Kamran Paynabar

Multivariate Time Series Data Imputation via Distributionally Robust Regularization

Jan 31, 2026Abstract:Multivariate time series (MTS) imputation is often compromised by mismatch between observed and true data distributions -- a bias exacerbated by non-stationarity and systematic missingness. Standard methods that minimize reconstruction error or encourage distributional alignment risk overfitting these biased observations. We propose the Distributionally Robust Regularized Imputer Objective (DRIO), which jointly minimizes reconstruction error and the divergence between the imputer and a worst-case distribution within a Wasserstein ambiguity set. We derive a tractable dual formulation that reduces infinite-dimensional optimization over measures to adversarial search over sample trajectories, and propose an adversarial learning algorithm compatible with flexible deep learning backbones. Comprehensive experiments on diverse real-world datasets show DRIO consistently improves imputation under both missing-completely-at-random and missing-not-at-random settings, reaching Pareto-optimal trade-offs between reconstruction accuracy and distributional alignment.

Optimal Labeler Assignment and Sampling for Active Learning in the Presence of Imperfect Labels

Dec 14, 2025Abstract:Active Learning (AL) has garnered significant interest across various application domains where labeling training data is costly. AL provides a framework that helps practitioners query informative samples for annotation by oracles (labelers). However, these labels often contain noise due to varying levels of labeler accuracy. Additionally, uncertain samples are more prone to receiving incorrect labels because of their complexity. Learning from imperfectly labeled data leads to an inaccurate classifier. We propose a novel AL framework to construct a robust classification model by minimizing noise levels. Our approach includes an assignment model that optimally assigns query points to labelers, aiming to minimize the maximum possible noise within each cycle. Additionally, we introduce a new sampling method to identify the best query points, reducing the impact of label noise on classifier performance. Our experiments demonstrate that our approach significantly improves classification performance compared to several benchmark methods.

Registration-Free Monitoring of Unstructured Point Cloud Data via Intrinsic Geometrical Properties

Nov 06, 2025Abstract:Modern sensing technologies have enabled the collection of unstructured point cloud data (PCD) of varying sizes, which are used to monitor the geometric accuracy of 3D objects. PCD are widely applied in advanced manufacturing processes, including additive, subtractive, and hybrid manufacturing. To ensure the consistency of analysis and avoid false alarms, preprocessing steps such as registration and mesh reconstruction are commonly applied prior to monitoring. However, these steps are error-prone, time-consuming and may introduce artifacts, potentially affecting monitoring outcomes. In this paper, we present a novel registration-free approach for monitoring PCD of complex shapes, eliminating the need for both registration and mesh reconstruction. Our proposal consists of two alternative feature learning methods and a common monitoring scheme. Feature learning methods leverage intrinsic geometric properties of the shape, captured via the Laplacian and geodesic distances. In the monitoring scheme, thresholding techniques are used to further select intrinsic features most indicative of potential out-of-control conditions. Numerical experiments and case studies highlight the effectiveness of the proposed approach in identifying different types of defects.

Single-Step Reconstruction-Free Anomaly Detection and Segmentation via Diffusion Models

Aug 06, 2025Abstract:Generative models have demonstrated significant success in anomaly detection and segmentation over the past decade. Recently, diffusion models have emerged as a powerful alternative, outperforming previous approaches such as GANs and VAEs. In typical diffusion-based anomaly detection, a model is trained on normal data, and during inference, anomalous images are perturbed to a predefined intermediate step in the forward diffusion process. The corresponding normal image is then reconstructed through iterative reverse sampling. However, reconstruction-based approaches present three major challenges: (1) the reconstruction process is computationally expensive due to multiple sampling steps, making real-time applications impractical; (2) for complex or subtle patterns, the reconstructed image may correspond to a different normal pattern rather than the original input; and (3) Choosing an appropriate intermediate noise level is challenging because it is application-dependent and often assumes prior knowledge of anomalies, an assumption that does not hold in unsupervised settings. We introduce Reconstruction-free Anomaly Detection with Attention-based diffusion models in Real-time (RADAR), which overcomes the limitations of reconstruction-based anomaly detection. Unlike current SOTA methods that reconstruct the input image, RADAR directly produces anomaly maps from the diffusion model, improving both detection accuracy and computational efficiency. We evaluate RADAR on real-world 3D-printed material and the MVTec-AD dataset. Our approach surpasses state-of-the-art diffusion-based and statistical machine learning models across all key metrics, including accuracy, precision, recall, and F1 score. Specifically, RADAR improves F1 score by 7% on MVTec-AD and 13% on the 3D-printed material dataset compared to the next best model. Code available at: https://github.com/mehrdadmoradi124/RADAR

Stream-Based Active Learning for Process Monitoring

Nov 19, 2024

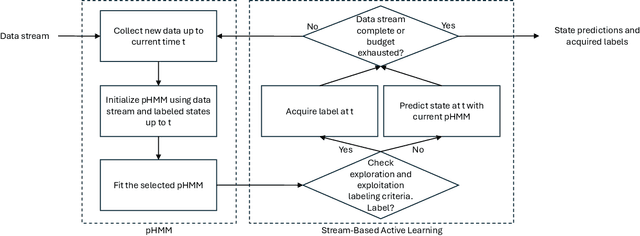

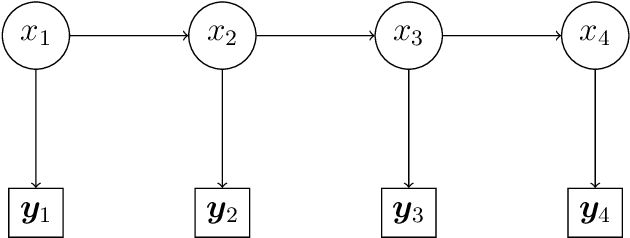

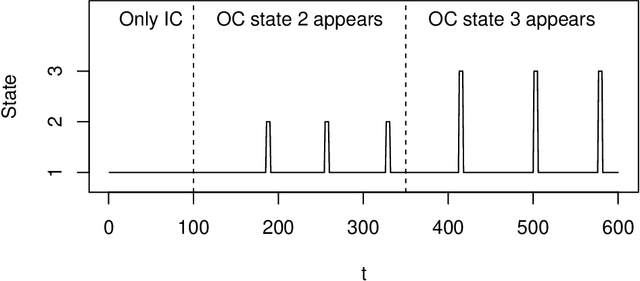

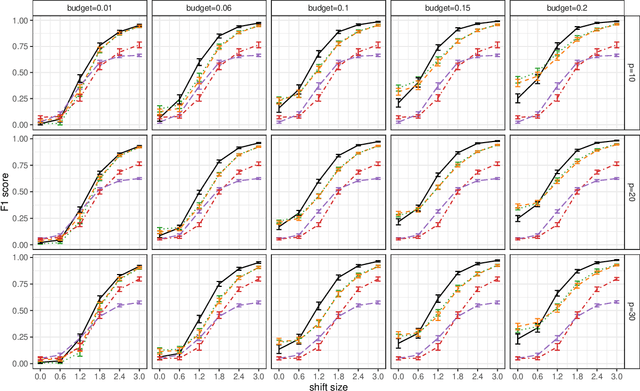

Abstract:Statistical process monitoring (SPM) methods are essential tools in quality management to check the stability of industrial processes, i.e., to dynamically classify the process state as in control (IC), under normal operating conditions, or out of control (OC), otherwise. Traditional SPM methods are based on unsupervised approaches, which are popular because in most industrial applications the true OC states of the process are not explicitly known. This hampered the development of supervised methods that could instead take advantage of process data containing labels on the true process state, although they still need improvement in dealing with class imbalance, as OC states are rare in high-quality processes, and the dynamic recognition of unseen classes, e.g., the number of possible OC states. This article presents a novel stream-based active learning strategy for SPM that enhances partially hidden Markov models to deal with data streams. The ultimate goal is to optimize labeling resources constrained by a limited budget and dynamically update the possible OC states. The proposed method performance in classifying the true state of the process is assessed through a simulation and a case study on the SPM of a resistance spot welding process in the automotive industry, which motivated this research.

Dynamic Exploration-Exploitation Trade-Off in Active Learning Regression with Bayesian Hierarchical Modeling

Apr 16, 2023Abstract:Active learning provides a framework to adaptively sample the most informative experiments towards learning an unknown black-box function. Various approaches of active learning have been proposed in the literature, however, they either focus on exploration or exploitation in the design space. Methods that do consider exploration-exploitation simultaneously employ fixed or ad-hoc measures to control the trade-off that may not be optimal. In this paper, we develop a Bayesian hierarchical approach to dynamically balance the exploration-exploitation trade-off as more data points are queried. We subsequently formulate an approximate Bayesian computation approach based on the linear dependence of data samples in the feature space to sample from the posterior distribution of the trade-off parameter obtained from the Bayesian hierarchical model. Simulated and real-world examples show the proposed approach achieves at least 6% and 11% average improvement when compared to pure exploration and exploitation strategies respectively. More importantly, we note that by optimally balancing the trade-off between exploration and exploitation, our approach performs better or at least as well as either pure exploration or pure exploitation.

Maximum Covariance Unfolding Regression: A Novel Covariate-based Manifold Learning Approach for Point Cloud Data

Mar 31, 2023Abstract:Point cloud data are widely used in manufacturing applications for process inspection, modeling, monitoring and optimization. The state-of-art tensor regression techniques have effectively been used for analysis of structured point cloud data, where the measurements on a uniform grid can be formed into a tensor. However, these techniques are not capable of handling unstructured point cloud data that are often in the form of manifolds. In this paper, we propose a nonlinear dimension reduction approach named Maximum Covariance Unfolding Regression that is able to learn the low-dimensional (LD) manifold of point clouds with the highest correlation with explanatory covariates. This LD manifold is then used for regression modeling and process optimization based on process variables. The performance of the proposed method is subsequently evaluated and compared with benchmark methods through simulations and a case study of steel bracket manufacturing.

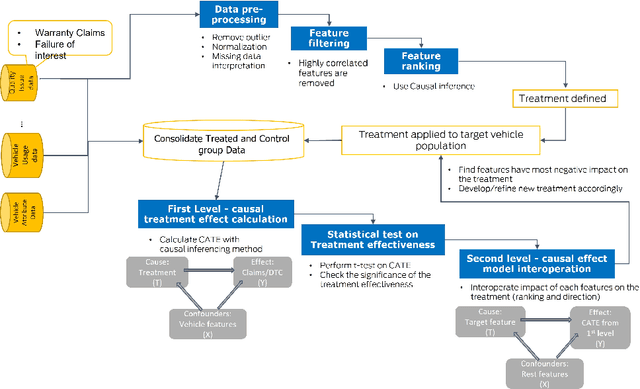

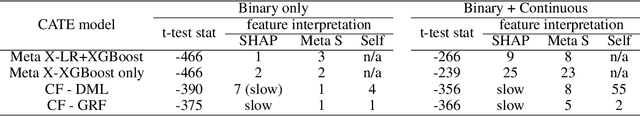

A Novel Two-level Causal Inference Framework for On-road Vehicle Quality Issues Diagnosis

Mar 31, 2023

Abstract:In the automotive industry, the full cycle of managing in-use vehicle quality issues can take weeks to investigate. The process involves isolating root causes, defining and implementing appropriate treatments, and refining treatments if needed. The main pain-point is the lack of a systematic method to identify causal relationships, evaluate treatment effectiveness, and direct the next actionable treatment if the current treatment was deemed ineffective. This paper will show how we leverage causal Machine Learning (ML) to speed up such processes. A real-word data set collected from on-road vehicles will be used to demonstrate the proposed framework. Open challenges for vehicle quality applications will also be discussed.

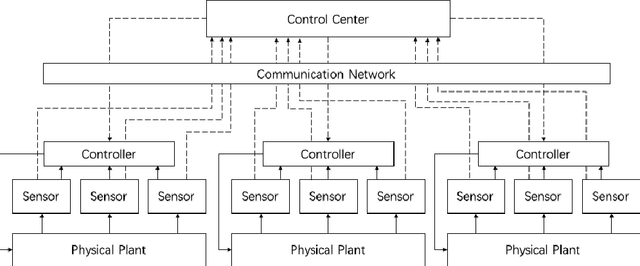

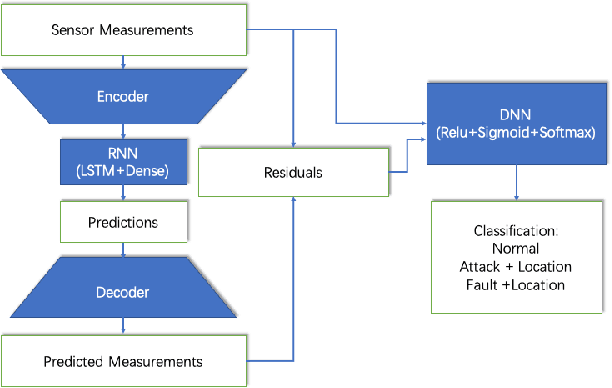

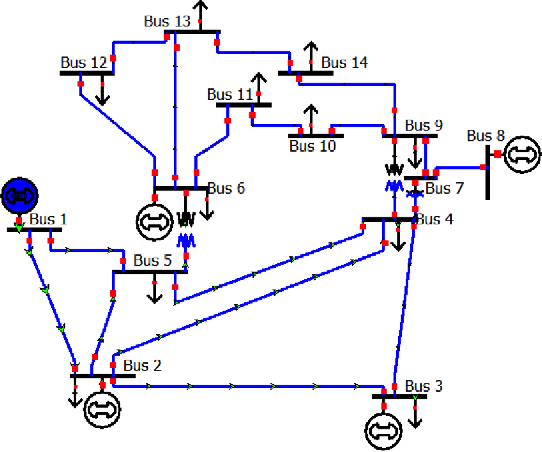

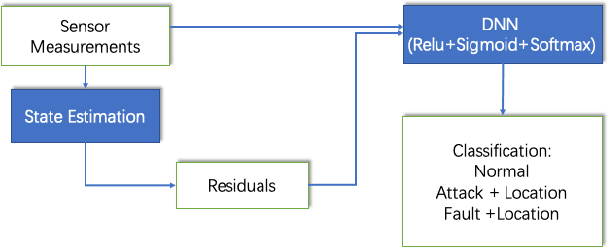

Deep Learning based Covert Attack Identification for Industrial Control Systems

Sep 25, 2020

Abstract:Cybersecurity of Industrial Control Systems (ICS) is drawing significant concerns as data communication increasingly leverages wireless networks. A lot of data-driven methods were developed for detecting cyberattacks, but few are focused on distinguishing them from equipment faults. In this paper, we develop a data-driven framework that can be used to detect, diagnose, and localize a type of cyberattack called covert attacks on smart grids. The framework has a hybrid design that combines an autoencoder, a recurrent neural network (RNN) with a Long-Short-Term-Memory (LSTM) layer, and a Deep Neural Network (DNN). This data-driven framework considers the temporal behavior of a generic physical system that extracts features from the time series of the sensor measurements that can be used for detecting covert attacks, distinguishing them from equipment faults, as well as localize the attack/fault. We evaluate the performance of the proposed method through a realistic simulation study on the IEEE 14-bus model as a typical example of ICS. We compare the performance of the proposed method with the traditional model-based method to show its applicability and efficacy.

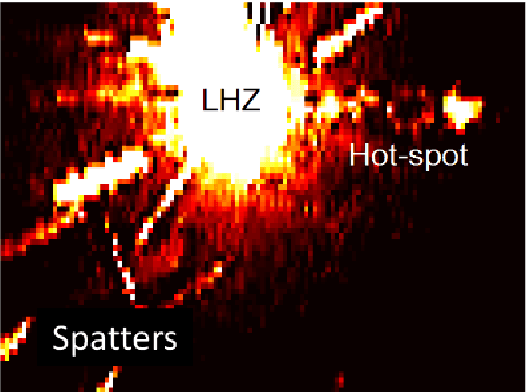

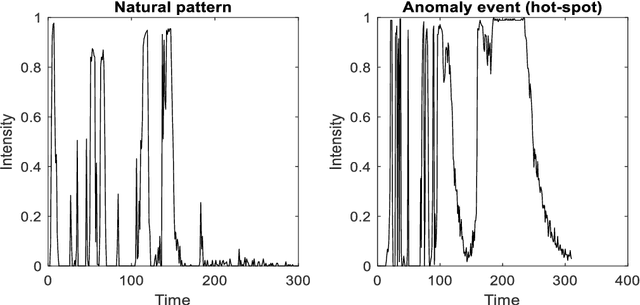

Real-time Detection of Clustered Events in Video-imaging data with Applications to Additive Manufacturing

Apr 23, 2020

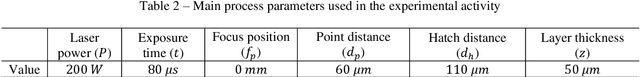

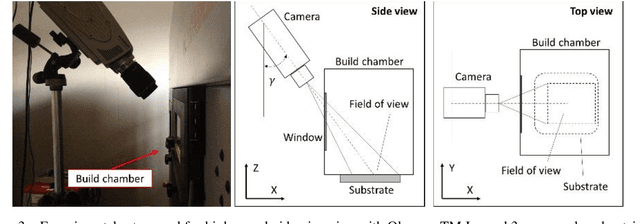

Abstract:The use of video-imaging data for in-line process monitoring applications has become more and more popular in the industry. In this framework, spatio-temporal statistical process monitoring methods are needed to capture the relevant information content and signal possible out-of-control states. Video-imaging data are characterized by a spatio-temporal variability structure that depends on the underlying phenomenon, and typical out-of-control patterns are related to the events that are localized both in time and space. In this paper, we propose an integrated spatio-temporal decomposition and regression approach for anomaly detection in video-imaging data. Out-of-control events are typically sparse spatially clustered and temporally consistent. Therefore, the goal is to not only detect the anomaly as quickly as possible ("when") but also locate it ("where"). The proposed approach works by decomposing the original spatio-temporal data into random natural events, sparse spatially clustered and temporally consistent anomalous events, and random noise. Recursive estimation procedures for spatio-temporal regression are presented to enable the real-time implementation of the proposed methodology. Finally, a likelihood ratio test procedure is proposed to detect when and where the hotspot happens. The proposed approach was applied to the analysis of video-imaging data to detect and locate local over-heating phenomena ("hotspots") during the layer-wise process in a metal additive manufacturing process.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge