Josh Pinskier

SimTO: A simulation-based topology optimization framework for bespoke soft robotic grippers

Jan 27, 2026Abstract:Soft robotic grippers are essential for grasping delicate, geometrically complex objects in manufacturing, healthcare and agriculture. However, existing grippers struggle to grasp feature-rich objects with high topological variability, including gears with sharp tooth profiles on automotive assembly lines, corals with fragile protrusions, or vegetables with irregular branching structures like broccoli. Unlike simple geometric primitives such as cubes or spheres, feature-rich objects lack a clear "optimal" contact surface, making them both difficult to grasp and susceptible to damage when grasped by existing gripper designs. Safe handling of such objects therefore requires specialized soft grippers whose morphology is tailored to the object's features. Topology optimization offers a promising approach for producing specialized grippers, but its utility is limited by the requirement for pre-defined load cases. For soft grippers interacting with feature-rich objects, these loads arise from hundreds of unpredictable gripper-object contact forces during grasping and are unknown a priori. To address this problem, we introduce SimTO, a framework that enables high-resolution topology optimization by automatically extracting load cases from a contact-based physics simulator, eliminating the need for manual load specification. Given an arbitrary feature-rich object, SimTO produces highly customized soft grippers with fine-grained morphological features tailored to the object geometry. Numerical results show our designs are not only highly specialized to feature-rich objects, but also generalize to unseen objects.

Programmable Telescopic Soft Pneumatic Actuators for Deployable and Shape Morphing Soft Robots

Nov 10, 2025Abstract:Soft Robotics presents a rich canvas for free-form and continuum devices capable of exerting forces in any direction and transforming between arbitrary configurations. However, there is no current way to tractably and directly exploit the design freedom due to the curse of dimensionality. Parameterisable sets of designs offer a pathway towards tractable, modular soft robotics that appropriately harness the behavioural freeform of soft structures to create rich embodied behaviours. In this work, we present a parametrised class of soft actuators, Programmable Telescopic Soft Pneumatic Actuators (PTSPAs). PTSPAs expand axially on inflation for deployable structures and manipulation in challenging confined spaces. We introduce a parametric geometry generator to customise actuator models from high-level inputs, and explore the new design space through semi-automated experimentation and systematic exploration of key parameters. Using it we characterise the actuators' extension/bending, expansion, and stiffness and reveal clear relationships between key design parameters and performance. Finally we demonstrate the application of the actuators in a deployable soft quadruped whose legs deploy to walk, enabling automatic adaptation to confined spaces. PTSPAs present new design paradigm for deployable and shape morphing structures and wherever large length changes are required.

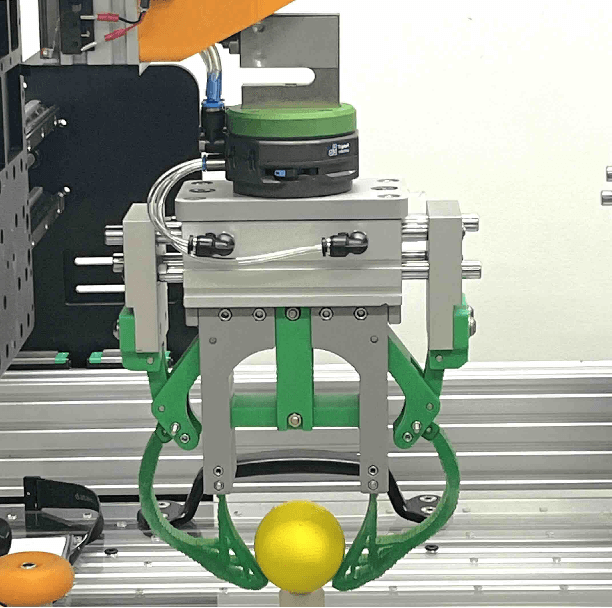

SoGraB: A Visual Method for Soft Grasping Benchmarking and Evaluation

Nov 28, 2024Abstract:Recent years have seen soft robotic grippers gain increasing attention due to their ability to robustly grasp soft and fragile objects. However, a commonly available standardised evaluation protocol has not yet been developed to assess the performance of varying soft robotic gripper designs. This work introduces a novel protocol, the Soft Grasping Benchmarking and Evaluation (SoGraB) method, to evaluate grasping quality, which quantifies object deformation by using the Density-Aware Chamfer Distance (DCD) between point clouds of soft objects before and after grasping. We validated our protocol in extensive experiments, which involved ranking three Fin-Ray gripper designs with a subset of the EGAD object dataset. The protocol appropriately ranked grippers based on object deformation information, validating the method's ability to select soft grippers for complex grasping tasks and benchmark them for comparison against future designs.

DexGrip: Multi-modal Soft Gripper with Dexterous Grasping and In-hand Manipulation Capacity

Nov 26, 2024

Abstract:The ability of robotic grippers to not only grasp but also re-position and re-orient objects in-hand is crucial for achieving versatile, general-purpose manipulation. While recent advances in soft robotic grasping has greatly improved grasp quality and stability, their manipulation capabilities remain under-explored. This paper presents the DexGrip, a multi-modal soft robotic gripper for in-hand grasping, re-orientation and manipulation. DexGrip features a 3 Degrees of Freedom (DoFs) active suction palm and 3 active (rotating) grasping surfaces, enabling soft, stable, and dexterous grasping and manipulation without ever needing to re-grasp an object. Uniquely, these features enable complete 360 degree rotation in all three principal axes. We experimentally demonstrate these capabilities across a diverse set of objects and tasks. DexGrip successfully grasped, re-positioned, and re-oriented objects with widely varying stiffnesses, sizes, weights, and surface textures; and effectively manipulated objects that presented significant challenges for existing robotic grippers.

PINN-Ray: A Physics-Informed Neural Network to Model Soft Robotic Fin Ray Fingers

Jul 11, 2024

Abstract:Modelling complex deformation for soft robotics provides a guideline to understand their behaviour, leading to safe interaction with the environment. However, building a surrogate model with high accuracy and fast inference speed can be challenging for soft robotics due to the nonlinearity from complex geometry, large deformation, material nonlinearity etc. The reality gap from surrogate models also prevents their further deployment in the soft robotics domain. In this study, we proposed a physics-informed Neural Networks (PINNs) named PINN-Ray to model complex deformation for a Fin Ray soft robotic gripper, which embeds the minimum potential energy principle from elastic mechanics and additional high-fidelity experimental data into the loss function of neural network for training. This method is significant in terms of its generalisation to complex geometry and robust to data scarcity as compared to other data-driven neural networks. Furthermore, it has been extensively evaluated to model the deformation of the Fin Ray finger under external actuation. PINN-Ray demonstrates improved accuracy as compared with Finite element modelling (FEM) after applying the data assimilation scheme to treat the sim-to-real gap. Additionally, we introduced our automated framework to design, fabricate soft robotic fingers, and characterise their deformation by visual tracking, which provides a guideline for the fast prototype of soft robotics.

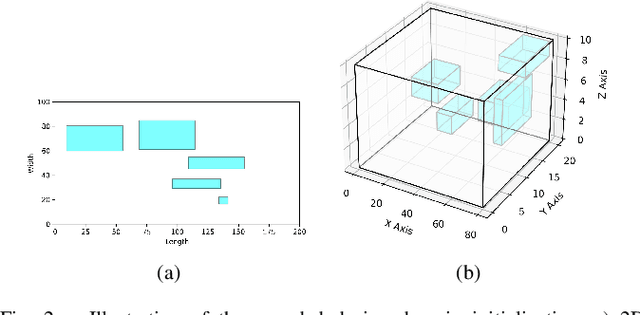

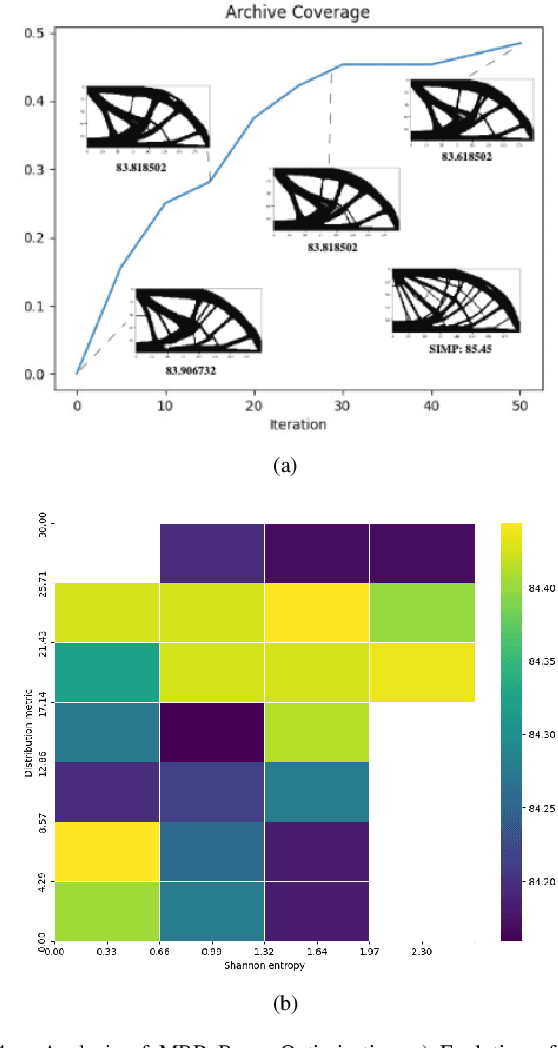

A 'MAP' to find high-performing soft robot designs: Traversing complex design spaces using MAP-elites and Topology Optimization

Jul 10, 2024

Abstract:Soft robotics has emerged as the standard solution for grasping deformable objects, and has proven invaluable for mobile robotic exploration in extreme environments. However, despite this growth, there are no widely adopted computational design tools that produce quality, manufacturable designs. To advance beyond the diminishing returns of heuristic bio-inspiration, the field needs efficient tools to explore the complex, non-linear design spaces present in soft robotics, and find novel high-performing designs. In this work, we investigate a hierarchical design optimization methodology which combines the strengths of topology optimization and quality diversity optimization to generate diverse and high-performance soft robots by evolving the design domain. The method embeds variably sized void regions within the design domain and evolves their size and position, to facilitating a richer exploration of the design space and find a diverse set of high-performing soft robots. We demonstrate its efficacy on both benchmark topology optimization problems and soft robotic design problems, and show the method enhances grasp performance when applied to soft grippers. Our method provides a new framework to design parts in complex design domains, both soft and rigid.

A Compliant Robotic Leg Based on Fibre Jamming

Aug 03, 2023

Abstract:Humans possess a remarkable ability to react to sudden and unpredictable perturbations through immediate mechanical responses, which harness the visco-elastic properties of muscles to perform auto-corrective movements to maintain balance. In this paper, we propose a novel design of a robotic leg inspired by this mechanism. We develop multi-material fibre jammed tendons, and demonstrate their use as passive compliant mechanisms to achieve variable joint stiffness and improve stability. Through numerical simulations and extensive experimentation, we demonstrate the ability for our system to achieve a wide range of potentially beneficial compliance regimes. We show the role and contribution of each tendon quantitatively by evaluating their individual force contribution in resisting rotational perturbations. We also perform walking experiments with programmed bioinspired gaits that varying the stiffness of the tendons throughout the gait cycle, demonstrating a stable and consistent behaviour. We show the potential of such systems when integrated into legged robots, where compliance and shock absorption can be provided entirely through the morphological properties of the leg.

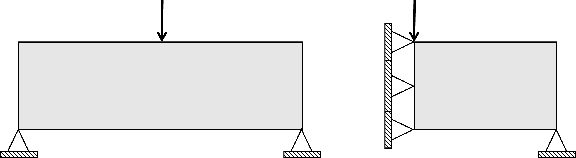

Automated design of pneumatic soft grippers through design-dependent multi-material topology optimization

Nov 25, 2022

Abstract:In recent years, soft robotic grasping has rapidly spread through the academic robotics community and pushed into industrial applications. At the same time, multimaterial 3D printing has become widely available, enabling monolithic manufacture of devices containing rigid and elastic section. We propose a novel design technique which leverages both of these technologies and is able to automatically design bespoke soft robotic grippers for fruit-picking and similar applications. We demonstrate the novel topology optimisation formulation which generates multi-material soft gippers and is able to solve both the internal and external pressure boundaries, and investigate methods to produce air-tight designs. Compared to existing methods, it vastly expands the searchable design space whilst increasing simulation accuracy.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge