Lessons Learnt from Field Trials of a Robotic Sweet Pepper Harvester

Paper and Code

Jun 19, 2017

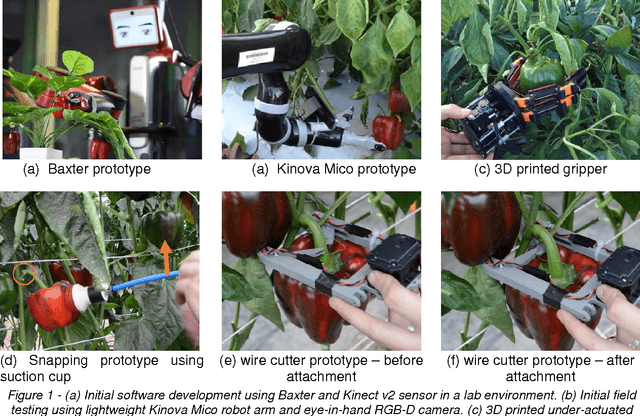

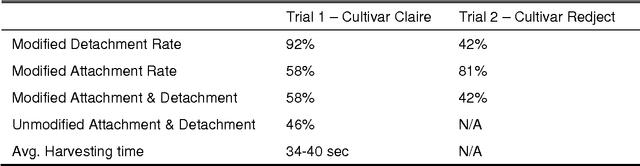

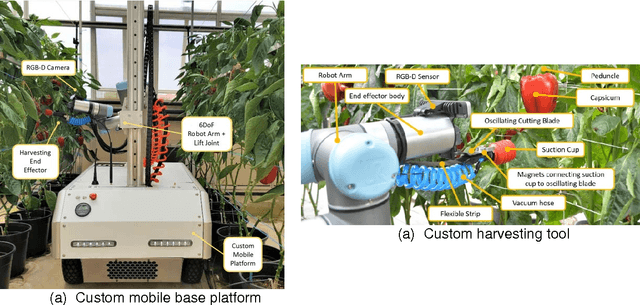

In this paper, we present the lessons learnt during the development of a new robotic harvester (Harvey) that can autonomously harvest sweet pepper (capsicum) in protected cropping environments. Robotic harvesting offers an attractive potential solution to reducing labour costs while enabling more regular and selective harvesting, optimising crop quality, scheduling and therefore profit. Our approach combines effective vision algorithms with a novel end-effector design to enable successful harvesting of sweet peppers. We demonstrate a simple and effective vision-based algorithm for crop detection, a grasp selection method, and a novel end-effector design for harvesting. To reduce the complexity of motion planning and to minimise occlusions we focus on picking sweet peppers in a protected cropping environment where plants are grown on planar trellis structures. Initial field trials in protected cropping environments, with two cultivars, demonstrate the efficacy of this approach. The results show that the robot harvester can successfully detect, grasp, and detach crop from the plant within a real protected cropping system. The novel contributions of this work have resulted in significant and encouraging improvements in sweet pepper picking success rates compared with the state-of-the-art. Future work will look at detecting sweet pepper peduncles and improving the total harvesting cycle time for each sweet pepper. The methods presented in this paper provide steps towards the goal of fully autonomous and reliable crop picking systems that will revolutionise the horticulture industry by reducing labour costs, maximising the quality of produce, and ultimately improving the sustainability of farming enterprises.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge