Shape, Size, and Fabrication Effects in 3D Printed Granular Jamming Grippers

Paper and Code

Apr 09, 2021

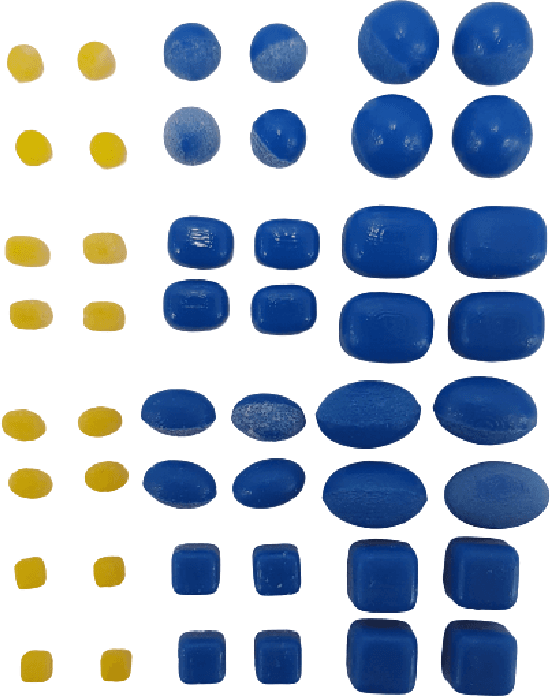

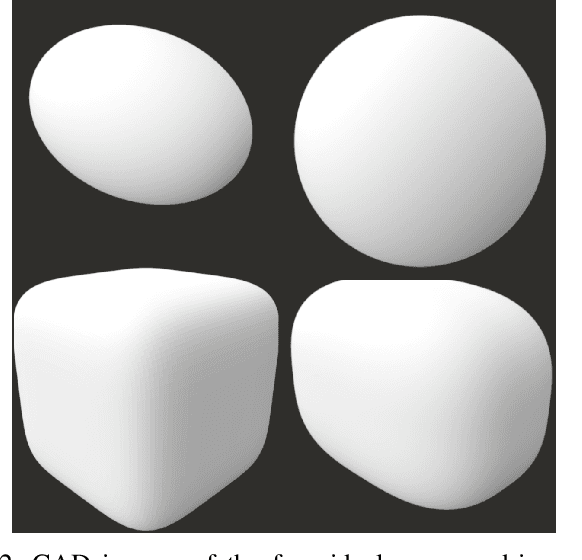

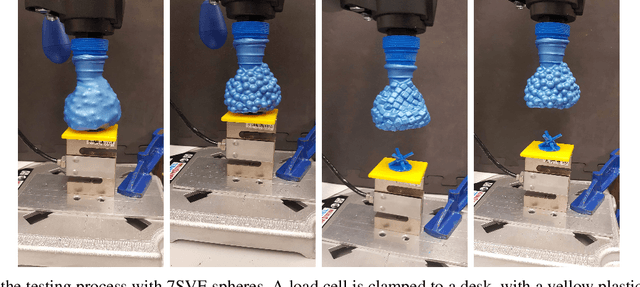

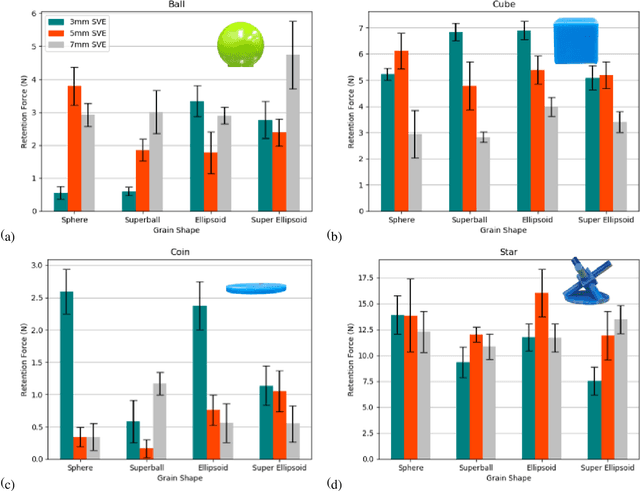

Granular jamming is a popular soft actuation mechanism that provides high stiffness variability with minimum volume variation. Jamming is particularly interesting from a design perspective, as a myriad of design parameters can potentially be exploited to induce a diverse variety of useful behaviours. To date, grain shape has been largely ignored. Here, we focus on the use of 3D printing to expose design variables related to grain shape and size. Grains are represented by parameterised superquadrics (superellipsoids); four diverse shapes are investigated along with three size variations. Grains are 3D printed at high resolution and performance is assessed in experimental pull-off testing on a variety of benchmark test objects. We show that grain shape and size are key determinants in granular gripping performance. Moreover, there is no universally-optimal grain shape for gripping. Optical imaging assesses the accuracy of printed shapes compared to their ideal models. Results suggest that optimisation of grain shape is a key enabler for high-performance, bespoke, actuation behaviour and can be exploited to expand the range and performance of granular grippers across a range of diverse usage scenarios.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge