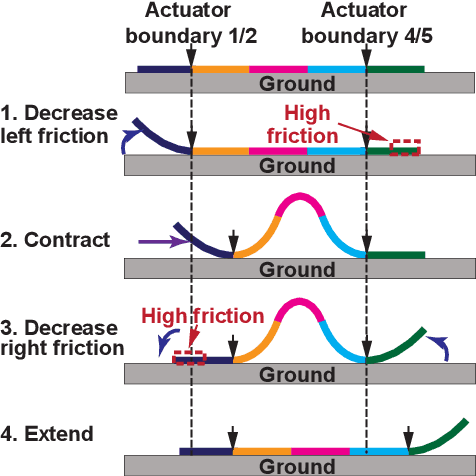

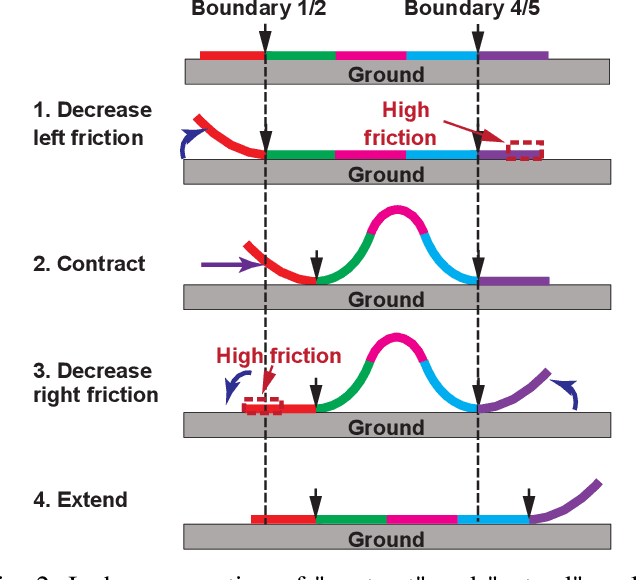

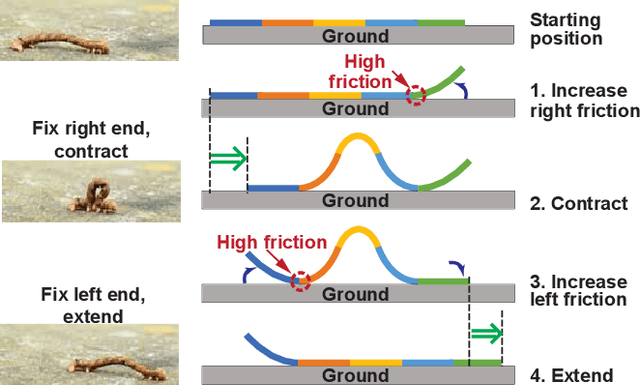

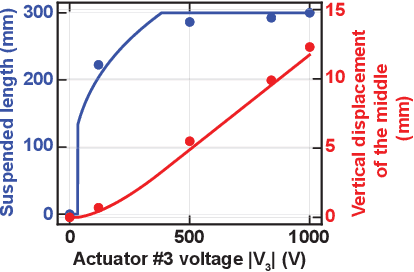

Piezoelectric Soft Robot Inchworm Motion by Controlling Ground Friction through Robot Shape

Nov 01, 2021

Abstract:Electrically driven soft robots enable small and light bodies, as well as environmental compatibility, various locomotion, and safe operation. In particular, electrostatic actuators (for example, piezoelectric actuators) are fast responded. However, scalable ways for seamless integration and untethered operation remain unclear. In addition, soft body nature modeling, including environmental interactions, is a long-standing challenge. Furthermore, more locomotion mechanisms need to be explored. In this paper, we have designed, modeled, and demonstrated a soft robot that, for the first time, starts to address all these questions. It has a linear array of five actuators in a planar structure, opening doors for integration and free operation. A new inchworm-inspired crawling motion mechanism was designed and validated by relying on posture self-adjustment. The first analytical soft body model including piezoelectricity, gravity, and ground interactions that well explain robot locomotion was developed and validated by experiments. We demonstrated the robot's forward and backward motion and explored the effects of payload and driving speed: 1.2 mm movement per cycle and up to 200 g payload (16x body weight) can be carried while moving. This work paves the way for fast-responding robots in complicated unknown environments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge