Quanliang Liu

Beyond designer's knowledge: Generating materials design hypotheses via large language models

Sep 10, 2024

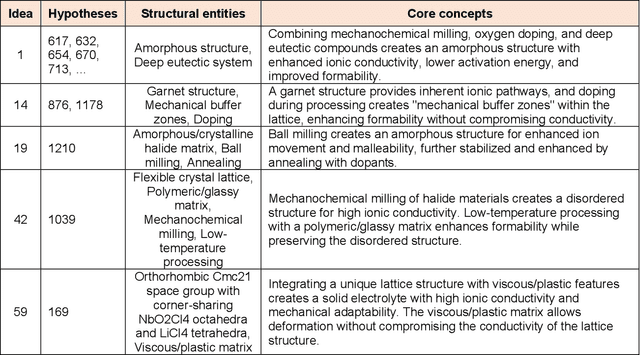

Abstract:Materials design often relies on human-generated hypotheses, a process inherently limited by cognitive constraints such as knowledge gaps and limited ability to integrate and extract knowledge implications, particularly when multidisciplinary expertise is required. This work demonstrates that large language models (LLMs), coupled with prompt engineering, can effectively generate non-trivial materials hypotheses by integrating scientific principles from diverse sources without explicit design guidance by human experts. These include design ideas for high-entropy alloys with superior cryogenic properties and halide solid electrolytes with enhanced ionic conductivity and formability. These design ideas have been experimentally validated in high-impact publications in 2023 not available in the LLM training data, demonstrating the LLM's ability to generate highly valuable and realizable innovative ideas not established in the literature. Our approach primarily leverages materials system charts encoding processing-structure-property relationships, enabling more effective data integration by condensing key information from numerous papers, and evaluation and categorization of numerous hypotheses for human cognition, both through the LLM. This LLM-driven approach opens the door to new avenues of artificial intelligence-driven materials discovery by accelerating design, democratizing innovation, and expanding capabilities beyond the designer's direct knowledge.

Inexpensive High Fidelity Melt Pool Models in Additive Manufacturing Using Generative Deep Diffusion

Nov 15, 2023

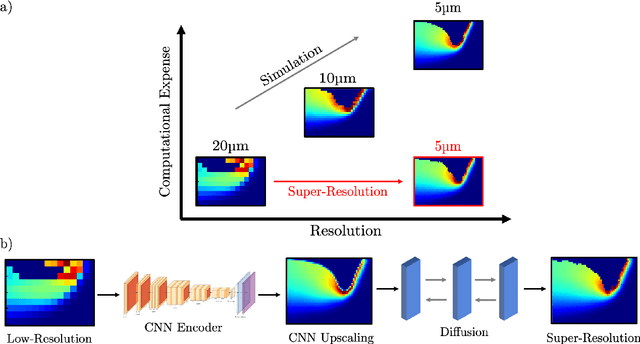

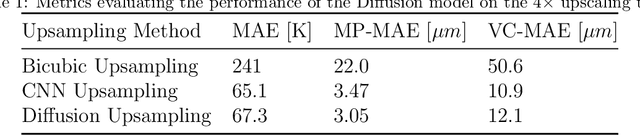

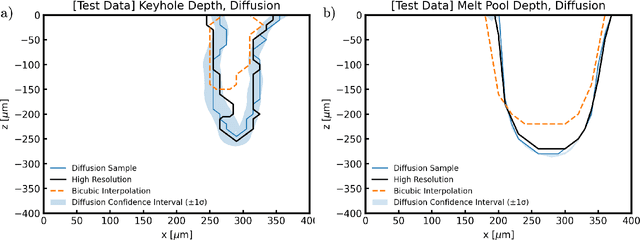

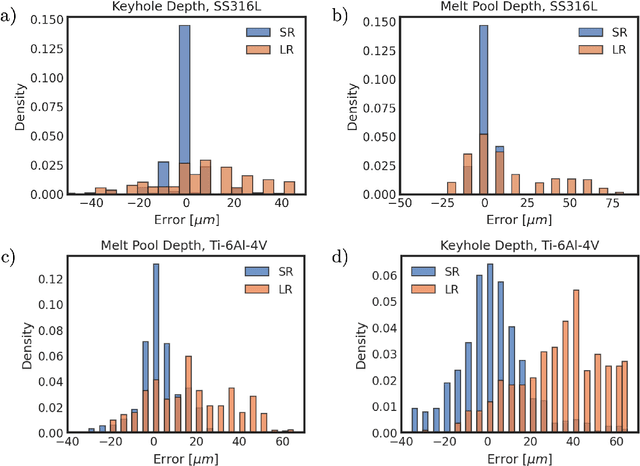

Abstract:Defects in laser powder bed fusion (L-PBF) parts often result from the meso-scale dynamics of the molten alloy near the laser, known as the melt pool. For instance, the melt pool can directly contribute to the formation of undesirable porosity, residual stress, and surface roughness in the final part. Experimental in-situ monitoring of the three-dimensional melt pool physical fields is challenging, due to the short length and time scales involved in the process. Multi-physics simulation methods can describe the three-dimensional dynamics of the melt pool, but are computationally expensive at the mesh refinement required for accurate predictions of complex effects, such as the formation of keyhole porosity. Therefore, in this work, we develop a generative deep learning model based on the probabilistic diffusion framework to map low-fidelity, coarse-grained simulation information to the high-fidelity counterpart. By doing so, we bypass the computational expense of conducting multiple high-fidelity simulations for analysis by instead upscaling lightweight coarse mesh simulations. Specifically, we implement a 2-D diffusion model to spatially upscale cross-sections of the coarsely simulated melt pool to their high-fidelity equivalent. We demonstrate the preservation of key metrics of the melting process between the ground truth simulation data and the diffusion model output, such as the temperature field, the melt pool dimensions and the variability of the keyhole vapor cavity. Specifically, we predict the melt pool depth within 3 $\mu m$ based on low-fidelity input data 4$\times$ coarser than the high-fidelity simulations, reducing analysis time by two orders of magnitude.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge