Francis Ogoke

AMGPT: a Large Language Model for Contextual Querying in Additive Manufacturing

May 24, 2024Abstract:Generalized large language models (LLMs) such as GPT-4 may not provide specific answers to queries formulated by materials science researchers. These models may produce a high-level outline but lack the capacity to return detailed instructions on manufacturing and material properties of novel alloys. Enhancing a smaller model with specialized domain knowledge may provide an advantage over large language models which cannot be retrained quickly enough to keep up with the rapid pace of research in metal additive manufacturing (AM). We introduce "AMGPT," a specialized LLM text generator designed for metal AM queries. The goal of AMGPT is to assist researchers and users in navigating the extensive corpus of literature in AM. Instead of training from scratch, we employ a pre-trained Llama2-7B model from Hugging Face in a Retrieval-Augmented Generation (RAG) setup, utilizing it to dynamically incorporate information from $\sim$50 AM papers and textbooks in PDF format. Mathpix is used to convert these PDF documents into TeX format, facilitating their integration into the RAG pipeline managed by LlamaIndex. Expert evaluations of this project highlight that specific embeddings from the RAG setup accelerate response times and maintain coherence in the generated text.

Integrating Multi-Physics Simulations and Machine Learning to Define the Spatter Mechanism and Process Window in Laser Powder Bed Fusion

May 13, 2024

Abstract:Laser powder bed fusion (LPBF) has shown promise for wide range of applications due to its ability to fabricate freeform geometries and generate a controlled microstructure. However, components generated by LPBF still possess sub-optimal mechanical properties due to the defects that are created during laser-material interactions. In this work, we investigate mechanism of spatter formation, using a high-fidelity modelling tool that was built to simulate the multi-physics phenomena in LPBF. The modelling tool have the capability to capture the 3D resolution of the meltpool and the spatter behavior. To understand spatter behavior and formation, we reveal its properties at ejection and evaluate its variation from the meltpool, the source where it is formed. The dataset of the spatter and the meltpool collected consist of 50 % spatter and 50 % melt pool samples, with features that include position components, velocity components, velocity magnitude, temperature, density and pressure. The relationship between the spatter and the meltpool were evaluated via correlation analysis and machine learning (ML) algorithms for classification tasks. Upon screening different ML algorithms on the dataset, a high accuracy was observed for all the ML models, with ExtraTrees having the highest at 96 % and KNN having the lowest at 94 %.

Deep Learning for Melt Pool Depth Contour Prediction From Surface Thermal Images via Vision Transformers

Apr 26, 2024

Abstract:Insufficient overlap between the melt pools produced during Laser Powder Bed Fusion (L-PBF) can lead to lack-of-fusion defects and deteriorated mechanical and fatigue performance. In-situ monitoring of the melt pool subsurface morphology requires specialized equipment that may not be readily accessible or scalable. Therefore, we introduce a machine learning framework to correlate in-situ two-color thermal images observed via high-speed color imaging to the two-dimensional profile of the melt pool cross-section. Specifically, we employ a hybrid CNN-Transformer architecture to establish a correlation between single bead off-axis thermal image sequences and melt pool cross-section contours measured via optical microscopy. In this architecture, a ResNet model embeds the spatial information contained within the thermal images to a latent vector, while a Transformer model correlates the sequence of embedded vectors to extract temporal information. Our framework is able to model the curvature of the subsurface melt pool structure, with improved performance in high energy density regimes compared to analytical melt pool models. The performance of this model is evaluated through dimensional and geometric comparisons to the corresponding experimental melt pool observations.

ThermoPore: Predicting Part Porosity Based on Thermal Images Using Deep Learning

Apr 23, 2024

Abstract:We present a deep learning approach for quantifying and localizing ex-situ porosity within Laser Powder Bed Fusion fabricated samples utilizing in-situ thermal image monitoring data. Our goal is to build the real time porosity map of parts based on thermal images acquired during the build. The quantification task builds upon the established Convolutional Neural Network model architecture to predict pore count and the localization task leverages the spatial and temporal attention mechanisms of the novel Video Vision Transformer model to indicate areas of expected porosity. Our model for porosity quantification achieved a $R^2$ score of 0.57 and our model for porosity localization produced an average IoU score of 0.32 and a maximum of 1.0. This work is setting the foundations of part porosity "Digital Twins" based on additive manufacturing monitoring data and can be applied downstream to reduce time-intensive post-inspection and testing activities during part qualification and certification. In addition, we seek to accelerate the acquisition of crucial insights normally only available through ex-situ part evaluation by means of machine learning analysis of in-situ process monitoring data.

Latent Neural PDE Solver: a reduced-order modelling framework for partial differential equations

Feb 27, 2024Abstract:Neural networks have shown promising potential in accelerating the numerical simulation of systems governed by partial differential equations (PDEs). Different from many existing neural network surrogates operating on high-dimensional discretized fields, we propose to learn the dynamics of the system in the latent space with much coarser discretizations. In our proposed framework - Latent Neural PDE Solver (LNS), a non-linear autoencoder is first trained to project the full-order representation of the system onto the mesh-reduced space, then a temporal model is trained to predict the future state in this mesh-reduced space. This reduction process simplifies the training of the temporal model by greatly reducing the computational cost accompanying a fine discretization. We study the capability of the proposed framework and several other popular neural PDE solvers on various types of systems including single-phase and multi-phase flows along with varying system parameters. We showcase that it has competitive accuracy and efficiency compared to the neural PDE solver that operates on full-order space.

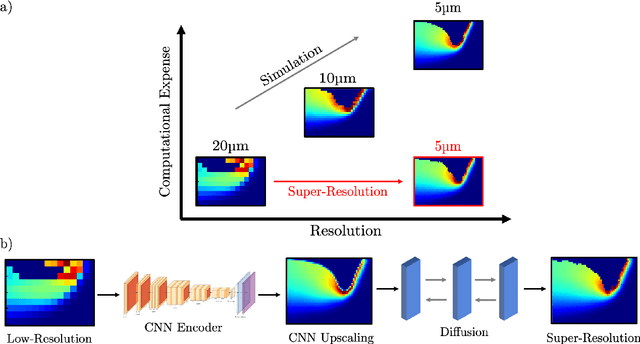

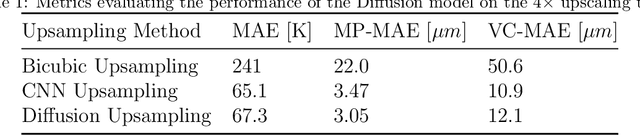

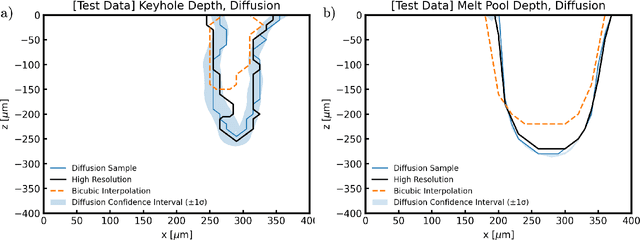

Inexpensive High Fidelity Melt Pool Models in Additive Manufacturing Using Generative Deep Diffusion

Nov 15, 2023

Abstract:Defects in laser powder bed fusion (L-PBF) parts often result from the meso-scale dynamics of the molten alloy near the laser, known as the melt pool. For instance, the melt pool can directly contribute to the formation of undesirable porosity, residual stress, and surface roughness in the final part. Experimental in-situ monitoring of the three-dimensional melt pool physical fields is challenging, due to the short length and time scales involved in the process. Multi-physics simulation methods can describe the three-dimensional dynamics of the melt pool, but are computationally expensive at the mesh refinement required for accurate predictions of complex effects, such as the formation of keyhole porosity. Therefore, in this work, we develop a generative deep learning model based on the probabilistic diffusion framework to map low-fidelity, coarse-grained simulation information to the high-fidelity counterpart. By doing so, we bypass the computational expense of conducting multiple high-fidelity simulations for analysis by instead upscaling lightweight coarse mesh simulations. Specifically, we implement a 2-D diffusion model to spatially upscale cross-sections of the coarsely simulated melt pool to their high-fidelity equivalent. We demonstrate the preservation of key metrics of the melting process between the ground truth simulation data and the diffusion model output, such as the temperature field, the melt pool dimensions and the variability of the keyhole vapor cavity. Specifically, we predict the melt pool depth within 3 $\mu m$ based on low-fidelity input data 4$\times$ coarser than the high-fidelity simulations, reducing analysis time by two orders of magnitude.

Surrogate Modeling of Melt Pool Thermal Field using Deep Learning

Aug 04, 2022

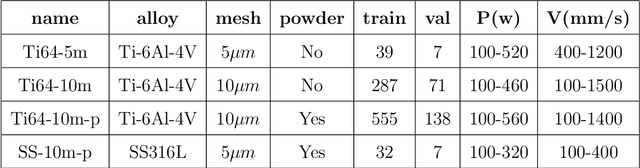

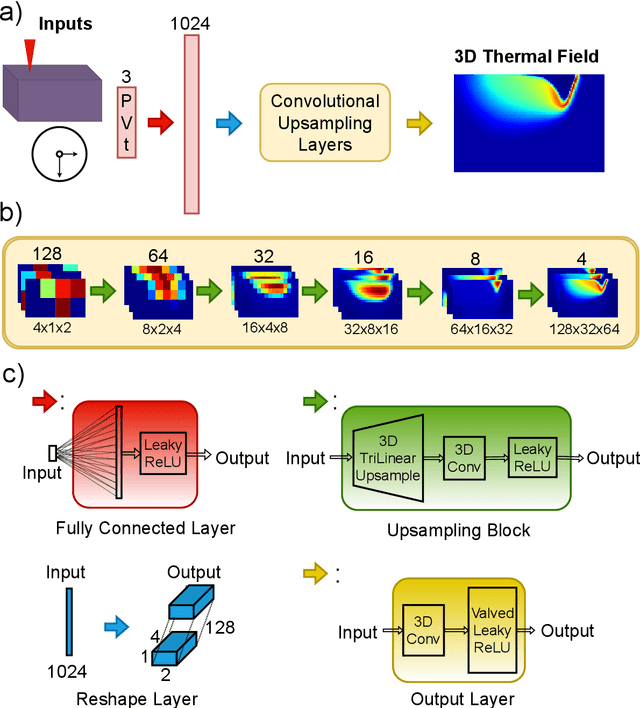

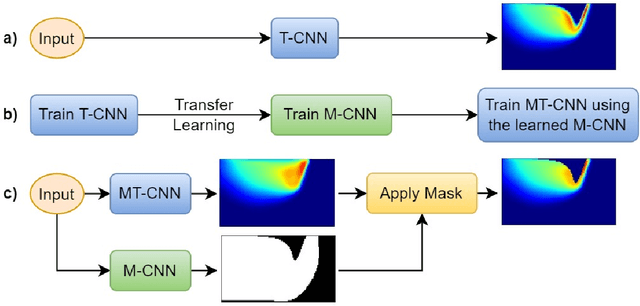

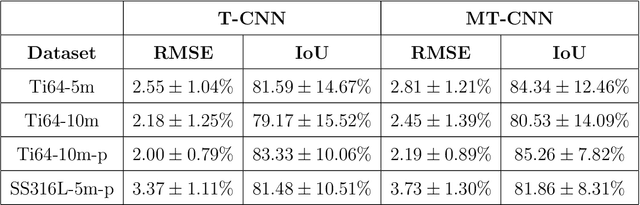

Abstract:Powder-based additive manufacturing has transformed the manufacturing industry over the last decade. In Laser Powder Bed Fusion, a specific part is built in an iterative manner in which two-dimensional cross-sections are formed on top of each other by melting and fusing the proper areas of the powder bed. In this process, the behavior of the melt pool and its thermal field has a very important role in predicting the quality of the manufactured part and its possible defects. However, the simulation of such a complex phenomenon is usually very time-consuming and requires huge computational resources. Flow-3D is one of the software packages capable of executing such simulations using iterative numerical solvers. In this work, we create three datasets of single-trail processes using Flow-3D and use them to train a convolutional neural network capable of predicting the behavior of the three-dimensional thermal field of the melt pool solely by taking three parameters as input: laser power, laser velocity, and time step. The CNN achieves a relative Root Mean Squared Error of 2% to 3% for the temperature field and an average Intersection over Union score of 80% to 90% in predicting the melt pool area. Moreover, since time is included as one of the inputs of the model, the thermal field can be instantly obtained for any arbitrary time step without the need to iterate and compute all the steps

Deep-Learned Generators of Porosity Distributions Produced During Metal Additive Manufacturing

May 11, 2022

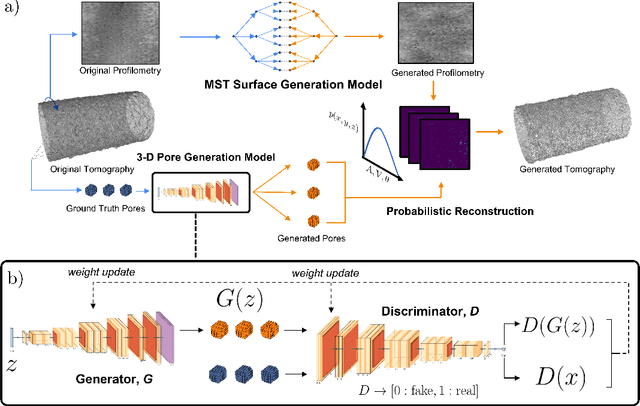

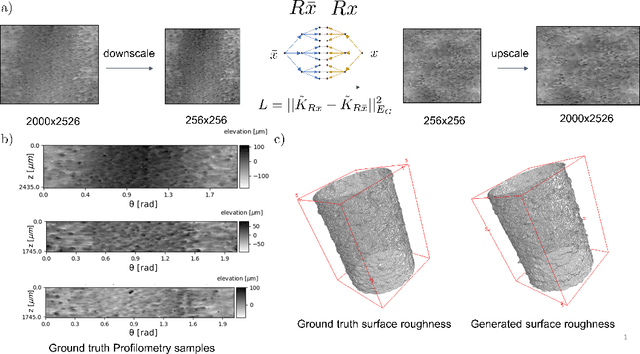

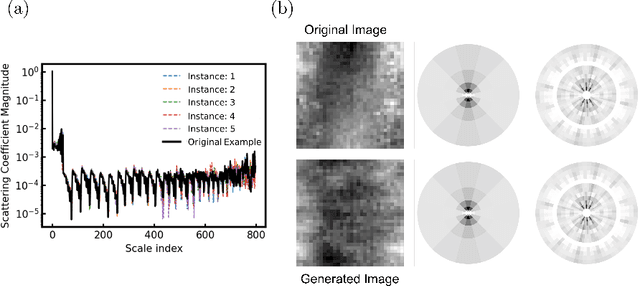

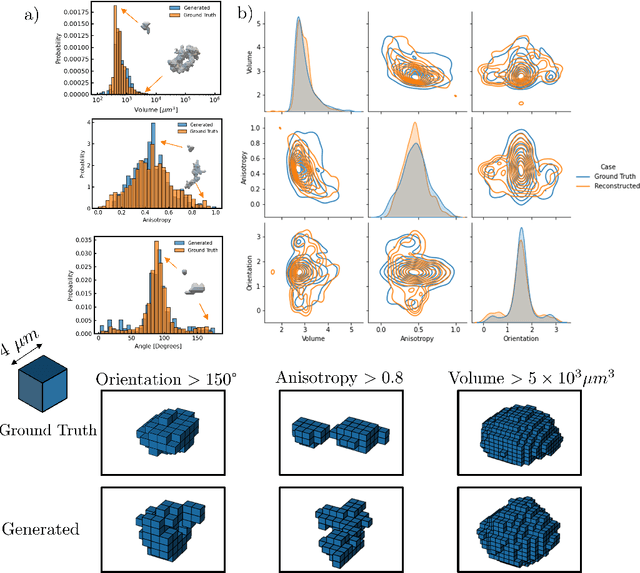

Abstract:Laser Powder Bed Fusion has become a widely adopted method for metal Additive Manufacturing (AM) due to its ability to mass produce complex parts with increased local control. However, AM produced parts can be subject to undesirable porosity, negatively influencing the properties of printed components. Thus, controlling porosity is integral for creating effective parts. A precise understanding of the porosity distribution is crucial for accurately simulating potential fatigue and failure zones. Previous research on generating synthetic porous microstructures have succeeded in generating parts with high density, isotropic porosity distributions but are often inapplicable to cases with sparser, boundary-dependent pore distributions. Our work bridges this gap by providing a method that considers these constraints by deconstructing the generation problem into its constitutive parts. A framework is introduced that combines Generative Adversarial Networks with Mallat Scattering Transform-based autocorrelation methods to construct novel realizations of the individual pore geometries and surface roughness, then stochastically reconstruct them to form realizations of a porous printed part. The generated parts are compared to the existing experimental porosity distributions based on statistical and dimensional metrics, such as nearest neighbor distances, pore volumes, pore anisotropies and scattering transform based auto-correlations.

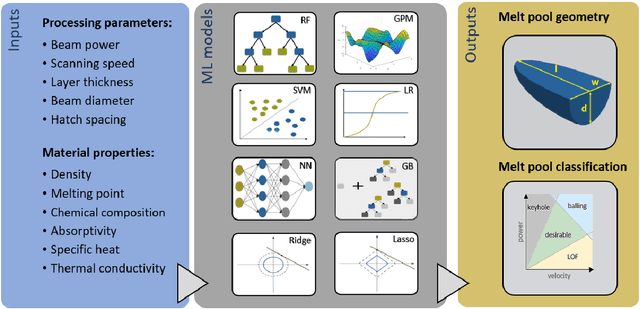

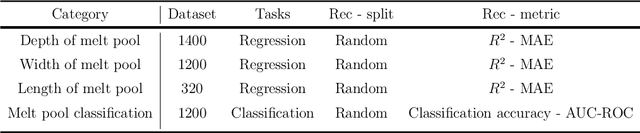

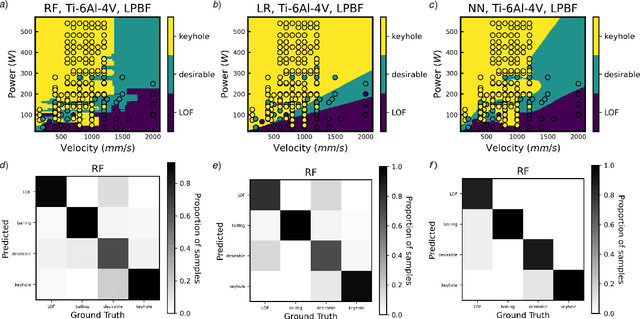

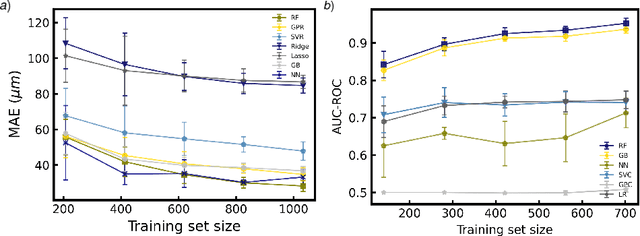

MeltpoolNet: Melt pool Characteristic Prediction in Metal Additive Manufacturing Using Machine Learning

Jan 26, 2022

Abstract:Characterizing meltpool shape and geometry is essential in metal Additive Manufacturing (MAM) to control the printing process and avoid defects. Predicting meltpool flaws based on process parameters and powder material is difficult due to the complex nature of MAM process. Machine learning (ML) techniques can be useful in connecting process parameters to the type of flaws in the meltpool. In this work, we introduced a comprehensive framework for benchmarking ML for melt pool characterization. An extensive experimental dataset has been collected from more than 80 MAM articles containing MAM processing conditions, materials, meltpool dimensions, meltpool modes and flaw types. We introduced physics-aware MAM featurization, versatile ML models, and evaluation metrics to create a comprehensive learning framework for meltpool defect and geometry prediction. This benchmark can serve as a basis for melt pool control and process optimization. In addition, data-driven explicit models have been identified to estimate meltpool geometry from process parameters and material properties which outperform Rosenthal estimation for meltpool geometry while maintaining interpretability.

Thermal Control of Laser Powder Bed Fusion Using Deep Reinforcement Learning

Jan 29, 2021

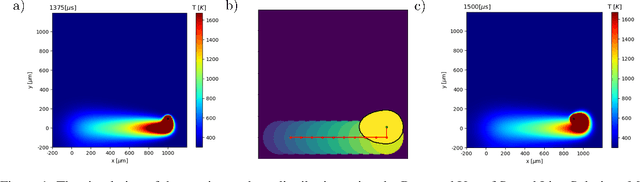

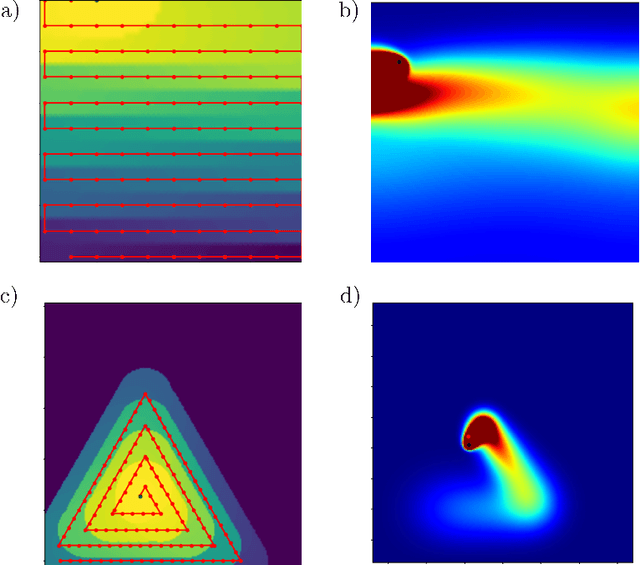

Abstract:Powder-based additive manufacturing techniques provide tools to construct intricate structures that are difficult to manufacture using conventional methods. In Laser Powder Bed Fusion, components are built by selectively melting specific areas of the powder bed, to form the two-dimensional cross-section of the specific part. However, the high occurrence of defects impacts the adoption of this method for precision applications. Therefore, a control policy for dynamically altering process parameters to avoid phenomena that lead to defect occurrences is necessary. A Deep Reinforcement Learning (DRL) framework that derives a versatile control strategy for minimizing the likelihood of these defects is presented. The generated control policy alters the velocity of the laser during the melting process to ensure the consistency of the melt pool and reduce overheating in the generated product. The control policy is trained and validated on efficient simulations of the continuum temperature distribution of the powder bed layer under various laser trajectories.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge