Jihoon Hong

LongMamba: Enhancing Mamba's Long Context Capabilities via Training-Free Receptive Field Enlargement

Apr 22, 2025Abstract:State space models (SSMs) have emerged as an efficient alternative to Transformer models for language modeling, offering linear computational complexity and constant memory usage as context length increases. However, despite their efficiency in handling long contexts, recent studies have shown that SSMs, such as Mamba models, generally underperform compared to Transformers in long-context understanding tasks. To address this significant shortfall and achieve both efficient and accurate long-context understanding, we propose LongMamba, a training-free technique that significantly enhances the long-context capabilities of Mamba models. LongMamba builds on our discovery that the hidden channels in Mamba can be categorized into local and global channels based on their receptive field lengths, with global channels primarily responsible for long-context capability. These global channels can become the key bottleneck as the input context lengthens. Specifically, when input lengths largely exceed the training sequence length, global channels exhibit limitations in adaptively extend their receptive fields, leading to Mamba's poor long-context performance. The key idea of LongMamba is to mitigate the hidden state memory decay in these global channels by preventing the accumulation of unimportant tokens in their memory. This is achieved by first identifying critical tokens in the global channels and then applying token filtering to accumulate only those critical tokens. Through extensive benchmarking across synthetic and real-world long-context scenarios, LongMamba sets a new standard for Mamba's long-context performance, significantly extending its operational range without requiring additional training. Our code is available at https://github.com/GATECH-EIC/LongMamba.

Towards Fully-Automated Materials Discovery via Large-Scale Synthesis Dataset and Expert-Level LLM-as-a-Judge

Feb 23, 2025Abstract:Materials synthesis is vital for innovations such as energy storage, catalysis, electronics, and biomedical devices. Yet, the process relies heavily on empirical, trial-and-error methods guided by expert intuition. Our work aims to support the materials science community by providing a practical, data-driven resource. We have curated a comprehensive dataset of 17K expert-verified synthesis recipes from open-access literature, which forms the basis of our newly developed benchmark, AlchemyBench. AlchemyBench offers an end-to-end framework that supports research in large language models applied to synthesis prediction. It encompasses key tasks, including raw materials and equipment prediction, synthesis procedure generation, and characterization outcome forecasting. We propose an LLM-as-a-Judge framework that leverages large language models for automated evaluation, demonstrating strong statistical agreement with expert assessments. Overall, our contributions offer a supportive foundation for exploring the capabilities of LLMs in predicting and guiding materials synthesis, ultimately paving the way for more efficient experimental design and accelerated innovation in materials science.

A Multi-State Diagnosis and Prognosis Framework with Feature Learning for Tool Condition Monitoring

Apr 30, 2018

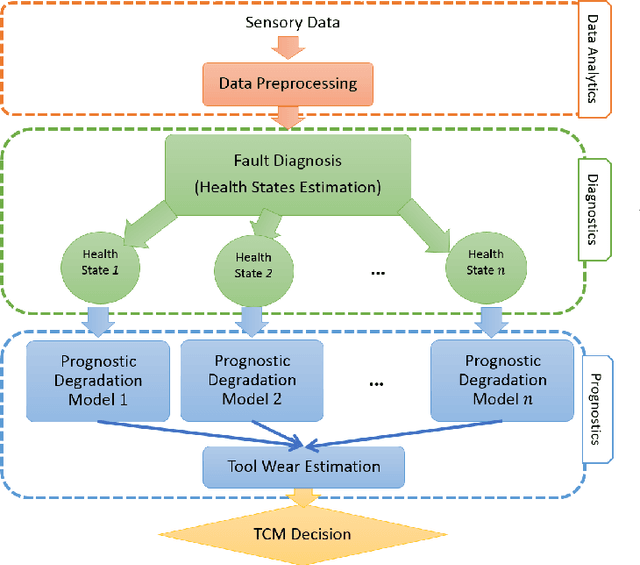

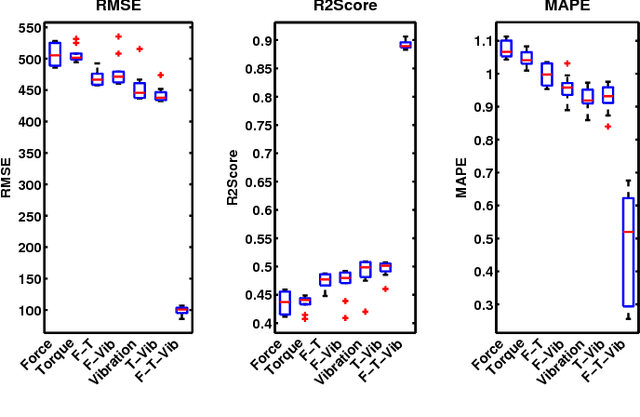

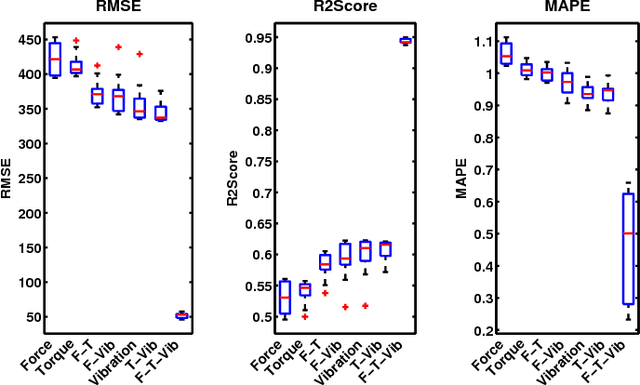

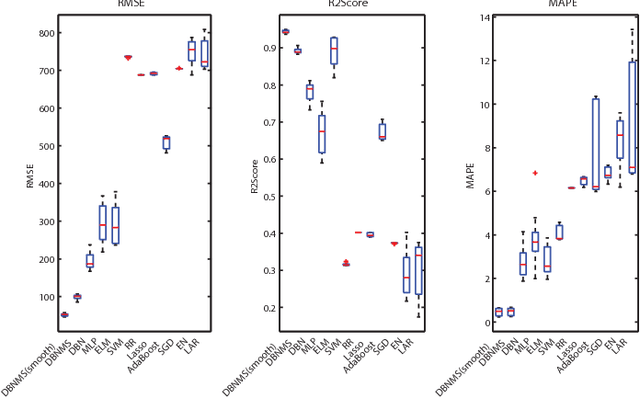

Abstract:In this paper, a multi-state diagnosis and prognosis (MDP) framework is proposed for tool condition monitoring via a deep belief network based multi-state approach (DBNMS). For fault diagnosis, a cost-sensitive deep belief network (namely ECS-DBN) is applied to deal with the imbalanced data problem for tool state estimation. An appropriate prognostic degradation model is then applied for tool wear estimation based on the different tool states. The proposed framework has the advantage of automatic feature representation learning and shows better performance in accuracy and robustness. The effectiveness of the proposed DBNMS is validated using a real-world dataset obtained from the gun drilling process. This dataset contains a large amount of measured signals involving different tool geometries under various operating conditions. The DBNMS is examined for both the tool state estimation and tool wear estimation tasks. In the experimental studies, the prediction results are evaluated and compared with popular machine learning approaches, which show the superior performance of the proposed DBNMS approach.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge