Christopher McCool

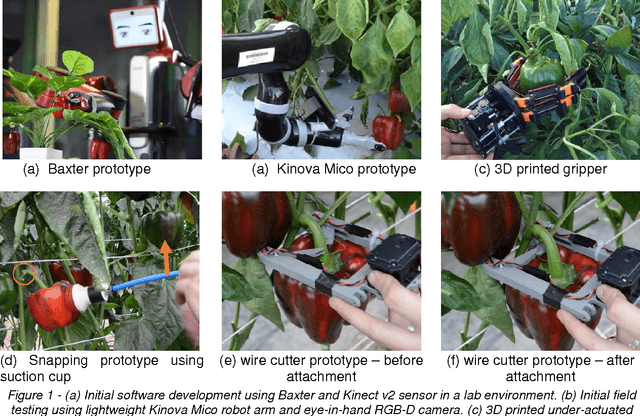

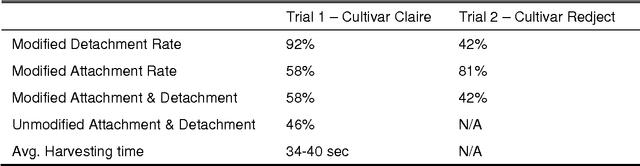

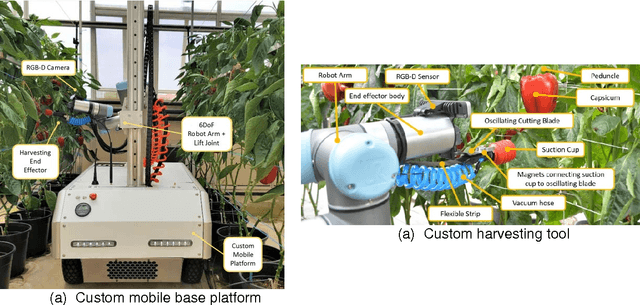

Lessons Learnt from Field Trials of a Robotic Sweet Pepper Harvester

Jun 19, 2017

Abstract:In this paper, we present the lessons learnt during the development of a new robotic harvester (Harvey) that can autonomously harvest sweet pepper (capsicum) in protected cropping environments. Robotic harvesting offers an attractive potential solution to reducing labour costs while enabling more regular and selective harvesting, optimising crop quality, scheduling and therefore profit. Our approach combines effective vision algorithms with a novel end-effector design to enable successful harvesting of sweet peppers. We demonstrate a simple and effective vision-based algorithm for crop detection, a grasp selection method, and a novel end-effector design for harvesting. To reduce the complexity of motion planning and to minimise occlusions we focus on picking sweet peppers in a protected cropping environment where plants are grown on planar trellis structures. Initial field trials in protected cropping environments, with two cultivars, demonstrate the efficacy of this approach. The results show that the robot harvester can successfully detect, grasp, and detach crop from the plant within a real protected cropping system. The novel contributions of this work have resulted in significant and encouraging improvements in sweet pepper picking success rates compared with the state-of-the-art. Future work will look at detecting sweet pepper peduncles and improving the total harvesting cycle time for each sweet pepper. The methods presented in this paper provide steps towards the goal of fully autonomous and reliable crop picking systems that will revolutionise the horticulture industry by reducing labour costs, maximising the quality of produce, and ultimately improving the sustainability of farming enterprises.

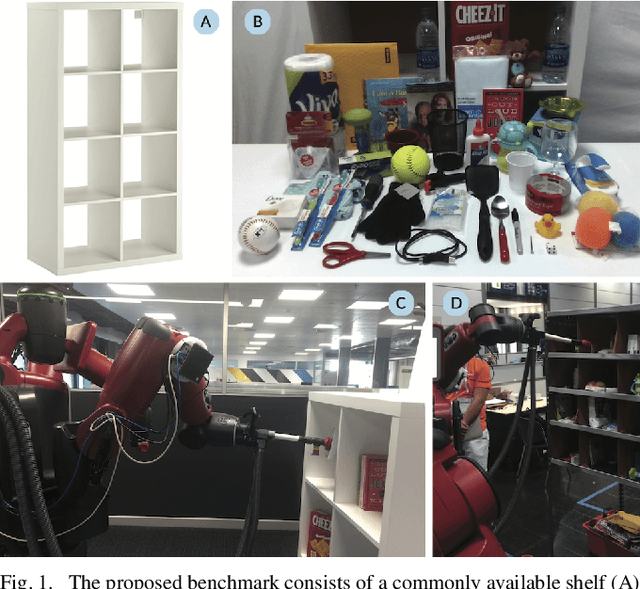

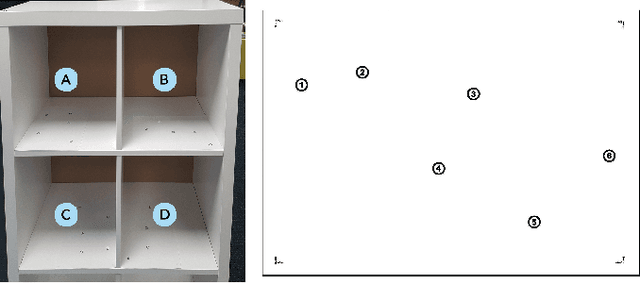

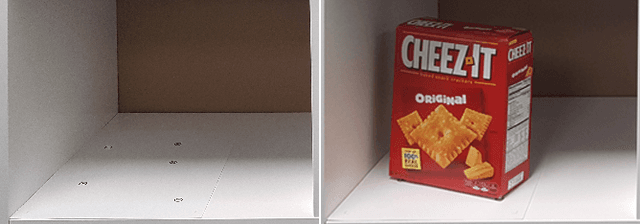

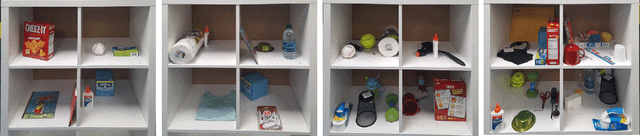

The ACRV Picking Benchmark : A Robotic Shelf Picking Benchmark to Foster Reproducible Research

Dec 14, 2016

Abstract:Robotic challenges like the Amazon Picking Challenge (APC) or the DARPA Challenges are an established and important way to drive scientific progress. They make research comparable on a well-defined benchmark with equal test conditions for all participants. However, such challenge events occur only occasionally, are limited to a small number of contestants, and the test conditions are very difficult to replicate after the main event. We present a new physical benchmark challenge for robotic picking: the ACRV Picking Benchmark (APB). Designed to be reproducible, it consists of a set of 42 common objects, a widely available shelf, and exact guidelines for object arrangement using stencils. A well-defined evaluation protocol enables the comparison of \emph{complete} robotic systems -- including perception and manipulation -- instead of sub-systems only. Our paper also describes and reports results achieved by an open baseline system based on a Baxter robot.

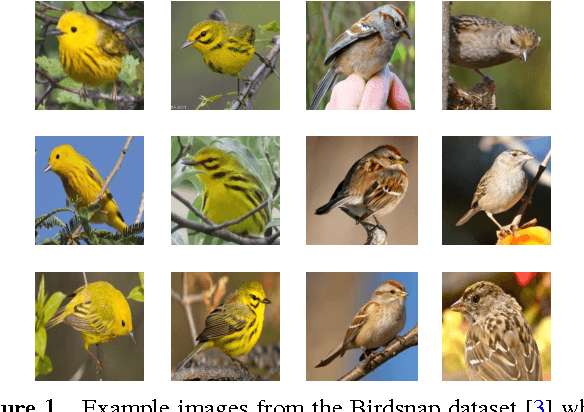

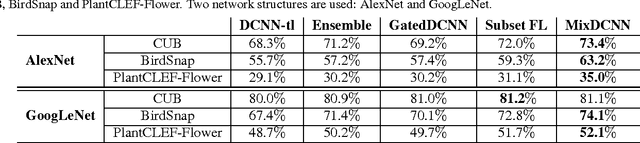

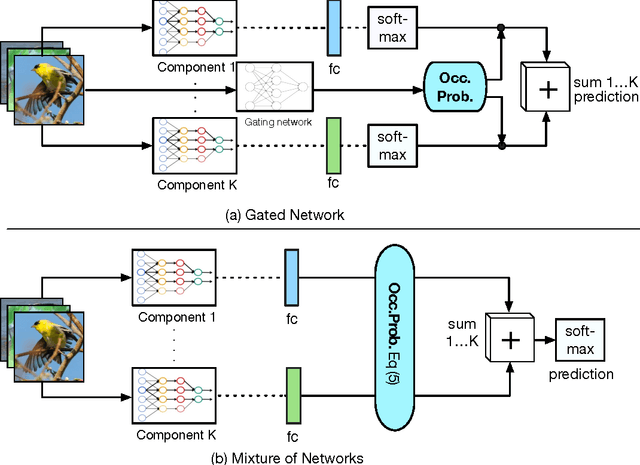

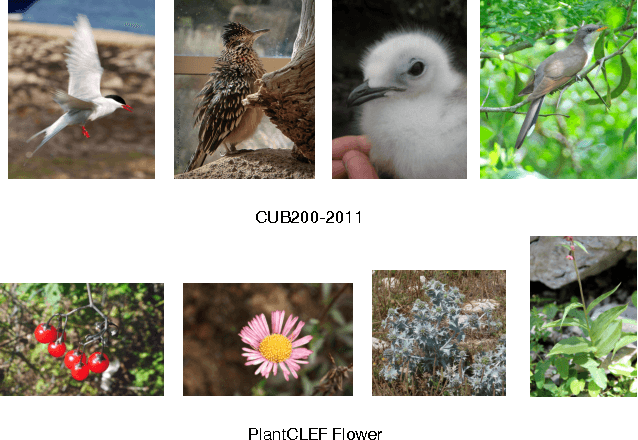

Fine-Grained Classification via Mixture of Deep Convolutional Neural Networks

Nov 30, 2015

Abstract:We present a novel deep convolutional neural network (DCNN) system for fine-grained image classification, called a mixture of DCNNs (MixDCNN). The fine-grained image classification problem is characterised by large intra-class variations and small inter-class variations. To overcome these problems our proposed MixDCNN system partitions images into K subsets of similar images and learns an expert DCNN for each subset. The output from each of the K DCNNs is combined to form a single classification decision. In contrast to previous techniques, we provide a formulation to perform joint end-to-end training of the K DCNNs simultaneously. Extensive experiments, on three datasets using two network structures (AlexNet and GoogLeNet), show that the proposed MixDCNN system consistently outperforms other methods. It provides a relative improvement of 12.7% and achieves state-of-the-art results on two datasets.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge