James Brett

A Compliant Robotic Leg Based on Fibre Jamming

Aug 03, 2023

Abstract:Humans possess a remarkable ability to react to sudden and unpredictable perturbations through immediate mechanical responses, which harness the visco-elastic properties of muscles to perform auto-corrective movements to maintain balance. In this paper, we propose a novel design of a robotic leg inspired by this mechanism. We develop multi-material fibre jammed tendons, and demonstrate their use as passive compliant mechanisms to achieve variable joint stiffness and improve stability. Through numerical simulations and extensive experimentation, we demonstrate the ability for our system to achieve a wide range of potentially beneficial compliance regimes. We show the role and contribution of each tendon quantitatively by evaluating their individual force contribution in resisting rotational perturbations. We also perform walking experiments with programmed bioinspired gaits that varying the stiffness of the tendons throughout the gait cycle, demonstrating a stable and consistent behaviour. We show the potential of such systems when integrated into legged robots, where compliance and shock absorption can be provided entirely through the morphological properties of the leg.

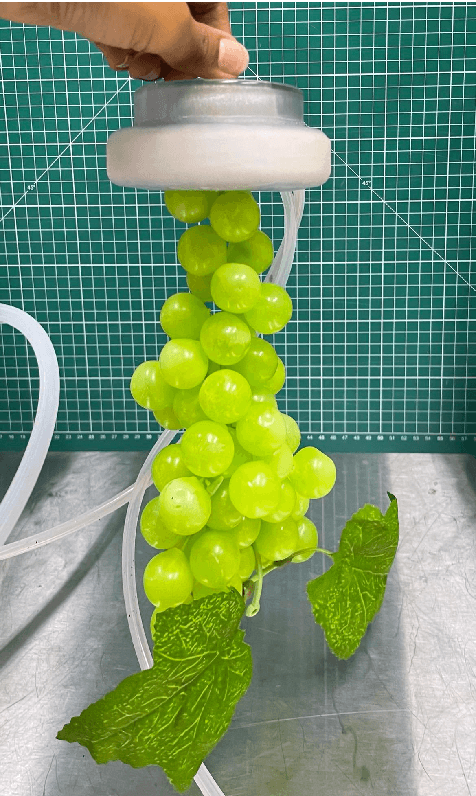

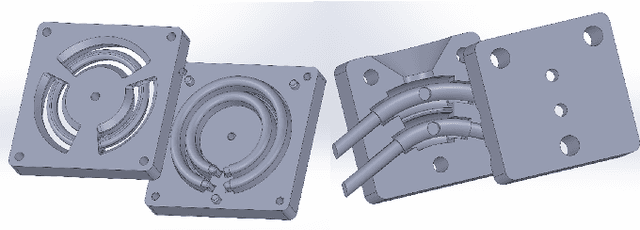

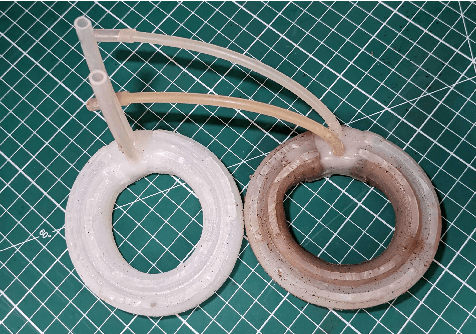

The Jamming Donut: A Free-Space Gripper based on Granular Jamming

Dec 13, 2022

Abstract:Fruit harvesting has recently experienced a shift towards soft grippers that possess compliance, adaptability, and delicacy. In this context, pneumatic grippers are popular, due to provision of high deformability and compliance, however they typically possess limited grip strength. Jamming possesses strong grip capability, however has limited deformability and often requires the object to be pushed onto a surface to attain a grip. This paper describes a hybrid gripper combining pneumatics (for deformation) and jamming (for grip strength). Our gripper utilises a torus (donut) structure with two chambers controlled by pneumatic and vacuum pressure respectively, to conform around a target object. The gripper displays good adaptability, exploiting pneumatics to mould to the shape of the target object where jamming can be successfully harnessed to grip. The main contribution of the paper is design, fabrication, and characterisation of the first hybrid gripper that can use granular jamming in free space, achieving significantly larger retention forces compared to pure pneumatics. We test our gripper on a range of different sizes and shapes, as well as picking a broad range of real fruit.

Active Vibration Fluidization for Granular Jamming Grippers

Dec 13, 2022

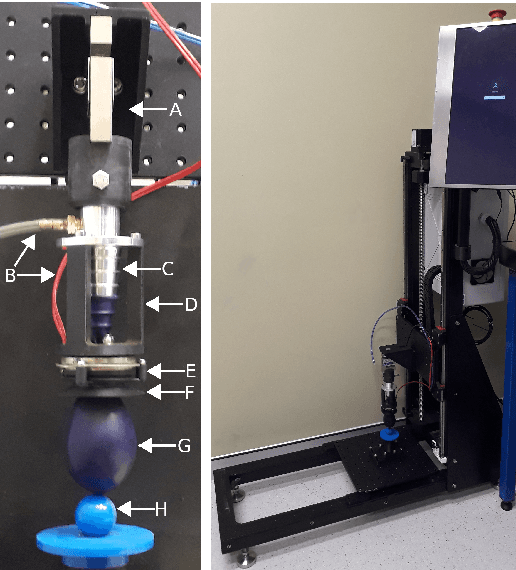

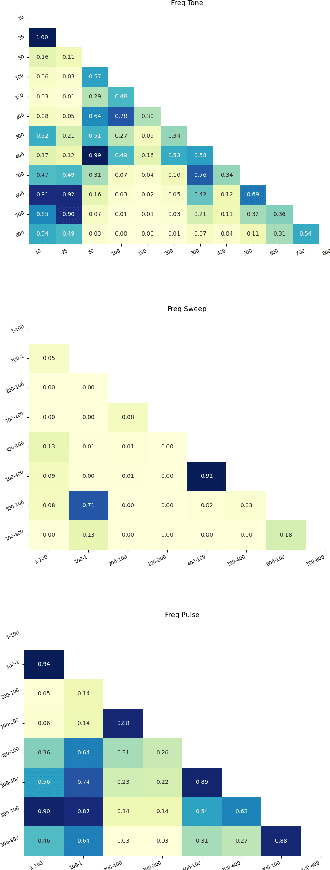

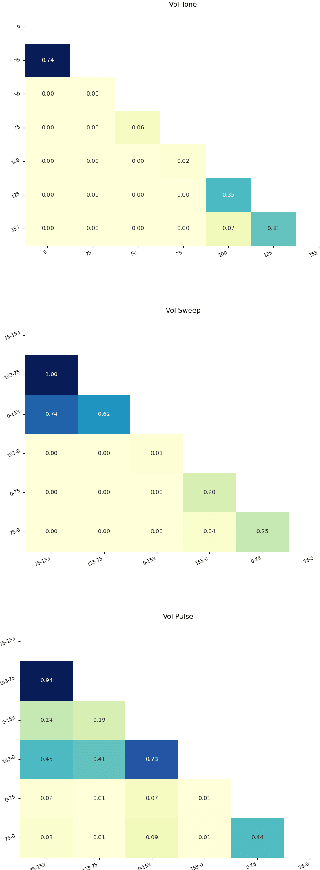

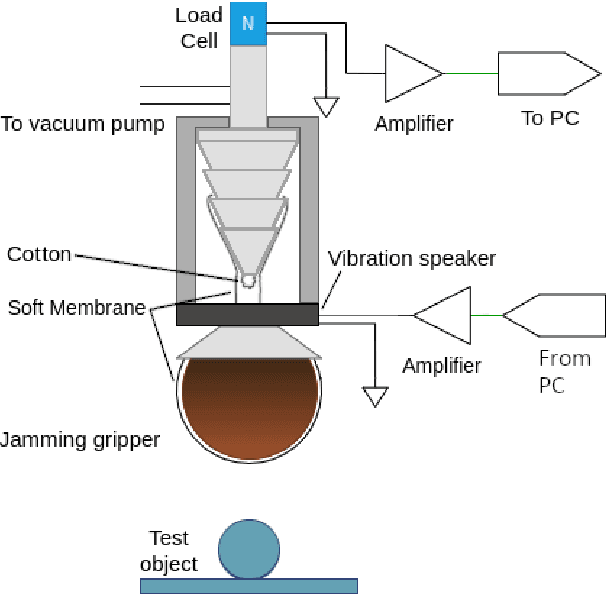

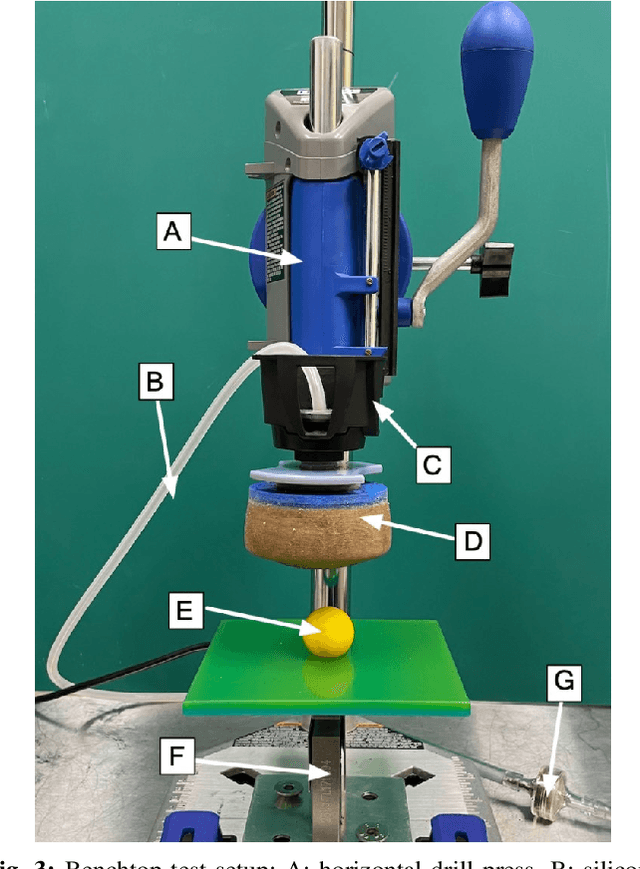

Abstract:Granular jamming has recently become popular in soft robotics with widespread applications including industrial gripping, surgical robotics and haptics. Previous work has investigated the use of various techniques that exploit the nature of granular physics to improve jamming performance, however this is generally underrepresented in the literature compared to its potential impact. We present the first research that exploits vibration-based fluidisation actively (e.g., during a grip) to elicit bespoke performance from granular jamming grippers. We augment a conventional universal gripper with a computer-controllled audio exciter, which is attached to the gripper via a 3D printed mount, and build an automated test rig to allow large-scale data collection to explore the effects of active vibration. We show that vibration in soft jamming grippers can improve holding strength. In a series of studies, we show that frequency and amplitude of the waveforms are key determinants to performance, and that jamming performance is also dependent on temporal properties of the induced waveform. We hope to encourage further study focused on active vibrational control of jamming in soft robotics to improve performance and increase diversity of potential applications.

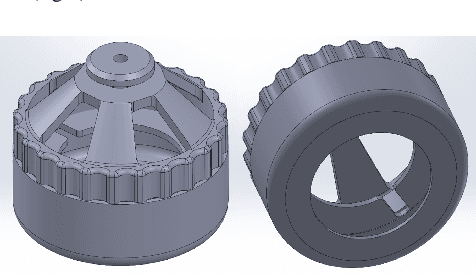

Getting a Grip: in Materio Evolution of Membrane Morphology for Soft Robotic Jamming Grippers

Nov 02, 2021

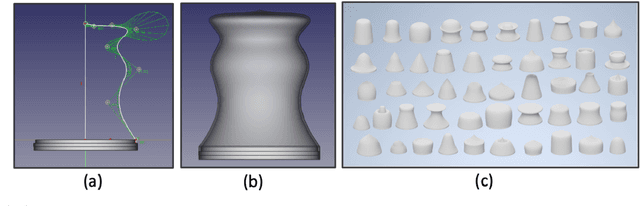

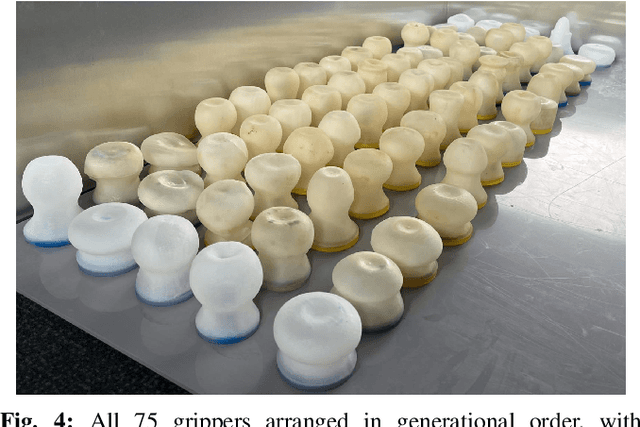

Abstract:The application of granular jamming in soft robotics is a recent and promising new technology offer exciting possibilities for creating higher performance robotic devices. Granular jamming is achieved via the application of a vacuum pressure inside a membrane containing particulate matter, and is particularly interesting from a design perspective, as a myriad of design parameters can potentially be exploited to induce a diverse variety of useful behaviours. To date, the effect of variables such as grain shape and size, as well as membrane material, have been studied as a means of inducing bespoke gripping performance, however the other main contributing factor, membrane morphology, has not been studied due to its particular complexities in both accurate modelling and fabrication. This research presents the first study that optimises membrane morphology for granular jamming grippers, combining multi-material 3D printing and an evolutionary algorithm to search through a varied morphology design space in materio. Entire generations are printed in a single run and gripper retention force is tested and used as a fitness measure. Our approach is relatively scalable, circumvents the need for modelling, and guarantees the real-world performance of the grippers considered. Results show that membrane morphology is a key determinant of gripper performance. Common high performance designs are seen to optimise all three of the main identified mechanisms by which granular grippers generate grip force, are significantly different from a standard gripper morphology, and generalise well across a range of test objects.

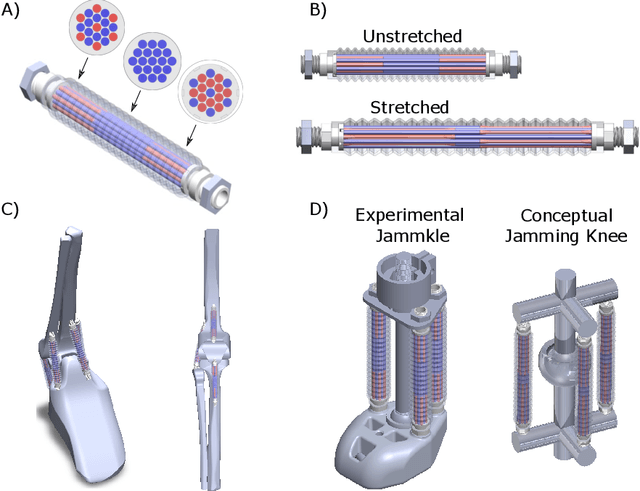

Jammkle: Fibre jamming 3D printed multi-material tendons and their application in a robotic ankle

Sep 13, 2021

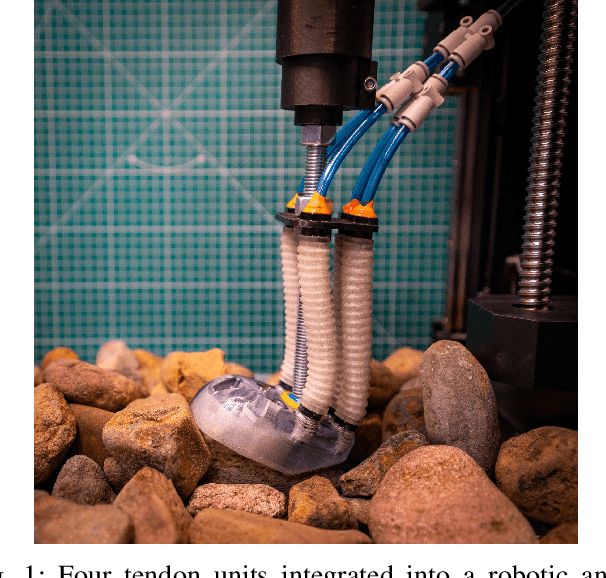

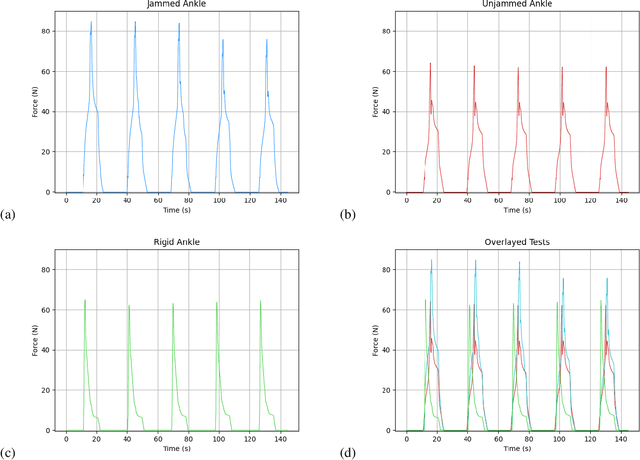

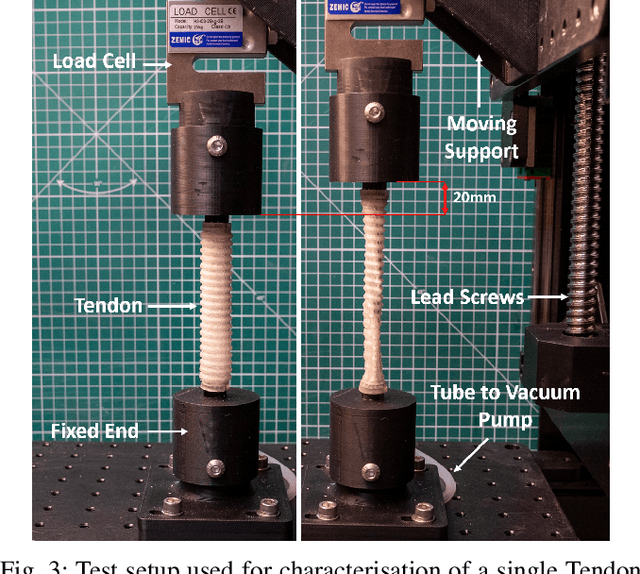

Abstract:Fibre jamming is a relatively new and understudied soft robotic mechanism that has previously found success when used in stiffness-tuneable arms and fingers. However, to date researchers have not fully taken advantage of the freedom offered by contemporary fabrication techniques including multi-material 3D printing in the creation of fibre jamming structures. In this research, we present a novel, modular, multi-material, 3D printed, fibre jamming tendon unit for use in a stiffness-tuneable compliant robotic ankle, or Jammkle. We describe the design and fabrication of the Jammkle and highlight its advantages compared to examples from modern literature. We develop a multiphysics model of the tendon unit, showing good agreement with experimental data. Finally, we demonstrate a practical application by integrating multiple tendon units into a robotic ankle and perform extensive testing and characterisation. We show that the Jammkle outperforms comparative leg structures in terms of compliance, damping, and slip prevention.

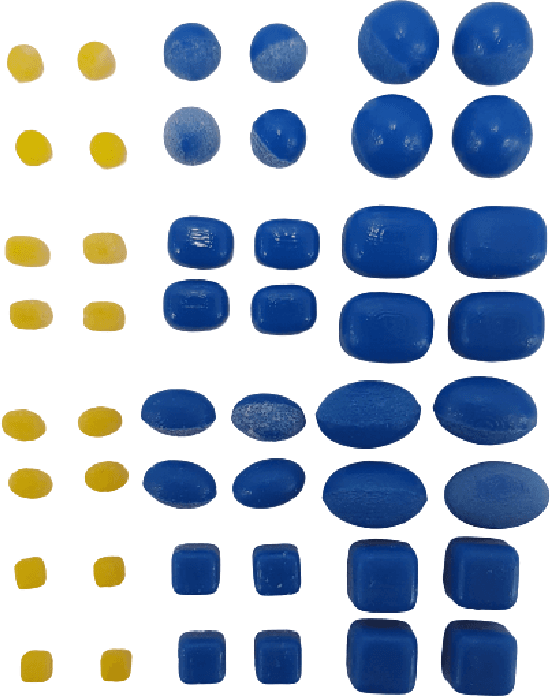

Shape, Size, and Fabrication Effects in 3D Printed Granular Jamming Grippers

Apr 09, 2021

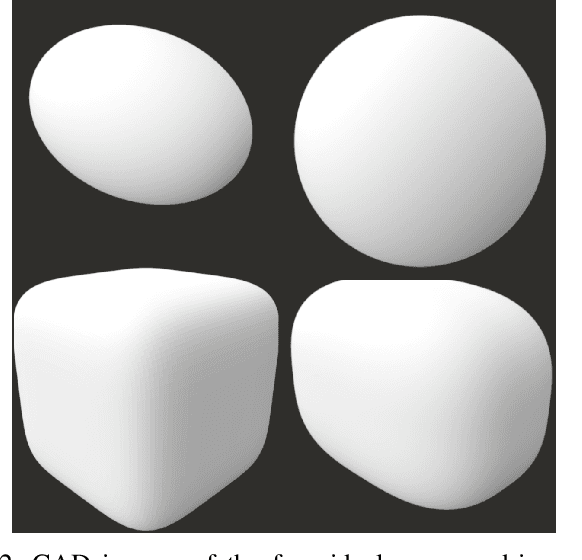

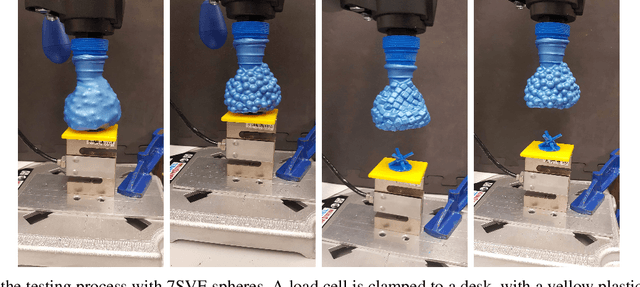

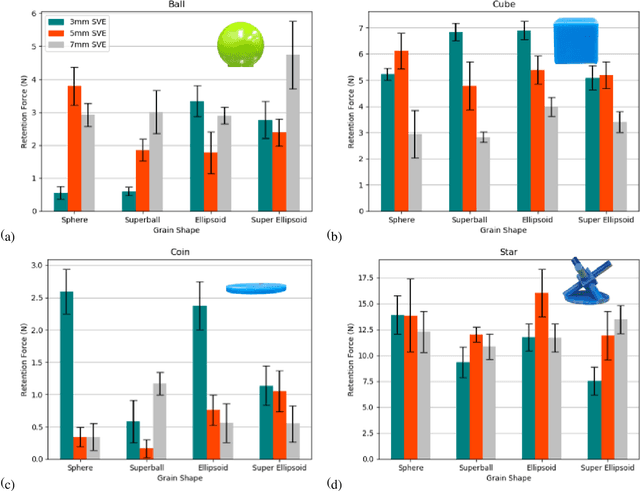

Abstract:Granular jamming is a popular soft actuation mechanism that provides high stiffness variability with minimum volume variation. Jamming is particularly interesting from a design perspective, as a myriad of design parameters can potentially be exploited to induce a diverse variety of useful behaviours. To date, grain shape has been largely ignored. Here, we focus on the use of 3D printing to expose design variables related to grain shape and size. Grains are represented by parameterised superquadrics (superellipsoids); four diverse shapes are investigated along with three size variations. Grains are 3D printed at high resolution and performance is assessed in experimental pull-off testing on a variety of benchmark test objects. We show that grain shape and size are key determinants in granular gripping performance. Moreover, there is no universally-optimal grain shape for gripping. Optical imaging assesses the accuracy of printed shapes compared to their ideal models. Results suggest that optimisation of grain shape is a key enabler for high-performance, bespoke, actuation behaviour and can be exploited to expand the range and performance of granular grippers across a range of diverse usage scenarios.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge