Kevin Haninger

Planning Human-Robot Co-manipulation with Human Motor Control Objectives and Multi-component Reaching Strategies

Dec 18, 2024Abstract:For successful goal-directed human-robot interaction, the robot should adapt to the intentions and actions of the collaborating human. This can be supported by musculoskeletal or data-driven human models, where the former are limited to lower-level functioning such as ergonomics, and the latter have limited generalizability or data efficiency. What is missing, is the inclusion of human motor control models that can provide generalizable human behavior estimates and integrate into robot planning methods. We use well-studied models from human motor control based on the speed-accuracy and cost-benefit trade-offs to plan collaborative robot motions. In these models, the human trajectory minimizes an objective function, a formulation we adapt to numerical trajectory optimization. This can then be extended with constraints and new variables to realize collaborative motion planning and goal estimation. We deploy this model, as well as a multi-component movement strategy, in physical collaboration with uncertain goal-reaching and synchronized motion tasks, showing the ability of the approach to produce human-like trajectories over a range of conditions.

Energy Consumption in Robotics: A Simplified Modeling Approach

Nov 05, 2024

Abstract:The energy use of a robot is trajectory-dependent, and thus can be reduced by optimization of the trajectory. Current methods for robot trajectory optimization can reduce energy up to 15\% for fixed start and end points, however their use in industrial robot planning is still restricted due to model complexity and lack of integration with planning tools which address other concerns (e.g. collision avoidance). We propose an approach that uses differentiable inertial and kinematic models from standard open-source tools, integrating with standard ROS planning methods. An inverse dynamics-based energy model is optionally extended with a single-parameter electrical model, simplifying the model identification process. We compare the inertial and electrical models on a collaborative robot, showing that simplified models provide competitive accuracy and are easier to deploy in practice.

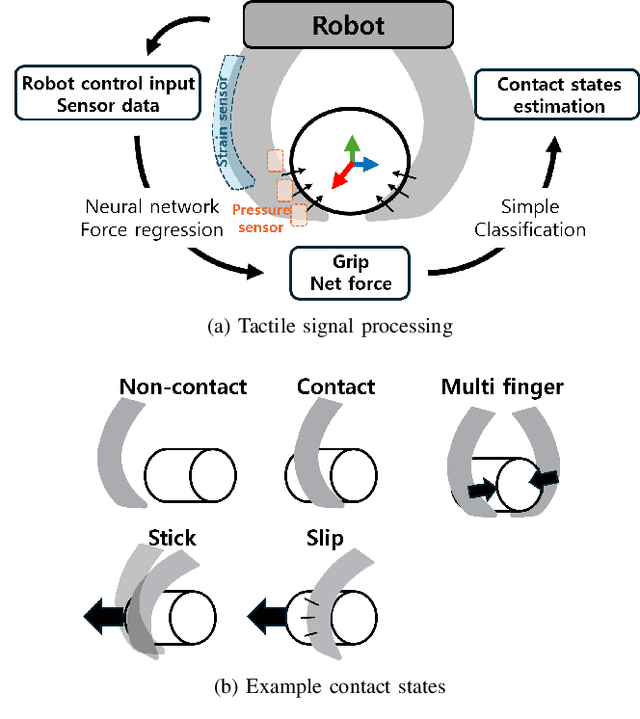

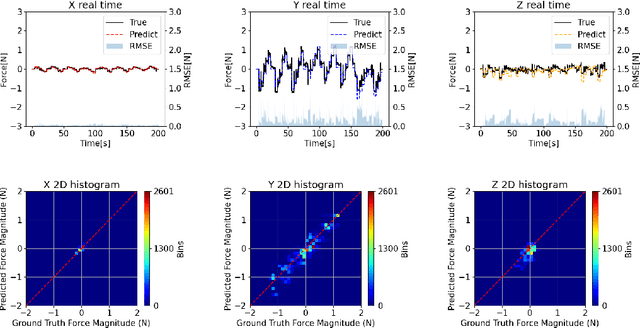

Soft Finger Grasp Force and Contact State Estimation from Tactile Sensors

Oct 25, 2024

Abstract:Soft robotic fingers can improve adaptability in grasping and manipulation, compensating for geometric variation in object or environmental contact, but today lack force capacity and fine dexterity. Integrated tactile sensors can provide grasp and task information which can improve dexterity,but should ideally not require object-specific training. The total force vector exerted by a finger provides general information to the internal grasp forces (e.g. for grasp stability) and, when summed over fingers, an estimate of the external force acting on the grasped object (e.g. for task-level control). In this study, we investigate the efficacy of estimating finger force from integrated soft sensors and use it to estimate contact states. We use a neural network for force regression, collecting labelled data with a force/torque sensor and a range of test objects. Subsequently, we apply this model in a plug-in task scenario and demonstrate its validity in estimating contact states.

Industrial Cabling in Constrained Environments: a Practical Approach and Current Challenges

Apr 16, 2024

Abstract:Cabling tasks (pulling, clipping, and plug insertion) are today mostly manual work, limiting the cost-effectiveness of electrification. Feasibility for the robotic grasping and insertion of plugs, as well as the manipulation of cables, have been shown in research settings. However, in many industrial tasks the complete process from picking, insertion, routing, and validation must be solved with one system. This often means the cable must be directly manipulated for routing, and the plug must be manipulated for insertion, often in cluttered environments with tight space constraints. Here we introduce an analysis of the complete industrial cabling tasks and demonstrate a solution from grasp, plug insertion, clipping, and final plug insertion. Industrial requirements are summarized, considering the space limitations, tolerances, and possible ways that the cabling process can be integrated into the production process. This paper proposes gripper designs and general robotic assembly methods for the widely used FASTON and a cubical industrial connector. The proposed methods cover the cable gripping, handling, routing, and inserting processes of the connector. Customized grippers are designed to ensure the reliable gripping of the plugs and the pulling and manipulation of the cable segments. A passive component to correct the cable orientation is proposed, allowing the robot to re-grip the plug before insertion. In general, the proposed method can perform cable assembly with mere position control, foregoing complex control approaches. This solution is demonstrated with an industrial product with realistic space requirements and tolerances, identifying difficult aspects of current cabling scenarios and potential to improve the automation-friendliness in the product design.

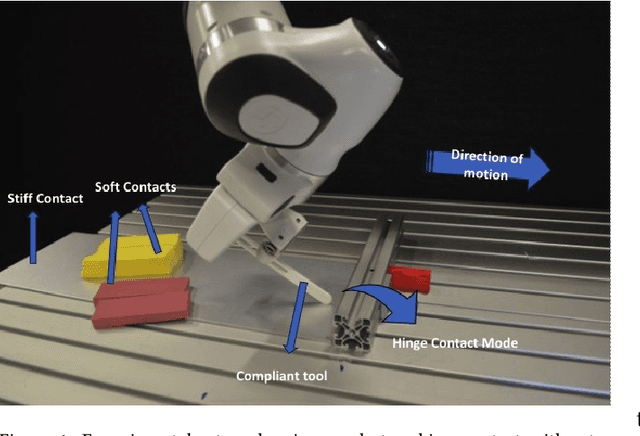

Combining Sampling- and Gradient-based Planning for Contact-rich Manipulation

Oct 07, 2023

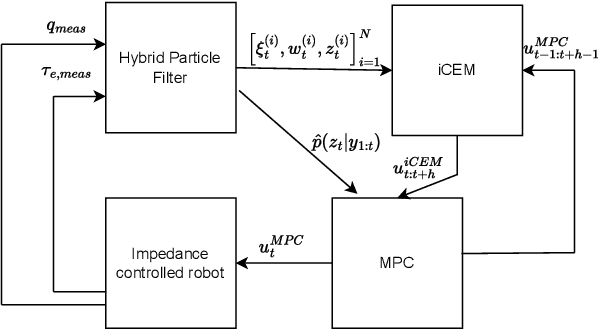

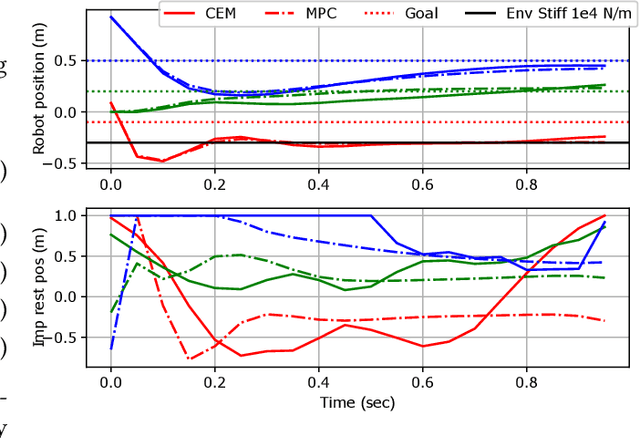

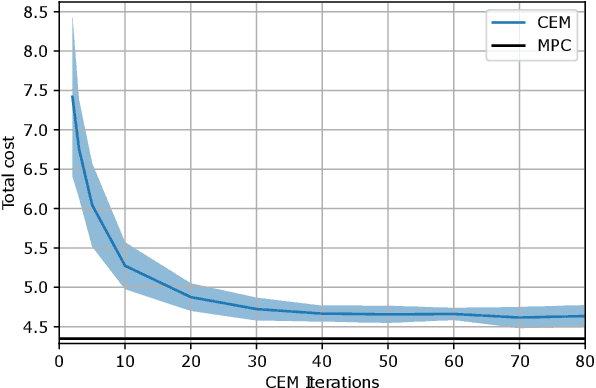

Abstract:Planning over discontinuous dynamics is needed for robotics tasks like contact-rich manipulation, which presents challenges in the numerical stability and speed of planning methods when either neural network or analytical models are used. On the one hand, sampling-based planners require higher sample complexity in high-dimensional problems and cannot describe safety constraints such as force limits. On the other hand, gradient-based solvers can suffer from local optima and convergence issues when the Hessian is poorly conditioned. We propose a planning method with both sampling- and gradient-based elements, using the Cross-entropy Method to initialize a gradient-based solver, providing better search over local minima and the ability to handle explicit constraints. We show the approach allows smooth, stable contact-rich planning for an impedance-controlled robot making contact with a stiff environment, benchmarking against gradient-only MPC and CEM.

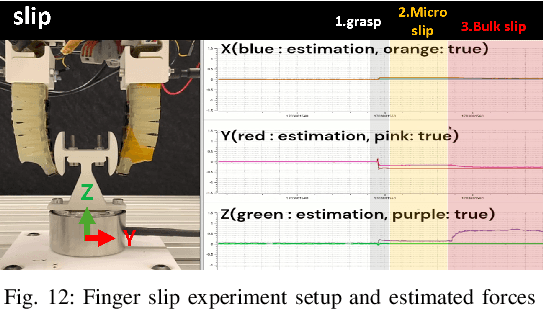

Soft finger dynamic stability and slip by Coulomb friction and bulk stiffness

Oct 07, 2023Abstract:Soft robotic fingers can safely grasp fragile or non-uniform objects, but their force capacity is limited, especially with less contact area: objects which are smaller, not round, or where an enclosing grasp is not feasible. To improve force capacity, this paper considers two types of grip failure, slip and dynamic rotational stability. For slip, a Coulomb model for soft fingers based on total normal and tangential force is validated, identifying the effect of contact area, pressure, and grip position on effective Coulomb coefficient, normal force and transverse stiffness. For rotational stability, bulk stiffness of the fingers is used to develop conditions for dynamic stability about the initial grasp, and a condition for when the rotation leads to slip. Together, these models suggest contact area improves grip by increasing transverse stiffness and normal force. The models are validated in a range of grasp conditions, shown to predict the influence of object radius and finger distance on grip stability limits.

High-speed electrical connector assembly by structured compliance in a finray-effect gripper

Jul 28, 2023Abstract:Fine assembly tasks such as electrical connector insertion have tight tolerances and sensitive components, requiring compensation of alignment errors while applying sufficient force in the insertion direction, ideally at high speeds and while grasping a range of components. Vision, tactile, or force sensors can compensate alignment errors, but have limited bandwidth, limiting the safe assembly speed. Passive compliance such as silicone-based fingers can reduce collision forces and grasp a range of components, but often cannot provide the accuracy or assembly forces required. To support high-speed mechanical search and self-aligning insertion, this paper proposes monolithic additively manufactured fingers which realize a moderate, structured compliance directly proximal to the gripped object. The geometry of finray-effect fingers are adapted to add form-closure features and realize a directionally-dependent stiffness at the fingertip, with a high stiffness to apply insertion forces and lower transverse stiffness to support alignment. Design parameters and mechanical properties of the fingers are investigated with FEM and empirical studies, analyzing the stiffness, maximum load, and viscoelastic effects. The fingers realize a remote center of compliance, which is shown to depend on the rib angle, and a directional stiffness ratio of $14-36$. The fingers are applied to a plug insertion task, realizing a tolerance window of $7.5$ mm and approach speeds of $1.3$ m/s.

Differentiable Environment Primitives for Contact State Estimation

Apr 03, 2023Abstract:In contact-rich manipulation, the robot dynamics are coupled with an environment that has application-specific dynamic properties (stiffness, inertia) and geometry (contact normal). Knowledge of these environmental parameters can improve control and monitoring, but they are often unobserved and may vary, either online or between task instances. Observers, such as the extended Kalman filter, can be used to estimate these parameters, but such model-based techniques can require too much engineering work to scale up to complex environments, such as multi-point contact. To accelerate environment modeling, we propose environment primitives: parameterized environment dynamics that can be connected in parallel and are expressed in an automatic differentiation framework. This simplifies offline gradient-based optimization to fit model parameters and linearization of the coupled dynamics for an observer. This method is implemented for stiffness contact models, allowing the fitting of contact geometry and stiffness offline or their online estimation by an extended Kalman filter. This method is applied to a collaborative robot, estimating external force, contact stiffness, and contact geometry from the motor position and current. The estimates of external force and stiffness are compared with a momentum observer and direct force measurements.

Teaching contact-rich tasks from visual demonstrations by constraint extraction

Apr 03, 2023Abstract:Contact-rich manipulation involves kinematic constraints on the task motion, typically with discrete transitions between these constraints during the task. Allowing the robot to detect and reason about these contact constraints can support robust and dynamic manipulation, but how can these contact models be efficiently learned? Purely visual observations are an attractive data source, allowing passive task demonstrations with unmodified objects. Existing approaches for vision-only learning from demonstration are effective in pick-and-place applications and planar tasks. Nevertheless, accuracy/occlusions and unobserved task dynamics can limit their robustness in contact-rich manipulation. To use visual demonstrations for contact-rich robotic tasks, we consider the demonstration of pose trajectories with transitions between holonomic kinematic constraints, first clustering the trajectories into discrete contact modes, then fitting kinematic constraints per each mode. The fit constraints are then used to (i) detect contact online with force/torque measurements and (ii) plan the robot policy with respect to the active constraint. We demonstrate the approach with real experiments, on cabling and rake tasks, showing the approach gives robust manipulation through contact transitions.

Compliant finray-effect gripper for high-speed robotic assembly of electrical components

Jan 20, 2023Abstract:Fine assembly tasks such as electrical connector insertion have tight tolerances and sensitive components, limiting the speed and robustness of robot assembly, even when using vision, tactile, or force sensors. Connector insertion is a common industrial task, requiring horizontal alignment errors to be compensated with minimal force, then sufficient force to be brought in the insertion direction. The ability to handle a variety of objects, achieve high-speeds, and handle a wide range in object position variation are also desired. Soft grippers can allow the gripping of parts with variation in surface geometry, but often focus on gripping alone and may not be able to bring the assembly forces required. To achieve high-speed connector insertion, this paper proposes monolithic fingers with structured compliance and form-closure features. A finray-effect gripper is adapted to realize structured (i.e. directional) stiffness that allows high-speed mechanical search, self-alignment in insertion, and sufficient assembly force. The design of the finray ribs and fingertips are investigated, with a final design allowing plug insertion with a tolerance window of up to 7.5 mm at high speed.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge