Marcel Radke

Industrial Cabling in Constrained Environments: a Practical Approach and Current Challenges

Apr 16, 2024

Abstract:Cabling tasks (pulling, clipping, and plug insertion) are today mostly manual work, limiting the cost-effectiveness of electrification. Feasibility for the robotic grasping and insertion of plugs, as well as the manipulation of cables, have been shown in research settings. However, in many industrial tasks the complete process from picking, insertion, routing, and validation must be solved with one system. This often means the cable must be directly manipulated for routing, and the plug must be manipulated for insertion, often in cluttered environments with tight space constraints. Here we introduce an analysis of the complete industrial cabling tasks and demonstrate a solution from grasp, plug insertion, clipping, and final plug insertion. Industrial requirements are summarized, considering the space limitations, tolerances, and possible ways that the cabling process can be integrated into the production process. This paper proposes gripper designs and general robotic assembly methods for the widely used FASTON and a cubical industrial connector. The proposed methods cover the cable gripping, handling, routing, and inserting processes of the connector. Customized grippers are designed to ensure the reliable gripping of the plugs and the pulling and manipulation of the cable segments. A passive component to correct the cable orientation is proposed, allowing the robot to re-grip the plug before insertion. In general, the proposed method can perform cable assembly with mere position control, foregoing complex control approaches. This solution is demonstrated with an industrial product with realistic space requirements and tolerances, identifying difficult aspects of current cabling scenarios and potential to improve the automation-friendliness in the product design.

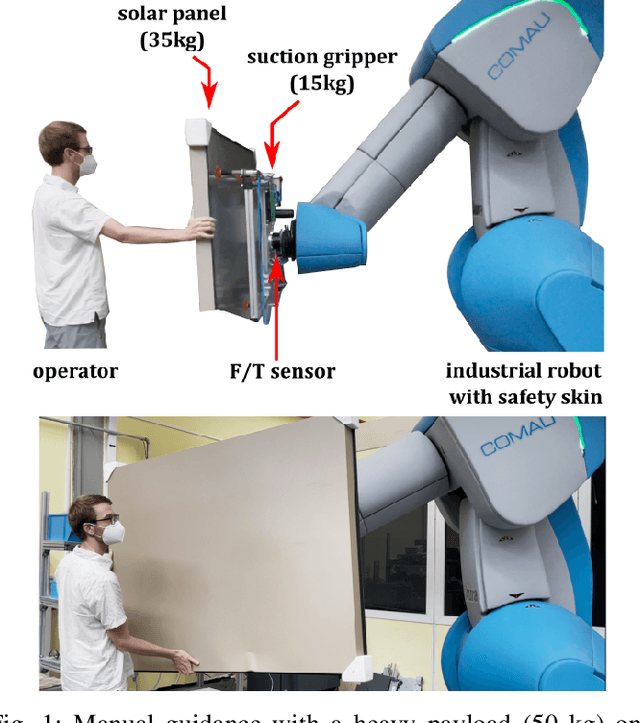

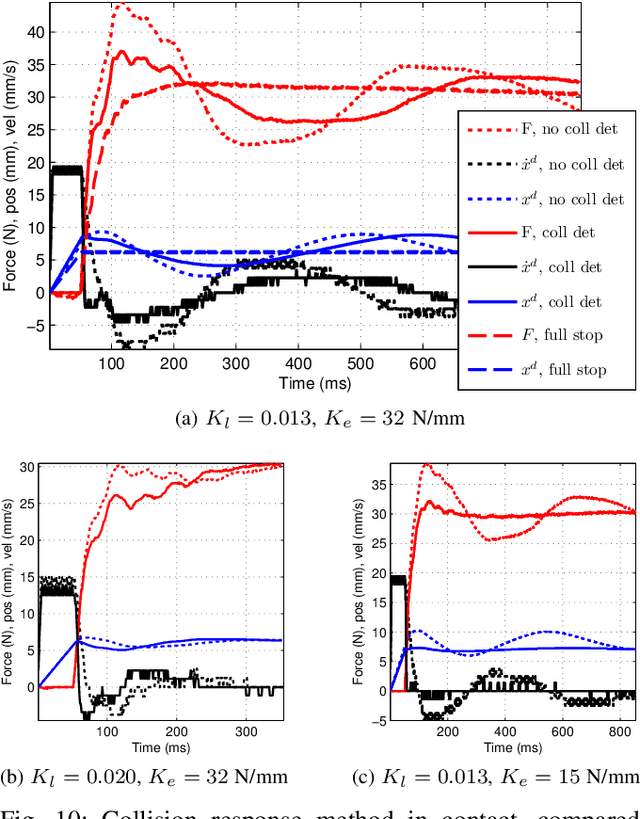

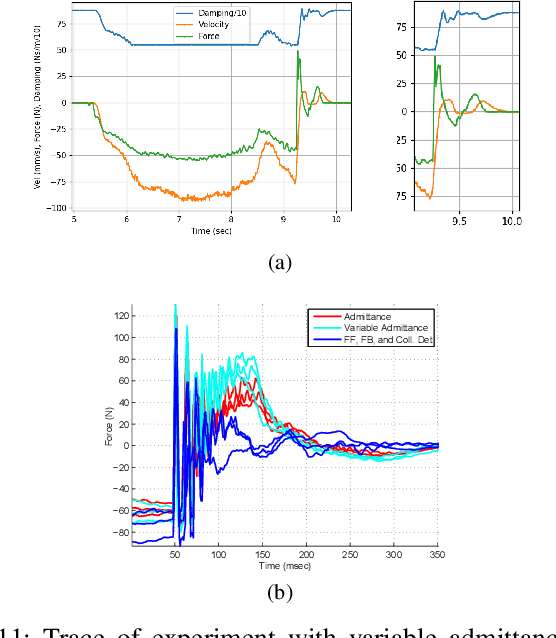

Towards High-Payload Admittance Control for Manual Guidance with Environmental Contact

Feb 02, 2022

Abstract:Force control enables hands-on teaching and physical collaboration, with the potential to improve ergonomics and flexibility of automation. Established methods for the design of compliance, impedance control, and \rev{collision response} can achieve free-space stability and acceptable peak contact force on lightweight, lower payload robots. Scaling collaboration to higher payloads can allow new applications, but introduces challenges due to the more significant payload dynamics and the use of higher-payload industrial robots. To achieve high-payload manual guidance with contact, this paper proposes and validates new mechatronic design methods: standard admittance control is extended with damping feedback, compliant structures are integrated to the environment, and a contact response method which allows continuous admittance control is proposed. These methods are compared with respect to free-space stability, contact stability, and peak contact force. The resulting methods are then applied to realize two contact-rich tasks on a 16 kg payload (peg in hole and slot assembly) and free-space co-manipulation of a 50 kg payload.

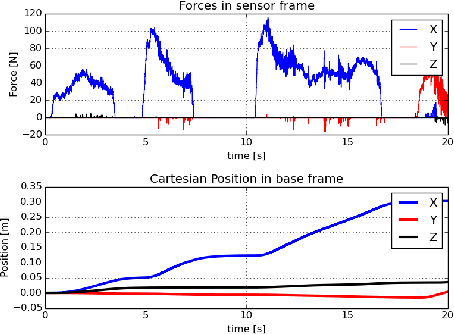

Contact Information Flow and Design of Compliance

Oct 24, 2021

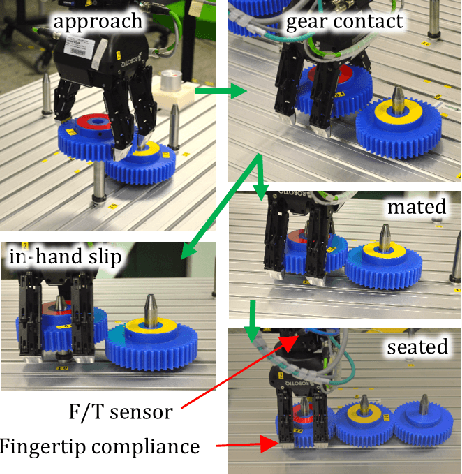

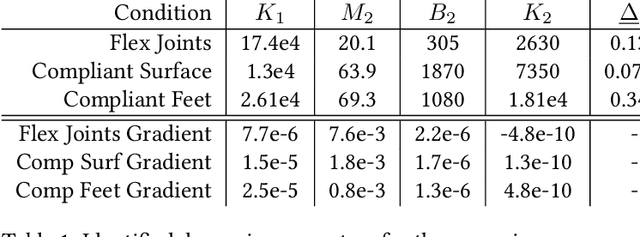

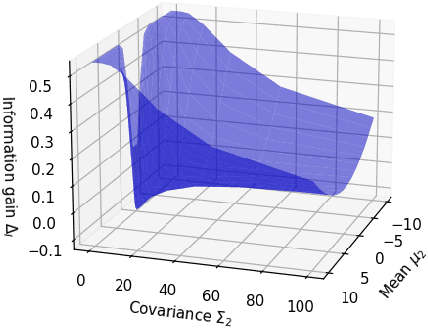

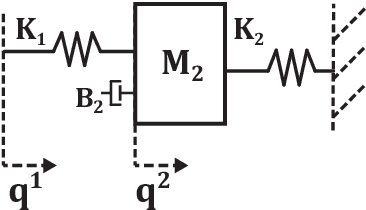

Abstract:The objective of many contact-rich manipulation tasks can be expressed as desired contacts between environmental objects. Simulation and planning for rigid-body contact continues to advance, but the achievable performance is significantly impacted by hardware design, such as physical compliance and sensor placement. Much of mechatronic design for contact is done from a continuous controls perspective (e.g. peak collision force, contact stability), but hardware also affects the ability to infer discrete changes in contact. Robustly detecting contact state can support the correction of errors, both online and in trial-and-error learning. Here, discrete contact states are considered as changes in environmental dynamics, and the ability to infer this with proprioception (motor position and force sensors) is investigated. A metric of information gain is proposed, measuring the reduction in contact belief uncertainty from force/position measurements, and developed for fully- and partially-observed systems. The information gain depends on the coupled robot/environment dynamics and sensor placement, especially the location and degree of compliance. Hardware experiments over a range of physical compliance conditions validate that information gain predicts the speed and certainty with which contact is detected in (i) monitoring of contact-rich assembly and (ii) collision detection. Compliant environmental structures are then optimized to allow industrial robots to achieve safe, higher-speed contact.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge