Ning-Yu Kao

MeltpoolNet: Melt pool Characteristic Prediction in Metal Additive Manufacturing Using Machine Learning

Jan 26, 2022

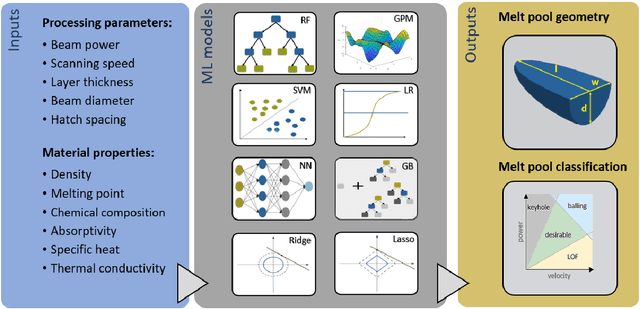

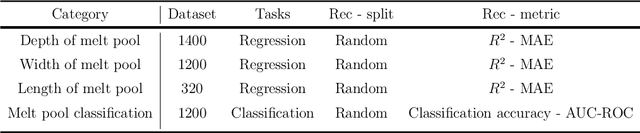

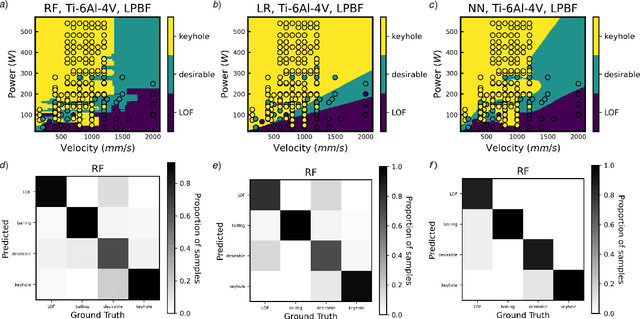

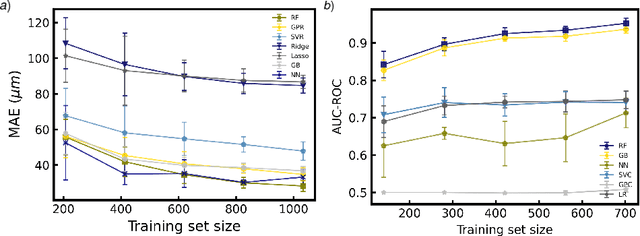

Abstract:Characterizing meltpool shape and geometry is essential in metal Additive Manufacturing (MAM) to control the printing process and avoid defects. Predicting meltpool flaws based on process parameters and powder material is difficult due to the complex nature of MAM process. Machine learning (ML) techniques can be useful in connecting process parameters to the type of flaws in the meltpool. In this work, we introduced a comprehensive framework for benchmarking ML for melt pool characterization. An extensive experimental dataset has been collected from more than 80 MAM articles containing MAM processing conditions, materials, meltpool dimensions, meltpool modes and flaw types. We introduced physics-aware MAM featurization, versatile ML models, and evaluation metrics to create a comprehensive learning framework for meltpool defect and geometry prediction. This benchmark can serve as a basis for melt pool control and process optimization. In addition, data-driven explicit models have been identified to estimate meltpool geometry from process parameters and material properties which outperform Rosenthal estimation for meltpool geometry while maintaining interpretability.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge