Kamaljyoti Nath

Leveraging Deep Operator Networks (DeepONet) for Acoustic Full Waveform Inversion (FWI)

Apr 14, 2025

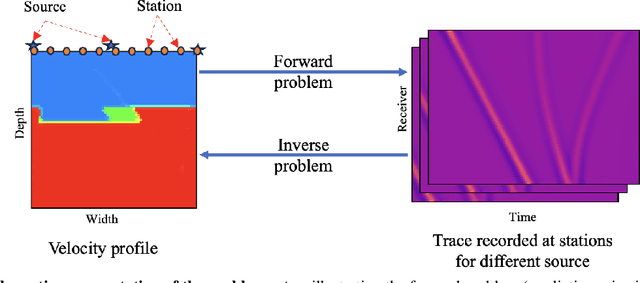

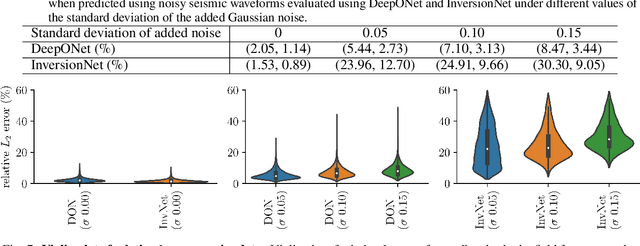

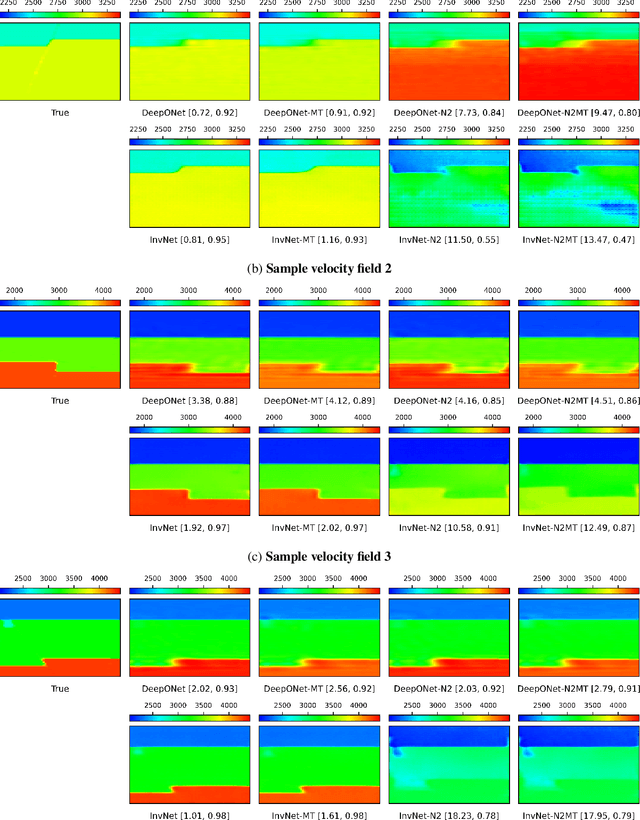

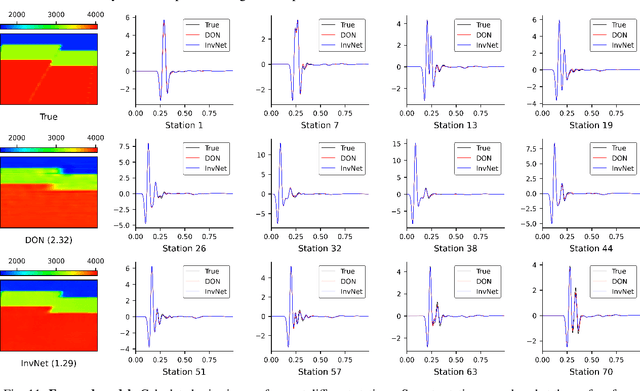

Abstract:Full Waveform Inversion (FWI) is an important geophysical technique considered in subsurface property prediction. It solves the inverse problem of predicting high-resolution Earth interior models from seismic data. Traditional FWI methods are computationally demanding. Inverse problems in geophysics often face challenges of non-uniqueness due to limited data, as data are often collected only on the surface. In this study, we introduce a novel methodology that leverages Deep Operator Networks (DeepONet) to attempt to improve both the efficiency and accuracy of FWI. The proposed DeepONet methodology inverts seismic waveforms for the subsurface velocity field. This approach is able to capture some key features of the subsurface velocity field. We have shown that the architecture can be applied to noisy seismic data with an accuracy that is better than some other machine learning methods. We also test our proposed method with out-of-distribution prediction for different velocity models. The proposed DeepONet shows comparable and better accuracy in some velocity models than some other machine learning methods. To improve the FWI workflow, we propose using the DeepONet output as a starting model for conventional FWI and that it may improve FWI performance. While we have only shown that DeepONet facilitates faster convergence than starting with a homogeneous velocity field, it may have some benefits compared to other approaches to constructing starting models. This integration of DeepONet into FWI may accelerate the inversion process and may also enhance its robustness and reliability.

A Neural Operator-Based Emulator for Regional Shallow Water Dynamics

Feb 20, 2025

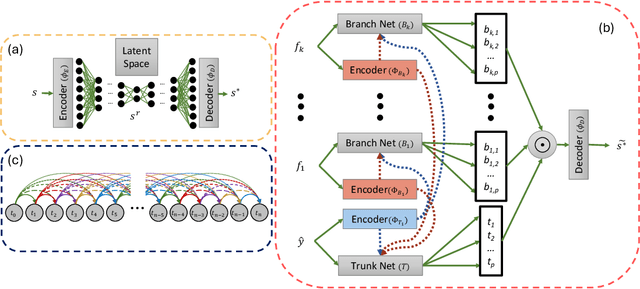

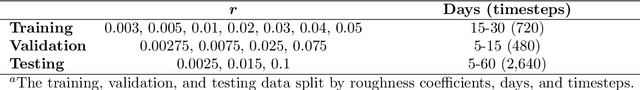

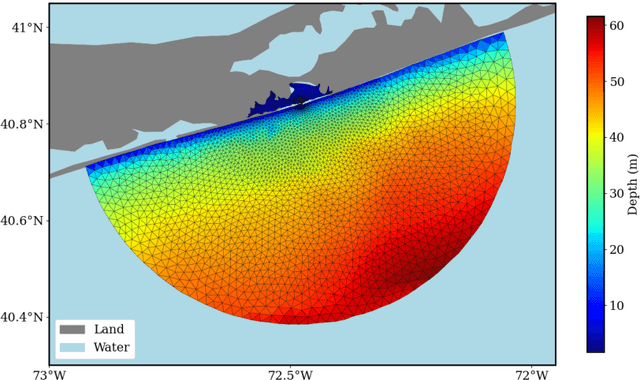

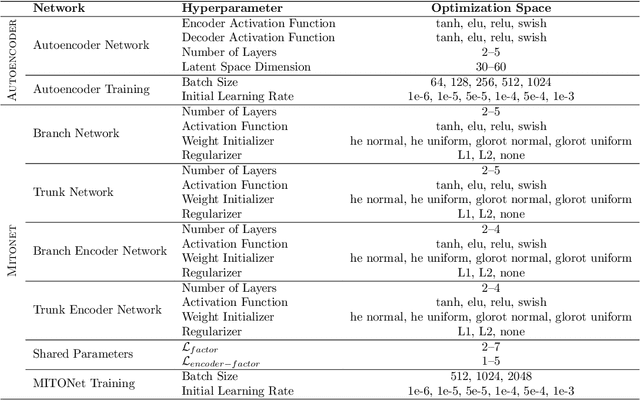

Abstract:Coastal regions are particularly vulnerable to the impacts of rising sea levels and extreme weather events. Accurate real-time forecasting of hydrodynamic processes in these areas is essential for infrastructure planning and climate adaptation. In this study, we present the Multiple-Input Temporal Operator Network (MITONet), a novel autoregressive neural emulator that employs dimensionality reduction to efficiently approximate high-dimensional numerical solvers for complex, nonlinear problems that are governed by time-dependent, parameterized partial differential equations. Although MITONet is applicable to a wide range of problems, we showcase its capabilities by forecasting regional tide-driven dynamics described by the two-dimensional shallow-water equations, while incorporating initial conditions, boundary conditions, and a varying domain parameter. We demonstrate MITONet's performance in a real-world application, highlighting its ability to make accurate predictions by extrapolating both in time and parametric space.

A Digital twin for Diesel Engines: Operator-infused PINNs with Transfer Learning for Engine Health Monitoring

Dec 16, 2024Abstract:Improving diesel engine efficiency and emission reduction have been critical research topics. Recent government regulations have shifted this focus to another important area related to engine health and performance monitoring. Although the advancements in the use of deep learning methods for system monitoring have shown promising results in this direction, designing efficient methods suitable for field systems remains an open research challenge. The objective of this study is to develop a computationally efficient neural network-based approach for identifying unknown parameters of a mean value diesel engine model to facilitate physics-based health monitoring and maintenance forecasting. We propose a hybrid method combining physics informed neural networks, PINNs, and a deep neural operator, DeepONet to predict unknown parameters and gas flow dynamics in a diesel engine. The operator network predicts independent actuator dynamics learnt through offline training, thereby reducing the PINNs online computational cost. To address PINNs need for retraining with changing input scenarios, we propose two transfer learning (TL) strategies. The first strategy involves multi-stage transfer learning for parameter identification. While this method is computationally efficient as compared to online PINN training, improvements are required to meet field requirements. The second TL strategy focuses solely on training the output weights and biases of a subset of multi-head networks pretrained on a larger dataset, substantially reducing computation time during online prediction. We also evaluate our model for epistemic and aleatoric uncertainty by incorporating dropout in pretrained networks and Gaussian noise in the training dataset. This strategy offers a tailored, computationally inexpensive, and physics-based approach for parameter identification in diesel engine sub systems.

Learning characteristic parameters and dynamics of centrifugal pumps under multi-phase flow using physics-informed neural networks

Oct 04, 2023Abstract:Electrical submersible pumps (ESP) are the second most used artificial lifting equipment in the oil and gas industry due to their high flow rates and boost pressures. They often have to handle multiphase flows, which usually contain a mixture of hydrocarbons, water, and/or sediments. Given these circumstances, emulsions are commonly formed. It is a liquid-liquid flow composed of two immiscible fluids whose effective viscosity and density differ from the single phase separately. In this context, accurate modeling of ESP systems is crucial for optimizing oil production and implementing control strategies. However, real-time and direct measurement of fluid and system characteristics is often impractical due to time constraints and economy. Hence, indirect methods are generally considered to estimate the system parameters. In this paper, we formulate a machine learning model based on Physics-Informed Neural Networks (PINNs) to estimate crucial system parameters. In order to study the efficacy of the proposed PINN model, we conduct computational studies using not only simulated but also experimental data for different water-oil ratios. We evaluate the state variable's dynamics and unknown parameters for various combinations when only intake and discharge pressure measurements are available. We also study structural and practical identifiability analyses based on commonly available pressure measurements. The PINN model could reduce the requirement of expensive field laboratory tests used to estimate fluid properties.

Physics-informed neural networks for predicting gas flow dynamics and unknown parameters in diesel engines

Apr 26, 2023Abstract:This paper presents a physics-informed neural network (PINN) approach for monitoring the health of diesel engines. The aim is to evaluate the engine dynamics, identify unknown parameters in a "mean value" model, and anticipate maintenance requirements. The PINN model is applied to diesel engines with a variable-geometry turbocharger and exhaust gas recirculation, using measurement data of selected state variables. The results demonstrate the ability of the PINN model to predict simultaneously both unknown parameters and dynamics accurately with both clean and noisy data, and the importance of the self-adaptive weight in the loss function for faster convergence. The input data for these simulations are derived from actual engine running conditions, while the outputs are simulated data, making this a practical case study of PINN's ability to predict real-world dynamical systems. The mean value model of the diesel engine incorporates empirical formulae to represent certain states, but these formulae may not be generalizable to other engines. To address this, the study considers the use of deep neural networks (DNNs) in addition to the PINN model. The DNNs are trained using laboratory test data and are used to model the engine-specific empirical formulae in the mean value model, allowing for a more flexible and adaptive representation of the engine's states. In other words, the mean value model uses both the PINN model and the DNNs to represent the engine's states, with the PINN providing a physics-based understanding of the engine's overall dynamics and the DNNs offering a more engine-specific and adaptive representation of the empirical formulae. By combining these two approaches, the study aims to offer a comprehensive and versatile approach to monitoring the health and performance of diesel engines.

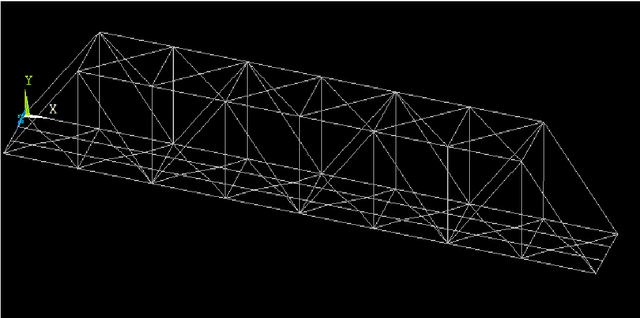

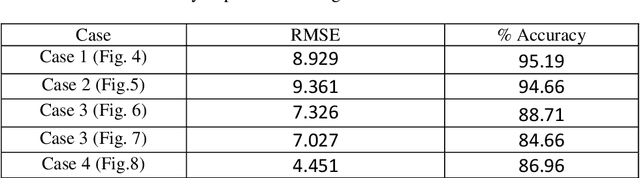

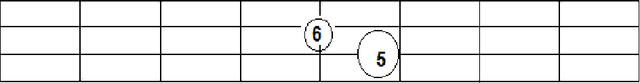

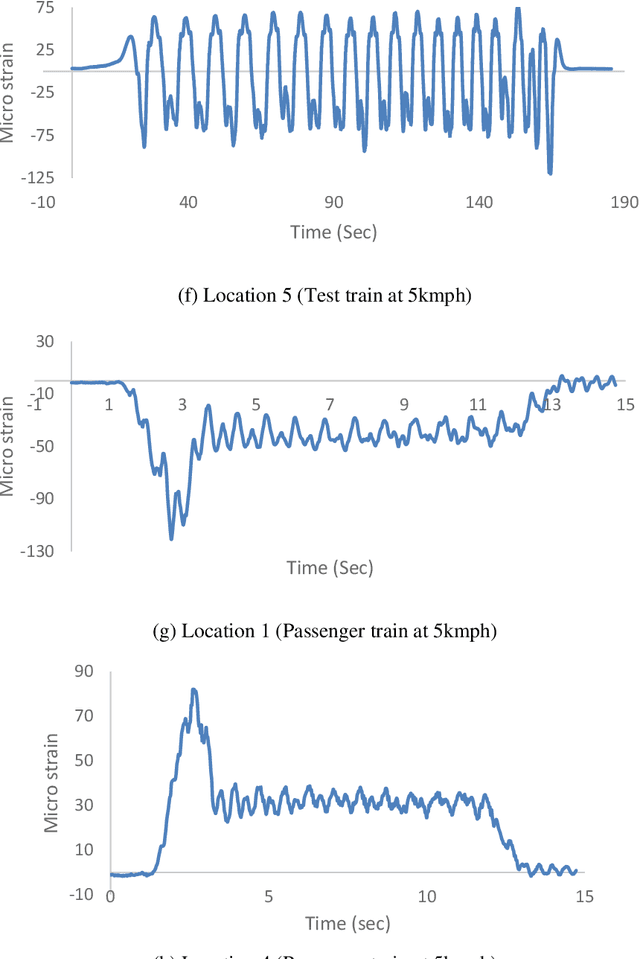

Learning via Long Short-Term Memory network for predicting strains in Railway Bridge members under train induced vibration

Nov 08, 2021

Abstract:Bridge health monitoring using machine learning tools has become an efficient and cost-effective approach in recent times. In the present study, strains in railway bridge member, available from a previous study conducted by IIT Guwahati has been utilized. These strain data were collected from an existing bridge while trains were passing over the bridge. LSTM is used to train the network and to predict strains in different members of the railway bridge. Actual field data has been used for the purpose of predicting strain in different members using strain data from a single member, yet it has been observed that they are quite agreeable to those of ground truth values. This is in spite of the fact that a lot of noise existed in the data, thus showing the efficacy of LSTM in training and predicting even from noisy field data. This may easily open up the possibility of collecting data from the bridge with a much lesser number of sensors and predicting the strain data in other members through LSTM network.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge