Olabode T. Ajenifujah

NANOGPT: A Query-Driven Large Language Model Retrieval-Augmented Generation System for Nanotechnology Research

Feb 27, 2025Abstract:This paper presents the development and application of a Large Language Model Retrieval-Augmented Generation (LLM-RAG) system tailored for nanotechnology research. The system leverages the capabilities of a sophisticated language model to serve as an intelligent research assistant, enhancing the efficiency and comprehensiveness of literature reviews in the nanotechnology domain. Central to this LLM-RAG system is its advanced query backend retrieval mechanism, which integrates data from multiple reputable sources. The system retrieves relevant literature by utilizing Google Scholar's advanced search, and scraping open-access papers from Elsevier, Springer Nature, and ACS Publications. This multifaceted approach ensures a broad and diverse collection of up-to-date scholarly articles and papers. The proposed system demonstrates significant potential in aiding researchers by providing a streamlined, accurate, and exhaustive literature retrieval process, thereby accelerating research advancements in nanotechnology. The effectiveness of the LLM-RAG system is validated through rigorous testing, illustrating its capability to significantly reduce the time and effort required for comprehensive literature reviews, while maintaining high accuracy, query relevance and outperforming standard, publicly available LLMS.

Modeling Melt Pool Features and Spatter Using Symbolic Regression and Machine Learning

Jan 15, 2025

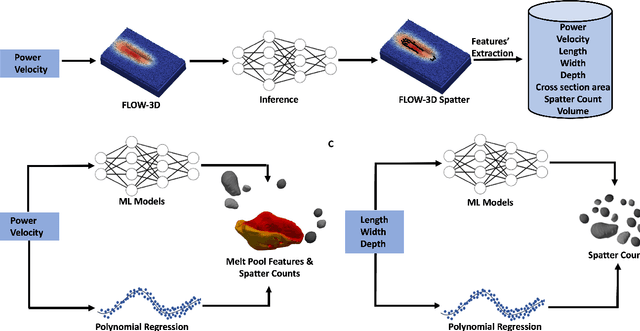

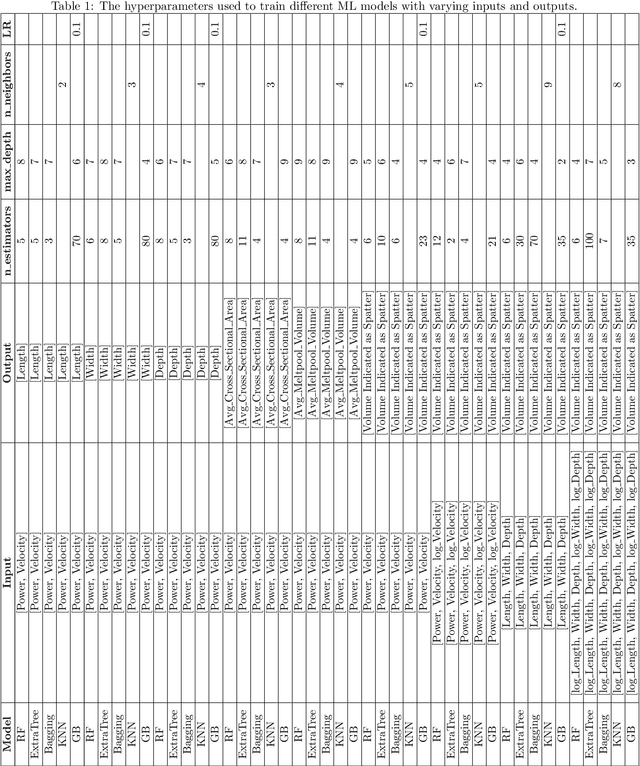

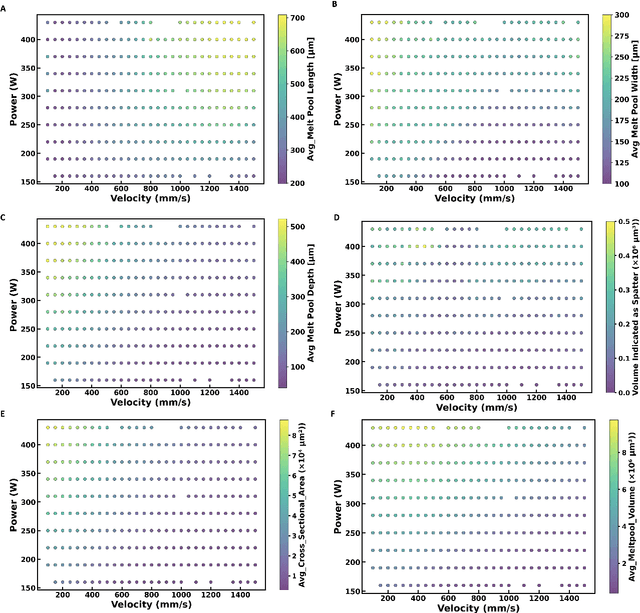

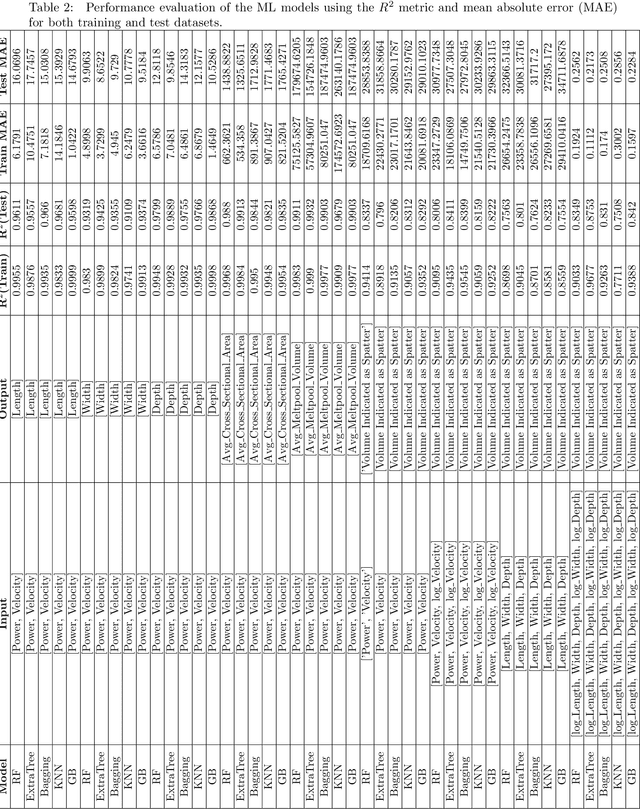

Abstract:Additive manufacturing (AM) is a rapidly evolving technology that has attracted applications across a wide range of fields due to its ability to fabricate complex geometries. However, one of the key challenges in AM is achieving consistent print quality. This inconsistency is often attributed to uncontrolled melt pool dynamics, partly caused by spatter which can lead to defects. Therefore, capturing and controlling the evolution of the melt pool is crucial for enhancing process stability and part quality. In this study, we developed a framework to support decision-making in AM operations, facilitating quality control and minimizing defects via machine learning (ML) and polynomial symbolic regression models. We implemented experimentally validated computational tools as a cost-effective approach to collect large datasets from laser powder bed fusion (LPBF) processes. For a dataset consisting of 281 process conditions, parameters such as melt pool dimensions (length, width, depth), melt pool geometry (area, volume), and volume indicated as spatter were extracted. Using machine learning (ML) and polynomial symbolic regression models, a high R2 of over 95 % was achieved in predicting the melt pool dimensions and geometry features for both the training and testing datasets, with either process conditions (power and velocity) or melt pool dimensions as the model inputs. In the case of volume indicated as spatter, R2 improved after logarithmic transforming the model inputs, which was either the process conditions or the melt pool dimensions. Among the investigated ML models, the ExtraTree model achieved the highest R2 values of 96.7 % and 87.5 %.

Integrating Multi-Physics Simulations and Machine Learning to Define the Spatter Mechanism and Process Window in Laser Powder Bed Fusion

May 13, 2024

Abstract:Laser powder bed fusion (LPBF) has shown promise for wide range of applications due to its ability to fabricate freeform geometries and generate a controlled microstructure. However, components generated by LPBF still possess sub-optimal mechanical properties due to the defects that are created during laser-material interactions. In this work, we investigate mechanism of spatter formation, using a high-fidelity modelling tool that was built to simulate the multi-physics phenomena in LPBF. The modelling tool have the capability to capture the 3D resolution of the meltpool and the spatter behavior. To understand spatter behavior and formation, we reveal its properties at ejection and evaluate its variation from the meltpool, the source where it is formed. The dataset of the spatter and the meltpool collected consist of 50 % spatter and 50 % melt pool samples, with features that include position components, velocity components, velocity magnitude, temperature, density and pressure. The relationship between the spatter and the meltpool were evaluated via correlation analysis and machine learning (ML) algorithms for classification tasks. Upon screening different ML algorithms on the dataset, a high accuracy was observed for all the ML models, with ExtraTrees having the highest at 96 % and KNN having the lowest at 94 %.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge