Sarah Baldwin

A Comprehensive Dataset of Grains for Granular Jamming in Soft Robotics: Grip Strength and Shock Absorption

Dec 13, 2022

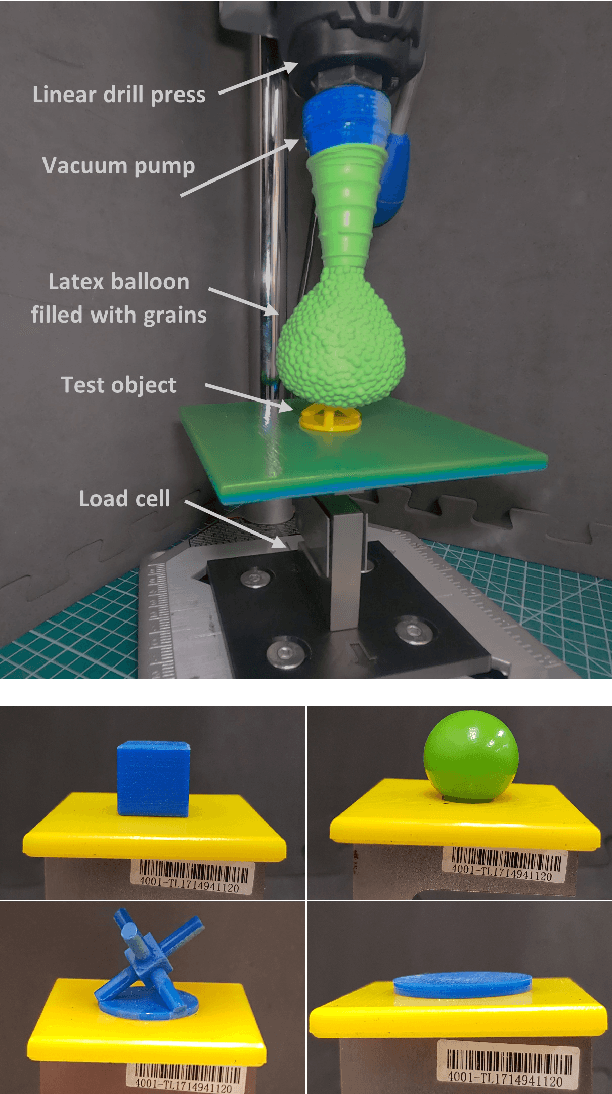

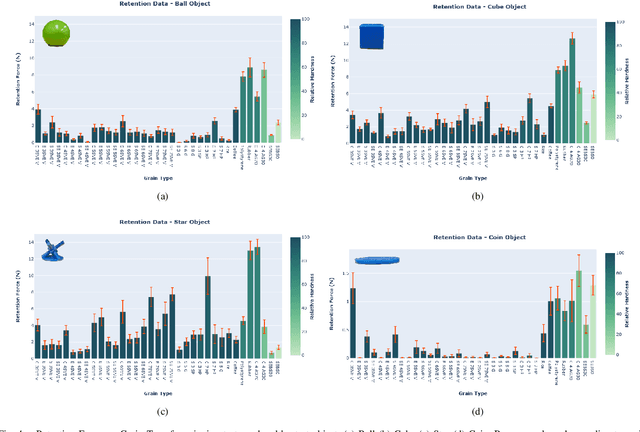

Abstract:We test grip strength and shock absorption properties of various granular material in granular jamming robotic components. The granular material comprises a range of natural, manufactured, and 3D printed material encompassing a wide range of shapes, sizes, and Shore hardness. Two main experiments are considered, both representing compelling use cases for granular jamming in soft robotics. The first experiment measures grip strength (retention force measured in Newtons) when we fill a latex balloon with the chosen grain type and use it as a granular jamming gripper to pick up a range of test objects. The second experiment measures shock absorption properties recorded by an Inertial Measurement Unit which is suspended in an envelope of granular material and dropped from a set height. Our results highlight a range of shape, size and softness effects, including that grain deformability is a key determinant of grip strength, and interestingly, that larger grain sizes in 3D printed grains create better shock absorbing materials.

The Jamming Donut: A Free-Space Gripper based on Granular Jamming

Dec 13, 2022

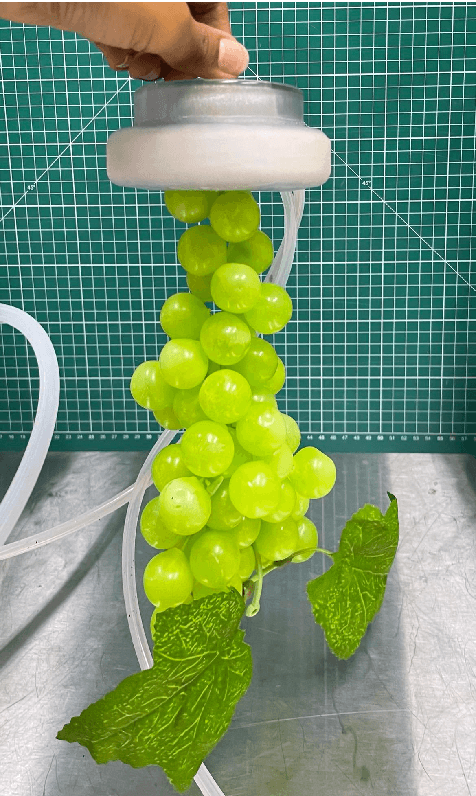

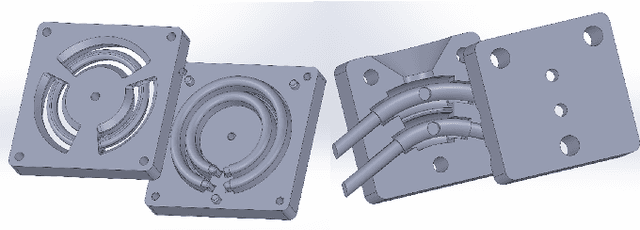

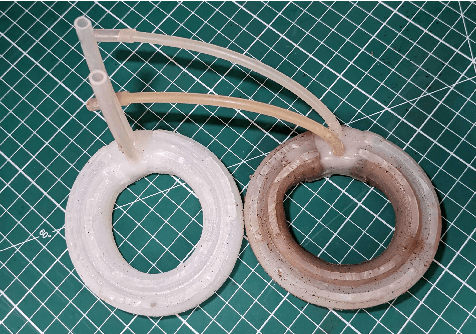

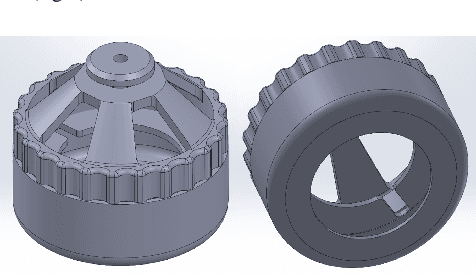

Abstract:Fruit harvesting has recently experienced a shift towards soft grippers that possess compliance, adaptability, and delicacy. In this context, pneumatic grippers are popular, due to provision of high deformability and compliance, however they typically possess limited grip strength. Jamming possesses strong grip capability, however has limited deformability and often requires the object to be pushed onto a surface to attain a grip. This paper describes a hybrid gripper combining pneumatics (for deformation) and jamming (for grip strength). Our gripper utilises a torus (donut) structure with two chambers controlled by pneumatic and vacuum pressure respectively, to conform around a target object. The gripper displays good adaptability, exploiting pneumatics to mould to the shape of the target object where jamming can be successfully harnessed to grip. The main contribution of the paper is design, fabrication, and characterisation of the first hybrid gripper that can use granular jamming in free space, achieving significantly larger retention forces compared to pure pneumatics. We test our gripper on a range of different sizes and shapes, as well as picking a broad range of real fruit.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge