Matthias Mayr

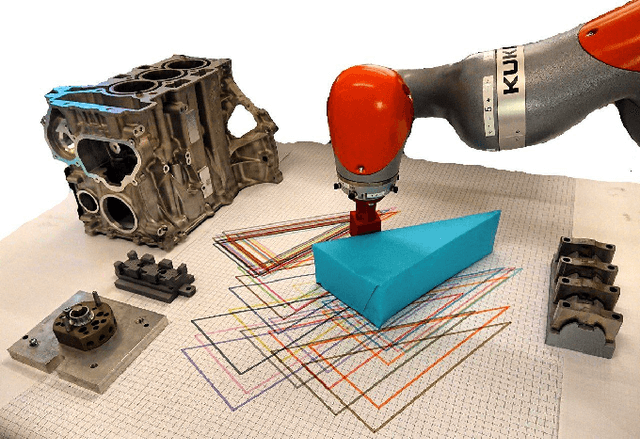

Adaptable Recovery Behaviors in Robotics: A Behavior Trees and Motion Generators(BTMG) Approach for Failure Management

Apr 09, 2024Abstract:In dynamic operational environments, particularly in collaborative robotics, the inevitability of failures necessitates robust and adaptable recovery strategies. Traditional automated recovery strategies, while effective for predefined scenarios, often lack the flexibility required for on-the-fly task management and adaptation to expected failures. Addressing this gap, we propose a novel approach that models recovery behaviors as adaptable robotic skills, leveraging the Behavior Trees and Motion Generators~(BTMG) framework for policy representation. This approach distinguishes itself by employing reinforcement learning~(RL) to dynamically refine recovery behavior parameters, enabling a tailored response to a wide array of failure scenarios with minimal human intervention. We assess our methodology through a series of progressively challenging scenarios within a peg-in-a-hole task, demonstrating the approach's effectiveness in enhancing operational efficiency and task success rates in collaborative robotics settings. We validate our approach using a dual-arm KUKA robot.

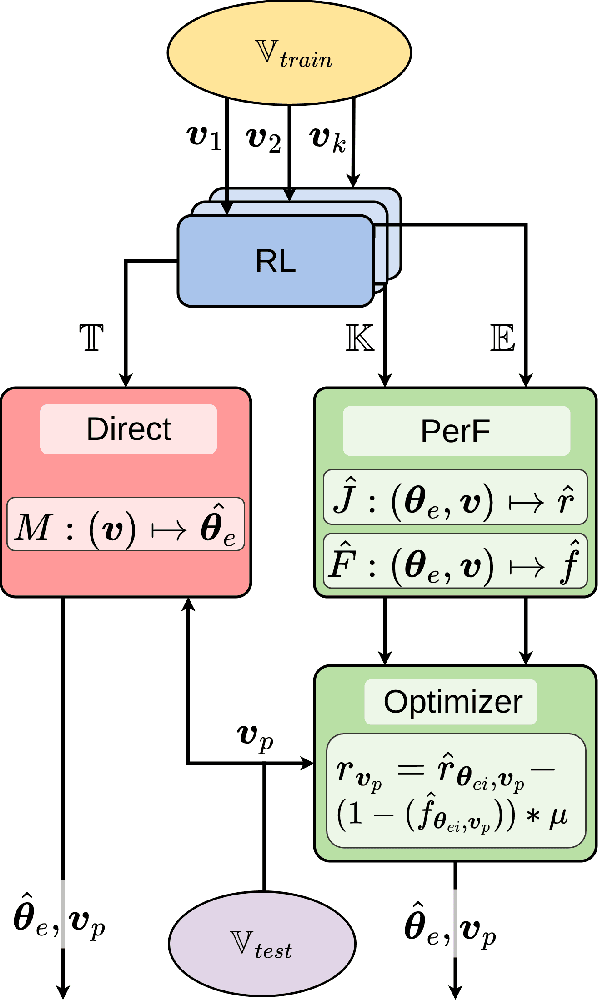

Flexible and Adaptive Manufacturing by Complementing Knowledge Representation, Reasoning and Planning with Reinforcement Learning

Nov 15, 2023Abstract:This paper describes a novel approach to adaptive manufacturing in the context of small batch production and customization. It focuses on integrating task-level planning and reasoning with reinforcement learning (RL) in the SkiROS2 skill-based robot control platform. This integration enhances the efficiency and adaptability of robotic systems in manufacturing, enabling them to adjust to task variations and learn from interaction data. The paper highlights the architecture of SkiROS2, particularly its world model, skill libraries, and task management. It demonstrates how combining RL with robotic manipulators can learn and improve the execution of industrial tasks. It advocates a multi-objective learning model that eases the learning problem design. The approach can incorporate user priors or previous experiences to accelerate learning and increase safety. Spotlight video: https://youtu.be/H5PmZl2rRbs?si=8wmZ-gbwuSJRxe3S&t=1422 SkiROS2 code: https://github.com/RVMI/skiros2 SkiROS2 talk at ROSCon: https://vimeo.com/879001825/2a0e9d5412 SkiREIL code: https://github.com/matthias-mayr/SkiREIL

BeBOP -- Combining Reactive Planning and Bayesian Optimization to Solve Robotic Manipulation Tasks

Oct 02, 2023

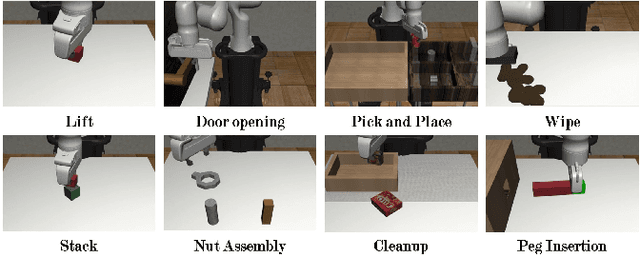

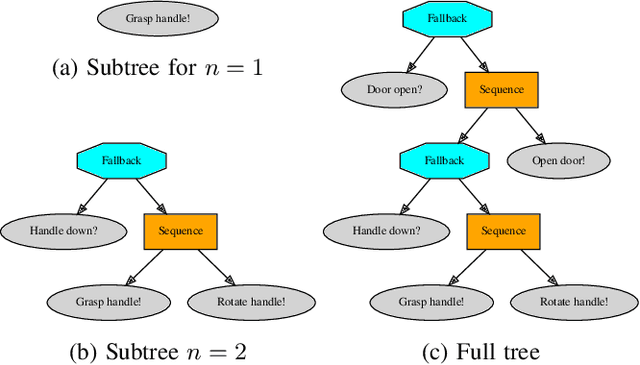

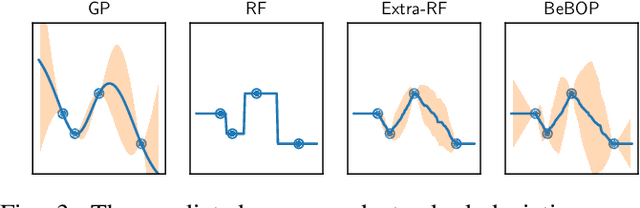

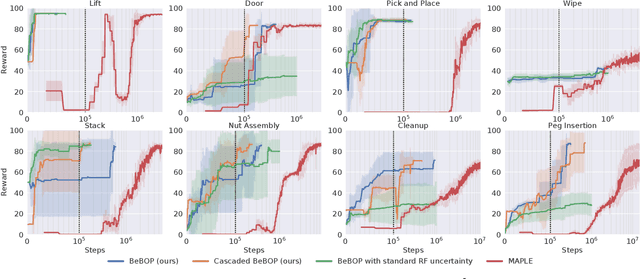

Abstract:Robotic systems for manipulation tasks are increasingly expected to be easy to configure for new tasks. While in the past, robot programs were often written statically and tuned manually, the current, faster transition times call for robust, modular and interpretable solutions that also allow a robotic system to learn how to perform a task. We propose the method Behavior-based Bayesian Optimization and Planning (BeBOP) that combines two approaches for generating behavior trees: we build the structure using a reactive planner and learn specific parameters with Bayesian optimization. The method is evaluated on a set of robotic manipulation benchmarks and is shown to outperform state-of-the-art reinforcement learning algorithms by being up to 46 times faster while simultaneously being less dependent on reward shaping. We also propose a modification to the uncertainty estimate for the random forest surrogate models that drastically improves the results.

Using Knowledge Representation and Task Planning for Robot-agnostic Skills on the Example of Contact-Rich Wiping Tasks

Aug 27, 2023Abstract:The transition to agile manufacturing, Industry 4.0, and high-mix-low-volume tasks require robot programming solutions that are flexible. However, most deployed robot solutions are still statically programmed and use stiff position control, which limit their usefulness. In this paper, we show how a single robot skill that utilizes knowledge representation, task planning, and automatic selection of skill implementations based on the input parameters can be executed in different contexts. We demonstrate how the skill-based control platform enables this with contact-rich wiping tasks on different robot systems. To achieve that in this case study, our approach needs to address different kinematics, gripper types, vendors, and fundamentally different control interfaces. We conducted the experiments with a mobile platform that has a Universal Robots UR5e 6 degree-of-freedom robot arm with position control and a 7 degree-of-freedom KUKA iiwa with torque control.

SkiROS2: A skill-based Robot Control Platform for ROS

Jun 29, 2023Abstract:The need for autonomous robot systems in both the service and the industrial domain is larger than ever. In the latter, the transition to small batches or even "batch size 1" in production created a need for robot control system architectures that can provide the required flexibility. Such architectures must not only have a sufficient knowledge integration framework. It must also support autonomous mission execution and allow for interchangeability and interoperability between different tasks and robot systems. We introduce SkiROS2, a skill-based robot control platform on top of ROS. SkiROS2 proposes a layered, hybrid control structure for automated task planning, and reactive execution, supported by a knowledge base for reasoning about the world state and entities. The scheduling formulation builds on the extended behavior tree model that merges task-level planning and execution. This allows for a high degree of modularity and a fast reaction to changes in the environment. The skill formulation based on pre-, hold- and post-conditions allows to organize robot programs and to compose diverse skills reaching from perception to low-level control and the incorporation of external tools. We relate SkiROS2 to the field and outline three example use cases that cover task planning, reasoning, multisensory input, integration in a manufacturing execution system and reinforcement learning.

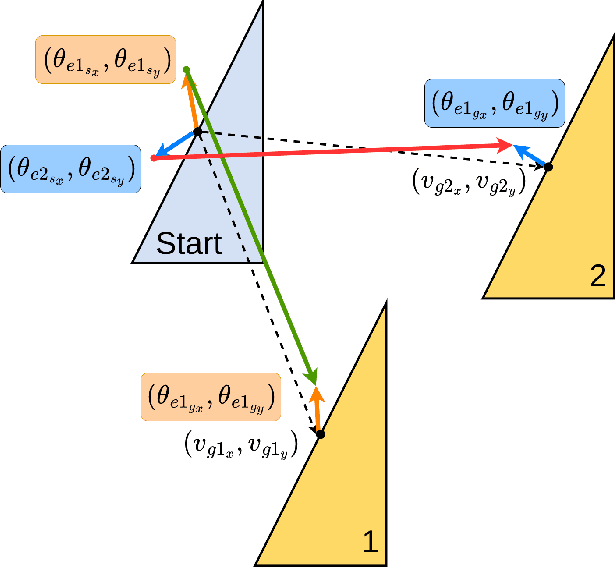

Learning to Adapt the Parameters of Behavior Trees and Motion Generators to Task Variations

Mar 14, 2023

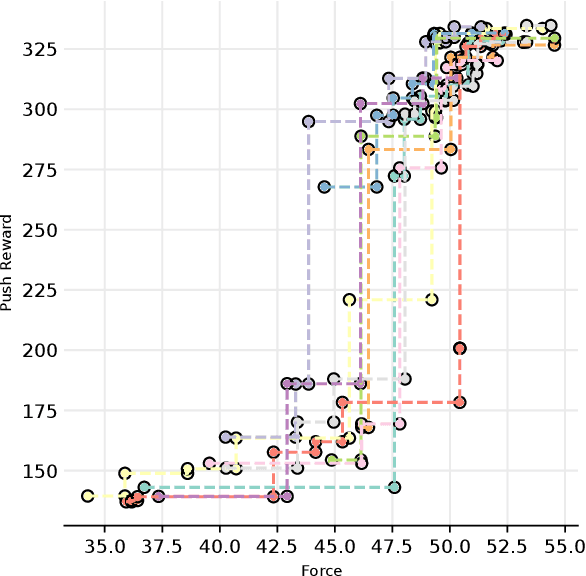

Abstract:The ability to learn new tasks and quickly adapt to different variations or dimensions is an important attribute in agile robotics. In our previous work, we have explored Behavior Trees and Motion Generators (BTMGs) as a robot arm policy representation to facilitate the learning and execution of assembly tasks. The current implementation of the BTMGs for a specific task may not be robust to the changes in the environment and may not generalize well to different variations of tasks. We propose to extend the BTMG policy representation with a module that predicts BTMG parameters for a new task variation. To achieve this, we propose a model that combines a Gaussian process and a weighted support vector machine classifier. This model predicts the performance measure and the feasibility of the predicted policy with BTMG parameters and task variations as inputs. Using the outputs of the model, we then construct a surrogate reward function that is utilized within an optimizer to maximize the performance of a task over BTMG parameters for a fixed task variation. To demonstrate the effectiveness of our proposed approach, we conducted experimental evaluations on push and obstacle avoidance tasks in simulation and with a real KUKA iiwa robot. Furthermore, we compared the performance of our approach with four baseline methods.

A C++ Implementation of a Cartesian Impedance Controller for Robotic Manipulators

Dec 21, 2022

Abstract:Cartesian impedance control is a type of motion control strategy for robots that improves safety in partially unknown environments by achieving a compliant behavior of the robot with respect to its external forces. This compliant robot behavior has the added benefit of allowing physical human guidance of the robot. In this paper, we propose a C++ implementation of compliance control valid for any torque-commanded robotic manipulator. The proposed controller implements Cartesian impedance control to track a desired end-effector pose. Additionally, joint impedance is projected in the nullspace of the Cartesian robot motion to track a desired robot joint configuration without perturbing the Cartesian motion of the robot. The proposed implementation also allows the robot to apply desired forces and torques to its environment. Several safety features such as filtering, rate limiting, and saturation are included in the proposed implementation. The core functionalities are in a re-usable base library and a Robot Operating System (ROS) ros_control integration is provided on top of that. The implementation was tested with the KUKA LBR iiwa robot and the Franka Emika Robot (Panda) both in simulation and with the physical robots.

Combining Planning, Reasoning and Reinforcement Learning to solve Industrial Robot Tasks

Dec 07, 2022Abstract:One of today's goals for industrial robot systems is to allow fast and easy provisioning for new tasks. Skill-based systems that use planning and knowledge representation have long been one possible answer to this. However, especially with contact-rich robot tasks that need careful parameter settings, such reasoning techniques can fall short if the required knowledge not adequately modeled. We show an approach that provides a combination of task-level planning and reasoning with targeted learning of skill parameters for a task at hand. Starting from a task goal formulated in PDDL, the learnable parameters in the plan are identified and an operator can choose reward functions and parameters for the learning process. A tight integration with a knowledge framework allows to form a prior for learning and the usage of multi-objective Bayesian optimization eases to balance aspects such as safety and task performance that can often affect each other. We demonstrate the efficacy and versatility of our approach by learning skill parameters for two different contact-rich tasks and show their successful execution on a real 7-DOF KUKA-iiwa.

Learning Skill-based Industrial Robot Tasks with User Priors

Aug 02, 2022

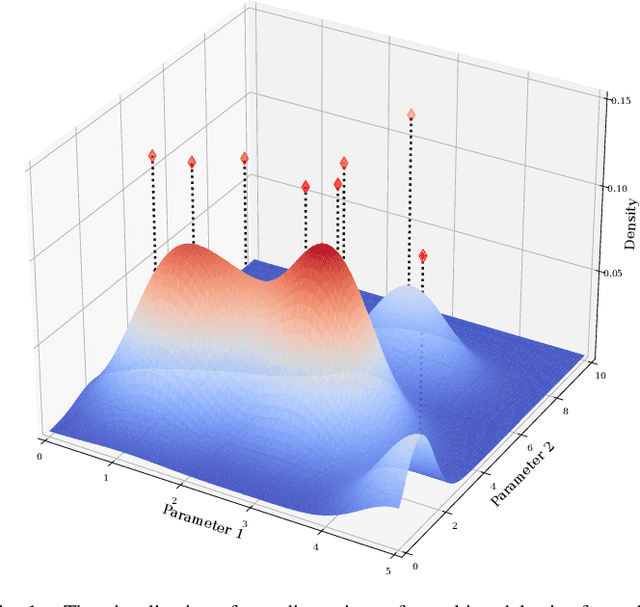

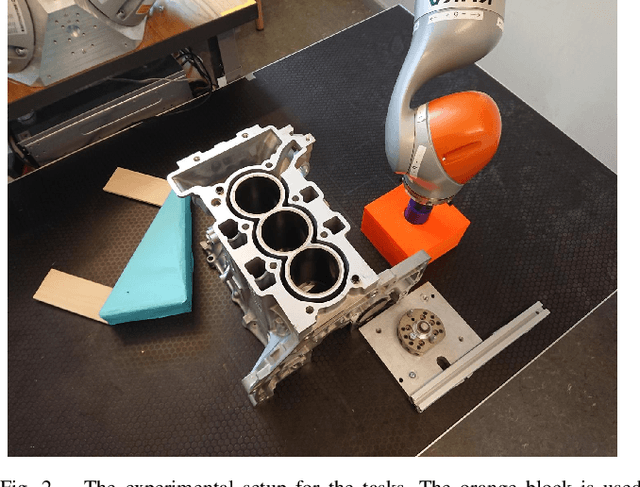

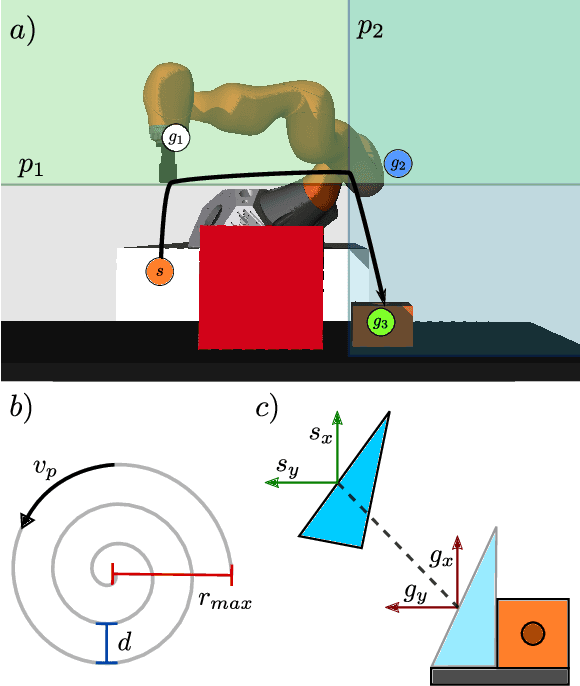

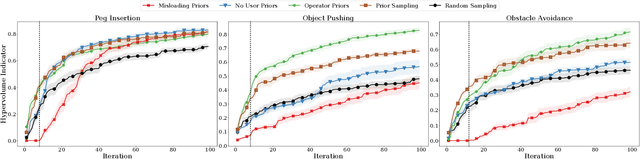

Abstract:Robot skills systems are meant to reduce robot setup time for new manufacturing tasks. Yet, for dexterous, contact-rich tasks, it is often difficult to find the right skill parameters. One strategy is to learn these parameters by allowing the robot system to learn directly on the task. For a learning problem, a robot operator can typically specify the type and range of values of the parameters. Nevertheless, given their prior experience, robot operators should be able to help the learning process further by providing educated guesses about where in the parameter space potential optimal solutions could be found. Interestingly, such prior knowledge is not exploited in current robot learning frameworks. We introduce an approach that combines user priors and Bayesian optimization to allow fast optimization of robot industrial tasks at robot deployment time. We evaluate our method on three tasks that are learned in simulation as well as on two tasks that are learned directly on a real robot system. Additionally, we transfer knowledge from the corresponding simulation tasks by automatically constructing priors from well-performing configurations for learning on the real system. To handle potentially contradicting task objectives, the tasks are modeled as multi-objective problems. Our results show that operator priors, both user-specified and transferred, vastly accelerate the discovery of rich Pareto fronts, and typically produce final performance far superior to proposed baselines.

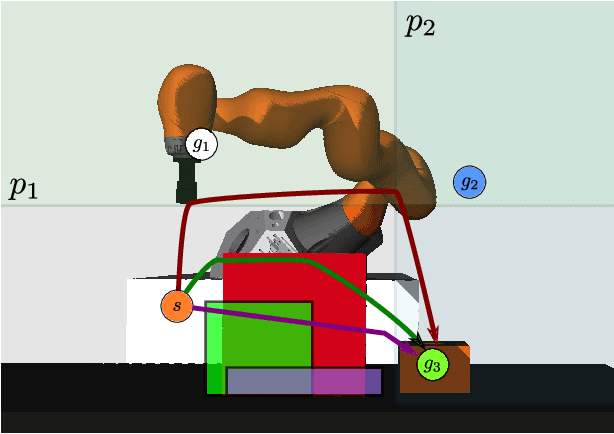

Skill-based Multi-objective Reinforcement Learning of Industrial Robot Tasks with Planning and Knowledge Integration

Mar 18, 2022

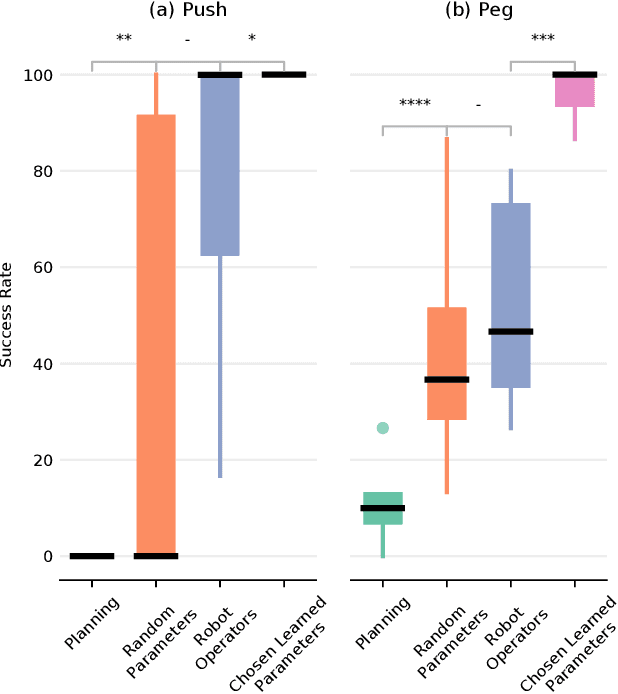

Abstract:In modern industrial settings with small batch sizes it should be easy to set up a robot system for a new task. Strategies exist, e.g. the use of skills, but when it comes to handling forces and torques, these systems often fall short. We introduce an approach that provides a combination of task-level planning with targeted learning of scenario-specific parameters for skill-based systems. We propose the following pipeline: (1) the user provides a task goal in the planning language PDDL, (2) a plan (i.e., a sequence of skills) is generated and the learnable parameters of the skills are automatically identified. An operator then chooses (3) reward functions and hyperparameters for the learning process. Two aspects of our methodology are critical: (a) learning is tightly integrated with a knowledge framework to support symbolic planning and to provide priors for learning, (b) using multi-objective optimization. This can help to balance key performance indicators (KPIs) such as safety and task performance since they can often affect each other. We adopt a multi-objective Bayesian optimization approach and learn entirely in simulation. We demonstrate the efficacy and versatility of our approach by learning skill parameters for two different contact-rich tasks. We show their successful execution on a real 7-DOF KUKA-iiwa manipulator and outperform the manual parameterization by human robot operators.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge